St Andrews Cross – Plans

advertisement

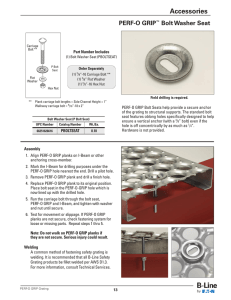

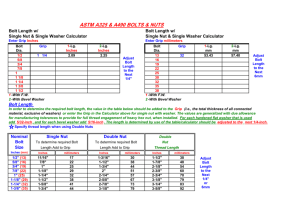

St Andrews Cross – Plans Materials List Timber 3 ½” x 1 ½” x 8’ 4’ x 4’ x ¾” 3 off 1 off Hardware Carriage Bolt 5” x ½” 1 off Washer ½” 1 off Nut ½” 1 off Eye Bolt 3/8” x 5” Flat washer 3/8” Loose Pin Hinge 3” Paint Grey Primer Black Gloss Enamel 8 off 8 off 3 off 196563 63307 196341 Method Firstly the 2 uprights need to be aiming for a 3’ spread but my angle, so using this I actually got mitered together, originally I was miter block gave me a 22 ½ o cut just over a 3’ spread. The easiest way to do this is to wood to the center line then leave the waste slightly high you for a perfect fit. When fitted the carriage bolt (seen here). saw another 3 cuts through the chisel out the waste wood, if you can sand or plane out the miters together drill the center hole for Next lay a straight edge corner to uprights and mark a straight line uprights (seen here bottom left corner of to measure the correct angle (I long straight edge). corner of the lower half of the 2 to saw the lower edges of the 2 Next drill the holes for the top eye ½” (to allow for washers) and the legs the first other 2 are a The ‘eye’ part draw nicely into prevent the bolt line when the bolts, these are ¾” to a depth of the nuts and then 3/8” through one is at 2” then the further 6” apart. of the eyebolt will the wood and from turning out of nuts are tightened. picture). This is easier than trying used the 3rd piece of wood as a The lower eye bolts are 4” on the inside legs from the base. You will need to cut a square hole the cross to allow the head of the the method I used was to tighten wood and gave me the pattern to need to cut is only about ¼” as the requires. Once cut assemble the bolt. (this will keep the cross on the front side of the center of carriage bolt to recess correctly, the bolt slightly, this marked the cut to using a chisel, the depth you bolt will form exactly the hole it basic cross and tighten the center rigid). You will now need to cut the rear support strut. The foot angle is 60o and top is 30o, the outside length is then 4’ 7 1/8” and the inside length is 3’ 11 7/8”, this gives a near vertical Cross, however if you want the cross to lean back then adjust these dimensions. Next remove the pins from 2 of the as they are very tight) and screw of the 2 uprights. Mark a line 30” hinges (I had to use ‘Mole Grips’ one half of the hinge to the bottom from the rear edge of the base plate, the other half of the hinge Do the same for the rear support be chiseled out slightly to allow for done offer up the Cross and refit for the rear support strut. These nicely. A ½” hole will need to be drilled 4” from the top of the support tap the carriage bolt through to drilled you will need to recess the large washer and nut (I simply chiseled it out). will be screwed to the base plate. bracket. The base plate will need to the hinges to lay flat. When this is the hinge pins loosely, do the same should now touch each other through this support strut (approx strut, however you may want to mark the exact position), once rear of the strut to allow for the drew round the washer and Reassemble the entire unit when completed, you will have noticed that the hinge pins will not be able to be fully reinserted, you will have to file a flat across the head of each pin so that they lay flat on the baseboard. I gave the uprights and the support 1 coat of primer and 2 coats of Black Enamel gloss, the base board required 2 coats of primer and 3 coats of gloss. Total Cost around $50. Copyright 2005 R J ROOK ( Master_Unicorn@mchsi.com )