Thermo-Mechanical Fatigue Optimization of Three

Dimensional Stress Concentration Features in a Tangentially

Bladed Rotor

by

Nicholas D. Aiello

A Thesis Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF MECHANICAL ENGINEERING

Approved:

_________________________________________

Prof. Ernesto Gutierrez-Miravete, Thesis Adviser

Rensselaer Polytechnic Institute

Troy, New York

April, 2012

© Copyright 2012

by

Nicholas D. Aiello

All Rights Reserved

ii

CONTENTS

LIST OF TABLES .......................................................................................................... ivv

LIST OF FIGURES ........................................................................................................... v

LIST OF SYMBOLS ........................................................................................................ vi

ACKNOWLEDGMENT ................................................................................................. vii

ABSTRACT ................................................................................................................... viii

iii

LIST OF TABLES

iv

LIST OF FIGURES

Figure 1: Load, Lock, and Shield Slot Configuration ....................................................... 3

Figure 2: NX CAD Model of 3D Sector ............................................................................ 4

Figure 3: Meshed 3D Sector Model................................................................................... 5

Figure 4: Element Types in 3D Model .............................................................................. 5

Figure 5: Node Files for Boundary Condition Mapping ................................................... 6

Figure 6: 3D Detail of Blade-Disk Interface Area............................................................. 8

v

LIST OF SYMBOLS

R = radial coordinate of cylindrical system, goes from rotor centerline outward in

3D finite element model

θ = circumferential coordinate of cylindrical system, follows “right hand rule” with

Z axis in 3D finite element model

Z = axial coordinate of cylindrical system, goes from forward to aft of rotor in 3D

finite element model

vi

ACKNOWLEDGMENT

Type the text of your acknowledgment here.

vii

ABSTRACT

Thermo-mechanical fatigue has become a significant concern with respect to rotor life in

turbine engines as maximum metal temperatures have increased in newer designs. Stress

concentration features, such as those present in a tangentially bladed rotor, tend to be the

primary areas of concern for this type of fatigue. This paper will explore the

optimization of a set of three dimensional stress concentration features, using both two

and three dimensional finite element analysis, subject to the realistic design constraints

of

a

functional

tangentially

bladed

viii

rotor

in

a

turbine

engine.

1. Introduction

Thermo-mechanical fatigue (TMF) is a mechanism that causes damage to parts

subjected to transient thermal loading in their within the operational envelope. This

failure mechanism is of concern in several industries including both automotive and

aerospace (3). In the aerospace industry, parts subjected to this type of fatigue include

blades/airfoils and disks/rotors (henceforth used interchangeably) in the high

temperature sections of gas turbine engines. This becomes even more of a concern as

new products push temperatures even higher to help meet industry demands for higher

efficiency propulsion systems.

Focusing on gas turbine engine rotors, the means by which thermo-mechanical

fatigue is introduced deals mainly with the mission profile of the engine. In commercial

aircraft engines, for example, a typical mission includes take-off, climb, cruise, descent,

and landing. The points of the mission in which thermal large thermal transients exist are

at the beginning of the mission (take-off/climb) and the end of the mission

(descent/landing). These are the primary points of interest in the analysis of rotor parts

for thermo-mechanical fatigue.

During the take-off portion of a commercial turbine engine mission, the gas path

of the engine heats up, while the portions of the engine inside the gas path annulus

remain cool. Since a typical rotor consists of a radially outboard and fairly thin rim

directly exposed to the gas path, a massive bore at the most radially inboard point, and

thin web connecting them, this sudden heating up of the gas path heats the rim of the

disk rapidly, but the disk’s massive bore takes much longer to heat up. This causes a

thermal fight in the disk as the rim wants to thermally expand, while the bore holds it

back. What results is a compressive hoop stress field in the rim of the disk that increases

to a maximum during the portion of take-off with largest transient thermals, and then

dissipates as the bore of the disk begins to respond to the increase in flow path

temperatures.

