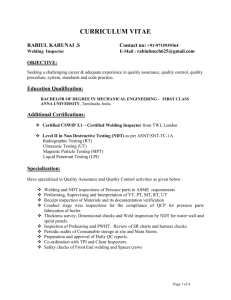

CURRICULAM VITAE

advertisement

CSWIP AUT /AWS SENIOR WELDING/ASNT LEVEL III INSPECTOR CURRICULAM VITAE Name : S.R.G. Prabhu (GURUNATHA PRABHU SRINIVASANALLUR Date of birth &Age : Marital status Permenant Address : : Nationality E-mail : Phone no : Passport details- no. Issued at Issued on valid upto Driving license no. Educational Qualification TECHNICAL QUALIFICATION : : : : : RAJAN) 07.11.1965 & 43 years Married No-3, Second street, Maris Avenue, Collector’s office Road, Contonment, Trichy - 620 017. Tamilnadu state. India. Indian srgprabhu@gmail.com prabhusrg@yahoo.com 0091 9600081598,00919840535959 (MOBILES) 0091 44 24 980795 G6225936 Trichy 30-11-2007 29-11-2017 F/tn/045/004170/1999(Indian) M.Sc. Instrumentation 1.CSWIP- AUT(PIPEWIZARD-PHASED ARRAY) DATA INTERPRETER LEVEL II FROM TWI- UK. (EN473 & ISO 9712 CERTIFICATION FOR NDT PERSONNEL). CSWIP CERTIFICATE NO :25040 : 2. ASNT LEVEL III (RT&UT) in Radiographic testing & Ultrasonic testing , certificate no:126353 valid upto Nov 2011. 3.AWS-SCWI(American Welding Society – SENIOR Certified Welding Inspector)valid upto 2011 . 4. ASNT LEVEL II in Magnetic particle Penetrant testing valid up to 2010. testing, 5. Basic Offshore Safety Induction and Emergency Training(BOSIET) including HUET and EBS, approved by OPITO and H2S training from International safety training center in Malta, valid upto May 2012. 6.Completed HANDS ON training in PHASED ARRAY UT with OLUMPUS OMNISCAN PHASED ARRAY FLAW DETECTOR in Madras-India by BLUESTAR INDIA/OLYMPUS NDT ACADEMY-CANADA in Dec 2007 7. AUT SYSTEMS FAMILIAR WITH 1. RTD-NETHERLAND'S ROTOSCAN 2. OLYMPUS-RD TECH-PHASED ARRAYPIPEWIZARD/OMNISCAN 3. SHAW PIPELINE AUT-INFOCUS 1 8. AUTOMATIC WELDING SYSTEMS FAMILIAR WITH: Saipem-Passo,SWS, S.A.Mcdermott – AWS,Allseas Pheonix,Serimer dasa and SAW for double joints. Work experience Total years:20 India: 9yrs Abroad: 11Yrs PRESENT JOB: Worked as AUT specialist for GASCO Abu Dhabi for AUT validation/verification of the contractor AUT system prior to their offshore pipe lay project and also during pipe lay, AUT performance audit, work ended by June 22nd. Completed working as AUT SPECIALIST for TOTAL EXPLORATION in their Angola GEP BLOCK17 PHASE -1(GAS EXPORT PIPELINE) pipe lay (24’’x29.6mm)project-offshore Angola from Feb 12 to April 11, auditing Saipem AUT ( pipe wizard) of pipeline girth welds. Involved in AUT validation of the system, verification of system set up and performance and day to day audit of production weld AUT testing on board Castoro 2. Completed working as STATOILHYDRO CLIENT AUT inspector onboard Solitaire vessel(ALLSEAS) in Persian gulf for a pipe lay job for about 105KMS 32’’ pipe /4 ‘’ piggy back since 14th Dec 2008to Feb01.The AUT system used here is SHAW’S INFOCUS. Inspected AUT system set up, qualification of the AUT system, and operators performance. . From oct 2007 till Dec 2008 Worked as Inspection Supervisor in Sabratha Platform ( ENIGAS Libya- ENI GROUP) offshore Libya Since Oct 2007,incharge for inspection /corrosion monitoring of the GAS gathering/treating platform equipment and piping. Incharge for corrosion and inspection activities on the GAS GATHERING and PRODUCTION platform performing inspection on vessels, tanks, plant piping, painting , corrosion monitoring , follow up of corrosion coupons, hydrogen probes and witnessing and approving Testing and Calibration of PRESSURE SAFETY VALVES(PSV). Also involved pipeline AUT survey onshore Libya for a short duration of 24 days in the month of Jan 2008. From April 2007 to Oct 2007 Completed the contract with QATAR GAS as CLIENT SENIOR(LEAD) INSPECTOR onboard McDermott barge DLB-KP1 offshore Qatar for the project QATAR GAS II LNG COMMON CONDENSATE SPM SLEEPER AND PIPELAY PROJECT since23 April overseeing AUT, and leading welding, NDT, Coating inspectors’ activities during pipe lay of 42” 22.4 mm pipe line to SPM. Reviewed equipment and personnel certifications, Contractor DPR's, minutes of safety meetings, Job safety analysis-JSA's, , Contractors Inspection and Test Plan (ITP), accident/incident reports, near miss reports, survey reports, as built