Long Period Gratings

advertisement

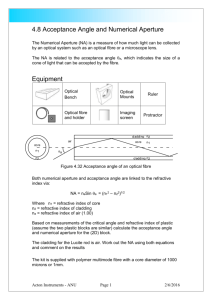

Long Period Gratings (LPG’s) for Cure Monitoring Applications S J Buggy, E Chehura, S W James, R P Tatam Engineering Photonics Group School of Engineering Cranfield University Cranfield Bedfordshire MK43 0AL s.j.buggy@cranfield.ac.uk Abstract. Composite materials are of fundamental importance across a broad range of industries, particularly aerospace and automotive. Optimum performance of these materials requires that the cure of the resin matrix is carried out in a well controlled fashion to minimize residual stress. The change in refractive index of the resin has also been used as a means for assessing the degree of cure. Optical fibre long period gratings (LPGs) and tilted fibre Bragg gratings (TFBGs) exhibit significant sensitivity to the external refractive index with no requirement for cladding removal. In this work, the centre wavelengths of the attenuation bands in the transmission spectra of an LPG and a TFBG immersed in a curing epoxy resin were monitored. For comparison, the refractive index was also measured by monitoring the Fresnel reflectivity of the end of an optical fibre immersed in the resin. The two techniques showed a good correlation, indicating the potential of the technique. TFBGS and LPGs are also sensitive to parameters such as temperature and strain. Thus the fibre gratings may be used to monitor the processing of the composite material, and subsequently fulfil a health and usage monitoring role over the lifetime of the component. 1. Introduction Many fibre optic techniques for the in-situ monitoring of the cure of epoxy resins have been reported [1], offering clear advantages over traditional monitoring techniques arising from their inherently small dimensions and high sensitivity. Spectroscopic methods predominantly use the fibre as a means for delivering the light to and from a sample [1]. However, direct interaction of the propagating mode with the surrounding environment has also been reported, achieved by etching or side polishing the optical fibre to remove the cladding and thus expose the evanescent tail of the core mode field [2]. Optical fibre long period gratings (LPGs) act as core to cladding mode couplers, producing a discrete set of attenuation bands in the transmission spectrum of the optical fibre [3]. The interaction of the cladding modes with the external environment enables the measurement of the surrounding refractive index without the need for etching or side polishing of the fibre. The refractive index sensitivity of LPGs has been exploited for a range of applications, including, chemical concentration sensing [4], liquid level sensing [5] and as a means of forming a tuneable spectral filter [6]. Tilted fibre Bragg gratings (TFBGs) also act as mode couplers, producing numerous resonances in the transmission spectrum of the optical fibre. The interaction with the cladding modes offers the prospect for the development of fibre Bragg grating based refractometers [7], again without the requirement for etching, side polishing [8] or tapering [9] the fibre. 1.1. Long Period Gratings An LPG consists of a periodic modulation of the refractive index of the core of an optical fibre. The period of the modulation is typically in the range 10 m to 1000 m, and promotes coupling between co-propagating modes of the optical fibre. In the case of single mode fibre, the coupling takes place between the guided mode and co-propagating cladding modes. Efficient coupling is possible to only a subset of the cladding modes [3]. As the cladding modes suffer from high attenuation, the transmission spectrum of an optical fibre containing a LPG contains a number of attenuation bands, each corresponding to coupling to a different cladding mode. The phase matching wavelengths are governed by the expression n i i neff _ cl eff _ co (1) where λi, neff_co, nieff_cl and Λ are the ith cladding mode resonance wavelength, effective index of the core, effective index of the ith cladding mode, and grating period respectively. The refractive index sensitivity of LPGs arises from the dependence of the coupling wavelength upon the effective index of the cladding mode. 1.2. Tilted Fibre Bragg Gratings A standard FBG consists of a refractive index modulation in the core of an optical fibre that acts to couple the fundamental forward propagating mode to the contra-propagating core mode. A TFBG consists of a refractive index modulation that is purposely blazed relative to the fibre axis in order to enhance coupling between the forward-propagating core mode and the contra-propagating cladding modes, as illustrated in figure 1. The contra-propagating cladding modes attenuate rapidly and are therefore not observable in reflection but are observed as numerous resonances in the transmission spectrum of the TFBG. Cladding mode Cladding θ Core ΛB Λ Figure 1. Schematic diagram of a TFBG. grating period, and blaze angle. The spectral response of the TFBG is governed by the phase matching condition: i i neff _ co neff _ cl cos (2) th where λi, neff_co, nieff_cl, θ and Λ cladding mode resonance wavelength, effective index of the core, effective index of the ith cladding mode, blaze angle and grating period respectively. In this paper the properties of LPGs and TFBGs as resin cure monitoring sensors are investigated. The index of refraction of a polymerising resin changes as the molecular density increases and as the atomic bonds involved in the polymerisation process are altered. The sensitivity of TFBGs and LPGs to changes in refractive index are exploited to monitor this change as an indication of cure. To aid cross comparison of results, a Fresnel reflection based refractometer was also designed and implemented [10]. 