32.1. Introduction There is currently a significant interest in replacing

advertisement

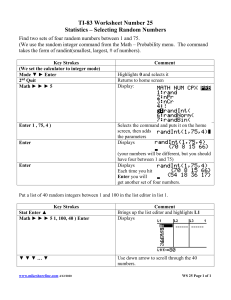

Module 32: Flexible and Conformable Displays 32.1. Introduction There is currently a significant interest in replacing the glass substrates on displays with plastic substrates for certain display applications. The ability to create a lightweight, flexible display is very attractive for applications that require inexpensive and robust displays. There have been many flexible displays concepts envisioned by the display community. The figure below demonstrates one of most attractive flexible display concepts as an example of a futuristic product and also puts it into historical perspective. The CRT is now more than 100 years old and is still the dominant desktop monitor for computing. There are now a significant number of LCD desktop monitors in the market because <20" diagonal screens are affordable. The active matrix LCD completely dominates the laptop market. the concept product illustrated in the above figure is a plastic that rolls out of a handle for use and rolls back into the handle for easy and convenient carrying. This rollable display has also been conceived as rolling out of a pen for PDA applications. 32.2. Transmission vs Reflection Then do not always go hand-in-hand, but when most people think about flexible displays, they also think about really low power and inexpensive display mediums. The figure below compares a transmissive LCD with a reflective portable LCD. The basic difference is that the transmissive display models a backlight and the reflective display modulates reflected ambient light. In most cases, reflective displays are largely manufactured for the portable market where power and weight are minimized. There have been plenty of demonstrations of OLEDs in flexible display configurations as well. The positive attributes of reflective displays are shown in the figure below. The bar chart also demonstrates the approximate power savings - a factor of two when the backlight is removed and enormous power savings of the material has bistable memory (e.g. Gyricon, e-ink, and cholesteric liquid crystals). 32.3. Converging Technology One interesting aspect of display technology in recent years is that there has been significant research and development investment in reflective display technology and plastic substrate technology. The figure below shows a schematic on the convergence of these two technologies, which can truly enable the rollable display concept. There are a number of issues with reflective display technology and flexible substrates that still need to be improved in order to realize such a far reaching applications the unraveling pen display. One of the most attractive features of a plastic displays in the possibility of using a roll-to-roll manufacturing process. If the display materials are compatible with such a process, the roll-to-roll manufacturing process may be feasible. With this high-throughput manufacturing process, it may be possible to create very inexpensive displays. 32.4. The E-Paper Chase The unraveling display application is certainly a wildly different application that can be enabled by a flexible substate technology, but electronic paper is equally compelling. Creating a paper surrogate is no easy task - paper is the ultimate display medium. Paper is foldable, rollable, and unbreakable, with a 180° viewing angle and a nice Lambertian reflection. There are a few contenders for e-paper - namely those display materials that are reflective and bistable (e.g. Gyricon, e-ink, and cholesteric LCDs) The cholesteric LCD is very mature and has the potential for full color. It has very attractive features such as high contrast (50:1), 40% reflectance at the Bragg wavelength, th, relative low switching voltage compared to other bistable reflective displays. One of the most attractive features about it is tat it has a well defined threshold and therefore passive matrix driving schemes can be used. A downfall of this technology is that it is difficult to achieve a white Lambertian appearance with one layer. The Gyricon technology consisting of a dispersion of bichromal balls in a elastomer matrix is very attractive because the materials to make such a device are inexpensive. The attractive features of the Gyricon displays are its Lambertian reflection and bistability. the disadvantages of Gyricon are that the drive voltages are relatively high for moderate reflectances. In addition, it is a thresholdless technology and would therefore need an active matrix for a medium to high resolution applications. E-ink is another potential for paper surrogate applications that is based on electrophoretic materials technology. E-inks encapsulate the electrophoretic particles to greatly improve robustness and stability of electrophoretic displays. They have a Lambertian reflectance that approaches 40%. The disadvantage is that the material is thresholdless and would therefore need an active matrix for medium for high resolution applications. An intriguing technology that is currently being developed at Philips, involves a 'paintable' electro-optic medium. A dispersion of LC and polymer is coated on a plastic substrate and irradiated with U light as shown below. The irrradiation is slow such that the liquid crystal will diffuse to the bottom surface and the polymer will form a top substrate as shown here. It is an exciting technology since it is only one substate and therefore very thin. In order to support the top polymer layer, they can create pixel walls between the layer as shown below. This technology has great potential. Organic light light emitting diode (OLED) technology has also been shown to be adaptable to plastic as shown below. OLED are attractive since they are an emissive technology and a bright display is possible. Here is an example of what they look like: There is however one downfall and that is that OLEDs seem to be quite sensitive to oxygen and moisture that diffuse through the plastic. Additional barrier layers are required to minimize the penetration of these impurities into the OLED material. Another technology is based on electroluminescent materials applied to a screen-like substrate, Developed by Visson, electrical pulses are applied to the rows and columns of the screen. As shown below, light emission is generated at the intersection. Another technology, based on interference, is being developed by Iridigm. This deformable membrane technology reflects bright iridescent colors or can be black & white. Full color is possible with Iridigm technology and the switching behavior and the deformable membrane has a well defined threshold so multiplexing is possible. 