Users Manual for Flex BMS

advertisement

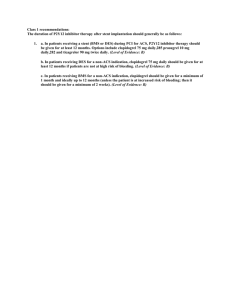

FLEX BMS

Software Version 0.6

Installation and Operations Guide

Applies to

BMS-36, BMS-48, BMS-60

1 Flex BMS Introduction

and Features

The Flex BMS provides a complete

Battery Management and Monitoring System solution for Lithium based electric vehicles.

The Flex BMS-36 product is designed to support 18-36 cell Lithium-ion based

electric vehicles which are typically DC powered, highway capable vehicles (57v115v).

The Flex BMS-48 product is designed to support 37-48 cell Lithium-ion based

electric vehicles which are typically DC powered, highway capable vehicles

(118v-153v).

The Flex BMS-60 product is designed to support 49-60 cell Lithium-ion based

electric vehicles which can DC or AC powered systems, highway capable

vehicles (156v-192v).

The Flex BMS is not chemistry specific and can be programmed for almost any type of

Lithium chemistry cell. The Flex BMS supports LiFePO4 cells from 10Ah to 180Ah

capacity.

The Flex-BMS architecture has a centralized data collection system and a small dash

mounted display Console. The data collection system monitors the voltage on each

battery and provides a battery balancing function. The dash console provides a simple

user interface to provide the primary battery condition information to the user. The dash

Console does not have to be constantly monitored; it will provide display and audible

alerts when there is a battery problem or when batteries have reached their low voltage

point.

ConvertTheFuture.com

-1-

BMS 0.6d

Installation and Operations Guide

The features of the Flex BMS are:

Dash mounted status display, provides simple

viewing of battery system.

Centralized monitoring of individual cell voltages, up

to 48 Lithium cells.

Up to 2 external temperature probes, and an internal

temperature probe.

Configurable Upper Voltage Threshold, Low Voltage

Threshold, and Balance Voltages

Configurable temperature threshold for alerts.

Automatic battery balancing, up to 1A per cell

Integrated, isolated charger cutoff switch, up to 240V, 20A

Balance at the end of each charge cycle and a separate Balance mode to

balance cycle the batteries.

Fully isolated architecture requires no vehicle 12v power or connections to

controller components.

Built-in logging function allows viewing of recent BMS activity and alerts.

What’s included with the Flex BMS:

Central BMS Box

Screwlock connectors for wiring harness connections

2 temperature thermisters

Display console

12’ Cat-5 shielded cable

BMS Options:

Current Monitor. Uses hall-effect sensor with ¾”

sensor opening that can be used with up to 2/0

cable. Allows installation without rewiring or new

current shunts. Current monitor show used KWh in

count-up mode or remaining KWh in count down

mode. Current monitor comes with a 4’ cable.

Data Logging Option. Uses internal USB stick to

log cell voltage, balance information and alerts

every minute. Logs errors as they occur. Data is recorded on a USB stick inside

the BMS Box. Data is in comma separated variable (csv) format that can be read

and analyzed using a spreadsheet program such as Excel. Data logging

formats are shown in Appendix C.

Note that wiring between the battery box and the batteries

is not included but can be ordered with the BMS.

ConvertTheFuture.com

-2-

BMS 0.6d

Installation and Operations Guide

2 Flex BMS Installation

The Flex BMS architecture includes a centralized monitoring box and a remote dash

mounted display. The Flex BMS monitoring box needs to be protected from direct water

splashing and requires left to right venting. The monitoring box can be mounted inside

the vehicle compartment or in the vehicle trunk.

The monitoring box connects with the dash mounted display thru a 12 or 14-foot Cat-5

cable, provided with the Flex BMS. It is not recommended to exceed this cable distance.

Figure 1 below show the basic wiring configuration for the Flex BMS.

12' Cat5 cable

Dash

Console

BMS

System 144V

Status: OK

Console

Connector A

Connector

A to:

Cells 1-12 and

Temperature Sensors

TA and TB

Connector B

Connector

B to:

Cells 13-24

Connector C

Connector

C to:

Cells 25-36

Connector D

Connector

D to:

Cells 37-48 and

Temperature Sensors

TC and TD

Isolated 240V

Charger 25A

Relay

Charger Power Cutoff

Figure 1. BMS Vehicle Connections

BMS-36 provides 3 board connectors with the BMS.

BMS-48 provides 4 board connectors with the BMS.

BMS-60 provides 4 board connectors with the BMS.

