POLA_26253_sm_SuppInfo

advertisement

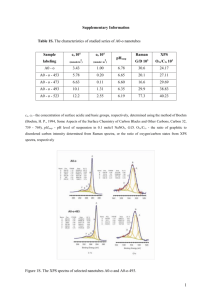

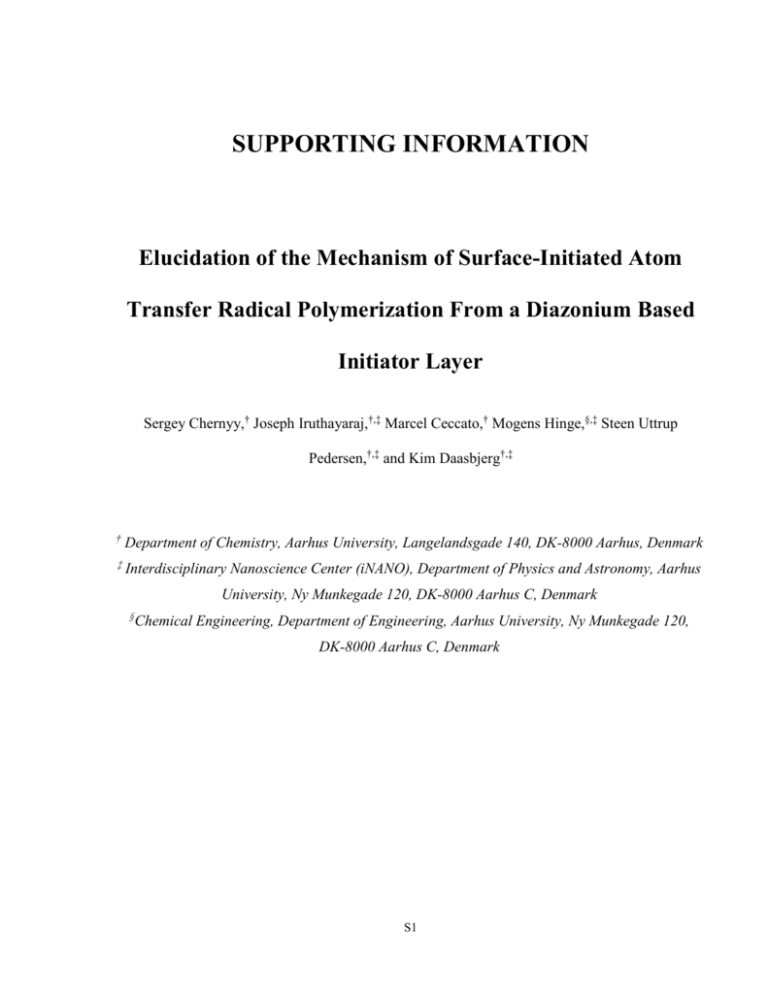

SUPPORTING INFORMATION Elucidation of the Mechanism of Surface-Initiated Atom Transfer Radical Polymerization From a Diazonium Based Initiator Layer Sergey Chernyy,† Joseph Iruthayaraj,†,‡ Marcel Ceccato,† Mogens Hinge,§,‡ Steen Uttrup Pedersen,†,‡ and Kim Daasbjerg†,‡ † Department of Chemistry, Aarhus University, Langelandsgade 140, DK-8000 Aarhus, Denmark ‡ Interdisciplinary Nanoscience Center (iNANO), Department of Physics and Astronomy, Aarhus University, Ny Munkegade 120, DK-8000 Aarhus C, Denmark § Chemical Engineering, Department of Engineering, Aarhus University, Ny Munkegade 120, DK-8000 Aarhus C, Denmark S1 ATRP medium. The choice of reaction medium for the SI-ATRP process was based on an investigation of the controllability of the corresponding solution reaction. Figure S1 shows the plots obtained of ln([MMA]o/[MMA]t) and conversion of MMA against time obtained for various 0.40 35 0.35 30 ln([MMA]0/[MMA]t) 0.30 25 0.25 20 0.20 15 0.15 10 0.10 Conversion (%) solvents (acetone, acetonitrile, and dioxane) and ligands (PMDETA, TPMA, and Me6TREN). 5 0.05 0.00 0 0 1 2 3 4 5 6 Polymerization time (h) Figure S1. Plots of ln([MMA]0/[MMA]t) and conversion versus polymerization time for solution ATRP of MMA. Ligand and solvent polarity were varied while keeping concentrations of all reagents constant: [CuBr] = 3.0 mM, [CuBr2] = 1.3 mM, [Ligand] = 4.7 mM, and [EtBriBu] = 6.0 mM. Conditions used were 50% acetone/PMDETA at 50 °C (♦), 50% acetone/TPMA at 25 °C (▲), 50% acetone/PMDETA at 25 °C (○), 30% acetonitrile/Me6TREN at 25 °C (■), 44% acetonitrile:dioxane (1:1)/Me6TREN at 25 °C (●), and 50% acetone/Me6TREN at 25 °C (□). Note that conversion is linearly correlated with ln([MMA]0/[MMA]t) up to 30% conversion. Attempts to conduct ATRP in acetonitrile failed due to the precipitation of PMMA shortly after addition of the initiator, i.e., EtBriBu. Adding dioxane or acetone to acetonitrile for solubilizing PMMA was of little help only, resulting in <5% conversion of the monomer. In contrast, using acetone as the main solvent (besides MMA) the ATRP process performed well as evidenced by the reasonably linear development in ln([MMA]0/[MMA]t) as a function of time, at least for the ligands PMDETA and TPMA. The curvature observed at the beginning of the polymerization at both 25 and 50 °C in these cases is a consequence of the persistence radical effect that regulates the ATRP S2 process during an initial pre-equilibrium time period. In this period deactivator species are accumulated through termination reactions occurring between propagating radicals, thereby indicating that the amount of deactivator added initially is not sufficient to establish the equilibrium between the dormant and active species (Scheme S1). Scheme