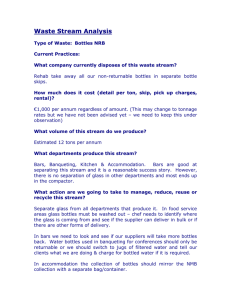

I`d like to speak today about some of the different types of bottles

advertisement

I’d like to speak today about some of the different types of bottles and flasks blown first in the Colonies and then in these United States during the 17th, 18th and first quarter of the 19th centuries. It will likely come as a surprise to many of you that initial attempts to blow glass in the colonies began as early as 1608 in Jamestown, an ill fated enterprise that ceased within the year. A second attempt to create a viable Glass House Jamestown began in 1622 and ended in 1624. There is some speculation that one or both of these glass houses successfully produced glass beads but most current glass scholarship indicates that neither venture was successful in the creation of glass window panes or bottles. Other short lived and/or low production 17th century enterprises include glass houses in Salem, Massachusetts (beginning in 1639) and Evert Duykinck’s New Amsterdam Glass House which operated from 1645 to 1674. Sadly, little is known of the bottles blown at these houses but it can be assumed that the bottles they produced were blown in the English or European tradition on a relatively limited scale. Because of the popularity and availability of imported glass, the bottles produced in 17th century Glass Houses were created for limited local consumption with the colonists’ need primarily satisfied by English and European imports. (CHANGE SLIDE) It was not until 1739 and the creation of the Wistarburgh Glass Works in Alloway, New Jersey that what would eventually become the American Glass Bottle Industry first took root and what I refer to as the “Colonial Period” of glass manufacturing had its start. Lasting roughly until 1815, this period is characterized by hand-crafted bottles blown in the English and Germanic tradition utilizing raw materials from our own shores. The reliance upon traditional Old Country forms and techniques was a natural result of two distinctly different forces. First, the craft of glassblowing remained an “art” that few colonial settlers fully understood. Glassblowers were a highly protected (and valuable) commodity across the European continent and only limited numbers of these skilled workers migrated to the colonies in order to share and practice their craft. As a consequence, glassblowing remained a closely guarded and somewhat mysterious “secret” throughout much of the 18th century. The second reason behind reliance on English and European forms is perhaps a bit more difficult for today’s Americans to understand. Although distaste for Mother England continued to grow throughout the 18th century, public opinion still overwhelmingly favored English and European arts and crafts, believing that they were “finer.” There was little support for domestic arts and/or industry, a situation that would not change until an independent American economy emerged in the aftermath of the War of 1812 and the Treaty of Ghent became effective in February of 1815. What then, were these English and Germanic inspired objects produced by the 18th and early 19th century Colonial Glass Houses? Although none of the bottles produced on our shores during this period are “marked” by their maker, excavations of the Wistarburgh Site, Steigel’s Works in Manheim, PA and the Pitkin Glass Works in Manchester, CT sheds a good deal of light on the production techniques used by these factories and their resulting wares. In addition, the pioneering works of George and Helen McKearin, Harry Hall White and others give students of today a broad range of knowledge from which to base their study of Colonial Period bottles. (CHANGE SLIDE) It could easily be argued that the most aesthetically pleasing of the colonial period bottles were the pattern molded pocket flasks blown at Baron Von Siegel’s Manheim, PA glass works. Dating back to the time of the Romans and revived during the Renaissance, the pattern molding technique involves use of a one piece cone shaped or sometimes two-piece hinged mold cut with ribs or designs. Of Continental ancestry, the pattern molded pocket bottles produced by Stiegel’s German glassblowers in the 5 year period from 1769 to 1774 have aroused more excitement and more confusion among collectors than any other type of bottles or flasks. (As an aside, much of this confusion relates to similar but thankfully distinguishable flasks blown by Emile Larson of Vineland, NJ in the 1930s.) Blown from a high grade of non-lead glass, Stiegel’s attractive vessels were artificially enhanced through the addition of metal oxides in the glass batch to produce striking shades of blues and amethysts. Created to be indistinguishable from English and European imports (and playing to the colonists’ notion that English and European Glass was the “best” glass) these flasks remain a perplexing study, as there is still little differentiation between those flasks blown at Manheim and those blown abroad. With that said, there are four patterns; the diamond daisy (CHANGE SLIDE), the 12 diamond(CHANGE SLIDE), the 28 honeycombs-above-flutes (CHANGE SLIDE), and the Daisy-inhexagon(CHANGE SLIDE) to which no exact English or European counterparts have been discovered. This fact, coupled with the discovery of numerous flasks of this type in and around Manheim during the earliest days of bottle collecting gives flasks