Table 1. Properties of cured organosilicate coatings

advertisement

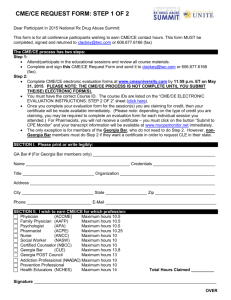

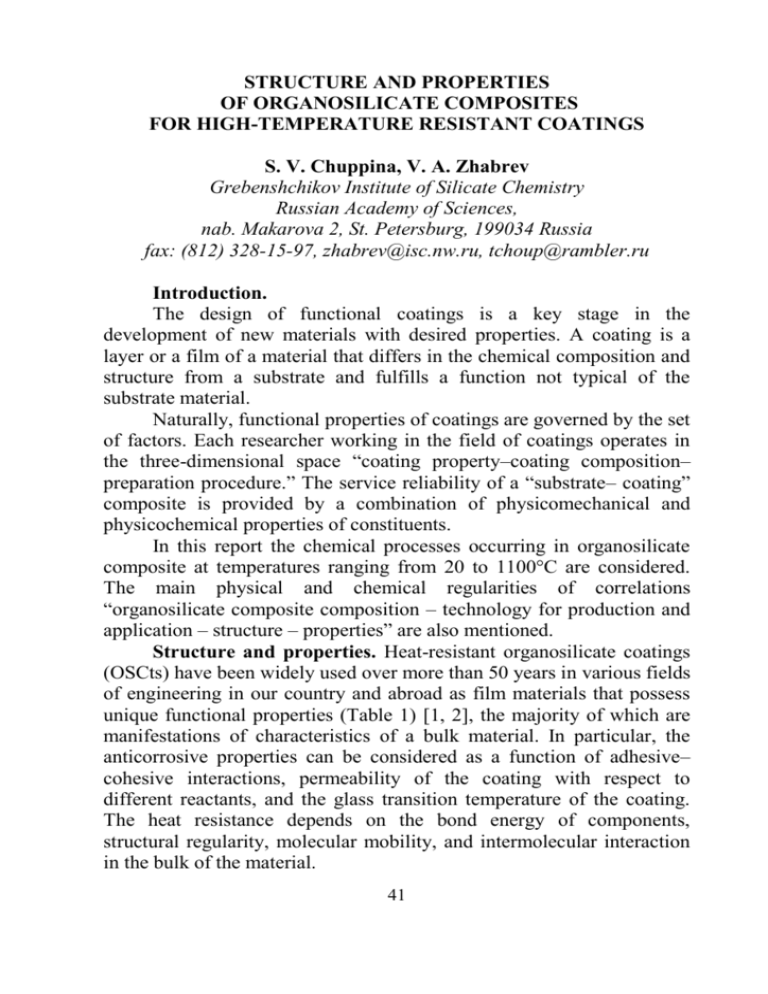

STRUCTURE AND PROPERTIES OF ORGANOSILICATE COMPOSITES FOR HIGH-TEMPERATURE RESISTANT COATINGS S. V. Chuppina, V. A. Zhabrev Grebenshchikov Institute of Silicate Chemistry Russian Academy of Sciences, nab. Makarova 2, St. Petersburg, 199034 Russia fax: (812) 328-15-97, zhabrev@isc.nw.ru, tchoup@rambler.ru Introduction. The design of functional coatings is a key stage in the development of new materials with desired properties. A coating is a layer or a film of a material that differs in the chemical composition and structure from a substrate and fulfills a function not typical of the substrate material. Naturally, functional properties of coatings are governed by the set of factors. Each researcher working in the field of coatings operates in the three-dimensional space “coating property–coating composition– preparation procedure.” The service reliability of a “substrate– coating” composite is provided by a combination of physicomechanical and physicochemical properties of constituents. In this report the chemical processes occurring in organosilicate composite at temperatures ranging from 20 to 1100°C are considered. The main physical and chemical regularities of correlations “organosilicate composite composition – technology for production and application – structure – properties” are also mentioned. Structure and properties. Heat-resistant organosilicate coatings (OSCts) have been widely used over more than 50 years in various fields of engineering in our country and abroad as film materials that possess unique functional properties (Table 1) [1, 2], the majority of which are manifestations of characteristics of a bulk material. In particular, the anticorrosive properties can be considered as a function of adhesive– cohesive interactions, permeability of the coating with respect to different reactants, and the glass transition temperature of the coating. The heat resistance depends on the bond energy of components, structural regularity, molecular mobility, and intermolecular interaction in the bulk of the material. 41 Table 1. Properties of cured organosilicate coatings Heat resistance, °C short-term long-term Impact strength according to GOST (National Standard) 4765, N cm (kgf cm) Flexural Strength according to GOST (National Standard ) 6806, mm 300–700 1200 250–500 (25– 50) 3–15 Hardness according to GOST (National Standard) 5283, arb. units. Adhesion to steel, aluminum according to GOST (National Standard ) 15140, (cross-hatch test), points 0.3–0.7 1–2 Adhesion to steel according to the 90º peel test, MPa 2–7 Volume electrical resistivity, Ώ cm: at 20 °С at 500 °С Dielectric strength at 20 °C, kV/mm Dielectric loss tangent Dielectric permittivity Temperature coefficient of linear expansion in an interval of 20–300 °C, K-1 Heat conductivity, W/ (m K) Specific heat capacity, kJ /(kg K) Radiation resistance: in beta and gamma radiations fields at doses, Gr (rad) in neutron fields (air–vapor medium) at integral dose, thermal neutrons/cm2: > 20 000 h, 280 °C > 10 000 h, 150 °C Diffuse reflectance of light from coatings: white color and light tones red, green, blue, brown, orange colors black color 42 1012–1015 up to 109 10–50 0.008–0.1 3.0–6.0 (1–2)×10-5 0.3–0.6 0.6–1.5 106–108 (108–1010) 1×1014 1×1021 85–92 60–80 50–55 However, there are a number of properties predominantly associated with the low-energy character of the surface of OSCts (such as low dirt- holding capacity, decontamination ability, hydrofobicity, etc.). At present, it has been universally accepted that the surface energy of the coating reflects not only the chemical nature