Blasting Practice Technical Bulletin No. 9 AFTER

advertisement

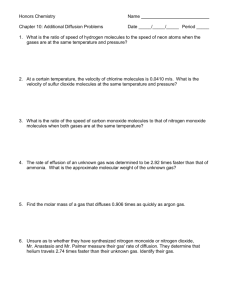

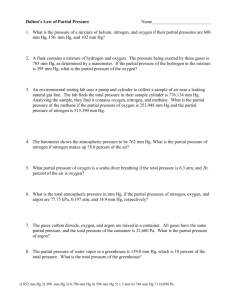

Blasting Practice Technical Bulletin No. 9 AFTER-BLAST FUMES 1 AFTER BLAST FUMES 1. Introduction. The reaction gases resulting from the detonation of explosives consist principally of Carbon Dioxide, Nitrogen and Water Vapor (steam). However, other, toxic gases may be formed such as Carbon Monoxide, Nitrogen Monoxide, Nitrogen Dioxide (Nitrogen Monoxide and Nitrogen Dioxide are often grouped together and given the combined name NOx and Ammonia. 2. The Effects of Toxic Fumes. Carbon Monoxide (CO) Carbon monoxide is a tasteless, non-irritating, odorless and colorless toxic gas which can cause lethal poisonings with very few and late occurring warning signs. CO binds to haemoglobin in blood and due to this mechanism, the oxygen transported by the blood is decreased and as a result some tissue damage can result from local hypoxia. Organs with a high oxygen requirement, such as the heart and the brain, arc sensitive to this effect and subjects with coronary artery diseases are especially susceptible. Nitrogen Monoxide (NO) Nitrogen monoxide (sometimes known as nitric oxide) is a colorless gas with a sharp, sweet odor. Nitrogen monoxide reacts with oxygen to produce nitrogen dioxide and in the occupational setting the two gases usually occur together. Studies in 2 animals show that long-term exposure to nitrogen monoxide can cause damage to the lungs, in the form of emphysema. Nitrogen Dioxide (NO2) Nitrogen dioxide is a red/brown gas with an irritating odor. Single exposures to nitrogen dioxide for brief periods of time (e.g. 15 minutes) at concentrations greater than 4 ppm cause irritation to the airway passages leading to effects such as sore throat. Studies in animals show that long-term exposure to nitrogen dioxide can cause damage to the lungs, in the form of emphysema. Ammonia (NH3) Ammonia is a colorless gas with a sharp, penetrating, intensely irritating odor. Inhalation of low concentrations can cause coughing, and nose and throat irritation. 3. Who is Exposed to these Fumes? Immediately following the blast the shot firer can be exposed to toxic gases if postblast fumes drift across the shot firing position or during the post-blast inspection. Fumes may also be emitted from the blast muck-pile during the loading operation although exposure levels are likely to be low. Under still atmospheric conditions toxic fumes may collect in low-lying areas of the excavation - including drainage sumps and these fumes may take some time to clear. Under some conditions it has been known for post-blast fumes to migrate for some distance from the blast area through broken or filled ground. This can be a particular problem when trench blasting close to 3 structures when fumes may find their way into the basements of nearby structures. 4. Exposure Limits for Toxic Gases. Reference should be made to local national standards regarding the permitted levels of exposure to toxic gases. 5. Factors Controlling the Production of Toxic Gases. The quantity of toxic gases depends upon a number of factors including: a. Explosive Chemistry. In general explosives are designed to be oxygen-balanced and this minimizes the degree of toxic fume production. b. Oxygen Balance In general an explosive that is oxygen positive will produce elevated levels of oxides of nitrogen whereas one that is oxygen negative will produce elevated levels of carbon monoxide. c. Homogeneity. The level of toxic fume production also depends upon how well the explosive components are mixed. A poorly mixed explosive will tend to be partly oxygen rich and partly oxygen negative therefore producing elevated levels of both carbon monoxide and oxides of nitrogen. 4 d. Presence of Water. If the explosive becomes mixed with water this can alter the chemistry of the product making it oxygen positive thus resulting in elevated levels of oxides of nitrogen. This is especially a problem when non-waterproof explosives are used in wet blast holes. Degree and Duration of Confinement. Most explosives detonate best under confined conditions producing the minimum amount of toxic fumes. If explosives are initiated under poor confinement then elevated levels can be expected. e. Contamination from the Rock. If the blast hole has been drilled through carbonaceous material such as coal then it is possible that drill dust can contaminate the explosives if bulk products are being employed. f. Explosive Desensitization. If an explosive has been subject to shock or gas pressure desensitization, then the explosive may deflagrate rather than detonate. Deflagrating explosives produce high levels of toxic fumes. For the factors controlling desensitization refer to Technical Bulletin No. 5. g. Chemical reactions Chemical reaction between the explosive and the material to be blasted. Under some conditions it is possible for ammonia gas to be generated during the blasting process. However, the concentration of ammonia generated is normally low. 5 6. Steps to Take to Minimize The Risks Associated with Toxic Post-Blast Fumes. Good blast design will result in minimum post-blast toxic fume production. Always follow the manufacturer's recommendations regarding the conditions under which a specific explosive should be used. Always use waterproof explosives under wet conditions. In countries where the site-mixing of Ammonium Nitrate and Fuel Oil is permitted particular care must be taken to ensure that a well-mixed and oxygenbalanced mixture is produced. Take all possible steps to minimize the exposure of people to post-blast fumes. 6