S1. Kinetic parameters that signify the ATRP equilibrium and polymerization process in terms of the activation rate constant, ka, deactivation rate constant, kd, propagation rate constant, kp, and termination rate constant, kt. The species RX denotes the initiator, M the monomer, and Pn the propagating polymer radical. The kinetic form of a radical polymerization having a constant radical concentration due to the absence of termination reactions is given by eq S1. ln M0 k p [Pn ]t k appt Mt (S1) In this expression [M]0 and [M]t refer to the concentration of the monomer initially and at a given time t, respectively, while kp denotes the propagation rate constant, kapp the apparent rate constant, and [ Pn ] the radical concentration. Further, taking into account the persistent radical effect the whole ATRP process may be described by eq S2.S1,S2 ln kp M0 2 (3k t K ATRP [CuX ]02 [RX ]02 t [CuX 2 ]30 ) 2 / 3 [CuX 2 ]02 M t 2k t K ATRP [CuX ]0 [RX ] 0 (S2) In this expression KATRP is the ATRP equilibrium constant (= ka/kd, where ka is the activation rate constant and kd is the deactivation rate constant), kt is the termination rate constant, and [CuX]0, S3 [CuX2]0, and [RX]0 are the initial concentrations of the activator, deactivator, and initiator, respectively. The linear regime in Figure S1 was fitted by eq S1 to obtain kapp and subsequently [ Pn ] = kapp/kp using calculated values of kp.S3 In a further treatment of the whole data range iterative fitting to eq S2 was carried out to extract values of KATRP (setting kt = 109 M-1 s-1).S4 All values obtained are collected in Table S1. Table S1. Kinetic Parameters Extracted for Solution ATRP of MMA in Acetone. Ligand TPMA PMDETA PMDETA T (°C) 105KATRPa 106kapp (s-1)b 25 25 50 7.4 ± 0.4 6.0 ± 0.2 4.9 ± 0.1 9.8 ± 0.4 8.2 ± 0.4 18 ± 1 kp (M-1 s-1)c 108[ Pn ] (M)d 309 ± 56 309 ± 56 606 ± 103 3.2 2.7 3.0 a Determined from eq S2. b Determined from eq S1. c Determined from the Arrhenius equation, i.e., k p Aexp(- Ea / RT ) , using values of the pre-exponential factor, A (= 2460477 M-1 s-1), and activation energy, Ea (= 21582 J mol-1), listed in the Polymer Handbook.S3 d Calculated from [ Pn ] = kapp/kp, see eq S1. From Table S1 it can be seen that the temperature dependence of KATRP is not significant, showing similar values for the PMDETA ligand at 25 and 50 °C. Furthermore, [ Pn ] is low ( 3 × 10-8 M), which is in line with previously reported values in the range from 10-9–10-7 M for the ATRP of MMA.S5 Solution ATRP procedure. In a dried Schlenk flask 8 ml acetone, 8 ml MMA, and 15.7 µL PMDETA (75.4 µmol) were mixed. The mixture was frozen in liquid nitrogen followed by addition of the activator, CuBr (6.9 mg; 48.0 µmol), and the deactivator, CuBr2 (4.6 mg; 20.6 µmol). The reaction medium was degassed by three freeze-pump-thaw cycles and backfilled with argon. After degassing, the mixture was stirred