of the film former but also a change in its composition and properties in the course of formation and operation [3, 4]. Organosilicate composites used in the technology of OSCts are suspensions of finely dispersed layered silicates and inorganic or organic pigments in solutions of organosilicon oligomers with different special modifiers (vitreous additives, finely dispersed metal powders, etc.). At present, film formers are represented by commercial organosilicon varnishes prepared by hydrolytic copolycondensation of mixtures of bi- and thrifunctional organochlorosilanes. Synthesized by this method oligomers have rather complex structure with random distribution of linear, branched, cyclolinear, and ladder fragments. Polyorganosiloxanes (POS) contain methyl and phenyl radicals at silicon atoms, and are characterized by a broad distribution of molecular masses, have silanol terminal groups. Both unmodified organosilicon polymers and those modified during so-called reactionary mixture of components by organic polymers, for example, by polyesters, glyptal and epoxy resins, are used extensively. Numerous properties of POS are considered to be features associated with the presence of the siloxane bond in the backbone, and with the chemical structure. OSCts are characterized by the following important feature. At temperatures below the destruction temperature of the organosilicon film former, the coating operates as a polymer material with a wide range of operating temperatures (as a rule, from –60 to +300°C). At temperatures above the destruction temperature, the OSCt operates as a hightemperature inorganic coating that is formed through the interaction of products of thermooxidative destruction of the polymer with mineral components and structural transformations in the material [2]. The structural features of macrochains of these POS are also responsible for a number of disadvantages inherent in the film formers under consideration. First and foremost, these are low physicomechanical properties, unsatisfactory resistance in liquid corrosive media and solvents, the necessity of high-temperature curing and the presence of toxic aromatic solvents (toluene, xylenes). 43 These disadvantages can be eliminated with the use of following techniques: filling and reinforcement of polymers; blending with different organic pitches containing polar groups; using various curious agents; introduction of functional groups into the organic fragments of the molecule, etc. Inorganic pigments and fillers are introduced into the composition for heat-resistant protective coatings. For OS-materials the choice of pigments is governed by the field of application and the corresponding operating properties. By present time a great positive experience of using organic pigments and dyes in composition of weatherproof OSCts has been accumulated. In formulations of chemically proof, heat-resistant, electro insulating OSCts inorganic pigments such as oxides and salts of transition metals have been predominantly used. The most widespread fillers of OSCts are the following mechanically dispersed natural fillers: chrysotile asbestos, muscovite mica, talc, barite, and synthetic filler Aerosil. Processes of formation of OSCts. In the case of low-temperature curing, different curing agents are introduced into the composition of organosilicate suspensions [2, 4]. The curing parameters affect the technological properties (the viscosity, durability, flow properties, drying time); hardness, adhesion, impact strength, flexural strength, and other physicomechanical properties; sol–gel fraction content; protective properties; heat resistance; and electrically insulating properties. As a rule, the set of these properties determines the service