2. Experiment A TFBG of length 5 mm, blaze angle 4.5°, was fabricated in boron-germanium co-doped optical fibre (Fibercore PS1250) with a cut off wavelength of 1240 nm using the near-field interference pattern of a tilted phase-mask. The photosensitivity of the fibre was enhanced by pressurizing it in hydrogen for a period of 2 weeks at a pressure of 150 bar at room temperature. The phase mask was illuminated with a UV beam at a wavelength of 266nm and a power of 40 mW. The TFBGs were interrogated by coupling the output from a super luminescent diode of bandwidth 60 nm into the optical fibre, and monitoring the transmission using a scanning fibre Fabry-Perot interferometer of free spectral range 43 nm and finesse 900 [11]. The transmission spectrum is shown in figure 2 (a). 1.12 100 Transmission (%) Transmission (a.u.) 1.08 1.04 1 0.96 0.92 0.88 1542.5 1547.5 1552.5 1557.5 Wavelength (nm) (a) 1562.5 1567.5 80 60 40 20 0 840 880 920 960 1000 1040 1080 Wavelength (nm) (b) Figure 2 (a). Transmission spectrum of a TFBG of blaze angle 4.5o. The dotted line indicates the position of the Bragg wavelength of the core mode. (b) Transmission spectrum of an LPG of 400μm period and 40mm in length on fibre with a cut off wavelength of 650nm. An LPG of length 40mm and 400µm period was fabricated in a fibre with a cut off wavelength of 650nm (Fibercore PS750). An amplitude mask was illuminated with a UV beam of 244nm and a power of 80mW. The transmission spectrum, shown in figure 2(b), was monitored using a CCD spectrometer (Ocean Optics S2000) with a 0.3nm resolution and a tungsten white light source. To aid cross comparison of results, a Fresnel refractometer was designed. The output from a laser diode (Sharp LT015MD0) operating at 833nm was intensity modulated using a mechanical chopper and was coupled into a network of 3dB directional couplers. The Fresnel reflection from the environment/fibre interface was monitored using photodiode, pd1, while the second arm acted as an intensity reference, pd2, facilitating the normalization of the signal to account for any change in power coupled into the optical fibre from the laser diode. The voltage outputs from the photodiodes were monitored using lock-in amplifiers. The ratio of the voltages for the air/glass interface and for that of the resin/glass interface was used to calculate the refractive index of the resin using the Fresnel equations. The experimental configuration is shown in figure 3. At each time interval the LPG and TFBG spectra were recorded and the reflection signal from the Fresnel probe. A UV cured epoxy resin was used (EpoTek OG134) as the test resin. A UV lamp was positioned to provide a fluence of 6.57mW/cm2 in order to slow cure the resin and allow the reaction to be recorded. The LPG bands respond to change in refractive index of the environment by a shift in wavelength. Relating this to refractive index was achieved by using a calibration curve fitted to the measured wavelength response of the LPG placed in a range of Cargille refractive index oils from 1.4 to 1.45. The TFBG spectral resonances are more complex and require a different method of analysis. Here, the area of the envelope fitting the spectral response is calculated [7]. This area is noted to change with a change in refractive index of the surrounding environment and is recorded. The area response was related to refractive index by using a calibration curve fitted to the measured area change of the spectrum when the TFBG was placed in a range of Cargille refractive index oils from 1.4 to 1.45. dc pd2 ml reference dc dc pd1 LPG BBS S BBS S spectrometer TFBG FP resin Figure 3. Experimental configuration. ml, modulated light source; pd, photodiode; dc, directional coupler; BBS, broadband source; FP, scanning Fabry Perot; LPG, long period grating; TFBG, tilted fibre Bragg Grating 3. Results Figure 4 shows the response of the three sensor types to the cure of the epoxy resin. The datum corresponds to the time at which the UV light source was switched on. Figure 4 (a) shows the wavelength response of the fifth attenuation band of the LPG. The initial wavelength shift observed at the start of the cure is attributed to the thermal response of the LPG to the heating of the sample by the UV lamp. Figure 4 (b) shows the Fresnel sensor response, measured at 833nm. The refractive index of the resin at the switch on of the UV source was determined to be 1.418, increasing to a value of 1.438 when the resin was cured. The responses have the same form. Using the calibrated refractive index sensitivity, the refractive indices determined by the TFBG and LPG sensors are plotted in figures 4 (c) and 4 (d). The TFBG indicates a saturation of the cure, at a refractive index of 