SCALE What is it? Why does it form? Types of scales: 1) Calcium

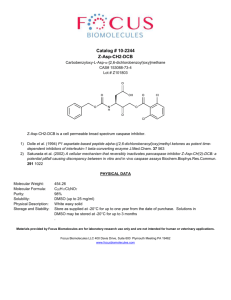

advertisement