32.5. Flexible Display Technology Creating a flexible conducting substrate is key to all technologies described above. Currently, there are two solutions, Iridium-tin-oxide (ITO) on plastic and conducting polymer on plastic as shown below: ITO on plastic (polyester or PET) currently has strong performance properties (transmission > 90% and sheet resistance < 50 ) comparable to ITO on glass. However, the ITO cracks where subjected to strain (~2%). Conducting polymer on PET, on the other hand, can sustain very high degrees of strain (>10%) but current materials exhibit transmissions (<85%) and sheet resistances 100-1000 . When a flexible ITO substrate substate is flexed cracking can occur in tension and buckling or cracking can occur in compression as shown below. Images from a scanning electron microsphere on SEM are shown below to demonstrate the cracking. A close-up of an ITO crack is also shown in the following figure. In order to quantify the degree of cracking and how it influences the resistance, a miniature Inston (stress-strain measurement) is used. The figure above shows a tremendous increasing resistance at 2& strain. It is interesting to note that after 2% strain, if the substrate is allowed to relax, the resistance is never restored to its original zero strain values as shown above. This suggest that once cracking occurs and the resistances get large, the substate does not 'heal' and therefore is unusable. Therefore, flexible applications must not except this value or catastrophic failure will occur. The figure below is another potential way to characterize ITO on PET. It is known as bulge testing, which introduces a biaxial strain on the material. An SEM image shows the complex cracking pattern as the material is subjected to a bulge. The figure below compares the ITO and PET to conducting polymer on PET directly. One can see that the conducting polymer is much less susceptible to strain, but its resistance is much less attractive. 32.6. Active Matrix on Plastic There are two schools of thought when it comes to enabling active matrix technology on plastic substrates as shown below. One option is to raise the processing temperatures of the substrate so that it is compatible with inorganic TFT technology. The other is to develop new TFT technology that can be processed at low temperatures. There are both inorganic and organic TFT approaches at low temperatures, but the performance parameters are inferior to the high temperature inorganic TFTs. 32.7. Conformable Displays Conformable displays (displays that can be deformed around curved surfaces) may also open up new product categories for displays. A conformable display can be as simple as securing a flexible display to a curved surface. The display will have to withstand the internal stresses over time introduced by the conformed deformation conformed display may find applications in wrist band applications as shown below, or they may be integrated into clothing for example. Another interesting off-spring of conformal displays is to permanently capture the deformation in the substrates as shown below. The glass transition temperatures Tg, of PET for example is around 90°C. If the substate is conformed (spiral deformation above) and heated to temperatures above Tg, and cooled down under deformation, the spiral will remain indefinitely. What is attractive about this process is shown in the graph above. The PET substrate is strained to 8% and then heated above Tg. The graph clearly shows the stress relaxing out of the substrate over time. This concept was tested on a Polymer Dispersed Liquid Crystal display shown below. When the voltage is on, the liquid crystal droplets align creating and indexing matching condition. In this state the display is transparent. In the off-voltage state, the droplets are randomly oriented thereby creating light scattering state (milky white) Since the liquid crystal is encapsulated in a polymer so it is extremely robust and can survive the conforming and heating process as shown below. The display is first manufactured in its planar state (step 1), subjected to strain (step 2), heated above Tg (step 3), and cooled to low temperature. The figure below shows some small 1" x 5" laboratory samples subject to the process under different deformations. What is even more impressive is that the display works after this process as demonstrated below. In fact, the threshold voltage or drive voltage decreases, the hysteresis is reduced and the contrast decreases. Most of these observations can be described by a shrinking cell gap (10-20%) during the process. Permanently conformed displays are possible with other display materials that can sustain the process. 32.8. Summary Flexible and conformable display is attractive and may open up many new product categories that currently do not exist, such as rollable and foldable displays, and electronic paper. There are still many challenges ahead but the industry is determined to create a viable flexible display technology.