Due_Diligence__Check_List

advertisement

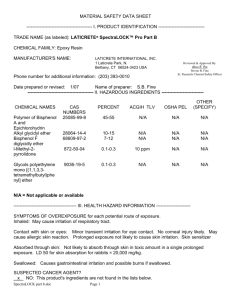

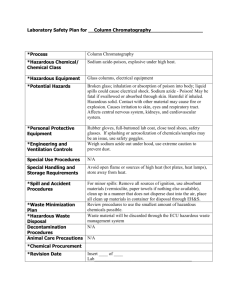

Power Generation Consulting Due Diligence List Technical: List of major capital projects (over 50K) –performed at each site over last 5 years List of future capital projects planned over next 3 years Copy of last performance test run Are winter/summer performance tests required by the ISO/Host Utility under the PPA? 5. Have any power augmentation studies been performed? 6. Historical averages of NSHRs’ for each unit over last 5 years 7. Copy of latest heat balance 8. Copy of unit output vs. temperature correction curves 9. Copy of plant system descriptions 10. Current chemistry limits for HRSG/Boiler 11. Current specification for water/steam for NOx abatement 12. Provide a copy of current site budget (plant direct costs) 13. Provide a copy of future years budget 14. Copy of any prior internal or external assessment reports 15. Copy of site LOTO/Confined Space Entry procedures 16. Review site emergency procedures 17. Tracking system in-place for unusual events? 18. Does a QA/QC program exist for code repairs? 19. For older fossil fuel plants, gas/oil/coal, review plant assessment, ISI, reports, NOx Retrofits which may include the following: 1. 2. 3. 4. Boilers economizer tubes downcomer tubes waterwall tubes superheater tubing reheater tubing primary superheater headers secondary superheater headers reheat inlet/outlet headers steam drums mud drums lower waterwall headers economizer inlet headers attemperators/desuperheaters ash hoppers windboxes burners structural steel/buckstays D:\533572047.doc 1 High Energy Piping main steam piping hot reheat piping cold reheat piping high energy valves extraction piping and valves Steam Turbines turbine rotor rotor bores turbine discs disk rims couplings blading blade roots erosion shields tie wires/tenons nozzle block turbine casing steam chest HT studs diaphragms control valves main stop/intercept valves Generators rotor rotor bores couplings Rrings stator windings Balance of Plant pumps FD/ID fans air preheaters FW heaters condensers deaerators ductwork precipitators stacks and liners cooling towers coal bunkers pulverizers D:\533572047.doc 2 Damage Mechanisms Present high cycle fatigue low cycle fatigue corrosion fatigue creep thermal fatigue oxidation graphitization corrosion Flow assisted corrision NOx Control Retrofits retrofits performed % NOx reduction impact on boiler efficiency impact on LOI fireside corrosion slagging, fouling 20. Site insurable events, 5 year loss history Administrative 1. 2. 3. 4. 5. 6. 7. Provide a current organizational chart for the site (by classification) Provide a pay scale for the site employees Is the site union? if so, provide copy of latest agreement Provide a summary/overview of site incentive plans and goals program Provide a list or matrix of plant training records for current year In general, are there administrative procedures for the site? Site employee Savings/Health Care Plans Corporate To be developed Fuel 1. Historical data on HHV of FO/natural gas 2. Most recent lab analysis of FO 3. P&ID’ for gas main from LDC 4. Existing maximum flow capability at gate station, pressure/flow in scfh 5. As above, do any load constraints occur due to low gas pressure? 6. Capability of on-site gas compression 7. Site tankage capability 8. Copy of latest API inspection records 9. Average coal inventory in tons 10. Copy of latest coal analysis 11. Copy of any existing fuel /purchase agreements D:\533572047.doc 3 12. Historical burner tip prices Operations: 1. Current staffing levels for Operations Dept/job classifications 2. Historical averages for each unit, last 5 years equivalent availability, equivalent forced outage rates, starting success of CT’s, 3. Total fired hours to date each engine, each site, total gas/oil fired hours, total fired starts each engine/each site 4. Copy of a daily operational/equipment/control room log 5. Prior year, gross/net total generation in MWHrs 6. YTD, same as above 7. Fundamental indicators of overall Plant Condition (the following items should be noted during the tour and prior to final bid Plant management should have set high standards for plant housekeeping and all facility equipment Equipment should be properly lubricated and have appropriate preventive maintenance records Equipment operating temperatures and vibration limits should be within acceptable limits Fluid system leaks should be minimal Equipment instruments and gages should be indicating properly and have evidence of periodic calibration Electrical equipment doors and closures should be in-place and properly installed Equipment Systems are properly protected to minimize exposure and corrosion Industrial safety hazards are being minimized Walkways and equipment access are clear and unobstructed General appearance of the equipment should be clean and free of debris Piping, valves, mechanical and electrical equipment should be clearly labeled. In general, no or minimal evidence of improper housekeeping should exist Facility lighting should be maintained at a high level Overall appearance of the Main Control Room should be clean and professional Audible and visual alarms should be operational MSDS, operational logs etc. should be stored orderly Fire Protection equipment should be operational l and properly charged Maintenance: 1. Copy of major inspection reports over last 5 years for STG, CTG.HRSG 2. Copy of planned inspections over next 3 years 3. Does an LTSA/LTMA exist? 