life and service reliability of OSCts. The energy characteristics of the surface of OSCts and the related decontamination ability, a low dirt-holding capacity, hydrophobicity, and anti-icing effect [5], i.e., the surface properties of OSCts, should be sensitive to a change in the chemical composition of the surface layer. The type of film former and a way of curing define gel fraction content of OSCts, the internal stresses, the glass transition temperature, energy characteristics of a surface, the permeability and, finally, a complex of operating properties. The curing of OSCts in the course of heat treatment, as a rule, is associated with the condensation of silanol groups of POS and the removal of H2O thus formed from the coating. An increase in the temperature accelerates these processes and makes it possible to achieve a more complete curing. The kinetics of curing and aging of organosilicate composites is affected by oxidants of the environment (for 44 example, oxygen) and the oxidizing and reducing agents introduced into the composition of organosilicate composites. Let us consider the main high-temperature interactions in heatresistant organosilicate composites and coatings based on “polydimethylphenylsiloxane (PDMPS)–muscovite–chrysotile asbestos– aluminoborosilicate glass–ZrO2–V2O5–BaO2” system at temperatures ranging from 20 to 1100°C [6]. On the processes occurring in composite in the course of heating. The differential thermal analysis (DTA) curve for composite differs radically from those characteristics of OSC (Fig. 1). In order to understand the processes occurring in composite in the course of heating, we analyze the DTA, IR spectroscopic, and X-ray diffraction data for the composite components (PDMPS, chrysotile asbestos, muscovite mica), their binary systems with the silicate–polymer ratio equal to 1 : 4, and some model systems (Table 2, Fig. 2 – 6) [6]. Fig. 1. The DTA-data for organosilicate composite of “PDMPS–muscovite– chrysotile asbestos–aluminoborosilicate glass–ZrO2–V2O5–BaO2” composition. 45 PDMPS. During the heating in air, the oxidation of PDMPS modified by the organic polyester manifests itself in a weak exothermic effect with a maximum at a temperature of 110°C (corresponding to the removal of the residual solvent, i.e., toluene) and a strong asymmetric exothermic peak with a maximum at a temperature of 630°C and a pronounced shoulder at 410°C (associated with the exothermic reactions of release of volatile products of decomposition of the PDMPS) (Table 2, Fig. 2). The sample weight decreases smoothly in the temperature range 20–400°C. The behavior of the sample weight changes sharply in the range 390–410°C, so that the maximum weight losses are observed in the temperature range 400–500°C. The aforementioned character of the release of the decomposition products is associated with the presence of the organic plasticizer in the film former and different types of bonds in the PDMPS molecule (the energy of these bonds increases in the order Si–Calk < Si–Carom < C–H < Si–O), as well as with the specific feature of the behavior of linear fragments of polyorganosiloxanes in the course of heating: the destruction (especially at the first low-temperature stage) occurs with the participation of terminal hydroxyl groups and the formation of volatile cyclic siloxanes. Fig. 2. The DTA-data for PDMPS. 