at 25 or 50 °C for half an hour resulting in a homogeneous yellowish solution. Degassed EtBriBu (14.1 µL; 96.0 µmol) was added to initiate the polymerization. The kinetics of the solution ATRP was followed by determining the instantaneous monomer concentration [M]t in 0.1 ml aliquots by monitoring the ratio of the vinyl to alkyl protons S4 using 1H NMR. Polarization modulation infrared reflection absorption spectroscopy (PM-IRRAS). PM-IRRAS spectra were recorded on a Nicolet 6700 FT-IR (Thermo Scientific) spectrometer equipped with an external experiment module with a narrow band mercury-cadmium-telluride (MCT) detector cooled in liquid nitrogen. The infrared beam was modulated at 37 kHz between s or p polarization by combining a gold wire polarizer with Hinds zinc-selenide photoelastic (PEM-90/II/ZS37) modulator. The PEM was adjusted so the s polarization was linear for wavenumbers around 1500 cm-1. The substrates were irradiated with an incident grazing angle of 71°. The two signals, Rp Rs, and, Rp + Rs, were extracted with a high-pass filter (EG&G model 189) and a lock-in amplifier (SR 810 DSP). Typically, 1000 spectra were accumulated to increase the signal to noise ratio. The differential surface reflectivity [Response = Rsample/Rsample = (Rp Rs)/(Rp + Rs)] spectra were obtained with 4 cm-1 resolution and converted to absorbance spectra by normalizing with respect to differential surface reflectivity of the freshly cleaned gold substrate, i.e., Absorbance = – log10[(Rsample/Rsample)/(Rblank/Rblank)]. The experimental PMIRRAS spectra were baseline-corrected using the facilities of OMNIC ver. 8.2. All spectra were recorded at room temperature in dry atmosphere. The spectrum corresponding to Au-1Br shows the presence of carbonyl, aromatic, and aliphatic functionalities, while the spectrum of Au-2Br features the carbonyl group and C‒H bending modes in accordance with expectations (Figure S2). S5 1736 0.040 Au-1Brplate; Au-2Brplate 0.010 1511 0.015 1465 1388 1371 0.020 1013 1278 0.025 1603 Absorbance 0.030 1107 1164 0.035 0.005 0.000 2000 1800 1600 1400 Wavenumber/cm 1200 1000 -1 Figure S2. PM-IRRAS spectra of the initiator layers on Au-1Br and Au-2Br. The signal at 1736 cm-1corresponds to C=O stretch, 1278 and 1164 cm-1 to C-O-C asymmetric and symmetric stretches, respectively, 1465 cm-1 to as (CH3), 1455 cm-1 to s (CH2), 1388 and 1371 cm-1 (doublet) to s (CH3), 1603, 1511, and 1466 cm-1 to aromatic ring stretch, and 1107 cm-1 to in-plane aromatic C-H bends. The ratio of the integrated areas of the carbonyl bands at 1736 cm-1, 1736 A1736 Au-1Br / A Au-2Br , is equal to 4.6 indicating higher initiator content on the diazonium based initiator films compared to the SAM based one. X-ray photoelectron spectroscopy (XPS). A Kratos Axis Ultra-DLD instrument operated with a monochromatic Al K X-ray source at a power of 150 W was employed for