There are more than half a million bridges in the

advertisement

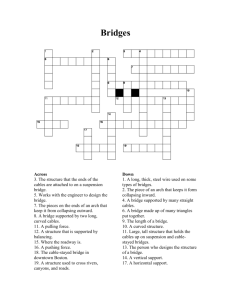

Bridge Building Name:___________________ __________________ period:__________________ There are more than half a million bridges in the United States, and you rely on them every day to cross obstacles like streams, valleys, and railroad tracks. But do you know how they work? Or why some bridges are curved while others are straight? Engineers must consider many things -- like the distance to be spanned and the types of materials available -- before determining the size, shape, and overall look of a bridge. Since ancient times, engineers have designed three major types of bridges to withstand all forces of nature. Why do we need bridges? Bridges make it possible to cross from one shore of a river to another. In earlier times, bridges allowed trade between farmers, and the movement of goods across a natural divide. Early man often placed stepping-stones in the narrow sections of small streams as a way to get to the other side. It is easy to see how a bridge might develop, using stepping-stones as a base for logs or planks. The earliest bridge was probably a toppled tree that had fallen across a nearby stream. Are bridges always over water? No, they can be over other roads, over railways, over deep gulleys. And they are not only for cars and people. Wooden trestle bridges were essential to the passage of the railway through the mountains in western Canada. Bridges over rivers allow the water to pass easily through the "holes in the bridge." Bridges allow traffic over obstacles (rivers, roads, ravines), without changing the obstacle. The beam bridge... Consists of a horizontal beam supported at each end by piers. The weight of the beam pushes straight down on the piers. The farther apart its piers, the weaker the beam becomes. This is why beam bridges rarely span more than 250 feet. The word "beam" comes from the old English word for tree. The first bridges were probably logs. "Pier": the bridge support How high do you make the piers? That depends on what has to travel underneath. "Span": the distance pier to pier the span depends on the strength and weight of the beam. The thicker the material, the more weight it will hold. The thicker the material, the further the span. But, the thicker the material, the heavier the bridge, so the more it takes to hold it up. A very strong beam could be too heavy for the "span" and sag into the river. We can lighten the beam by using a truss. Beam Bridge: Forces When something pushes down on the beam, the beam bends. Its top edge is pushed together, and its bottom edge is pulled apart. Can we make the span longer another way? There is a type of Beam Bridge called a cantilever. It is related to a lever. The truss bridge...consists of an assembly of triangles. Truss bridges are commonly made from a series of straight, steel bars. The Firth of Forth Bridge in Scotland is a cantilever bridge, a complex version of the truss bridge. Rigid arms extend from both sides of two piers. Diagonal steel tubes, projecting from the top and bottom of each pier, hold the arms in place. The arms that project toward the middle are only supported on one side, like really strong diving boards. These "diving boards," called cantilever arms, support a third, central span. Truss Bridge: Forces Every bar in this cantilever bridge experiences either a pushing or pulling force. The bars rarely bend. This is why cantilever bridges can span farther than beam bridges. The arch bridge...has great natural strength. Thousands of years ago, Romans built arches out of stone. Today, most arch bridges are made of steel or concrete, and they can span up to 800 feet. Arch Bridge: Forces The arch is squeezed together, and this squeezing force is carried outward along the curve to the supports at each end. The supports, called abutments, push back on the arch and prevent the ends of the arch from spreading apart. The suspension bridge... Can span 2,000 to 7,000 feet -- way farther than any other type of bridge! Most suspension bridges have a truss system beneath the roadway to resist bending and twisting. Suspension Bridge: Forces In all suspension bridges, the roadway hangs from massive steel cables, which are draped over two towers and secured into solid concrete blocks, called anchorages, on both ends of the bridge. The cars push down on the roadway, but because the roadway is suspended, the cables transfer the load into compression in the two towers. The two towers support most of the bridge's weight. The biggest difference between the four is the distances they can cross in a single span. A span is the distance between two bridge supports, whether they are columns, towers or the wall of a canyon. A modern beam bridge, for instance, is likely to span a distance of up to 200 feet (60 meters), while a modern arch can safely span up to 800 or 1,000 feet (240 to 300 m). A suspension bridge, the pinnacle of bridge technology, is capable of spanning up to 7,000 feet (2,100 m). What allows an arch bridge to span greater distances than a beam bridge, or a suspension bridge to span a distance seven times that of an arch bridge? The answer lies in how