46 Table 2. Thermal analysis data for the coating components Sample and total weight losses ∆m, wt % Organosilicate Composite ∆m =19.8 (20–1000°C) PDMPS ∆m=46.1 (20–1060°C) Muscovite mica ∆m=4.7 (20–1200°C) Chrysotile asbestos ∆m=16.2 (20–1340°C) PDMPS + mica ∆m=13.9 (100–1440°C) PDMPS + asbestos ∆m=24.2 (100–880°C) Temperature ranges of destruction (°C) and ∆m (wt %) 120–270 (exo), ∆m = 1.6 270–380 (without thermal effect), ∆m=2.3 380–485 (shoulder) – 535 (shoulder) – 660 (exo), ∆m = 13.7 660–880 (endo), ∆m = 1.9 880–900, 900–930, 930–970 (endo), ∆m=0.4 20–110–240 (exo), ∆m = 1.75 240–410 (shoulder) (exo), ∆m = 12.45 410–720 (exo), ∆m = 30.2 695–800 (shoulder)–820 (shoulder)–1010 (endo), ∆m = 2.95 1010–1075 (shoulder) – 1180 (endo), ∆m=0.1 575–780 (endo), ∆m = 8.0 780–850 (exo), ∆m = 1.0 20–140–430 (exo), ∆m = 1.4 430–500 (shoulder) (exo), ∆m = 1.6 500–620–690–750 (exo), ∆m = 8.1 1000–1100–1170 (endo), ∆m = 0.2 1170–1250 (shoulder) – 1330 – 1360 (shoulder) – 1400 (exo), ∆m = 0.35 20–135–275 (exo), ∆m = 0.6 275–510 (shoulder) (exo), ∆m = 5.7 510–660 (exo), ∆m = 13.5 660–725 (exo), ∆m = 2.8 760–795 (exo), ∆m = 0.55 The thermooxidative destruction of the PDMPS usually leads to the release of silicon-free volatile products, such as methane, benzene, formic acid, formaldehyde, carbon dioxide, carbon monoxide, and water, as well as trimer and tetramer methylcyclosiloxanes, i.e., hexamethylcyclotrisiloxane D3 and octamethylcyclotetrasiloxane D4; in 47 this case, the main contribution to the weight losses is made by the compounds D3 and D4. Therefore, the thermal effects in the temperature ranges 240–410 and 410–720°C can be attributed to the burnout of the polyester, release of trimers D3 and tetramers D4, oxidation of the side (methyl, phenyl) groups of the PDMPS, and formation of the oxidation products. The important feature of the thermooxidative destruction of the PDMPS is that the hydroxyl groups appear in place of organic radicals removed as a result of destruction and in place of broken siloxane bonds, for example, upon formation of cyclic products. A number of these hydroxyl groups possessing acidic properties enter into the anhydrocondensation reactions with the formation of new siloxane bonds and more complex structures (branchings, three-dimensional networks); i.e., the so-called “siloxane structuring” takes place. Other silanol groups in linear segments of the macrochain favor the breaking of siloxane bonds. To put it differently, the thermooxidative destruction and structuring reactions proceed in the PDMPS in the course of heating. The change in the PDMPS composition during the heating is in agreement with the IR spectroscopic data. At higher temperatures (720–1060°C), the weight losses (Table 2) are small and vary very slowly. The nonvolatile decomposition product is represented by silica, which, according to the X-ray diffraction data, remains amorphous to a temperature of 900°C. In the temperature range 900–1200°C, the structure of amorphous silica undergoes a transformation accompanied by the formation of the lattice of the hightemperature cristobalite phase (at 1150–1200°C), which upon cooling transforms into the low-temperature modification. By summarizing the above results, it should be noted that a high strength of the siloxane bond and the siloxane structuring (in the polymer sample, this process occurs especially intensively in the outer layers, which, as a result, do not undergo destruction and retard the access of oxygen inside the sample) are responsible for the high heat resistance of the PDMPS. The following inference is important for the further analysis: the thermooxidative destruction of the PDMPS in the range 500–650°C is attended by the formation of the reactive amorphous silica enriched in hydroxyl groups, which can contribute to the acid–base interaction and to the formation of the silicon–oxygen matrix of the coating. 