ConvertTheFuture.com

-3-

BMS 0.6d

Installation and Operations Guide

16

15

5 4

3 2

1

Figure 2. BMS Board Connector pin identification.

Ref Digikey ED1972-ND

The BMS connects to the batteries using a wiring harness. The BMS has 3, 4, or 5

internal boards with connectors that allow a harness to be assembled and tested prior to

connection to the BMS boards. The BMS boards closest to the center of the box is

number 1, and the boards at the edge of the box are the highest numbed boards.

An example schematic for the Flex BMS system installation is shown in Figure 3 below.

The BMS 48 has 4 battery connectors 1, 2, 3 and 4. The BMS box contains 4 battery

connector sockets labeled 1, 2, 3, and 4. The connectors attach to separate isolated

boards. The #1 connector is for the lowest potential batteries, thru the #4 connector

which is for the highest potential batteries. It is recommend that battery groups be in the

order specified to aid in battery identification. Each of the other battery connectors can

be connected to between 6 and 12 batteries to monitor.

2 Temperature Sensors are available on Board #1. If unused, the Temperature Sensors

inputs can be left open.

Connection cable for the wiring harness between the BMS and the batteries is not

included. It is recommended to use 22, 24 or 26 gauge cable1. Use of multicolored

ribbon cable allows the easier identification of battery connections. Recommend

stripping and tinning the stranded ends with solder prior to screwlock in the green BMS

battery connector. Carefully check battery connections and polarity with a voltmeter prior

to connecting to the BMS box.

The charger cutoff relay is located inside the BMS box. Power cables are used for

charger power cutoff.

If a current monitor option is installed, a 5 pin DIN connector on the BMS box is used to

connect to the current monitor module. Connection cable is included with this option.

Install the current monitor anywhere in the battery current path.

A stand-by switch in included for long periods of BMS inactivity. The BMS consumes a

small amount of energy (about 25 mA) from the battery system for monitoring. When the

1

Recommend 3m 22 Ga 10 conductor Ribbon cable from Arrow Electronics. Part number 3319/10

ConvertTheFuture.com

-4-

BMS 0.6d

Installation and Operations Guide

BMS is not needed, put the stand-by switch into stand-by mode to save battery power.

After switching back to “ON”, Restart the BMS from the main menu.

.

“A”

Connector

Digikey

On-shore

ED1972-ND

A-15

A-14

A-13

...

A-16

A-7

A-6

A-5

A-4

A-3 A-2 A-1

Wiring

Harness

Allied:

3M 22ga x10

Rainbow Ribbon

+

+

...

Cell 12 Cell 11 Cell 10

-

Cell 3 Cell 2

Cell 1

TA: (optional) 10K

NTC Thermister

Mouser

871B57871S103F1

TB: (optional) 10K

NTC Thermister

Figure 3. BMS Battery Connection Schematic

If less than 12 batteries are connected on the #4 Connector, tie the unused highest

potential leads to the highest voltage on the system, as shown in Figure 4.

Figure 4. Partial use of #4 connector for a 46 Cell Configuration.

ConvertTheFuture.com

-5-

BMS 0.6d

Installation and Operations Guide

3 Flex BMS Configuration

When the BMS is first started, it will perform diagnostics and then display the main

menu. Configuration is necessary prior to starting the monitoring program. The Flex

BMS is configured using the BMS console. Select is the rotary encoder on the BMS

Console, which can be rotated or pressed. Configuration settings are stored in nonvolatile EEPROM memory.

The following configuration settings are necessary prior operation and monitoring.

1. Configure number of cells to Monitor. BMS 48 with four monitoring boards can

monitor between 36 and 48 cells.

a. From the main menu rotate the Select knob until configuration is indicated

in brackets. The configuration menu is displayed. Rotate the Select knob

until “Config: is displayed, and press Select.

b. Push Select until “Number of Boards:” appears and rotate Select until the

desired the number of boards shows “4”. Press Select. Note: use “3” for

BMS-36, “4” for BMS-48, and “5” for BMS-60

c. Push Select until “Cells in Board 1:” appears and turn Select until the

actual number of connected cells in the first board is shown and press

Select. Continue entering cells in boards 2, 3 and 4.

d. Pressing Select until the Config menu appears, then select “Back” to get

to the Main Menu.

2. Configure Battery Monitoring Voltage Thresholds. The BMS has adjustable

thresholds for battery monitoring. These thresholds can be adjusted to

accommodate different battery chemistries, or to suit user needs. Consult your

battery manufacturer for specific recommendations. Typical Thresholds are

shown in Table 1. Balance voltage setting should be .1v below the battery High

voltage cutoff voltage.