the XPS analysis. Survey scans were acquired by accumulating two sweeps in the 0–1100 eV range at a pass energy of 160 eV. High-resolution scans were acquired at a pass energy of 20 eV. The pressure in the main chamber during the analysis was in the order of 10–11 bar. The generated XPS data were processed using the CasaXPS software. Atomic surface concentrations were determined by fitting the core spectra using Gaussian line shapes and a linear background. Binding energies of the components in the spectra were determined by calibrating against the C–H/C–C peak in the C1s spectra at 285.0 eV. The systematic error is estimated to be of the order of 5–10%. Thickness determination using XPS. The ratio of intensities of Au4f signal corresponding to bare and modified Au substrate is related to the thickness (d) of the overlayer and the angle of observation (θ) as shown in eq. S3. ln I0 d I λ cos (S3) S6 In the expression I0 is the intensity of the Au4f signal from a clean gold substrate, I is the measured intensity in the presence of an organic layer, d is the thickness of the layer (nm), λ is the inelastic mean free path of Au4f electrons attenuated by the organic layer (= 4.2 nm),S6 and θ is the angle between the surface normal and the analyzer axis. The calculated values for precursor and initiator layers at θ = 0 are 7.9 and 5.5 nm, respectively, which are in agreement with ellipsometry results (Table S3). Characterization of the initiator layers by XPS. In Figure S3 XPS survey scans on the Au-1BrQCM and Au-2BrQCM samples show the total atomic % of the elements for two different initiator structures. As seen the Au atomic % is almost 5 times lower for Au-1BrQCM compared with Au-2BrQCM which is due to the fact that the larger film thickness of the diazonium based multilayer results in a comparatively larger attenuation of the XPS beam. It is easily shown that the percentage of alcohol groups, %Conv, converted to initiator groups in the reaction with 2-bromoisobutyryl bromide may be calculated from the measured O/Br and C/Br ratios according to eqs S4 and S5. %Conv = 100%/(O/Br ratio 1) (S4) %Conv = 800%/(C/Br ratio 4) (S5) It is important to emphasize that these formulas assume that there are no contributions whatsoever from carbon and oxygen on the surfaces themselves. S7 At% 11.04 71.35 5.70 0.20 8.01 3.69 6 1.2x10 6 1.0x10 6 8.0x10 5 6.0x10 5 4.0x10 5 2.0x10 5 0 Pos. 533 285 85 163 182 At% 7.74 49.76 38.49 1.71 2.29 Au 4f Au-2BrQCM Name O 1s C 1s Au 4f S 2p Br 3p Br 3p S 2p Pos. 533 285 400 1074 84 183 1.4x10 C 1s 1x10 5 Name O 1s C 1s N 1s Na 1s Au 4f Br 3p CPS 5 Au 4f 2x10 Br 3p 3x10 5 C 1s 5 N 1s 4x10 O 1s Au-1BrQCM O 1s 5 Na 1s CPS 5x10 0.0 1000 800 600 400 200 0 1000 800 Binding Energy/eV 600 400 200 0 Binding Energy/eV Figure S3. Surface atomic concentrations of various elements for Au-1BrQCM and Au-2BrQCM measured by XPS. Characterization