blown in these molds a well accepted attribution of having been blown at Stiegel’s Works. And, although not ALL bottles blown in similar forms using 18 and 20 rib molds (CHANGE SLIDE) as well as a mold known as “small diamonds over flutes” were blown at Manheim, it is probable that SOME were. (CHANGE SLIDE) Also blown in this period were flasks made in the “German half-post” method which are colloquially referred to as Pitkintype (based upon notions of early collectors that they were peculiar to the Pitkin Glass Works of Manchester, CT), though today we understand that flasks of this type were a regular product of numerous glass houses. These German half-post flasks were created by first slightly inflating the gather of metal (a glassblowers term for the glass in the melting pot) on the end of the blowpipe, then reinserting the gather into the batch of molten glass for a “half-post” (double-dipped, so to speak) before expanding the gather within a ribbed mold, removing the gather and finally expanding the flask to its final size and shape. If the flask were to be “double patterned” (i.e. both vertical and spiral ribbing) there would be a second insertion into the mold before finalizing the form. (CHANGE SLIDE) Popular in Germany and Eastern Europe throughout the 17th and 18th centuries, this technique would certainly have been practiced by the six German blowers who came to Wistarburgh in 1739 and it is quite probable that German half-post flasks were among the vessels produced there. It would follow then, that the Germans who first manned Stiegel’s furnaces would also have carried the technique with them and produced flasks of this type prior to 1774 and concurrent with the aforementioned Diamond Daisy. (CHANGE SLIDE) It is with the birth of glassblowing in New England and the Midwest however, that the production of German half-post bottles and flasks reached their zenith. Blown in great numbers in Connecticut at the Pitkin Glass Works (beginning in 1791), the Glastenbury Glass Works, Mather’s Glass Works in East Hartford, the Coventry Glass Works, and also at the Keene Glass Works in Keene, NH, German half-post bottles were THE most common pocket bottles produced in the original colonies until the emergence of the figured flask in or around 1815. (CHANGE SLIDE) The German half-post design appealed to Glassblowers and commoners alike in that they were lightweight but sturdy (strengthened by the second gather of metal) and presumably easy to grasp. That they are also aesthetically pleasing is to my mind no unintended result, as the glassblowers of this period still perceived themselves as craftsmen and not cogs in an industrial machine. Flasks of this type were blown in (roughly) halfpint and full pint sizes and they appear primarily in naturally occurring earthy tones without artificial enhancement. (CHANGE SLIDE) The German half-post technique was also practiced across the Midwest in Pittsburgh and Ohio, first appearing sometime around the turn of the 19th century. (CHANGE SLIDE) More varied in both colors and rib counts than their New England counterparts, Midwestern German half-post bottles have a distinctly 18th century “feel,” although few are that early and some were actually blown into the 1820s and perhaps even the 1830s. (CHANGE SLIDE) In addition to producing flasks in the half-post method, many of the Midwestern Glass Houses also produced “single dipped” pattern molded flasks that were not reinserted into the metal and thus did not exhibit the “halfpost.” Flasks of this type are thus not “Pitkin-type” but rather simply “pattern molded.” With their antecedents in the Diamond Daisy and other flasks blown in Manheim, PA, pattern molded flasks were made in substantial numbers at the Pittsburgh District Glass Houses of the early 19th century and in greater numbers yet at the Ohio Glass Houses throughout the first quarter of the nineteenth century. These flasks were blown in a variety of shapes and colors utilizing differently numbered “ribbed” and variously patterned “diamond” molds as a means of decoration. As a general rule these vessels are rounder than their New England counterparts (which tend towards the elliptical) and blown from a brilliant higher quality metal. It has been argued that the quality of glass from the region is a result of either (or both) access to coal and/or higher quality raw materials such as sand. (CHANGE SLIDE) Similar techniques were utilized in the manufacture of pattern molded bottles within the area. Produced in numerous forms, it is the globular and club shaped bottles that are most notable. As with the pattern molded flasks of the region, these bottles are blown from brilliant metal and they are as a rule startlingly well-made and symmetrical, though still, obviously individually crafted. The popularity of these Midwestern bottles and flasks among local populations was such that production of them lingered well into the 1820s and perhaps into the 1830s, a decade or more after pattern molded bottles had lost favor in the coastal cities. Still, bottles and flasks of this type fit comfortably with the “colonial period” as they are decidedly influenced by 18th century Continental design. (CHANGE SLIDE) Other vessels produced at 18th century Glass Houses include a wide variety of coarsely made black glass “junk bottles” that as with the pattern molded flasks were blown in the English