Maker_Supplementary Materials_revised-with sol

advertisement

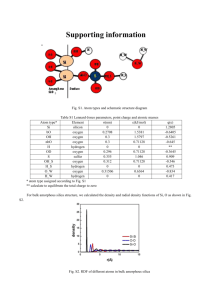

Supplementary Materials for: Heterodyned Toroidal Microlaser Sensor Ashley J. Maker and Andrea M. Armani Calculating the noise level for each sensing method To determine the amount of background noise in the measurements, the sensing signal is measured under ambient conditions with no temperature change for 1-3 minutes. This allows approximately 100 data points to be collected for the OSA, and 2000 points for the oscilloscope and ESA. The distributions in the signal for each measurement are plotted in Fig. S1-S3. A Gaussian is fitted to the fluctuations, and the noise level is determined from the value of 3σ from the center. The measured noise levels are 0.0027nm for the resonant wavelength shift, 0.0068nm for the OSA, and 0.030GHz (1.1x10-4nm) for the ESA. These noise levels are comparable to the 2.6pm linewidth of the resonant peak and significantly larger than the 7.1x10-3pm theoretical linewidth of the microlaser. Sources of noise, such as coupling variations, result in it being difficult to reach the limit of sensitivity in air environments. Fig. S1. The measured noise fluctuations in resonant wavelength shift data are 2.7pm, which is close to the 2.6pm linewidth of the resonant peak, indicating that the measurements approached the theoretical detection limit of this device. Fig. S2. The measured noise in the lasing wavelength shift background is 6.8pm. Due to the resolution limit of the OSA, only four different lasing wavelength values were measured. The bin size is 3.0pm, which corresponds to the OSA limit. Fig. S3. The noise level in the heterodyne background data is 0.030GHz, which corresponds to a lasing wavelength shift of 0.11pm. Converting Sensitivity values to dn/dT To change the d/dT values to dn/dT values, the following expression from microcavity physics is used: n/n= Fabricating the alumina and neodymium-doped silica sol gels Silica films are doped with 0.1 mol% Nd3+ and 2 mol% Al2O3 (to enhance the Nd3+ emission near 1064nm) using the following sol gel method. First, tetraethoxysilane (TEOS, Alfa Aesar, 99.999%), aluminum isopropoxide (Sigma Aldrich, 99.99%), ethanol, deionized water, and HNO3 (EMD, 68%), are combined in a glass bottle, stirring 5 minutes between each addition. The molar ratios of (TEOS:aluminum isopropoxide:ethanol:water:HNO3) are set to (1:0.02:4:4:0.05) 1. After addition of HNO3, the mixture is stirred for 1 hour at 70°C. Meanwhile, neodymium nitrate (Alfa Aesar, 99.99%) is dissolved in deionized water in a 1:10 molar ratio. When the TEOS solution has finished stirring, the neodymium nitrate and TEOS solutions are combined and stirred for an additional 30 minutes, and finally aged for 60 hours in ambient conditions. Silica films are produced by spin-coating the aged sol gels onto bare silicon wafers. The coated wafers are then dried on a 75°C hot plate for 5 minutes and annealed in a tube furnace at 900°C for 2 hours with a ramp rate of 1°C/minute. After annealing, silica toroids approximately 40µm in diameter are fabricated from the sol gel films in a Class 100/1000 cleanroom using standard photolithography, buffered oxide etching, XeF2 etching, and CO2 laser reflow procedures (Fig 1b, c) 2. Characterizing the synthesized sol gel films To verify that the silica sol gels had successfully annealed and produced a silica matrix, infrared spectroscopy measurements were taken using an attenuated total internal reflection FTIR (Bruker Alpha-P). As can be seen in the FTIR spectra (Fig. S4), all of the samples had infrared absorption peaks near 460cm-1, 810cm-1, and 1080-1130cm-1, corresponding to the formation of Si-O and Si-O-Si bonds3. This indicates the addition of 0.1 mol% neodymium and 2 mol% alumina did not disrupt the silica matrix. While the addition of alumina may cause the infrared absorption peaks to shift4, no significant differences were observed in our samples since the 2 mol% concentration of alumina is still quite low. Based on previous results, this is expected. Fig. S4. FTIR measurements confirm that all the sol gel silica samples contained silica’s characteristic infrared absorption peaks. References 1 J. W. Zhai, B. Shen, X. Yao, and L. Y. Zhang, Ceramics International 28 (7), 737 (2002). 2 Ashley J Maker and Andrea M Armani, in Journal of Visualized Experiments (2012), Vol. 65; D. K. Armani, T. J. Kippenberg, S. M. Spillane, and K. J. Vahala, Nature 421 (6926), 925 (2003). 3 Philip J Launer, in Silicone Compounds Register and Review (1987), pp. 100; P. Innocenzi, Journal of Non-Crystalline Solids 316 (2-3), 309 (2003). 4 X. Zhang, Y. Y. Wu, S. Y. He, and D. Z. Yang, Mater. Chem. Phys. 114 (1), 179 (2009).