1401822

advertisement

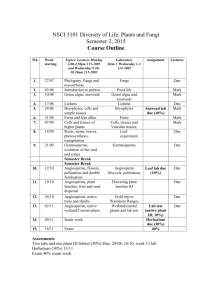

1 DEVELOPMENT OF DAN KWIAN CLAY FOR USING 2 IN CERAMIC TILE INDUSTRIAL 3 4 Running head: Development of Dan Kwian clay for using as ceramic tiles 5 6 Anurat Poowancum 7 8 School of Ceramic Engineering, Institute of Engineering, 9 Suranaree University of Technology, Nakhorn Ratchacima, 30000, Thailand 10 E-mail: anurat@sut.ac.th 11 12 13 Abstract The serious problem of pottery village in Thailand, especially Dan Kwian 14 village is the falling prices of products due to oversupply of products. The aim 15 of this work is to develop the properties of Dan Kwian clay for using to produce 16 the ceramic tiles which have a big distributing market. Feldspar and quartz 17 were used to improve the firing properties of Dan Kwian clay. The 18 compositions of mixture were designed by tri-axial diagram. The samples were 19 formed by uniaxial dry press, and were sintered at 1200 oC for 1 hour. The 20 results show that by adding small amount of feldspar, i.e., 10 mass%, the firing 21 properties of Dan Kwian Clay are significantly improved, and useable for 22 ceramic wall tile and floor tile. 1 23 24 25 Keywords: Dan Kwian, Dan Kwian clay, Ceramic tiles, Dan Kwian tiles, Ceramic tile industrial 26 27 Introduction 28 Dan Kwian village is the famous pottery village of Thailand, is located in Tambon 29 Dan Kwian, Chock Chai district, Nakhon Ratchasima province. Almost products of 30 Dan Kwian village are the unglazed earthenware, and are made from Dan Kwian 31 clay. Dan Kwian clay is a one kind of secondary clay, has red color, has high 32 plasticity, and has high firing strength. Although, Dan Kwian clay has the useful 33 properties for producing various kinds of ceramic products, almost factory in Dan 34 Kwian village produce only a pottery. Nowadays, the falling prices of products are 35 the serious problem of Dan Kwian village. The causes are the intense market 36 competition and oversupply of products. 37 There are numerous researchers try to improve a price of Dan Kwian 38 products by developing a new glaze, changing a fabrication process, and changing 39 a fuel of Dan Kwian kiln [1-5]. However, the problems of Dan Kwian village are 40 not solved due to the new knowhow totally change the original process, and too 41 complicate for Dan Kwian village. Moreover, all research works still focus on the 42 old product, i.e., pottery, which cannot increase the distributing market. Therefore, 43 a simple production process and a large distributing market are the solution for 44 sustainable problem solving of Dan Kwian village. 2 45 Ceramic tiles are the products in the group of construction and building 46 materials, are required in large number, and have a big market for distributing 47 products. In addition, the processing process of ceramic tiles is not complicate, can 48 be made in a small or a large production scale, and can be produced by handmade 49 or the high technology machines. 50 The aim of this work is to develop Dan Kwian clay for using as ceramic 51 wall tile and/or ceramic floor tile. Feldspar and quartz are used to improve the firing 52 properties of Dan Kwian clay. 53 54 Materials and Methods 55 Dan Kwian Clay from Dan Kwian village was dry by oven at 150 oC for 24 hours 56 before was milled by disk mill then was passed through sieve number 120 mesh to 57 obtain the powder of Dan Kwian Clay. Other Raw materials used in this work 58 including feldspar powder (Sibelco minerals) and quartz powder (Sibelco 59 minerals). Particle size of feldspar powder and quartz powder was 45 µm. All raw 60 materials were dry at 150 oC for 24 hours before were packed into a brass cone 61 mold. The packed powder was heated to 1200 oC, heating rate of 5 K/min, and 62 soaking time of 1 hour, after that, the cone high changed was measured to examine 63 the fusion of raw materials. 64 Dan kwian clay powder, feldspar powder and quartz powder were mixed by 65 porcelain mortar. The rations of mixtures were designed by a tri-axial diagram as 66 shown in figure 1. The mixed powder was uniaxially pressed into a rectangular 67 shape under 15 MPa for 30 second, then was sintered by the electric furnace at 3 68 1200 oC, heating rate of 5 K/min, and soaking time of 1 hour. Sintered samples were 69 cut into a size of 5 mm x 5 mm x 30 mm for testing water absorption and flexural 70 strength. 