Table 1: BMS Threshold Settings for Lithium Battery Chemistries.

LiFeP04

(3.2v)

Over V: High

Voltage Cutoff

Under V: Low

Voltage Cutoff

Bal V: Balance

Voltage

Hysteresis

Voltage

Li-Cobalt

(3.6v)

Li

Manganese

(3.7v)

Ni-CoManganese

(3.2v)

3.912v

4.20v

4.20v

4.104v

2.496v

2.496

2.496

2.496

3.864v

4.104v

4.104v

4.008v

0.0465

0.0465

0.0465

0.0465

From the main menu select:

SETUP->CONFIG.

a. Low Voltage Cutoff: Push Select until “Under Voltage:” appears. Turn

Select until the desired voltage is shown and press Select.

ConvertTheFuture.com

-6-

BMS 0.6d

Installation and Operations Guide

b. High Voltage Cutoff: Push Select until “Over Voltage:” appears. Turn

Select until the desired voltage is shown and press Select.

c. Balance Voltage: Push Select until “Balance Voltage:” appears. Turn

Select until the desired voltage is shown and press Select.

d. Push Select until “Temp limit:” appears, set the maximum temperature

(35 degrees C is recommended) and press Select

Continue pressing select until the Config menu appears, then select “Back” to

get to the main menu.

Restart the BMS: from the main menu, Select “Restart” and press Select.

3.1 Current Monitor Option

If the current monitor option is installed, the current monitor needs to be configured.

The current monitor displays instantaneous current usage in run mode, and track KWh

power used by the battery system. The power tracking data is collected every 1 second,

and is either counted UP for total used or counted down from the current monitor limit.

The configuration and limits are set from the configuration menu.

From the main menu select:

SETUP->CONFIG.

Select Current monitor: Yes

Current Monitor Count Up: Yes.

Current Monitor Limit: 13 KWH

During initial installation, suggest is to count up and set the limit to well above the

expected battery capacity. Once the battery system has been cycled, the upper limit of

power battery power as measured from the current monitor will be known. This limit can

be set into the configuration for a count-down available battery power. Power calculation

is done as measured Pack Voltage * measured Current usage, measured each second.

Pukerts effect are not factored into the battery power usage.

Remaining or used power is displayed on line 2 of the display in run mode. Power

usage is reset on system startup, or when any balancer is activated

4 Flex BMS Operations

This section covers the basic operations of the BMS. The complete software menu

hierarchy is listed in Appendix B. There are two operations modes, Monitor for day-today operations of the BMS, and Balance, for running charging/balancing cycles to

balance the battery pack.

4.1 BMS Monitor

To start the BMS monitor. From the main menu, turn Select to “Run” and press Select.

The BMS will enter the monitoring mode. To exit the monitor mode, press and hold the

select button as described in the Administration section.

ConvertTheFuture.com

-7-

BMS 0.6d

Installation and Operations Guide

In the monitor mode, the BMS monitor display has two lines. The top line will indicate

the Monitoring State, the current pack voltage and highest temperature.

The monitoring states are:

OK: this state indicates that all cell voltages and temperatures are within set

tolerance. The BMS system does not detect significant change in pack voltage

indicating charge or discharge.

BAL+: This state indicates that one or more cells is above the balance threshold and

the balancer load in enabled for a cell. The charger is on.

BAL-: This state indicates that one or more cells is above the balance threshold and

the balancer load in enabled for a cell. This charger is off. This mode is only used in

balance mode.

END : End of charge cycle. When a single cell reaches the cut-off threshold, the

charger is cut-off, balancer loads disabled. The BMS will stay in this state until the

select button is pressed.

TEMP!: This state indicates that a temperature threshold has been exceeded.

Charge is cutoff, balancers are cutoff, and the fan is on. An Alert is displayed.

In monitor mode, the Console may display Alerts by flashing the backlight. (Audible alert

is in next version). An Alert is cleared by pressing the “Select” for one second.

Alerts may occur for many reasons, including:

Over Temperature

Low Battery Threshold

System Error

The bottom line on the monitor rotates thru several messages:

Min X.XXXv nn

This identifies the Minimum cell voltage on cell nn, with

voltage x.xxx volts

Max X.XXXv nn

This identifies the Maximum cell voltage on cell nn, with

voltage x.xxx volts

Bal Cells n

When cell balancers are active, this indicates the number of

cells balancers enabled.