reports, management of change (MOC) reports, corrective action reports (CAR).Reviewed all AUT scans for the 24hours everyday before signing. Discussed repair rates and nature of defects with welding supt etc. Job includes monitoring inspectors’ field reports , attending daily progress meetings, CAR, and MOC follow ups, installation monitoring. This project clients are EXXONMOBIL and QATARGAS . Reporting to Vessel lead (EXXON MOBIL).Monitored contractor’s safety health implementation and assisted in audit and improvement. Contract finished Oct 2007. From Sep 2006 to Jan 2007 Worked as client AUT auditor for STATOIL-NORWAY in Iran offshore since 01Sep 2006 till Jan 2007 on the pipe lay barge PLB 132 for the pipe lay project for phase 8 SOUTH PARS FIELD for the LNG GAS pipelines 32” and 4” piggy back. I was the only AUT auditor for the entire client inspectors’ team. Reviwed all the scans during other shift and closely monitored AUT performance and Automatic Welding Progress (SERIMER DASA) advising time to time for improvement in Qulaity. From Nov 2005 to March 2006 Visited China for an AUT demo for the proposed Iran offshore project. I was the AUT specialist for this program with in charge for the procedure preparation, execution, monitoring the AUT sub contractor(CHINA NATIONAL PETROLEUM PIPELINE INSPECTION COMPANY) with the AUT system used being RDTECH’S PHASED ARRAY.I was employed by m/s Emirates industrial laboratories, a leading 2 inspection company in the UNITED ARAB EMIRATES as an AUT specialist, since Nov 2005 till March 31rst 2006. My job involved training technicians and also monitoring AUT jobs in India also. From July 2005 to Nov 2005 SAKHALIN II-Phase II project in offshore Sakhalin .Worked as AUT AUDITOR for RGS(Russian German Sakhalin Consortium)seconded by Germanischer Lloyd-Moscow-Russia since July 16th to 01 Nov 2005.Job included monitoring the contractor’s(SAIPEM-UK) AUT operators (RD-TECH’S PHASED ARRAY)during pipe lay operations. Done 30 inch dia/30.2 mm GAS pipelines 12 KMS each . Done a short term job for DNV-ANGOLA in onshore lifting equipment inspections as Senior Welding and NDT inspector in classification and certification processes, from March to April 2005. CLIENT INSPECTOR:From June 2003 to March 2004- deep water J lay SHELL Deepwater Nigeria-SNEPCO -Shell Bonga FPSO Project-Senior AUT Auditor and Welding inspector since June 2003 till March 2004.Was looking after s-lay and j-lay pipe lay at about 1300mts deepwater Nigeria. Monitoring Auto UT and welding inspection of various pipelines, flow lines and risers…was in Paris for a month for AUT and welder, welding procedure specifications qualifications. worked both in offshore and onshore, and various locations including double joint fabrication in Nigerdock-Lagos Inspected SCR(Steel catenary Risers) pipe joints,clad pipes also. Seconded to Shell by ITI-International Testing and inspection services inc- Louisiana - Texas-U.S.A. Worked as MobilClient Inspector –Welding/ NDT in the Riser Repair Project in offshoreNigeria from June 2001 till Jan2003.(Seconded to Exxon Mobil) Duties included review of all welding procedures ,witness the qualification of procedures and welders ,identification and verification of incoming materials from QIT Terminal, participating in weekly progress meetings , interpretation of radiographs, witnessing of strength testing of pipe spools and bends assigned for the project in the Alusteel yard, witnessing of NDT on pipes and weldments (UT,MT&PT), and following instructions from construction supervisor(Mobil) ,when assigned for onshore .also undergone Riserclad training by Riser clad International in Alusteel premises and witnessed divers performing the cladding of risers. also inspected the fabrication of cofferdams for underwater welding and NDT works of the risers in offshore, repaired and replaced risers in Asabo, Ekpe platforms. witnessing of welding and NDT on the welds and material verification, welder/welding consumables verification, radiographic interpretation and witnessing ultrasonic testing& mpi testing and verification of job completion reports as per project specific procedures