or European tradition. Blown to hold ale, beer, porter and cider (all of which were consumed in great quantities by the colonists), these bottles were relatively thick walled (out of necessity) and generally blown of dark “black” glass. And, although it is true that many of the ale and cider bottles used by colonists during this period were imported from England, there is ample evidence showing that bottles of this type were blown at Germantown, in Manheim and at the South Boston Works prior to 1815. In addition, recent findings show that “junk” bottles were almost certainly a regular product of the New Geneva Glass Works, blown in great enough quantities that in April of 1800, Albert Gallatin reported that he would have “some thousands of black bottles blown for the French market” ready by month’s end. That such bottles were also blown at Wistarburgh, the Pitkin Glass Works and other Glass Houses of the period is a probability, even though it is today nearly impossible to distinguish them from English and Continental imports. Like the English made bottles that they emulated, these bottles were typically roughly one pint in size and blown with the aid of a shallow dip-mold to give the bottles a generally cylindrical form. As a result, the junk bottles of the 18th century show some symmetry but they are decidedly non-uniform in both size and capacity, reflecting the personality of the blower. This same manufacturing technique was utilized in the production of larger wine and spirits bottles, which like the pint-sized porters and ales were blown to emulate the familiar products of English Glass Works. (CHANGE SLIDE) The earliest of the black glass English spirits bottles were blown with a squat, low slung body and extended neck, gradually becoming taller and more slender through the Revolution and up to the creation of the three-piece mold in or around 1815. Though Helen McKearin proposes that some of the earliest English type bottles (the shaft and globe) MAY have been produced at the Salem Glass Works in the 1650s, it is not until the mid 18th century that we can find solid evidence of black glass wine and spirits bottles blown on American soil. (CHANGE SLIDE) In his extensive archeological research at the site of the Germantown Glass Works, Richmond “Boo” Morcom (a NH legend, by the way) found black glass seals and remnants of black glass spirits bottles in great enough quantities to indicate that they were a product of that Glass Works and not simply remains of cullet. Among the seals is an extraordinary piece dated 1755 with the name of “Thomas Hutchinson.” At the time a young Boston lawyer, Hutchinson would eventually become Governor of the Commonwealth. Also found by Morcom at Germantown was a seal impressed “J. Mascarene” and dated 1748. This seal has caused some controversy over the years (in that the Germantown Works were purportedly not in existence until 1750) but Morcom makes a strong argument in favor of Germantown production by noting that the dates impressed on a seal typically referred to the year in which the contents were distilled and NOT the year in which the bottle was blown. If that is the case, the “J. Mascarene 1748” seal would be the earliest piece of dated glass known to have been blown in the colonies. (CHANGE SLIDE) Wine and spirits bottles were also blown at Wistarburgh and the Corning Museum Collection includes a bottle from the 1760s with an impressed seal of “RW,” probably made for the son of the Glass Houses’ founder, Richard Wistar. Blown from a light green glass typical of Wistarburgh products, the bottle is decidedly English/Continental in form but is lighter in color (typical of the Jersey sand) and appears lighter in weight than the coal fired English glass of the period. Further evidence of Wistarburgh spirits bottles was found by Morcom during construction of I95 in downtown Philadelphia. Among his findings were numerous black glass bottles, shards and two seals, each impressed “S. Lewis / Haverford / Pennsylvania.” Located just 35 miles Northwest of Alloway (and the site of Wistarburgh) it is far from a stretch to believe that these bottles and seals were blown at Wistarburgh for local consumption. (CHANGE SLIDE) In addition to dip molded spirits bottles our 18th and early 19th century glass houses also produced many thousands of the ubiquitous chestnut and globular bottles with which many of you are familiar, in great enough numbers in fact, that these bottles remain relatively common today. The earliest of these bottles were blown at Wistarburgh and they are typically rather large (8”) with elongated, somewhat pear shaped bodies and heavily applied collared mouths. Found in shades of both natural bottle glass greens and ambers, it would appear that these bottles were a mainstay of Wistarburgh’s production. (CHANGE SLIDE) Blown first in New England at Pitkin in or around 1791, and later at all of the New England Glass Houses of the period, these simple, freeblown and/or dip-molded bottles were produced en masse to meet both commercial and domestic demands. Suitable for a wide range of uses, the often asymmetrical chestnuts and globs were typically rendered from a coarse grade of wood fired bottle glass. Generally light in weight and pale in color, these relatively simple vessels were the most popular of the all-purpose domestically manufactured bottles of the Colonial Period. (CHANGE