P xx.xx KWh left

If current monitoring enabled in count down mode this

indicates the calculated power left in the battery pack

P xx.xx KWh used

If current monitoring enabled in count up mode this

indicates the calculated power used.

Any system errors are listed in the bottom line of the display. The bottom line can be

read as:

Severity Code [Board ID-Cell ID]

Severity is either LOG for a simple log report, WARN indicating a Warning condition, and

ERR indicating a serious error or fault. Codes are listed in the Appendix A. Board ID

ConvertTheFuture.com

-8-

BMS 0.6d

Installation and Operations Guide

and Cell ID are the Board number [0 to 7] and cell on the board [0-11] that reported the

fault.

The BMS continues to operate in the Monitor mode indefinitely. To exit the monitor

mode, hold down the select button as described in the Administration section.

During charging in monitor mode, a charge cycle will near completion using balancing,

and after one cell has passed the over voltage threshold, the charger will be cutoff,

balancers turned off, The BMS will be in the ‘END’ state. To re-enable the charger,

press the select button.

4.2 BMS Balance

The BMS can be run in a Balance Mode to cycle thru up to 20 charger or balance cycles

to balance the Li batteries. The Balance cycle should be used whenever battery any

battery is replaced or one of the batteries is consistently low. Balancing will help bring

the lower voltage batteries up to the same level as the rest of the pack.

To start the BMS Balance mode, exit the monitor mode by holding down the select

button as described in the administration section. From the main menu, select BAL.

Then select the number of balance cycles [1-20]. Generally, 4-5 balance cycles should

balance most lithium battery packs.

In this mode, the charger will activate, and the balancers will trigger upon balance

voltage. When a battery reaches the high voltage cut-off, the charger will be cut-off, and

the balancers will stay enabled until all are below the balance voltage, then the charger

will be re-enabled. This will cycle the specified number of cycles.

The balance and charge cycles will stop when all balancers are activated.

The balance function will keep batteries in balance. New batteries may come from the

factory in charged or discharged state. New batteries that have significantly difference

state of charge may need to be manually balanced or individually charged.

5 Administration

To administer and configure the BMS, the BMS must be out of the monitor mode. To

exit the monitor mode, press and hold the Select knob for at least 15 seconds, until

the display changes. This will bring up the Main Menu.

The Log Function:

A log function is provided to keep the latest 50 log entries in the BMS. To view the log

entries, the system must be out of the monitor mode.

To administer the Log, from the main menu, select “Setup”, then select “Log”. This

brings up the Log Menu.

ConvertTheFuture.com

-9-

BMS 0.6d

Installation and Operations Guide

To view the Log, select “ViewLog”. Turn the Select knob to the right for later entries,

turn to the left for earlier entries. Entry format is the same as Line 2 of the monitor

mode. Time is included on the second line to indicate the relative number of seconds

since the system was restarted. Log codes are found in Appendix A. Press Select to

exist the log viewing mode.

To reset the Log, select “ClearLog”.

For more information contact

Mark Hardy, Hardy EV LLC

Hardy.mark@convertthefuture.com

ConvertTheFuture.com

- 10 -

BMS 0.6d

Installation and Operations Guide

Appendix A

Log Codes and Explanation

Logged errors and warnings may be displayed during system startup, during any read

operation or during monitoring. Log information is useful for diagnosing problems with

the system. Codes are displayed as a CODE followed by a [board-cell] indicator.

Codes are listed in the appendix. Board and Cell are the Board number [0 to 7] and cell

on the board [0-11] that reported the fault.

Table A-3 Log Codes

Meaning

Value

(decimal)

1

Title

3

UNDER_VOLTAGE_CELL

5

CELL_ERROR

7

8

9

11

MONITOR_START

MONITOR_STOP

POWER_ON

OVER_TEMPERATURE

12

13

14

SELF_TEST_FAIL

PEC_ERROR

ACK_WARNING

15

OPEN_WIRE_ERROR

16

LOAD_FAILURE

17

NO_CELL_READING

20

21

22

CHARGE_START

CHARGE_STOP

POLL_ERROR

23

TEMP_OK

25

EXT_POWER_OFF

OVER_VOLTAGE_CELL

ConvertTheFuture.com

- 11 -

An individual cell recorded overvoltage

An individual cell recorded undervoltage

A cell’s value were out of range.

Wiring for the cell may be faulty, or

the cell balancer may be damaged.

Monitor program started.

Monitor program stopped

BMS started

Sensor recorded over –

Temperature

Initialization self test failed.

Communications PEC error

Operator presses Select to

acknowledge and clear alert..