and construction supervisor’s instructions .continued the job in SPSLl 215 barge at Asabo.Repaired 4” to24” risers, both oil& gas lines with replacing riser clamp and worked with cofferdams if the welding takes place below sea level. Inspected all structural and piping works for the Asabo short term project in Willbros Choba base prior to shipping to offshore and monitored and inspected installation in offshore also. M/s.Gulf petrochemical services and trading llc(Cross Country Pipeline project) Muscat-Oman (From Feb2001 to April2001 ) Worked as PDO (petroleum development oman) approved qc inspector for their cross country pipeline projects. Completed HDPE lined c/s pipeline between stations-20 inch and 55 kms GRE line with Ameron of Netherlands .job involved 100% monitoring of welding/ joining of GRE piping and reporting with heat input etc. - CCC(consolidated contractors company)position held: welding Saudi Arabia - from Feb 2000 Gazlan II power plant project toJjuly ’00 2400MW inspector 3 - Job involved welding inspection in Gazlan power plant ii for chimney liners, structural welding and piping (pccp and cs/ss piping) representing both Mariani Battista Arabia limited and ccc. client Sceco. contractor-Mitsubishi/ Bechtel consortium. QatarGgeneral Petroleum : for shutdown and maintanence NGL- 2 shut down (April 1999) position held : QA/QC supervisor company -Masaied - Doha- Job included inspection of static equipments (sensitive and non-sensitive) such as exchangers, vessels, coolers, filters, columns, tanks, furnaces, pressure vessels, etc. inspection was carried out prior to client to final inspection. Co-ordination with plant operation, maintenance and inspection departments. hydro testing and pneumatic testing of exchangers (shell side and tube side). Inspected welding of plant piping (repair works). Co-ordinated with NDT contractor for everyday planning of NDT works and monitoring all NDTjobs for the shut down. Saudi Arabia : position held : QC inspector July 1997 to Aug 1998 Saudi Aramco – Rastanura –Refinery upgradation project M/S Mohammad Almojil group QA/QC department Visual inspection of fitup and welding were done for construction of new pipelines and replacements in the upgradation of the plant. NDT inspection and RTinterpretation were done, as per Saudi Aramco engineering standards. Punch listing was done. SABIC – AR RAZI IV petrochemical Inspection of piping in the existing plants AR RAZI I ,II, & III. Also involved in QC inspection of construction activities in AR RAZI IV,like fit up and visual inspection of welding, joint identification as per drawing, dimensional verification, NDT coordination with NDTt subcontractor, inspection scheduling and coordinating with client inspectors , monitoring repair works etc SWCC-Alkhobar-Desalination job included static equipment inspections like installation and alignment inspections of pump and motors , rotating and band screen inspections, visual welding inspection, etc Saudi aramco : position held : Plant WELDING/NDT inspector Shell Refinery Al Jubail (October ’96 to December ’96) shut down and maintenance job involved major shut down works like thickness gauging (corrosion monitoring) on piping & tank forms, vessels, columns etc. floating roof inspection on oil storage tanks was done. the job extended after the shutdown and for maintenance work in the plant. India : position held: Inspection Engineer Reliance Industries Ltd. ( petrochemical)May 1991 to Oct 96 Third party inspection of construction of petrochemical plant in surat, India. job involved visual welding inspection, welder qualification ,radiographic interpretation, hydro testing, and other related inspections M/S. GB NDT Eng. Services, from 1998 sep to 2000 feb : Welding inspector job involved visual inspection of welding for pressure vessels, piping fabrication in the b.h.e.l. industrial area. position held : NDT co-ordinator (86 to 89)job involved ndt work on boilers and pressure vessel fabrication for B.H.E.L., Trichy. codes familiar with : API 1104, ASME B 31. 3, B31.6,B 31.8 ASME sec V, ,sec IX, API RP 2X, shell dep. AWS-D 1.1. Place : Trichy Date : S.R.G.PRABHU. 4