During the descent portion of this typical mission, the opposite of this

phenomenon is in effect. Going from a cruise condition, where the entire engine is

essentially at a thermal equilibrium, to descent, the engine’s gas path suddenly takes on

cooler air. This cools the rim of the disk rapidly, while the bore remains hot. This time

1

the thermal fight in the rotor occurs in the opposite direction. The disk rim wants to

contract due to the decrease in gas path temperature, while the hot bore will not let it.

This results in a tensile hoop stress field at the rim of the disk that behaves in the

opposite manner as compared to the takeoff cycle, meaning the thermally induced hoop

stresses decrease as the bore cools after reaching a maximum transient point during the

descent.

The thermo-mechanical stresses introduced on the rim of a rotor throughout a

mission become particularly problematic when the rotor has some sort of stress

concentrating feature, such as a slot, in the rim of the disk. In the case of a tangentially

bladed rotor, stress concentrating feature generally consist of locking and loading slots.

Loading slots serve as a means of installing blades into a tangential disk. Locking slots

accept locks that are loaded intermittently between blades. These locks serve as a means

of transmitting load between the blades and disk at low power (until friction takes over)

such that the blades don’t freewheel in the disk as well as a means of ensuring the blades

cannot escape through the loading slot. The shape and orientation of these stress

concentrating features to one another is dictated by several design considerations, but

also can have an impact on how large of a stress concentration (or Kt) each feature

actually imposes upon the disk rim. This paper will focus on optimizing the shape and

location of these stress concentrating features, subject to constraints of design

considerations, in order to maximize TMF life for the rotor part.

2

2. Methodology

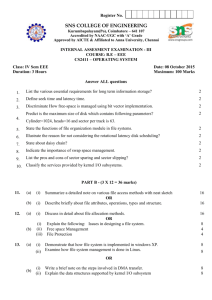

The objective of this thesis project is to create a method of optimizing three

dimensional features, in this particular case a load, lock, and shielding slot configuration

(See Figure 1), for a tangentially bladed rotor such as that of a turbine engine. The

optimization routine explores the design space of the problem, given a set of inputs, and

chooses an optimal solution based on output parameters/targets. Inputs to the

optimization routine account for the shape of the whole rotor, the thermal profile for the

rotor, the mission that the part is subjected to, a parameterized shape of each slot, and the

shape of the blade root that must fit in the loading slot; and output parameters are

stresses in each feature and in corresponding far-field locations of the rotor at several

mission points, the corresponding temperatures at which these stresses occur, and a

calculated TMF life using these outputs. The optimal solution maximizes TMF life in

these features within pre-set boundaries by balancing their lives with one another while

still allowing for installation of a tangential blade into the rotor.

Figure 1: Load, Lock, and Shield Slot Configuration

3

The first step in this project is to evaluate a baseline design for the rotor. The

analysis is conducted on a three dimensional (3D) sector model of a bladed disk and is

run for a complete mission (using ANSYS as a finite element solver). More specifically,

the model is of the area surrounding the tangential groove of disk, from the upper web to

the disk rim (see Figure 2). This was made by first creating a CAD (computer aided

design, NX Unigraphics used) model of the geometry to be analyzed in 3D, then creating

a finite element mesh representation of that model (meshed using ANSYS, see Figure 3).

The mesh consists primarily of 3 types of elements: 10 node tetrahedron elements for the

complex geometry of the area surrounding the 3D slot features, 8 node brick elements

for the axi-symmetric portions of the disk to help keep the element count down and

increase run speed, and 20 node brick elements that collapse to form the pyramid shaped

elements that connect the other 2 element types (see Figure 4). The blades in the model

are represented as a finite element mesh of the portion of the blade root below the neck

(also called the blade stump) with a mass point at the center-of-gravity of the upper

portion of the blade connected to the blade stump by high stiffness spring elements.