4. Current inspection intervals for STG, CTG, HRSG at each site 5. Computer run of major spare parts (over 10K) 6. Total inventory values of spare parts each site 7. Specific spares for CTs’ used for Combustor/Hot Gas Path/Major Inspections 8. Explain type and use of CMMS 9. Current staffing levels for maintenance dept/job classifications 10. List of PM tasks performed for CTG, STG, HRSG 11. Copies of major equipment manuals D:\533572047.doc 4 12. CTG/STG/HRSG/GSU Nameplate ratings 13. List of any predictive maintenance tasks performed. 14. Site philosophy for utilization of outside contractors Plant Dispatch and Cost 1. 2. 3. 4. Current rated capacity of each unit at site Describe the plants’ dispatch characteristics (if bid into a Power Pool) Does a dispatch model exist for the site? Regarding the electrical PPA, do any constraints exist such as minimum generation alerts? What has been the historical impact? 5. What is the current operating/dispatch rate for the site ($/MWh)? How was it calculated? 6. Dispatch rates for each fuel, oil vs. natural gas (coal if applicable) 7. Incremental cost curves? 8. Do any peak ratings exist for the CTGs’? 9. Fuel switching on the CTGs’, is it tested on a regular basis? 10. Do any thermal limits or de-rates exist on the units during periods of high ambient temperatures? 11. Current start costs for each CTG 12. Copy of site fixed and variable costs? 13. Ancillary Services for each unit? (focus on spinning reserve, AGC and Black Start cap), how are the services qualified with the Power Pool? 14. Plant start-up times, hot/warm/cold calculated? 15. MMBTU for each type of start 16. Limits on maximum operating hours/unit/year due to air permit? Limits on oil firing? 17. Discussion of capacity and energy revenues, how are they calculated? Cogeneration: 1. 2. 3. 4. 5. 6. 7. Provide a copy of current Steam Sales Agreement Provide a copy of electrical sales agreement with host utility Relationship with Steam Host? Financial viability of the Steam Host? Prior year Qf calculation and current YTD Average hourly steam take in lbs./hr Long term concerns regarding Qf issues, change in steam host process, trends of yearly steam takes 8. Electrical/thermal capability of the site in a Merchant scenario (no extraction) 9. Discussion of a potential scenario in which the steam sale agreement is severed D:\533572047.doc 5 Environmental, Health & Safety Issues I. SITE INFORMATION: 1. Current Site Information Describe current use of property and facility. Describe site ground water depth, and known use of ground water. Is location urban or rural? Is area industrial, commercial, residential or undeveloped? Describe surface water within 500 feet. Provide size of property (in acres) and map of the area. Describe any major demolition that occurred on site. 2. Site Reconnaissance During site visit look for and inquire about: Areas of exposed soil or dead vegetation (locate on map) Newly surfaced areas or disturbed soil (locate on map) Any signs of sludge, discoloration, or oil sheen Any evidence of spills, releases, or contamination (locate on map) Describe any previous, current, or planned remediation on this property. Make appropriate inquiry to determine whether operation of the facility requires or contemplates construction, dredging, or other land alterations in or on any body of water, waterway, wetland, or flood plain. If so, describe. Discharges to ground and surface waters, POTWs, etc. Verify emission sources compare to air permit Determine if potential exists for contamination (possible need for Phase II type work) due to the historical or current use of or adjacent property use of: Solvents – Lead – Gasoline/diesel – PCB – Fuel Oil – Asbestos – Mercury - other 3. Site History List previous use of the facility for the last 60 years (via interviews, aerial photos, fire insurance records, etc.). If a title search is used, attach it as an exhibit to your report. Provide the following: a) b) c) d) e) f) The period of ownership or operation The type of activity or manufacturing process conducted at the facility Any potential on-site contamination How wastes were disposed of Description of wastes stored, treated, or disposed on property. Review