HTS ASSAY Development Request - High Throughput Screening

1

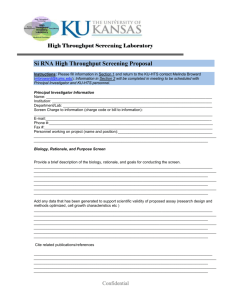

High Throughput Screening Laboratory

HTS ASSAY Development Request

(Fill in information that is available)

Instructions: Please fill information in Section 1 and return to the KU-HTS contact Melinda Broward

( mbroward@kumc.edu

). Information in Section 2 will be completed in meeting to be scheduled with

Principal Investigator and KU-HTS personnel .

SECTION 1

Principal Investigator Information

Name:

Institution:

Department/Lab:

Screen Charge to information (charge code or bill to information):

E-mail:

Name:

Phone#:

Fax #:

Personnel working on project (name and position):

Assay, Rationale, and Technology of the Screen

Provide a brief description of the biology, rationale, and goals for conducting the screen.

Describe the assay materials and methods

C o n f f i i d e n t t i i a l l

2

If you would like to add additional information on biology, scientific rationale for the target, preliminary data etc., please attach your write up to this document. Limit attachment to NOT more than 5 pages.

SECTION 2

This Section to be completed during consultation meeting with KU-HTS personnel.

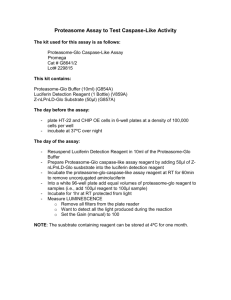

Assay Protocol

If commercial kits are available, provide brief description.

Manufacturer name and Catalog #:

General Assay parameters to be optimized:

Throughput mode

False positive/negative rates (historic information)

Sensitivity of the assay

Signal window

Cell seeding process

Coefficient of variation (CV)

Z and Z’ values

Cost of reagents during scale-up

Assay Signal Stability

Miniaturization of the Assay in microplate format:

A. Biochemical Assays

Volume adjustment: 70-90ul (384-wells) or 100-200 ul (96-well)

Assay sensitivity and specificity

Order of reagent addition

DMSO sensitivity

Substrate/Ligand concentration

Incubation time and degree of substrate depletion

Windows between positive and negative controls

Assay reproducibility (2 plates, 2 days)

IC50 curves of known compounds

Enzyme/substrate stability, storage, freeze-thaw effects

B. Cell-based Assays

Cell cycle and cell-passage dependence

Cell numbers at seeding in 384-well and 96-well formats

Time course of read-out

Cell harvesting conditions

Signal-background ratios

Incubation time with test compounds: pre-incubation possibities

Minimized pipetting steps, washing steps and no. of buffers

Influence of the order of reagent addition/possibility of pooling reagents

Try to use the same model of instruments (e.g. detection and liquid handling) for both assay development and screening, if possible.

Check reagents for screening

C o n f f i i d e n t t i i a l l

3

Scaling-up for HTS

Identification of vendor/contractor for outsourcing reagent preparation

Negotiating Reagent costs

Large-scale protein production

Optimization of parameters for large-scale cell-growth (pH, media, confluence, CO

2 levels, detachment, osmolarity

(ion-channel targets only)

Tips on improving expression, minimize edge effects, cellaggregation

Original completed form goes to HTS file and electronic copy to Project Director Melinda Broward at mbroward@kumc.edu

.

C o n f f i i d e n t t i i a l l