SLIDE) Evidence of the wide range of storage needs for which they were used is shown in the variety of sizes in which they were blown – examples can be found today ranging from 2” all the way to 16” with all sizes in between covered. It is likely that the smallest of these bottles (both globular and chestnut shaped) were used by doctors and druggists and perhaps by household bottlers and merchants as well for the storage of essences and/or medicinals. The larger bottles (more typically globular but sometimes chestnut-shaped) were presumably blown for bulk storage of wines, liquors and perhaps medicines. (CHANGE SLIDE) Not surprisingly, chestnut and globular bottles were also produced at the Midwestern Glass Houses and like the pocket bottles of the era, their usage lingered beyond that of the Eastern output. Heavier and blown from a more refined metal than similar objects blown in New England, these chestnut and globular bottles attained some favor among local consumers, though their relative scarcity today indicates a preference amongst Midwesterners for the pattern molded wares I discussed earlier. (CHANGE SLIDE) Also blown during this period were freeblown and dip molded jars that were designed for a multitude of uses. Created from both window and bottle glass, jars of this period were used by Doctors and Druggists for powdered ingredients, in the home for storage and food preservation and commercially for the packaging of pickles, sweets and other preserves. (CHANGE SLIDE) In its design, the jar’s heavily contracted shoulder and wide, flanged mouth served as the perfect anchor for securing cork, bladder or cloth as would have been used in the preservation of perishables. Although blown in sizes ranging from a few inches to vessels holding several gallons, it would appear that most jars of the period were of substantial size, meant to hold products in bulk. (CHANGE SLIDE) Other bottles of the Colonial Period include medicine vials as first advertised by Stiegel in 1772. Typically quite narrow with short necks and delicately flared lips, the capacity of these vials generally ranged from one half ounce to eight ounces. It appears from advertisements of the period that freeblown and dip molded medicine vials were a regular production item for bottle glass houses, window glass houses and flint glass houses into the 1820s. (CHANGE SLIDE) Typically blown using coarse, olive amber metal and formed with the aid of a dip mold, snuff and blacking bottles of the Colonial period were produced in a plethora of shapes and sizes. A regular production item in every Glass House of the period, snuffs and blackings were sometimes round, more often square or rectangular and rarely, polygonal. During his excavations at the site of the Germantown Glass Glassworks, Richmond Morcom found shards of heavily collared rectangular snuff bottles in great enough quantities to show that they were blown there, although it can be presumed that bottles of this type were also imported from England. Snuff bottles are also known to have been blown at Wistarburgh and at Stiegel’s Works in Manheim, where account books show that 1,084 snuff bottles were blown in February of 1767 alone. (CHANGE SLIDE) Production of snuff bottles (in response to increasing consumer demand) continued throughout the colonial period, with examples of particular aesthetic appeal blown in East Hartford and other early Connecticut Glass Houses. (CHANGE SLIDE) There is sound documentation of snuff bottle production in the Midwest as well, though at this point it appears the form and design of these bottles does not distinguish them from the output of the New England Houses. (CHANGE SLIDE) As with the flasks of the colonial period, inkwells were both freeblown and pattern molded in Glass Houses of both the East and the West. Most notable among the Eastern ink bottles are the pattern-molded Pitkin-types, which like the flasks, were constructed in the German half-post method. Blown in both square and generally conical forms, Pitkin-type inkwells are by their nature asymmetrical and varied in their sizes and capacities. Other New England inks were pattern molded, though not using the half-post, as is the case with the so-called pattern molded “melon” inks. Inks of this type were also blown without use of a pattern mold and in a variety of sizes. Though typically attributed to the early Connecticut Glass Houses, freeblown and pattern molded inks were also almost assuredly blown in Keene and at Mount Vernon, NY. (CHANGE SLIDE) As I suggested at the beginning of the talk, the Colonial period of glassmaking comes to end in or around 1815 with the creation of the two-piece mold figured flask and the invention of blown three mold glass. Distinctively American in form, design, execution and imagery, it is with these types of bottles that American Glass Houses began to shrug off the bonds of English and European tradition and create objects that were distinctly our own. (This is the point where we MAY show additional slides) I’d love to open up the floor for questions but before doing so I’ll also let you know that we have brought some material from our inventory that folks are welcome to handle before they leave. As we are all dealers I’ve left our price tags on not to impress anyone but rather to convey the general value of some of these bottles in the current marketplace. Thank you.