and provide copies of available topographic maps, geologic surveys, historical maps, and aerial photographs of the facility. Discuss the results of the review, including any indicators of potential on-site contamination. g) Determine whether the property was ever the site of an industrial or manufacturing concern or whether property was ever a disposal site for wastes generated on or off site. D:\533572047.doc 6 h) Obtain and evaluate copies of any filing and/or inspection reports concerning the facility, or adjoining property, by any federal, state, or local environmental authorities. i) Make appropriate inquiry to determine whether any past owner or operator of the facility received notice that it is or may be a potentially responsible person in connection with response costs, including costs of removal or remedial action under CERCLA. (This question should address both on-site and offsite notifications.) j) Contact appropriate agencies to determine whether there is any known ongoing environmental investigation by federal, state, or local government agencies of any site within a two-mile radius of the facility. 4. Adjacent Property For each adjacent property: a) b) c) d) e) f) Describe the current use Describe previous uses Does the adjacent property have any environmental impact on this facility? Is any of the adjacent property used for petroleum storage or delivery? Is any of the adjacent property used for chemical manufacturing? Is there any indication of on-site disposal or soil contamination? Identify the following using commercially available databases of federal and state agency files to compile this information a) b) c) d) e) f) g) National Priorities List sites in the area CERCLIS sites and comparable state list sites in the area Active landfill or land disposal sites in the area Inactive or closed landfill or land disposal sites in the area Any other potential concerns in the area Any past or current treatment of disposal sites that may cause liabilities State/local abandoned waste or uncontrolled release sites (e.g. Superfund) or other sites inventoried for potential or confirmed hazardous waste release h) Hazardous waste treatment, storage, and disposal facilities (TSDF) i) Injection wells k) Leaking underground storage tanks Obtain and evaluate copies of any filings and/or inspection reports concerning adjoining properties by the federal, state, or local environmental authorities. (This question is particularly important if we suspect contamination at an adjacent property.) 5. Site Investigation/Remediation Activities Describe potentially responsible party (PRP) notifications that the owner or operator has received or expects to receive. (A PRP notification could indicate a major cash flow impact. We should attempt to quantify the potential impact.) Describe any known or suspected environmental problems associated with the property (current and past). If on site, locate on map. D:\533572047.doc 7 Describe any previous, current, or planned remediation on this property. Contact appropriate agencies to determine whether there are any known ongoing environmental investigations or any noncompliance issued by federal, state, or local government agencies. Make appropriate inquiry to determine whether current owners have received notification from any private citizen, group, or governmental entity of an intent to file a lawsuit alleging a violation of federal or state environmental laws or damage to natural resources. Obtain and evaluate copies of any such notices. Make appropriate inquiry to determine whether any suits have been instituted by private citizens or governmental entities that seek civil or criminal damages or injunctive relief arising out of alleged violation of federal or state environmental laws, damage to natural resources, or alleging trespass or nuisance. Determine if any environmental testing has been carried out at the property (e.g., well sampling of ground water, surface soil sampling, soil boring sampling, or ambient air monitoring). Locate on map. Determine whether any of the following has been conducted at the facility: a) b) c) d) e) f) g) Previous Phase I, II, III reports Environmental assessments or audits Regulatory inspections Soil, air or water sampling Environmental impact statement Reports to planning, zoning, or community boards Ask for copies of any reports. Review previous reports for items that may trigger significant costs. II. AIR ISSUES: 1. Emission Inventory List all Emission Sources 2. Air Permits- Obtain copies of all current permits Title V State PSD 3. Check for emissions control equipment and records Maintenance records Continuous monitoring System (CMS) or Continuous Emissions Monitoring (CEMs) records Certification records Monitoring records RATA and calibration records Operational, maintenance and calibration procedures for site Excess Emission Reports 4. Check routine regulatory reports (annual Title V Certification, quarterly EDRs, annual emission fee submittals, etc.). 