1.436, after 180 minutes. The LPG response indicates a higher refractive index, with a value of 1.438 after 180mins. The discrepancy may be a result of the dispersion properties of the resin, the TFBG sensor working at longer wavelengths ~1550nm than the LPG ~1000nm. Both sensors show the thermal effect at switch on. The close agreement of the response of the three sensor types offers the prospect of sensors with minimal intrusion for the monitoring of the cure of resins and resin systems. The optical bandwidth requirements for both grating based sensors are comparable. This is because a sufficient number of spectral resonances of a TFBG are necessary for a spectral area envelope to be calculated for a given change in refractive index. Whilst an LPG bands peak to peak separation is closer at bands near to cutoff, it is the longer wavelength bands which are more sensitive to refractive index change. These longer wavelength bands exhibit a wavelength shift for a given refractive index change comparable with that of the total bandwidth necessary for analysis of the TFBG response using the spectral envelope technique. In contrast the Fresnel based sensor is a fixed wavelength system and spectral processing is not required. The sensitivity of the LPG and TFBG sensors to both temperature and refractive index is highlighted in the results and illustrates a problem in extracting a single parameter from a single sensor. These issues may be resolved by exploiting the knowledge that the dependence of the sensitivity of the attenuation bands of LPGs upon the order of the cladding mode to which coupling takes place has been previously shown to facilitate multi-parameter sensing[12]. In the case of the TFBG, the insensitivity of the Bragg wavelength to the surrounding refractive index may be exploited to measure the temperature. 1.445 1.440 -2.5 Index of refraction Wavelength shift (nm) -3.0 -2.0 -1.5 -1.0 1.435 1.430 1.425 1.420 1.415 1.410 1.405 -0.5 0 30 60 90 120 150 0 180 30 60 90 120 150 180 120 150 180 Time (mins) Time (mins) (a) (b) 1.445 1.445 1.440 1.435 Index of refraction Index of refraction 1.440 1.430 1.425 1.420 1.415 1.435 1.430 1.425 1.420 1.415 1.410 1.410 1.405 0 30 60 90 Time (min) 120 150 180 1.405 0 30 60 90 Time (mins) (c) (d) Figure 4 (a). LPG band 5 wavelength shift for refractive index change of epoxy during cure. (b) Calculated refractive index change from Fresnel network. (c) Refractive index change from TFBG sensor. (d) Refractive index change from LPG sensor. 4. Summary In summary, three methods of monitoring the cure of a resin have been demonstrated. The mode resonances of a TFBG and a LPG are shown to have sensitivity to refractive index change during the cure of an epoxy and this is shown to be comparable with that of a fibre optic Fresnel reflection technique. The authors gratefully acknowledge the support for this work from the Engineering and Physical Sciences Research Council (EPSRC), UK under grant No. GR/P00710/01. References [1] Degamber, B. and Fernando, G. F. (2002), 'Process Monitoring of Fiber-Reinforced Polymer Composites', MRS Bulletin, Vol. 27, pp. 370-380. [2] Takeo, T. and Hattori, H. (1982), ‘Optical fiber sensor for measuring refractive index, Vol. 21, pp. 1509-1512. [3] James, S. W. and Tatam, R. P. (2003), 'Optical Fibre Long-period Grating Sensors: Characteristics and Application', Measurement Science and Technology, Vol. 14, pp. R49R61. [4] [5] [6] [7] [8] [9] [10] [11] [12] Allsop, T., Zhang, L. and Bennion, I. (2001), 'Detection of organic aromatic compounds in paraffin by a long-period fiber grating optical sensor with optimized sensitivity', Optics Communications, Vol. 191, pp. 181-90. Sarfraz, K. (2003), Fibre Optic Long Period Fibre Gratings for Sensing Applications (PhD thesis), Cranfield University. Min-Suk Kwon and Sang-Yung Shin (2004), 'Tuneable notch filter using a thermo-optic long-period grating', Journal of Lightwave Technology, Vol. 22, pp. 1968-75. Laffont, G. and Ferdinand, P. (2001), ‘Tilted short-period fibre-Bragg-grating-induced coupling to cladding modes for accurate refractometry', Measurement Science & Technology, Vol. 12, pp. 765-70. Asseh, A., Sandgren, S., Ahlfeldt, H., Sahlgren, B., Stubbe, R. and Edwall, G. (1998), 'Fiber optical Bragg grating refractometer', Fiber and Integrated Optics, Vol. 17, pp. 51-62. Grobnic, D., Mihailov, S.J., Huimin Ding and Smelser, C.W. (2006), 'Bragg grating evanescent field sensor made in biconical tapered fiber with femtosecond IR radiation', IEEE Photonics Technology Letters, Vol. 18, pp. 160-2. Kim, C.B. and Su, C. B. (2004), 'Measurement of the Refractive Index of Liquids at 1.3 and 1.5 Micron Using a Fibre Optic Fresnel Ratio Meter', Measurement Science and Technology, Vol. 15, pp. 1683-1686. Chen-Chun Ye, Staines, S.E., James, S.W. and Tatam, R.P. (2002), ‘A polarizationmaintaining fibre Bragg grating interrogation system for multi-axis strain sensing', Measurement Science & Technology, Vol. 13, pp. 1446-9. Bhatia, V., Cambell, D. K., Sherr, D., D'Alberto, T. G., Zabaronick, N. A., Ten Eyck, G. A., Murphy, K. A., and Claus, R. O. (1997), 'Temperature-insensitive and Strain-insensitive Long-period Grating Sensors for Smart Structures', Optical Engineering, Vol. 36, pp. 18721876.