48 The “PDMPS + 10 wt % ZrO2” Model System. In the temperature range 20–1000°C, the ZrO2 oxide is inert, as is evidenced by the absence of effects according to the DTA, TG, and DTG data. In this temperature range, the ZrO2 oxide acts as inert filler with respect to the PDMPS, because the curves in the derivatogram for the PDMPS–ZrO2 system and the weight loss curves (with allowance made for the introduced filler) exhibit the same behavior as for the PDMPS sample. The “PDMPS –Silicate” Model Systems. As follows from the thermal analysis data, the filling of the PDMPS with silicates results in a complication of the destruction process. In the DTA, TG, and DTG curves, this manifests itself in the form of additional shoulders, steps, and kinks. Furthermore, the temperature of the onset of destruction according to estimates from the temperature corresponding to ∆m = 4% increases, the total weight losses decrease considerably (to a larger extent as compared to the theoretical decrease in the weight losses), and the temperature ranges of destruction are shifted toward higher temperatures. A comparison of the thermal analysis data for the asbestos-containing and muscovite-containing samples (Fig. 5 and 6) indicates that the PDMPS samples filled with the muscovite have a higher heat resistance. The components of the system affect each other: the presence of PDMPS has an effect on the thermal destruction of the silicates and vice versa. The DTA curve of the PDMPS–muscovite system does not contain an endothermic effect with a maximum of 845°C characteristic of the muscovite and exhibits a weak endothermic effect at 1100°C associated with the breaking of the muscovite crystal lattice. In this case, numerous exothermic reactions proceed in the temperature ranges 430– 750 and 1170–1400°C. According to the IR spectroscopic data, the organic environment of PDMPS in the PDMPS–muscovite system is completely removed to a temperature of 600°C. This is in agreement with the results of the chemical analysis: the carbon content in the sample is less than 1 wt %. The removal of hydroxyl groups in the system under investigation begins at 600°C and is virtually completed upon heating to a temperature of 650°C, at which this process in the muscovite only starts. Recall that PDMPS or, more exactly, the product of its thermooxidative destruction contains hydroxyl groups at temperatures in the range 500–650°C and that the heating to temperatures above 650°C leads to the disappearance of the absorption 49 bands associated with the vibrations of SiO–H bonds. Therefore, compared to pure PDMPS, the process of the removal of hydroxyl groups in the presence of the muscovite begins at higher temperatures, is completed at lower temperatures, and proceeds in a narrower temperature range (from 600 to 650°C). It should be noted that, compared to the destruction of muscovite, the dehydroxylation in the PDMPS–muscovite system is completed at a temperature lower by approximately 150°C. At a temperature of 900°C, the X-ray diffraction pattern of the PDMPS–muscovite system virtually coincides with that of the muscovite. At 1000°C, there appear new phases, such as γ-Al2O3, mullite 3Al2O3 · 2SiO2, and spinel MgO · Al2O3. The content of these phases increases with an increase in the temperature. The exception is provided by the γ-Al2O3 phase, which transforms into the α-Al2O3 modification at temperatures above 1100°C. The DTA curve of the PDMPS–chrysotile asbestos system does not involve the endothermic effect at 670°C typical of the chrysotile asbestos. However, the DTA curve of this system contains no less than four exothermic effects, including the sharp exothermic effect with a maximum at 780°C. This effect has a shape characteristic of the chrysotile asbestos and manifests itself for the given systems at a lower temperature as compared to the asbestos. According to the IR spectroscopic data, the organic environment of the organosilicon film former in the