5. Check for source testing requirements, and if available, source test records. D:\533572047.doc 8 6. Check if site uses solvent based cleaners Identify all such units Review procedures for use Review solvent tracking records 7. Check for refrigeration equipment Identify all units Review comfort cooling equipment maintenance/ repair records Review small appliance repair records. Review motor vehicle a/c repair records. Identify all refrigerants maintained on site and volume 8. Have any permitted sources been modified or undergone operational changes requiring regulatory notification since the permit or most recent revision has been issued. 9. Are there any notices of violation or administrative orders in place? Past and closed Current and open 10. Have there been any recorded complaints from neighbors? 11. Are there any plans for upcoming facility modifications or fuel changes that could affect emissions? 12. Is the project involved in any trading programs? NOx Budget program Acid Rain Other (e.g., RECLAIM) 13. Any outstanding issue with regulators, third parties or other persons regarding air issues that should be disclosed at this time? III. WATER ISSUES – Discharge, Intake, and Stormwater: 1. Describe all discharge points for site (Industrial, Domestic and Stormwater) To navigable waters or wetlands To groundwater To Publicly Owned Treatment Works (POTW) 2. Secure copies of all applicable permits Industrial NPDES/SPDES (surface and groundwater) permits Private POTW permits Stormwater Discharge Permits Water withdraw for consumptive use permits 3. Monitoring and Record keeping requirements D:\533572047.doc 9 Sample Discharge Monitoring Reports or other similar monitoring reports for industrial wastewater discharge for past three years Review past three years of water withdrawal reports Is there a written QA/QC plan for water quality sampling and analysis Does the site do its own lab analysis for reports and if so is the site lab certified? Is there a Best Management Plan (BLM) in place? Does the site have a groundwater monitoring system installed to monitor for potential or known groundwater contamination? If groundwater is monitored, review reports submitted to regulatory agencies for the past 3 years. 4. Are there any permits (specific or General) issued by the Army Corp of Engineers for work in navigable waters or wetlands associated with the facility? Examples include the following. Section 9 Section 10 Section 316(b) Section 404 5. What is (are) the nearest receiving stream or body of water to the facility? 6. Provide all sources for facility intake water. Are all of them covered by license? 7. Have any permitted systems been modified or undergone operational changes requiring regulatory notification since the permit or most recent revision has been issued. 8. Are there any notices of violation or administrative orders in place? Past and closed Current and open 9. Have there been any recorded complaints from neighbors? 10. Are there any plans for upcoming facility modifications or changes that could affect either intake supply, wastewater discharge or stormwater monitoring programs? 11. Any outstanding issue with regulators, third parties or other persons regarding water issues that should be disclosed at this time? 12. What is the site’s drinking water source? If non-public (e.g., site well) is the water tested and are there records of testing for review? IV. RESOURCE CONSERVATION RECOVERY ACT (RCRA) ISSUES: 1. Is documentation of facility hazardous waste generator classification (federal and/or state) available? D:\533572047.doc 10 2. Are lists of solid and hazardous wastes and monthly volumes generated over the past year available? 3. Are copies of the Manifests for the past year available? 4. If applicable, is there documentation of all contaminated areas on site or for active or inactive waste disposal areas. 5. Is a listing of all commercial waste transporters and Treatment/Storage/Disposal operators used by the facility available? 6. Are all site pre-treatment units (oil/water separators, wastewater neutralizers, etc. operated in accordance with local and federal requirements? 7. Are audit of the waste transport and disposal vendor facilities available? 8. Describe any waste minimization plans/procedures that are in use. 9. Are there any notices of violation or administrative orders in place? Past and closed Current and open 10. Have there been any recorded complaints from neighbors? 11. Are there any plans for upcoming facility modifications or changes that could affect the hazardous waste management program? 