of the precursor complex by XPS. A series of ex-situ adsorption experiments were made in which Au-1Brplate was immersed in solutions of either CRM (containing both CuI and CuII) or a mixture of IRM and CuII denoted “IRM+CuBr2” for different time intervals. The results of the 4 5 1.0x10 5 Br 3p 4 1.0x10 5.0x10 4 3 0.0 800 600 1.1x10 4 1.0x10 3 9.5x10 938 936 934 932 930 Binding Energy/eV 1000 N 1s 4 1.1x10 4 1.1x10 9.5x10 Au 4f 1.5x10 B C 1s 5 O 1s Br 3p Cu 2p 4 1.1x10 4 5.0x10 2.0x10 CPS 5 CPS 1.0x10 Au 4f 5 C 1s 1.5x10 A N 1s 5 O 1s 2.0x10 CPS CPS XPS analysis are shown in Figure S4 and Table S2. 938 936 934 932 930 Binding Energy/eV 0.0 400 200 0 1000 Binding Energy/eV 800 600 400 Binding Energy/eV S8 200 0 5 3x10 5 2x10 5 1x10 5 4 4 CPS 1.3x10 4 4 1.1x10 938 936 934 932 930 Binding Energy/eV C 1s 1.1x10 4 3 938 936 934 932 930 Binding Energy/eV 0.0 800 600 400 O 1s 3 9.0x10 Cu 2p 1.0x10 9.5x10 1000 4 1.4x10 Br 3p S 2p Br 3p 4 5.0x10 4x10 D Au 4f Au 4f C 1s N 1s O 1s 1.1x10 4 5 1.2x10 4 5 5x10 1.4x10 CPS 1.0x10 5 CPS CPS 1.5x10 C Cu 2p 2.0x10 5 0 200 0 1000 Binding Energy/eV 800 600 400 200 0 Binding Energy/eV Figure S4. XPS survey spectra recorded for (A) Au-1BrPlate after immersion into the solution of CRM at 25 oC for 60 s, (B) Au-1Brplate after immersion into “IRM + CuBr2” at 25 ºC for 60 s, (C) Au-1Brplate after immersion into the solution of CRM at 50 oC for 30 s and (D) Au-2Brplate after immersion into the solution of CRM at 25 ºC for 60 s. Insets: (A) high resolution XPS spectra of the CuI 2p3/2 component and (C, D) high resolution XPS spectra with fitted CuI 2p3/2 and CuII 2p3/2 components. Noteworthy, CuII 2p3/2 components were identified at 934.4 eV for the cases C and D in Figure S4. In addition, shake-up satellites expected to arise at 941.5 and 943.1 eV were detected in the range of 940 – 944 eV for the cases presented in Figure S4 C and D but not resolved due to the interference from noisy background signal in that region. Thus, high resolution XPS spectra were used only qualitatively. Table S2. Atomic Percentages (At. %) of Different Elements Detected on Au-1Br or Au-2Br After Immersion in CRM and “IRM+CuBr2” Solutions for Various Times. Time (s) 0 Substrate/ Medium Au-1Br/None Cu 2p (At. %) 0 O 1s (At. %) 8.9 ± 0.3 C 1s (At. %) 69.6 ± 0.5 N 1s (At. %) 5.6 ± 0.8 Au 4f (At. %) 12.2 ± 0.1 Br 3p (At. %) 3.8 ± 0.1 5 Au-1Br/CRM 0.9 ± 0.1 8.8 ± 0.2 68.4 ± 0.1 6.2 ± 0.5 12.2 ± 0.3 3.5 ± 0.4 10 Au-1Br/CRM 0.7 ± 0.1 9.3 ± 0.2 69.3 ± 0.2 5.0 ± 0.4 11.8 ± 0.1 3.8 ± 0.1 30 Au-1Br/CRM 0.9 ± 0.1 9.6 ± 0.2 68.7 ± 0.1 5.0 ± 0.6 11.9 ± 0.1 3.9 ± 0.5 60 Au-1Br/CRM 0.6 ± 0.1 10.1 ± 0.2 69.1 ± 0.8 6.2 ± 0.3 10.2 ± 0.1 3.9 ± 0.3 120 Au-1Br/CRM 0.7 ± 0.1 11.5 ± 0.2 68.7 ± 1.3 6.2 ± 0.8 9.9 ± 0.1 3.0 ± 0.3 1 Au-1Br/CRM b 2.6 ± 0.1 13.6 ± 0.1 66.2 ± 0.4 3.5 ± 0.1 9.8 ± 0.3 4.3 ± 0.1 5 Au-1Br/CRM b 2.5 ± 0.1 12.8 ± 0.6 67.1 ± 0.4 5.1 ± 0.5 8.8 ± 0.1 3.6 ± 0.2 S9 10 Au-1Br/CRM b 2.5 ± 0.2 12.6 ± 0.2 65.6 ± 1.2 6.8 ± 1.0 8.8 ± 0.1 3.6 ± 0.5 30 Au-1Br/CRM b 2.0 ± 0.1 13.1 ± 0.4 68.3 ± 0.1 4.4 ± 0.3 8.7 ± 0.2 3.5 ± 0.5 120 Au-1Br/CRM b 1.5 ± 0.1 17.0 ± 0.1 69.3 ± 0.4 3.4 ± 0.3 6.0 ± 0.1 2.9 ± 0.2 60 Au-1Br/ 0 9.4 ± 0.5 69.0 ± 0.1 5.1 ± 0.1 13.3 ± 0.2 3.1 ± 0.4 0 9.2 ± 0.2 69.4 ± 0.6 4.8 ± 0.1 13.1 ± 0.1 3.6 ± 0.1 “IRM+CuBr2”c 120 Au-1Br/ “IRM+CuBr2”c 0 Au-2Br/Noned 0 5.1 ± 0.5 35.9 ± 0.1 - 53.7 ± 0.2 2.4 ± 0.1 60 Au-2Br/CRMe 2.8 ± 0.2 7.0 ± 0.7 35.1 ± 0.6 2.6 ± 0.3 48.7 ± 0.3 0.9 ± 0.1 At 25 C, unless otherwise stated; uncertainties are based on measurements made on two different spots. b Performed at 50 C with the initiator layer being immersed in IRM for 1 h prior to the actual adsorption experiment in CRM. c “IRM+CuBr2” denotes a solution of IRM containing 3.0 mM CuBr2/PMDETA (added). d Atomic % of S 2p = 2.8 ± 0.7%. e Atomic % of S 2p = 2.6 ± 0.5%. a Characterization of the PMMA brushes by XPS. Two types of background are observed for thin (10.7 nm) and thick PMMA (220 nm) coatings in the survey spectra. In the case of thin PMMA films, the Au 4f doublet is clearly seen and the background signal is arch-shaped due to the contribution from inelastically scattered electrons (Figure S5 A). For thick films the background is flatter as a result of elastic scattering (Figure S5 B). From high resolution XPS spectra of PMMA four different kinds of carbon in the C1s region and two types of oxygen in the O1s region were identified in accordance with the structure of a repetitive unit of PMMA, as seen from the peak fitting results in Figure S5 C and D. S10 5 5 5 5 Name O 1s C 1s Au 4f 4 0.0 B C 1s O 1s At% 26.2 73.9 5 1.0x10 5.0x10 Pos. 533 285 1.0x10 Pos. 533 285 84 Au 4f CPS 1.5x10 Name O 1s C 1s CPS 2.0x10 O KLL 5 1.5x10 A C 1s O 1s 2.5x10 At% 21.6 77.2 1.24 4 5.0x10 0.0 1000 800 600 400 200 0 1000 Binding Energy/eV 800 600 400 200 0 Binding Energy/eV C 3 8.0x10 3 6.0x10 Pos. 285.0 285.7 286.8 289.0 FWHM 1.2 1.1 1.3 1.2 C Area,% 39.9 19.6 21.4 19.2 4 1.0x10 Pos. 532.2 533.9 D FWHM Area,% 1.3 43.7 1.5 56.3 3 8.0x10 CPS CPS 3 3 4.0x10 6.0x10 3 4.0x10 3 2.0x10 3 2.0x10 0.0 0.0 294 292 290 288 286 284 282 280 538 Binding Energy/eV 536 534 532 530 528 Binding Energy/eV Figure S5. Survey spectra of (A) 10.7 nm and (B) 220 nm thick PMMA brushes on gold with corresponding high resolution spectra of (C) C1s and (D) O1s regions for the survey B. Atomic Force Microscopy (AFM). AFM analysis was carried out in air using a NanosurfeasyScan 2 AFM instrument (Nanosurf, Switzerland) operated in noncontact tapping mode with resonant frequency of 146–236 kHz. PPP-NCLR-20, AFM cantilevers were purchased from NanosensorsTM (Switzerland). The spring constant of the cantilever was 21–98 N m-1. The images were recorded with a scan rate of 170–256 px s-1, resolution of 256 pixels per line and scan