71 Water absorption of the fired samples was measured following the 72 International Organization for Standardization (ISO) standard 10545-3 [6]. The 73 samples were immersed in water and held in a vacuum chamber of 100 kPa for 30 74 min to fill up the open pores with water. Flexural strength was measured by the 75 three-loading method (Universal Testing Machine, Instron 5565) according to ISO 76 10545-4 [7]. Chemical compositions of Dan Kwian clay were evaluated by X-ray 77 fluorescence (XRF, Horiba XGT-5200). 78 79 Results 80 Chemical compositions of Dan Kwian clay are shown in table 1. Silica 81 (SiO2) is the main composition, i.e., 72.95 mass%. Figure 2 shows the raw-material 82 fusion test. Cone high of feldspar and Dan Kwian clay is collapsed 26% and 12%, 83 respectively. Cone high of quartz does not change after firing. 84 Water absorption of Dan Kwian clay after firing is 8.2%, is reduced by 85 adding feldspar as illustrated in figure 3. By adding feldspar 10 mass%, water 86 absorption of Dan Kwian clay is reduced to 6%, and is continuously declined with 87 increasing feldspar amount. On the other hand, figure 3 show quartz increase water 88 absorption of Dan Kwian clay. 89 Flexural strength of Dan Kwian clay after firing is 12.2 MPa, and 90 significantly increased by adding feldspar as shown in figure 4. By adding feldspar 4 91 10 mass%, flexural strength of Dan Kwian clay is 34.5 MPa. On the other hand, 92 quartz reduce flexural strength of Dan Kwian clay. 93 By using feldspar combine with quartz to improve the firing properties of 94 Dan Kwian clay, flexural strength of the compositions that locate close to the quartz 95 area are lower than flexural strength of the compositions that locate close to the 96 feldspar area, as illustrated in figure 5. Likewise, water absorption of the 97 compositions that locate close to the quartz area are higher than water absorption 98 of the compositions that locate close to feldspar area, as illustrated in figure 6. 99 100 Discussion 101 Although, numerous properties are required for the ceramic tiles, the most 102 importance properties are strength and water absorption. Table 2 shows ISO 103 standard for flexural strength and water absorption of ceramic wall tile and floor 104 tile [8], and demonstrates that Dan Kwian clay cannot be used alone for producing 105 ceramic tiles. Because, flexural strength and water absorption of Dan Kwian clay 106 does not correspond to the ISO standard. Feldspar is a flux material, is melted at the 107 sintering temperature, and increase liquid phase in the fired samples. Liquid phase 108 fills up pore in the samples during the firing process. Therefore, by adding feldspar, 109 flexural strength of Dan Kwian clay is significantly increased, while water 110 absorption of Dan Kwian clay is reduced. In contrast, quartz is a refractory material, 111 and it increases the sintering temperature. The main chemical composition of Dan 112 Kwian clay is quartz. As a result, by adding small amount of quartz, firing strength 5 113 of Dan Kwian clay is significantly reduced, while water absorption of Dan Kwian 114 clay is increased. 115 Figure 7 shows the areas of compositions that suitable to be used as ceramic 116 wall tile or floor tile, and there are feldspar in all compositions. By adding feldspar 117 10 mass%, the fired sample is useable for both of ceramic wall tile and floor tile. 118 Ceramic wall tile requires a lower strength and a higher porosity in comparison with 119 ceramic floor tile. Consequently, the combination of quartz and feldspar can be used 120 to modify Dan Kwian clay for making ceramic wall tile. There are not any 121 compositions between quartz and Dan Kwian clay that usable for producing 122 ceramic floor tile and wall tile. 123 124 Conclusions 125 The results in present work show that Dan Kwian Clay is a useful raw material for 126 using in the ceramic tile industrial. By adding small amount of feldspar, i.e., 10 127 mass%, the firing properties of Dan Kwian Clay are significantly improved, and 128 functional for ceramic wall tile and floor tile. Quartz increase water absorption, 129 while reduce firing strength of Dan Kwian Clay. The mixture between quartz and 130 Dan Kwian clay cannot be used for making the both of ceramic wall tile and floor 131 tile. For using quartz as a raw material, feldspar is required in the compositions to 132 modify the properties of Dan Kwian clay for using as a ceramic wall tile. 133 The knowledge in this work opens an opportunity to utilize Dan Kwian clay 134 for making a new product except pottery, and introduce a new raw material source 135 for the ceramic tile industrial. 