12. Any outstanding issues with regulators, third parties or other persons that should be disclosed at this time regarding site hazardous material/waste management. V. EMERGENCY PLANNING AND COMMUNITY RIGHT TO KNOW (EPCRA) ISSUES: 1. Is documentation of the quantities of listed hazardous or extremely hazardous substances used and stored on site available? 2. Are there listed chemicals on-site which require a Risk Management Plan (RMP), such as chlorine, ammonia, etc? Are the initial and follow-up assessment reports available? 3. Has annual reporting of applicable site substances been routinely made and are copies of the following available, where applicable? SARA Title III, Section 311 (MSDS and initial notification) SARA Title III, Section 312 (annual Tier I/ Tier II Reporting) SARA Title III, Section 313 (annual Toxic Chemical Release forms (TRI)). D:\533572047.doc 11 4. Are there any notices of violation or administrative orders in place for this program? Past and closed Current and open 5. Have there been any recorded complaints from neighbors? 6. Are there any plans for upcoming facility modifications or changes that could affect the use of listed hazardous substances on-site and this program? 7. Any outstanding issues with regulators, third parties or other persons regarding issues that should be disclosed at this time regarding listed hazardous substance use and management. VI. ASBESTOS MANAGEMENT: 1. Is there asbestos containing material (ACM) present on-site, if so has it been described? (e.g., flooring, or roofing material, ceiling tiles, etc.) 2. Is any of the material friable and if so has the following been done? Have engineering controls been installed? Have warning signs been put in place or material labeled? 3. Has any ACM been removed or disposed of in the past five years? VII. FEDERAL INSECTICIDE, FUNGICIDE AND RODENTICIDE (FIFRA) ISSUES: 1. Is information available as to brand, supplier, volume used/year and volume stored of chemicals applicable to this program? Herbicides Pesticides VIII. SOLID WASTE – OTHER MANAGEMENT ISSUES: 1. Where does the facility send solid wastes (non-hazardous material, e.g., filter cake, scrap metals, domestic garbage, etc.). Is a list available? 2. How and where does the facility dispose of “special wastes”, such as light ballasts, batteries, fluorescent and mercury vapor lamps, etc? Is this information documented? 3. How and where does the facility dispose of waste oil and waste oil accessories such as filter, etc? Is this information documented? D:\533572047.doc 12 4. How and where does the facility dispose of coal combustion by-product wastes such as fly ash, bottom ash, scrubber sludges, etc? Is this information documented? IX. OIL AND CHEMICAL RELEASE MANAGEMENT ISSUES: 1. Is the site subject to the federal Spill Prevention Control and Countermeasure (SPCC) program? If so, is a current copy of the plan available? 2. Is the site subject to the Oil Pollution Act of 1990 (OPA) program? If so, is a current copy of the plan available? 3. Is the site subject to any state specific spill plan (e.g., the New Jersey Discharge Prevention Control and Countermeasure Plan (DPCC)? If so, is a current copy of the plan available? 4. Does the facility have an in-house set of spill response procedures? If so, is a current set available? 5. Do the facility management plans contain updated notification lists and telephone numbers? 6. Do impermeable containments surround each chemical and oil storage and transfer area, properly sized for the largest container in the area? How is this documented? 7. Are all oil and chemical storage tanks on a routine inspection and preventative maintenance schedule? How is this tracked and documented? 8. Are copies of the most recent integrity test (both active and passive) from all applicable storage tanks available? 9. Are all aboveground and underground storage tanks identified on a site drawing and is a copy of that drawing(s) available. 10. If there area underground storage tanks on site, describe what is contained in them and whether or not the units and associated piping have been upgraded to comply with all current UST requirements under 40 CFR 280. 11. Are there any notices of violation or administrative orders in place regarding the storage tanks? Past and closed Current and open 12. Have there been any recorded complaints from neighbors? 13. Are there any plans for upcoming facility modifications or changes that could affect current storage tank use? D:\533572047.doc 13 14. Any outstanding issues with regulators, third parties or other persons regarding air issues that should be disclosed at this time regarding site oil and chemical storage tanks – including both aboveground and underground units, as applicable. 15. Have there been any reportable spills of either oil or chemical products within the past five years. If so, is documentation available as to who was notified and the nature of the spill? X. TOXIC SUBSTANCE CONTROL ACT (TSCA) ISSUES: 1. Are there any known PCB containing material located on the plant site (e.g., transformers, ballasts, etc.)