Balancer check failure, check

system wiring.

Balancer check failure, check

system wiring

No cell voltage found, check config

system wiring.

Charger was turned off

Charger relay was turned off

Board polling time was out of

parameters

Temperature reduced to to below

high threshold

External Power Switch turned off.

BMS 0.6d

Installation and Operations Guide

Appendix B

Software Menus

Main Menu

Run:

Bal:

Read:

Config:

Restrt:

Starts the monitoring program

Starts the balancing program

Reads and displays current cell voltages for each cell

Configuration Menu

Restarts the BMS

Configuration Menu

Setup:

Sets configuration parameters

Over V:

Sets the cell over voltage threshold

Under V:

Sets the cell under voltage threshold

Bal V:

Sets the cell balance voltage threshold [3.8

Max Temp:

Sets the system maximum temperature (celcus) [45]

Boards [1-8]:

Sets the number of boards in the BMS system

Cells on Board n [4-12]: Sets the number of cells on each board

Hysteresis:

Sets the hysteresis voltage for balance turn off. [0.04]

Current Monitor:

Yes/No whether the current monitor is installed.

Current Count Up: Yes/No sets whether KWh are counted up or down

Max KWatt-Hrs:

Sets the number of KWh for count down.

Tst:

Test Menu

Log:

Log Menu

Light:

Turns on the backlight

Back:

Returns to Main Menu

Log Menu

ViewLog: Displays all the log entries

Clear:

Deletes all log entries

Back:

Returns to Main Menu

Test Menu

CelTst:

ComTst:

AmpTst:

Back:

ConvertTheFuture.com

Runs Diagnostics on each cell, check balancers

Runs Diagnostics on the interboard communications

Runs test program for the current monitor

Returns to Main Menu

- 12 -

BMS 0.6d

Installation and Operations Guide

Appendix C

Data Logging and Formats

If the USB Data Logging option is provided with the BMS, the BMS will detect the

presence of a USB stick in the BMS. If the USB memory stick is not detected at startup,

USB recording will be disabled. The BMS can be restarted using the ‘Restrt’ option

from the main menu.

The USB Data Logging option uses internal USB stick to log cell voltage, balance

information and alerts every minute. Logs errors as they occur. Data is recorded on a

USB stick inside the BMS Box. Data is in comma separated variable (csv) format that

can be read and analyzed using a spreadsheet program such as Excel.

Data logging starts when the BMS is restarted. A file is created or opened called

‘BMSLOG.TXT’ Each row of data is in ASCII format, and ends with a carriage return and

line feed.{CR-LF}.

After restart the first line of data recorded is “Start BMS Log {CR-LF}”.

The next line of data recorded is the header information to help identify each data

element when imported into in a spreadsheet. The length of the header depends on the

number of cells configured. The example below show a system configured for 12 cells

on one board:

Time (s), Pack_Voltage (v), Max_temp (c), Monitor_state,cell 1[0-0], cell

2[0-1], cell 3[0-2], cell 4[0-3], cell 5[0-4], cell 6[0-5], cell 7[0-6], cell

8[0-7], cell 9[0-8], cell 10[0-9], cell 11[0-10], cell 12[0-11], Balance 0-7

(hex), Last Log {CR-LF}

Each of these data elements are explained in the data logging formats in Table C-1

Log Data Element

Time (s),

Pack_Voltage (v),

Max_temp (c),

Monitor_state,

cell 1[0-0],

cell 2[0-1],

cell 3[0-2],

…

Balance 0-7 (hex),

Last Log

ConvertTheFuture.com

Table C-1. Data Logging Format

Value

Decimal number of seconds since the BMS was

restarted.

Total pack voltage, in Volts

Maximum temperature of all active probes, in degrees

celcius

State of the monitor, see table C-2

Cell Voltage for board id 0, cell id 0, in Volts

Cell Voltage for board id 0, cell id 1, in Volts

Cell Voltage for board id 0, cell id 2, in Volts

Hex code identifying the balancers that are active. Bit 1

is cell id 0.

Log entries are given with a severity level (Log, Warn,

Error), a code number (See Table A-1), followed by the

board and cell number.

- 13 -

BMS 0.6d

Installation and Operations Guide

Monitor State Code

10

12

15

17

ConvertTheFuture.com

Table C-2 Monitor State Codes

Meaning

Monitor Mode, charge enabled

Balance Mode, at least on balancer is enabled

Over Temperature mode, balancers and charger

disabled

End of Charge state, charger disabled.

- 14 -

BMS 0.6d

Installation and Operations Guide