Jerry & Carol`s Hybrid GH. - Klamath Sustainable Communities

advertisement

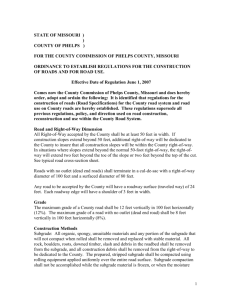

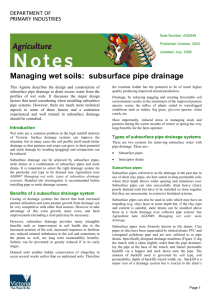

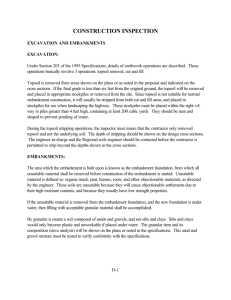

Jerry & Carol’s Hybrid Greenhouse (“Hybrid greenhouse” is what we call the result of combining a hoop-house with a solar greenhouse.) We had hoped to combine the relatively low cost of a hoop-house with the strength and warmth of a more typical solar GH. We achieved part of this: the structure is strong and well-anchored, and we think the covering should withstand the 80-mile-an-hour winds that blew down our first GH a few years ago. But the cost came to about $3,000, for the 14’ x 22’ space, which is pretty expensive for a hoop-house. We do have a nice high interior, well-insulated opaque walls, and a modest heat storage that keeps the interior probably 5 degF warmer than outside. (view of W end) For easy access, each end has a door; we can increase the ventilation in summer by removing the 4 x 8-foot panel next to each door. (The cover can also be rolled up to admit light and air at any season, see below.) We made the hoops from 1” PVC pipe, which we bent between the N and S walls. Because of the heavy snow load – which has collapsed several hoop-houses in this area – we placed them only 2 feet apart, and strengthened the whole structure with a ridge beam supported on posts tied to the end-walls. We also added horizontal “purlins”, as well as diagonal braces on both sides. (completed frame) (with cover in place) After the frame was complete, we found we could flex it only 1/8” by leaning hard against the end posts; so we believe that the greenhouse is sound. The GH cover is of 6-mil polyethylene (“Visqueen” is one brand), with the south edge wrapped around a 3” pipe fitted with a crank. (The vent openings in the S. wall are from a previous venting plan.) It took us three tries to install the cover, as the first two times a wind came up and we couldn’t keep it in place. To pull the cover into place we used a trick: at three places near one edge we bunched up the cover around clumps of rags, making small “heads” around which we tied lengths of twine, with weights on the other end. We threw the weights across the GH, then used the twine to pull the cover into place, holding it while we fastened it temporarily. We attached the cover to the end-walls by taping heavy pipe wrap to the edge, then attaching that to the endwalls with short lengths of 1x2’s. Where the cover will be rolled up, we used pipe wrap tape again to strengthen the edges, then passed twine through holes and tied it to projecting screw-heads. To turn the roller, we fastened a piece of wood in the roller pipe, then cross-drilled to accept copper pipe handles. With the cover rolled partway up, it looks like this: Growing bed: As the south wall shades part of the floor in winter, we built a raised growing bed there to catch some winter sun. The south wall is 2 feet high, so it was natural to allow storage underneath the bed. To keep water out of the stored stuff, we built a corrugated steel “drainage table” just under the bed . We clothed the bottom of the bed in row-cover fabric to contain the soil. A slight peak at the center of the drainage table lets each half drain into a bucket at the outer end. (drainage table) (lettuces growing) For heat storage we have four 55-gallon drums filled with water. In winter, the top part of each barrel freezes, and they don’t seem to be helping the nighttime temperature very much. Maybe we’ll figure something out…