? 2. If no, how was this determined (testing, best available information age of equipment)? 3. If PCB or PCB contaminated materials are on site is there a description of these and is this information available. 4. Are there transformers on-site? If so, Is there an inventory/ description of all transformers, including serial numbers? Do all transformers have containment? Have all transformers been tested for PCB or PCB contamination? Are records available regarding the questions above? 5. Have there been any reportable leaks or spills from equip containing PCB or PCB contaminated fluids. If so, are copies available? 6. Are there any notices of violation or administrative orders in place? Past and closed Current and open 7. Have there been any recorded complaints from neighbors? 8. Are there any plans for upcoming facility modifications or changes that could affect the current status of the site PCB management program? 9. Any outstanding issues with regulators, third parties or other persons regarding issues that should be disclosed at this time regarding site PCB management? XI. MANAGEMENT SYSTEMS / TOOLS AVAILABLE 1. Is there a matrix, chart or automated system available, which provides a schedule/summary of, required periodic maintenance, monitoring, notification, reporting and or other similar environmental commitments? D:\533572047.doc 14 2. Is training provided (and documented) in the following environmental program areas, where applicable and required? Clean Air Act (CAA) Clean Water Act (CWA) Safe Drinking Water Act (SDWA) Oil and chemical leaks and spills Resource Conservation and Recovery Act (RCRA) Toxic Substance Control Act (TSCA) Asbestos Management Federal Insecticide, Fungicide and Rodenticide Act (FIFRA) Community and Work Right to Know programs and Material Safety Data Sheet (MSDS) awareness XII. SAFETY PROGRAM: 1. In accordance with OSHA requirements, does the facility have the past five years of the annual A-200 annual report? Are these available? 2. Worker Right to Know Program: Has the facility been evaluated for hazardous chemicals stored and used onsite. How often is this review updated and revised? Copies available? Have MSDS’s been developed or obtained for all applicable materials used and/or stored on-site? Are all containers with listed hazardous substances properly labeled? 3. Is the facility subject to OSHA Process Safety Management Program? If so, is there a plan covering the 14 elements in place? Is there open mechanical integrity or other process hazardous analysis issues/recommendations that will need capital dollars to address? 4. Are there any outstanding worker’s compensation claims or dollars reserved for such claims? 5. Are there any contractor/subcontractor claims threatened or pending regarding safety or health issues? 6. Are any utilities provided to the public or company offices? Natural Gas – odorized or un-odorized Water – potable or non-potable (drinking/eyewash/showers/toilets/ice machines, etc.) 7. Determine if potential for any special exposure issues exist, i.e. coal dust, asbestos, lead, radon, benzene, H2S, etc. D:\533572047.doc 15 XIII. PIPELINES: Are natural gas pipelines associates with these projects, i.e. designed, constructed, operated/maintained? If so, is the pipeline jurisdictional under DOT Office of Pipeline Safety regulations? What is the line class location? What class location standard was the line built to? What is the MAOP? Show documentation. Is the pipeline “smart pig” ready? Is the line cathodically protected? If not yet built, has the pipeline ROW been permitted for threatened endangered species, wetland issues, and cultural resource issues? If so, how and where is this documented? Has an operation and maintenance plan been developed/approved? Is drug testing in place? XIV. BUDGET (G/A and Capital): Review budget for: a) Current/future capital costs associated with remediation projects and emission control equipment, cultural resource/wetland mitigation. b) Current/future G/A costs associated with remediation O&M, EH&S personnel salaries/wages and benefits. c) Determine EH&S personnel associated with these assets (position/area of responsibility). Site Potential: Transmission “get away” capability at each site Have any site expansion studies been performed? Copy of electrical single lines Copy of gas transmission maps (showing LDC interconnect to main interstate line) 5. Source of make-up water for each site, limits in gallons/day/year. 6. Any known gas flow constraints, pressure/flow 7. Copy of site real estate map 8. Property available in acres for additional generation /each site 9. Flood plain issues if any 10. Any known noise issues at closest property lines? 11. Aerial photographs of the site? 12. Copy of existing interconnection agreements 1. 2. 3. 4. D:\533572047.doc 16