Figure 2: NX CAD Model of 3D Sector

4

Figure 3: Meshed 3D Sector Model

Figure 4: Element Types in 3D Model

5

The effect of the rest of the disk is simulated by mapping deflections from a

previously created two dimensional (2D) model onto the corresponding cut boundaries

of the 3D model for each mission point analyzed with that model. This was done by first

exporting the nodes of the 3D finite element model into a separate file. These nodes,

representing the shape of the 3D model, were then all rotated to the mid-plane of the

model (i.e. θ=0), after ensuring their nodal coordinate systems were set to the cylindrical

system being used in the rest of the model. The completed model, containing all of the

nodes of the 3D model compressed into a 2D format (see Figure 5), was saved as another

separate file for use in mapping the thermal response of the rotor. Continuing work on

the node file for mapping of deflection boundary conditions, compressed nodes now in

2D that are not located on the model’s cut boundaries were deleted, leaving only the

nodes residing directly on the boundaries (see Figure 5). The deflections from the 2D

model were then mapped onto these nodes for each mission point that the 3D model will

analyze, ensuring that compensation was made for any differences in coordinate

assignments, and degree-of-freedom boundary conditions files were created for each

point. Similarly, the node file containing all of the 3D model nodes compressed into a

2D format is used to map temperatures on each node for each 3D mission point and

creating thermal boundary condition files for each point. These boundary condition files

are later loaded into the 3D finite element model when the analysis is run.

Figure 5: Node Files for Boundary Condition Mapping

6

Before the model can be run, though, there are a few more boundaries in the 3D

finite element model that need to be resolve, those being the free sides of the disk sector

and the interface of the blade stumps to the disk. The free sides of the disk sector were

given the boundary condition of not allowing movement in the circumferential (θ)

direction. This still allows the disk model to move radially and axially at the boundaries,

but the lack of circumferential motion simulates the existence of the rest of the axisymmetric portion of the rotor. Doing this does not allow for any three dimensional

effects to transfer through the end of the 3D rotor section, so it is important that model

sector is chosen such that the behavior near the sector edges is indicative of the axisymmetric behavior of the rotor. That resolved, the last issue is the interface of blade

stumps to the disk’s bearing surface in the tangential groove (see Figure 6). This

interface was resolved using contact elements between the corresponding sets of faces.

The contact elements used were set to frictionless contact with no separation of face,

which allows the blade to slide along the disk’s bearing surface but not separate from it.

This contact behavior was chosen as an approximation of the actual blade/disk interface

behavior because it helps simplify the model in a way that increases run speed and

decreases likelihood of non-convergence of the finite element solution. The final step in

completing boundary resolution of the 3D model was to constrain the airfoils so that

they, too, could not move in the circumferential direction. This resolves the

circumferential movement still possible with no-separation contacts, and is a fairly

accurate approximation of blade behavior in a tangential disk as the friction force on the

blade bearing surface due to radial blade pull generally keeps a blade in place

circumferentially at most engine operational speeds.

7

Figure 6: 3D Detail of Blade-Disk Interface Area

With the boundary conditions of the 3D model now resolved, the model is ready

to run. A run file was created that loads the various inputs (finite element model with

internal boundary conditions, deflection cut boundary conditions, and thermal

conditions), and applies the correct set of inputs and rotational speeds for each mission

point in the set.

8

3. References

1. Determination of stress concentration factors of a steam turbine rotor using FEA

Nagendra Babu, R.; Ramana, K.V.; Rao, K. Mallikarjuna Source: Proceedings of the 2nd

WSEAS International Conference on Engineering Mechanics, Structures and Engineering

Geology, EMESEG '09, p 56-59, 2009, Proceedings of the 2nd WSEAS International

Conference on Engineering Mechanics, Structures and Engineering Geology, EMESEG

'09

2. Overview of High Temperature and Thermo-mechanical Fatigue (TMF)

Sehitoglu, H. Source: University of Illinois Mechanical and Industrial Engineering

3. Simulation of complex thermomechanical fatigue

Bardenheier, R.; Rogers, G. Source: Acta Metallurgica Sinica (English Letters), v 17, n 4,

p 400-406, August 2004

4. Thermo-Mechanical Fatigue Life Prediction: A critical Review

Zhuang, W.Z.; Swansson, N.S. Source: DSTO Aeronautical and Maritime Research

Laboratory, January 1998

5. Turbine blade fir-tree root design optimisation using intelligent CAD and finite

element analysis

Song, Wenbin; Keane, Andy; Rees, Janet; Bhaskar, Atul; Bagnall, Steven Source:

Computers and Structures, v 80, n 24, p 1853-1867, September 2002

9