8101 Retaining walls 2008

advertisement

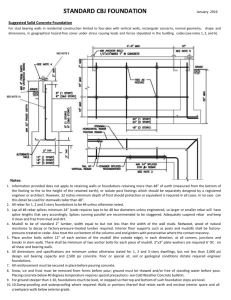

8101 RETAINING WALLS 1. GENERAL This section relates to the supply and erection of proprietary, fabricated, retaining wall systems. 1.1 DOCUMENTS Documents referred to in this section are: NZBC E1/AS1 Surface water, 3.0 Drainage system materials and construction AS 2439.1 Perforated Plastics Drainage and Effluent Pipes and Fittings AS/NZS 1254 PVC Pipes and fittings for Stormwater and Surface Water applications AS/NZS 4671 Steel reinforcing materials NZS 3104 Specification for concrete production NZS 3602 Timber and wood-based products for use in building NZS 3605 Timber piles and poles for use in buildings 1.2 MANUFACTURER’S DOCUMENTS Manufacturer’s and supplier’s documents relating to work in this section are: ~ Copies of the above literature are available from ~ Web: ~ Email: ~ Telephone: ~ Facsimile: ~ 1.3 QUALIFICATIONS Carry out retaining wall work using competent, experienced people, familiar with the materials and techniques specified. 2. PRODUCTS 2.1 CONCRETE Prescribed mix to NZS 3104, minimum 17.5 MPa. Maximum aggregate size 10 mm. Timber retaining walls 2.2 TIMBER ELEMENTS Radiata pine, to NZS 3602, table 1A, Requirements for wood-based building components to achieve a 50-year durability performance. 2.3 TIMBER POLES Radiata pine, selected in accordance with NZS 3605, treated H5 to NZS 3602 table 1A, Requirements for wood-based building components to achieve a 50-year durability performance and to NZS 3605 for cross-section, length, straightness and strength branding. Do not put cut ends into ground. Treat all cut ends or notches with a liberal brush coat of copper napthenate or equivalent wood preservative before sealing with a bituminous sealer. Precast concrete retaining walls 2.4 PRECAST CONCRETE UNITS Reinforcing steel: grade 300 to AS/NZS 4671. Cover: minimum 40 mm. Concrete strength: a minimum 28 day strength of 20MPa. 2.5 INTERLOCKING CONCRETE BLOCK WALLS Precast concrete blocks with connecting pins. Pins: 12 mm diameter. Construction adhesives as required by the precast concrete unit manufacturer. 2.6 BASE LEVELLING PADS Well graded compacted crushed stone, or concrete, to the retaining wall manufacturer's requirements. © CIL Masterspec Basic Educational 2008 8101 RETAINING WALLS Page 1 General 2.7 FIELD RELIEF DRAINS Perforated plastic piping with filter fabric over. 2.8 FIXINGS AND BOLTS Hot dipped galvanized steel. 2.9 FILTER FABRIC High density polyethylene or polypropylene mesh. 2.10 DRAINAGE MATERIAL Free draining crushed stone, 7 mm to 20 mm in size. 2.11 BACKFILLING MATERIAL To NZBC E1/AS1: 3.9.5. 3. EXECUTION 3.1 STORAGE Take delivery of retaining wall elements in protected pallets, undamaged and dry. Store on level hard standings, protect from damage and keep dry until laid. Timber retaining walls 3.2 ERECT TIMBER CRIB WALLS Excavate, form base for and erect in accordance with the crib wall manufacturer's requirements and standard details. 3.3 ERECT DRIVEN TIMBER POLE WALLS Excavate, drive poles, and erect planks; all in accordance with the pole wall manufacturer's requirements and standard details. Drive poles small end down. Install timber rails with staggered joints. All rail joints close butted at poles. Set-out tolerances From pole centre line: Misalignment: Minimum back slope: 3.4 Maximum 20 mm from centre line Maximum 25 mm at ground level and/or top 3 degrees back slope from vertical ERECT DRILLED TIMBER POLE WALLS Excavate, drill to required depth, and set in concrete in pre-drilled holes, and erect planks; all in accordance with the pole wall manufacturer's requirements and standard details. Place poles butt end down. Install timber rails with staggered joints. All rail joints close butted at poles. Set-out tolerances From pole centre line: Misalignment: Minimum back slope: Drill diameter: Min concrete encasement: Maximum 60 mm from centre line Maximum 20 mm at retaining face 3 degrees back slope from vertical Pole butt end diameter + 100 mm 25 mm over the timber pole Concrete retaining walls 3.5 ERECT CONCRETE CRIB WALLS Excavate, form base for and erect in accordance with the crib wall manufacturer's requirements and standard details. 3.6 ERECT INTERLOCKING CONCRETE BLOCK WALLS Excavate, form base for and erect in accordance with the block wall manufacturer's requirements and standard details. © CIL Masterspec Basic Educational 2008 8101 RETAINING WALLS Page 2 Accessories 3.7 SUBSOIL RELIEF DRAINS Lay perforated DN 100 PVC pipe (made from DN 100 PVC Stormwater pipe to AS/ NZS 1254 class SN 4) or DN 110 corrugated coil HDPE subsoil drainage pipe to stiffness requirements of AS 2439.1 class 200 or equivalent, firmly in a granular bed in straight runs to correct gradients, discharging into a cesspit. Carry a free draining granular bed up and over the pipes without disturbing them, to a total depth of 300 mm. Cover with filter fabric, to the pipe manufacturer's requirements. Carry the high end of all lines up to the surface in capped, solid PVC to provide for flushing out. 3.8 BACKFILLING Compact backfilling in 150 mm loose layers, using a suitable vibrating roller, until no further compaction is discernible. Top with 150 mm of clean topsoil. 3.9 TAKE AWAY Take away from the site plant and material not used. 4. SELECTIONS Timber retaining walls 4.1 TIMBER ELEMENTS Timber: ~ Treatment: ~ 4.2 TIMBER POLES Timber: ~ Treatment: ~ Minimum pole butt diameter: Pole finish: ~ 4.3 TIMBER RAILS Timber: Treatment: Size: ~ mm ~ ~ ~ mm x ~ mm Precast concrete retaining walls 4.4 PRECAST CONCRETE UNITS Brand: ~ Type: ~ 4.5 INTERLOCKING CONCRETE BLOCK WALLS Brand: ~ Type: ~ Colour: ~ General 4.6 FIELD RELIEF DRAINS Pipe brand/type: ~ Fabric brand/type: ~ 4.7 FIXINGS AND BOLTS Minimum coating thickness: 4.8 FILTER FABRIC Brand: Type: ~ ~ ~ © CIL Masterspec Basic Educational 2008 8101 RETAINING WALLS Page 3