each bridge type deals with two important forces called compression and tension: Compression is a force that acts to compress or shorten the thing it is acting on. Tension is a force that acts to expand or lengthen the thing it is acting on. A simple, everyday example of compression and tension is a spring. When we press down, or push the two ends of the spring together, we compress it. The force of compression shortens the spring. When we pull up, or pull apart the two ends, we create tension in the spring. The force of tension lengthens the spring. Compression and tension are present in all bridges, and it's the job of the bridge design to handle these forces without buckling or snapping. Buckling is what happens when the force of compression overcomes an object's ability to handle compression, and snapping is what happens when the force of tension overcomes an object's ability to handle tension. The best way to deal with these forces is to either dissipate them or transfer them. To dissipate force is to spread it out over a greater area, so that no one spot has to bear the brunt of the concentrated force. To transfer force is to move it from an area of weakness to an area of strength, an area designed to handle the force. An arch bridge is a good example of dissipation, while a suspension bridge is a good example of transference. What shapes are the strongest? Squares Triangles Tubes With cardboard sticks and two pronged pins, build a square and a triangle. Try pushing the sides together. The triangle resists, but the square collapses, unless the angles are braced. You could create a brace for the square by constructing a diagonal - which, in effect, is making two triangles. The triangle is the strongest shape. Triangles are used to make a very strong form called a truss. Another very strong shape is a tube. Think about bicycle frames and bamboo shoots. Try this! Can you make a sheet of newspaper hold up a book? Try folding it twice lengthwise and rolling it into a tube. This newspaper tube is strong enough to hold up a book. Does the bridge material make a difference in the strength of the bridge? Shape is important for strength, but so is the material. A steel beam will hold more weight that a wooden beam of equivalent size. Today, bridges are built of steel and reinforced concrete. Reinforced concrete beams are created by placing steel bars into the concrete before it hardens. This skeleton of steel helps the concrete withstand the tension that develops when long, unsupported beams are subjected to bending under heavy weight loads. The CN Tower, in Toronto, at 553 meters, is still the tallest free-standing structure in the world. How was this tower built? Construction engineers used a slip form. Vertical rods were put into place; a mould was built around these rods and the concrete was poured. When the concrete had hardened enough to support weight, the mould (slip form) was pushed vertically up the rods, and more concrete was poured. This process was repeated again and again until the desired height was attained. Another famous tower and another Compression (Squeezing): _________________________________________________ ________________________________________________________________________ ________________________________________________________________________ ____________________________________________________________ The lower columns of a skyscraper are squeezed by the heavy weight above them. This squeezing force is called compression. Tension (Stretching) : ___________________________________________________ ________________________________________________________________________ ________________________________________________________________________ ____________________________________________________________ The weight of the roadway and all the cars traveling on it pull on the vertical cables in this suspension bridge. The cables are in tension. Bending: _____________________________________________________________ ________________________________________________________________________ ________________________________________________________________________ ____________________________________________________________ The top side of the metal bar is pulled apart in tension, and the bottom side is squeezed together in compression. This combination of opposite forces produces an action called bending. Shear (Sliding): ________________________________________________________ ________________________________________________________________________ ________________________________________________________________ During an earthquake, parts of this roadway slid in opposite directions. This sliding action is called shear. Torsion (Twisting): _____________________________________________________ ____________________________________________________________________ In 1940, the Tacoma Narrows Bridge twisted violently in strong winds and collapsed. The twisting force that tore this bridge in half is called torsion. deck: ________________________________________________________________ ____________________________________________________________________ engineer: _____________________________________________________________ ____________________________________________________________________ girder: _______________________________________________________________ span: ________________________________________________________________ stress: ______________________________________________________________ ____________________________________________________________________ truss: _________________________________________________________ _________________________________________________________ You will be using the West Point Bridge Designer to Design a Bridge that will span a distance. Before you start to design on the computer you must come up with 3 alternative plans for your bridge. On the next pages using the basic diagram, draw out three different bridge plans that you may want to use for you bridge. After you practice with the bridge building program you can write down which bridge you decided to use. Remember the shapes and metal types spoken about earlier in this packet! Your Bridge will Cross this gap Look at the picture and fill in the joints and members for your bridge. A joint acts like a joint in your elbow it attaches the top portion of your arm to the bottom portion. A member is the beams which make up the bridge attached by the joints. Design 1 Design 2 Design 3 Working with the West Point Bridge Designer: You will be selecting the smallest, simple span bridge. The concrete, asphalt and bottom joints of the bridge will already be there just like for your alternative drawings. There will be four buttons to choose from for your design tools. The circle is the joint button. You must lay out all of the joints needed first, before any members can be selected. The next button a bar is for members. You click on a joint and then connect them with members. A joint must be attached to a member. You cannot have members unattached to joints or joints unattached to members. The arrow button is to select items you can select them and press the delete button or select and then move them or change to thickness or metal type, or select multiple joints and members to delete them or change metal types. The last button is an eraser, to erase anything you no longer wish to have on your design. You can select multiple or single members and then increase the thickness or type of metal used. After you have a completed design you can then test it! You can select the turquoise testing button to drive a simulated truck over your bridge design. If there is a problem you can go back to the design screen by selecting the button next to it with drafting tools on it. The CHALLENGE: You must design a bridge that will cross the span work with the truck simulation and be under $6,000! At the bottom of the design page the cost will be shown. After Coming up with a workable design Print! You will hand this design on to your teacher who will take that design and blow it up to make it big enough to test in class with the bridge crusher! Using your 2 blown up templates you are going to build your bridge out of ¼ inch pine. We will build the 2 sides like your design and the top and bottom sections to attach them. You will then test all bridges in class by crushing them. May the best bridge LIVE! AFTER QUESTIONS: Your breaking weight? _______________ lbs. Which design did you finally choose out of your three originals? Why? What was the hardest thing about this project? If you could build another bridge what would you change about your design? Why? Compression (Squeezing): the act of pressing or pushing. Compression is a force that squeezes a material together. When a material is in compression, it tends to become shorter. The lower columns of a skyscraper are squeezed by the heavy weight above them. This squeezing force is called compression. Tension (Stretching) : the act of stretching or pulling . A force that stretches a material apart. When a material is in tension, it tends to become longer. Tension- The weight of the roadway and all the cars traveling on it pull on the vertical cables in this suspension bridge. The cables are in tension. Bending: When a straight material becomes curved, one side squeezes together and the other side stretches apart. This action is called bending. The top side of the metal bar is pulled apart in tension, and the bottom side is squeezed together in compression. This combination of opposite forces produces an action called bending. Shear (Sliding): A force that causes parts of a material to slide past one another in opposite directions. During an earthquake, parts of this roadway slid in opposite directions. This sliding action is called shear. Torsion (Twisting): is an action that twists a material. In 1940, the Tacoma Narrows Bridge twisted violently in strong winds and collapsed. The twisting force that tore this bridge in half is called torsion. deck: platform extending horizontally that often carries the roadway engineer: person who uses mathematical and scientific principles to design and construct efficient structures and machines girder: a horizontal beam used for support span: portion of a bridge between two supports stress: the force acting on a body divided by the body's cross-sectional area. Force per unit area. truss: a rigid triangular framework