Press release

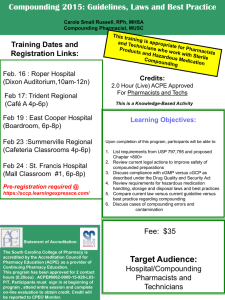

advertisement

Contact Bettina Koenig Marketing Coordinator Coperion GmbH Theodorstrasse 10 70469 Stuttgart / Germany Telefon +49 (0)711 897 2215 Telefax +49 (0)711 897 3940 bettina.koenig@coperion.com www.coperion.com Coperion Press Breakfast at NPE 2012 3D simulation of a turnkey compounding line at NPE 2012 Coperion’s modular turnkey compounding systems for maximum added value Orlando/USA, April 4, 2012 – Coperion has set itself the strategic aim of strengthening its position in the market for complete turnkey compounding plants for the plastics industry. By offering these complete solutions Coperion implements compounding plants in the shortest time possible on a fixed cost basis. The customer has only one supplier and only one contact person from start to finish, from the initial planning and design stage through to the engineering and the production of the individual units and the final commissioning of the installation. A special feature in the segment of turnkey compounding plants are the systems in modular design. Coperion’s Modular Turnkey Systems (MTS) are custom designed with standardized, pre-assembled modules that have been integrated into a steel structure that expedites delivery and installation. From raw material handling to the ZSK twin screw extruder and all downstream equipment, plant design is optimized to meet customer’s requirements. Before delivery, the modules are assembled at Coperion and pre-tested prior to delivery, which can be witnessed by the customer. Coperion’s modular plants are available in a wide range of capacities ranging from ZSK 26 laboratory extruder to complete system for a ZSK with 133 mm. So far, more than 70 modular turnkey systems have been installed in China, Europe, North America, South America and the Middle East with some processes involving very complex setups. For instance a line for filled polyolefins with 17 feeders for raw materials and additives and April 2012 a capacity of approximately 5 metric tons per hours was implemented on green field site in only 15 months from order to start of production. From engineering and assembly, to the commissioning of the compounding plants, Coperion integrates all of a system’s components with one another on a fixed cost basis. The entire time schedule is specified at the start of the project right through to delivery, installation and commissioning. Silos, conveying and metering equipment for the raw material, the core ZSK twin screw extruder, all downstream peripheral equipment including finished product handling and bagging, and the fully integrated control system for the entire process are all coordinated through a single source, saving compounders considerable effort in planning and procurement. The custom tailored, fully tested system modules can be quickly installed and are ready for operation in shortest time after utility hook up. Coperion’s worldwide service network supports on-site installation and commissioning and offers the training of operating personnel before delivery and comprehensive after-sale service, making an MTS plant an ideal solution for setting up production facilities in emerging market countries. The steel structure of the modular systems eliminates the need for rigorous building requirements, allowing the plant to be housed in a simple shell, warehouse type building. Due to the modular concept the entire plant can easily be relocated if the market situation changes. With the modular concept plant duplication in multiple locations becomes very easy and convenient. Visitors to Coperion’s booth # 6463 in West Hall at NPE 2012 (Orlando, April 2 to 5, 2012) will experience an extraordinary insight into the design and construction of a complete turnkey plant: a compounding line, which in reality would be a good 150 metres long, is presented in a 3D simulation using virtual reality technology. All essential stages in the process are shown in detail, from the raw material feed and pneumatic conveying systems to the actual compounding process and immediate downstream logistics. The 3D viewer allows each individual process stage to be experienced and permits the view at the compounding line in real dimensions. Seite 2 von 5 April 2012 Coperion (www.coperion.com) is the international market and technology leader in compounding systems, bulk materials handling systems and services. Coperion designs, develops, manufactures and maintains systems, machines and components for the plastics, chemicals, food and aluminium industries. With its three Competence Centers Compounding & Extrusion, Materials Handling and Service, 1,700 employees and nearly 30 sales and service companies worldwide, Coperion achieves annual sales of 400 to 600 million euros. Dear Colleagues, an MS-WORD file of this press release in English and German and a printable-grade copy of the enclosed image are available for download at http://www.coperion.com/en/news/newsroom/ Editorial contact and voucher copies: Dr. Diether Burkhardt, KONSENS Public Relations GmbH & Co. KG, Hans-Kudlich-Straße 25, D-64823 Groß-Umstadt Phone: +49 (0)60 78/93 63-0, Fax: +49 (0)60 78/93 63-20 E-Mail: mail@konsens.de, Internet: www.konsens.de Seite 3 von 5 April 2012 Turnkey modular compounding plant during testing at Coperion, Stuttgart Photo: Coperion, Stuttgart/Germany Seite 4 von 5 April 2012 3D simulation of a Coperion compounding plant. The 3D simulation is on display at Coperion's NPE 2012 booth. Photo: Coperion, Stuttgart/Germany Seite 5 von 5