PDMPS–asbestos system is completely removed to a temperature of 500°C. The removal of hydroxyl groups in the system under investigation begins at 500°C and is virtually completed to 600°C. This process in the asbestos is observed in the range 550–600°C. Therefore, the process of the removal of hydroxyl groups in the presence of the asbestos begins and is completed at lower temperatures than that in the unfilled PDMPS sample. Compared to the destruction of asbestos, the dehydroxylation in the PDMPS–asbestos system is completed at a temperature lower by approximately 180°C. As follows from the X-ray diffraction data, the first change in the phase composition of the PDMPS–asbestos system occurs at a temperature of 700°C: there appear reflections, which suggest the formation of two new crystalline phases, namely, forsterite and enstatite. However, not all reflections characteristic of these compounds clearly manifest themselves. This can indicate that, in the presence of the PDMPS or, more exactly, the products of its destruction, the above phases are formed at a lower rate. Upon annealing of the sample at 50 temperatures of 1150–1200°C, there appear reflections, which demonstrate the formation of the Mg(Fe,Cr)2O4 spinel. Fig. 3. The DTA-data for muscovite Fig. 4. The DTA-data for chrysotile asbestos 51 Fig.5. The DTA-data for PDMPS+mica Fig.6. The DTA-data for PDMPS+asbestos. 52 Therefore, the removal of hydroxyl groups from the silicate structures in the composite materials containing the chrysotile asbestos or muscovite is observed at temperatures lower than that in pure minerals. The hydroxyl groups of the amorphous product of polymer destruction accelerate the dehydroxylation of silicates, which contain a large number of defects after long-term mechanochemical treatment of components in the ball mills used for preparing the organosilicate composites. However, the given interaction leads to the formation of the polymer composites with a higher heat resistance: the filling of the PDMPS with silicates results in a substantial decrease in losses of the weight, which exceeds substantially the theoretical value. This indicates that the silicate fillers play an active role and that heat-resistant metastable structures are formed in the PDMPS filled with the silicates upon heating. The “PDMPS –Chrysotile Asbestos–Aluminoborosilicate Glass” Model Composite. The aluminoborosilicate glass retards the transformation of the asbestos into forsterite and silica by preventing the interaction of the magnesium and silicon oxides and the formation of magnesium silicate crystalline phases, thus leading to a decrease in the depth of destruction due to the decrease in the fraction of cyclosiloxanes in the volatile products of polymer decomposition [6]. This circumstance explains the high heat resistance of composites containing vitreous additives. The “Polydimethylphenylsiloxane–Aluminoborosilicate Glass– BaO2–V2O5” Model Composite. A comparison of the X-ray diffraction patterns of composite A (containing BaO2) and composite B (without BaO2) heat treated at 20, 300, and 500°C for 3 h demonstrates that heat treatment is attended by a change in the intensities of the diffraction lines attributed to the vanadium oxide V2O5 and barium peroxide for composite A and the diffraction line assigned to the V2O5 oxide for composite B. A broad smeared reflection in the range of 2 θ angles equal to 8.0°–18.0° corresponds to the amorphous aluminoborosilicate glass. The heat treatment results in a change in the intensity of the diffraction reflections of the aluminoborosilicate glass for both samples. The ratio between the reflection intensities for the samples heat treated at temperatures of 20, 300, and 500°C is equal to 1.57 : 1.32 : 1.00 for composite A and 1.38 : 1.21 : 1.00 for composite B. This suggests that the chemical interactions in composite A containing the vanadium oxide 53 and barium peroxide are more pronounced and associated with the incorporation of the barium peroxide into the aluminoborosilicate glass matrix. However, a comparison with the results obtained earlier demonstrates that these changes are less pronounced than those in composites that do not contain the aluminoborosilicate glass additive. In the X-ray diffraction patterns, the lines corresponding to the barium peroxide and vanadium oxide V2O5 disappear and the lines associated with the zirconia remain unchanged. The initial aluminoborosilicate glass is X-ray amorphous, and its X-ray diffraction pattern exhibits a broad smeared peak in the range 2 θ = 10°–40°. The thermal aging at temperatures up to 800°C leads to the formation of vanadium-containing glass-ceramic phases. Therefore, one more type of chemical interactions manifests itself during thermal aging: the silicon–oxygen network formed by the asbestos, mica, and glass is broken, and vanadium oxide is incorporated into this network. A comparison of the X-ray diffraction patterns of the sample heat treated at 180°C for 3 h and the sample heat treated at 980°C for 3 h shows that the ratio between the intensities of the reflections attributed to the aluminoborosilicate glass for the initial sample and the sample heat treated at the high temperature is equal to 1.14 : 1.00. This means that the content of the aluminoborosilicate glass in the system decreases. Moreover, high-temperature treatment leads to a decrease in the intensities of the diffraction lines associated with V2O5, BaO2, chrysotile asbestos, and muscovite and, conversely, to an increase in the relative intensity of the diffraction lines corresponding to the ZrO2 oxide. In the X-ray diffraction pattern of the composite heat treated at 980°C, there appear reflections attributed to the barium metavanadate BaV2O6. Conclusion Thus, the main types of chemical interactions during the formation of coatings and their influence on the coating structure were considered. It was established that the introduction of the low-alkali aluminoborosilicate glass and V2O5 and BaO2 oxides into the PDMPS– muscovite–chrysotile asbestos–ZrO2 system leads to an increase in the 54 heat resistance and an improvement of the physiochemical properties of the composites. 1. 2. 3. 4. 5. 6. References N.P. Kharitonov, V.A. Krotikov and V.V. Ostrovskii, Organosilikatnye kompozitsii. Katalog-spravochnik (Organosilicate Composites: A Catalog and Handbook), Leningrad: Nauka, 1980 in Russian]. S.V. Chuppina, The Current State of the Art in Materials Science of Organosilicate Composites, Fiz. Khim. Stekla, 2006, vol. 32, no. 2, pp. 339–351 [Glass Phys. Chem. (Engl. transl.), 2006, vol. 32, no. 2, pp. 243–253]. P.P. Pugachevich, E.M. Beglyarov and I.A. Lavygin, Poverkhnostnye yavleniya v polimerakh (Surface Phenomena in Polymers), Moscow: Khimiya, 1982 [in Russian]. S.V. Chuppina, V.A. Zhabrev, Changes in the Energy Characteristics of the Surface of Organosilicate Coatings in the Course of Formation, Fiz. Khim. Stekla, 2007, vol. 33, no. 6, pp. 872–883 [Glass Phys. Chem. (Engl. transl.), 2007, vol. 33, no. 6, pp. 636–645]. S.V. Chuppina, Anti-Icing Gradient Organosilicate Coatings, Fiz. Khim. Stekla, 2007, vol. 33, no. 5, pp. 691–702 [Glass Phys. Chem. (Engl. transl.), 2007, vol. 33, no. 5, pp. 502–509]. S.V. Chuppina, V.A. Zhabrev, Chemical reactions in the Course of Curing of Organosilicate Composites and Aging of Organosilicate Coatings, Fiz. Khim. Stekla, 2008, vol. 34, no. 1, pp. 82–90 [Glass Phys. Chem. (Engl. transl.), 2008, vol. 34, no. 1, pp. 79 – 87]. 55