6 136 137 138 139 Acknowledgements The financial of this research was supported by Office of the Higher Education Commission, Thailand. 140 141 References 142 Sirirat, R. (2007). Dan Kwian Clays for Slip Casting. ScienceAsia. 33:239-243 143 Srilomsak, S., Montinee, W., Molrudee, K., Rattanaporn, A., Rungchai, S., 144 Ruethairut, T., Luxsanawadee, U., and Wanwisa, T. (2006). Celadon Glaze 145 on Dan Kwian Pottery. Suranaree J. Sci. Technol. 13(2):197-205. 146 Jarinee, J., and Kiatfa, T. (2011). Simulation of Temperature Distribution without 147 Products inside a Clay Pottery Kiln at Dan Kwian, Thailand, KKU Research 148 Journal. 16(2): 127-135. 149 Den, R., and Watchrin, S. (2013), Development and Technology Transfer of Clay 150 Body and Glaze on Dan Kwian Pottery Tradesman, Nakhonratchasima 151 Province. RMUTP Research Journal Special in the 5th Rajamangala 152 University of Technology National Conference. Pages 1-9. 153 Srilomsak, S., Pattanasiriwisawa, W., Somphon, W., Tanthanuch, W., and 154 Meethong, N. (2014). Effect of Firing ConditionS on Properties of Dan 155 Kwian 156 http://ird.sut.ac.th/e-journal/Journal/pdf/1401718.pdf. 157 158 Pottery. Suranaree J. Sci. Technol. Available from: ISO 10545-3 (1995):CeramicTiles—Part 3:Determination of waterabsorption, apparent porosity, apparentrelative density and bulk density. 7 159 160 161 162 ISO 10545-4 (2004):Ceramic Tiles—Part 4:Determination of modulus of rupture and breaking strength, second edition. ISO 13006 (1998): Ceramic Tiles — Definitions, classification, characteristics and marking. 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 8 182 Table 1. Chemical compositions of Dan Kwian clay Compounds Content (wt%) SiO2 72.95 Al2O3 18.76 K2O 1.02 CaO 0.38 MgO 1.19 TiO2 0.84 Fe2O3 4.72 Other 0.14 183 184 185 186 187 188 189 190 191 192 193 194 195 196 9 197 198 Table 2. International standard for ceramic wall tile and floor tile according to ISO 13006 Type of ceramic tiles Properties Flexural strength Water absorption Ceramic floor tile > 22 MPa 3%-6% Ceramic wall tile > 15 MPa > 10 % 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 10 217 218 Figure 1 Tri-axial diagram; Compositions in points 1 to 10 compose of Dan Kwian 219 clay and feldspar, points 11 to 19 compose of Dan Kwian clay and quartz, and all 220 other points compose of three raw materials including Dan Kwian clay, feldspar and 221 quartz. 222 223 224 225 226 227 228 229 11 230 231 232 Figure 2 raw material fusion test; cone high of feldspar and Dan Kwian clay is made 233 shorter after firing, while cone high of quartz does not change. 234 235 236 12 237 238 Figure 3 water absorption of the fired sampled; Water absorption of Dan Kwian clay 239 is reduced by adding feldspar, but is increased by quartz. 240 241 242 243 244 245 246 247 248 249 13 250 251 Figure 4 Flexural strength of the fired samples; Flexural strength of Dan Kwian clay 252 is increased by adding feldspar, but is reduced by adding quartz. 253 254 255 256 257 258 259 260 261 262 14 263 264 Figure 5 Flexural strength of the fired samples; Flexural strength of the compositions 265 that locate close to quartz area are lower than Flexural strength of the compositions 266 that locate close to feldspar area. 267 268 269 270 271 272 273 274 15 275 276 Figure 6 Water absorption of the fired samples; Water absorption of the compositions 277 that locate close to quartz area are higher than Water absorption of the compositions 278 that locate close to feldspar area. 279 280 281 282 283 284 285 286 287 288 16 289 290 Figure 7 Areas of compositions which useable for producing (a) wall tile and (b) floor 291 tile. 292 293 294 295 296 17