size of 5 × 5 μm2. Average (Sa) and root mean square surface (Sq) roughnesses were determined from 3 selected areas (5 × 5 µm2) using the Nanosurf Easyscan 2 software. Ellipsometry. Film thicknesses below 50 nm were measured by means of a rotating analyzer ellipsometer (Dre, Germany) with a HeNe laser (λ = 632.8 nm) at 75° angle of incidence. The ellipsometric parameters of the bare (s, s) and grafted (g, g) substrates were measured in air at S11 ambient temperature, where is the phase shift and tan() is the amplitude ratio upon reflection. The complex refractive index of the bare substrate was calculated from the measured s and s values. A three-layer optical modelS7,S8 consisting of a substrate with a complex refractive index, the grafted layer given by its refractive index and thickness and the surrounding medium (air) was used to calculate the overall reflection coefficients for in-plane (Rp) and out-of-plane (Rs) polarized lights. The real and the imaginary parts of the refractive index of the bare substrate were obtained by measuring the clean plates prior to modification. Ellipsometric measurements were performed on the same area of the plates before and after electrografting. Because the measurements are carried out on a dried and thus collapsed film, the refractive index of the layer is fixed at a constant value (real = 1.55; imaginary = 0), independent of the thickness. The average and the standard deviation values reported correspond to data points obtained from measuring three spots on each plate (Table S3). Table S3. Ellipsometrically Determined Thicknesses and Contact Angles for Various Surface Films. Filma χBr SI-ATRP time (h) ldryb (nm) Contact angle Au-1plate - 0 4.0 ± 0.2 49.7 ± 3.3 Au-1Brplate 1 0 7.9 ± 0.3 68.8 ± 3.9 Au-1Brplate 0.5 0 8.1 ± 0.1 73.6 ± 1.7 Au-1Brplate 0.3 0 8.0 ± 0.1 80.0 ± 1.3 Au-1Brplate 0.1 0 8.8 ± 0.2 75.5 ± 2.4 Au-2Brplate 1 0 1.2 ± 0.3 70.2 ± 3.2 Au-1BrQCMa 1 5 11.1 ± 0.3 75.0 ± 3.1 Au-1Brplatea 1 4 8.2 ± 0.3 76.7 ± 2.0 Au-1Brplatea,c 1 3 88 ± 4 73.5 ± 1.8 a ATRP conditions for PMMA brush formation: [CuBr] = 3.0 mM, [CuBr2] = 1.3 mM, and [PMDETA] = 4.7 mM in MMA/acetone = 1/1 (v/v) at 25 °C, unless otherwise stated. b Dry film thickness measured by means of ellipsometry, unless otherwise stated. c At 50 °C, dry film thickness was measured by profilometry. S12 Profilometry. Film thicknesses above 50 nm were measured by means of a Dektak 150 Surface Profiler by scanning the surface of the substrate across the grafted and non-grafted parts. In the case of bad contrast the grafted material was scratched off by a plastic spatula and the scan was made across the scratch. Typically, 3 runs with 2.9 × 10-5 kg m s-2 styles force, 40 m s-1 scanning speed, and 1200 µm scanning distance were used in order to obtain an average thickness value and standard deviation. Contact angle measurements. A drop of deionized water (1 µl) was placed on the surface of a substrate. ImageJ software with installed contact angle measurements plug-in was used to elaborate the right and left contact angles. The procedure was repeated at least twice for each substrate and the resulting data were averaged (Table S3). The values obtained for PMMA coatings do not depend on the thickness of the layer and are in agreement with literature-reported contact angles.S9 The values reported for Br-terminated substrate are similar for different initiator coverages and relative to a OH-terminated precursor layer, they are higher by 30 degrees in accordance with expectations. Modeling parameters for QCM-D data. Density of the complete reaction medium ( b ) was measured to be equal to 0.873 ± 0.001 g cm-3. Shear viscosity of the fluid (ηb) was calculated from eq S6 by measuring the resonance frequency of the QCM crystal in air and the complete reaction mixture, respectively, for the third overtone.S10 1 f b n2 q3 q 1.18 10 4 [kg m 1s 1 ] 10 n f0 b 2 (S6) In this expression n denotes the overtone number, q is the density of quartz (= 2.648 g cm-3), q the shear modulus of quartz (= 2.947 × 1011 g cm-1 s-2), f0 the fundamental frequency for an unmounted QCM crystal suspended in air (= 4.95 × 106 Hz), and fn is the frequency change upon transferring the crystal from air to liquid (= 668 ± 10 Hz for n = 3). S13 In the fitting of the experimental data (using the analysis software QTools from Q-Sense) eqs 1 and 2 in the main paper were used. The density of the polymer layer (L ) was assumed to be equal to 1.100 g cm-3 for all series of simulations. In Figure S6 an example of a fit is shown. fitted data Au-1BrQCM 7 D3 6 D5 D7 5 -20 f /Hz 6 4 D (x 10 ) 0 -40 3 2 -60 F7 1 F5 F3 0 -80 -1 0 4000 8000 12000 16000 Time/s Figure S6. Example of fit using QTools software. The parameters D3, D5, D7 and F3, F5, F7 denote dissipation and frequency changes for 3rd, 5th, and 7th overtones, respectively. Au-1BrQCM (χBr = 1) was used in the following ATRP conditions: [CuBr] = 3.0 mM, [CuBr2] = 1.3 mM, [PMDETA] = 4.7 mM, MMA/acetone = 1/1 (v/v) at 25 °C. S14 References (S1) Fukuda, T.; Goto, A.; Tsujii, Y. In Handbook of Radical Polymerization; John Wiley & Sons, Inc.: 2003, p 407. (S2) Fischer, H. J. Polym. Sci., Part A: Polym. Chem. 1999, 37, 1885. (S3) Brandrup, J.; Immergut, E. H.; Grulke, E. A.; Abe, A.; Bloch, D. R. Polymer Handbook (4th Edition); John Wiley & Sons. (S4) Fischer, H.; Paul, H. Acc. Chem. Res. 1987, 20, 200. (S5) Matyjaszewski, K.; Xia, J. Chem. Rev. 2001, 101, 2921. (S6) Bain, C. D.; Whitesides, G. M. J. Phys. Chem. 1989, 93, 1670-1673 (S7) Tiberg, F.; Landgren, M. Langmuir 1993, 9, 927. (S8) Landgren, M.; Joensson, B. J. Phys. Chem. 1993, 97, 1656. (S9) Watts, J. F. Surf. Interface Anal. 1993, 20, 267-267 (S10) Keiji Kanazawa, K.; Gordon, J. G. Anal. Chim. Acta 1985, 175, 99. S15