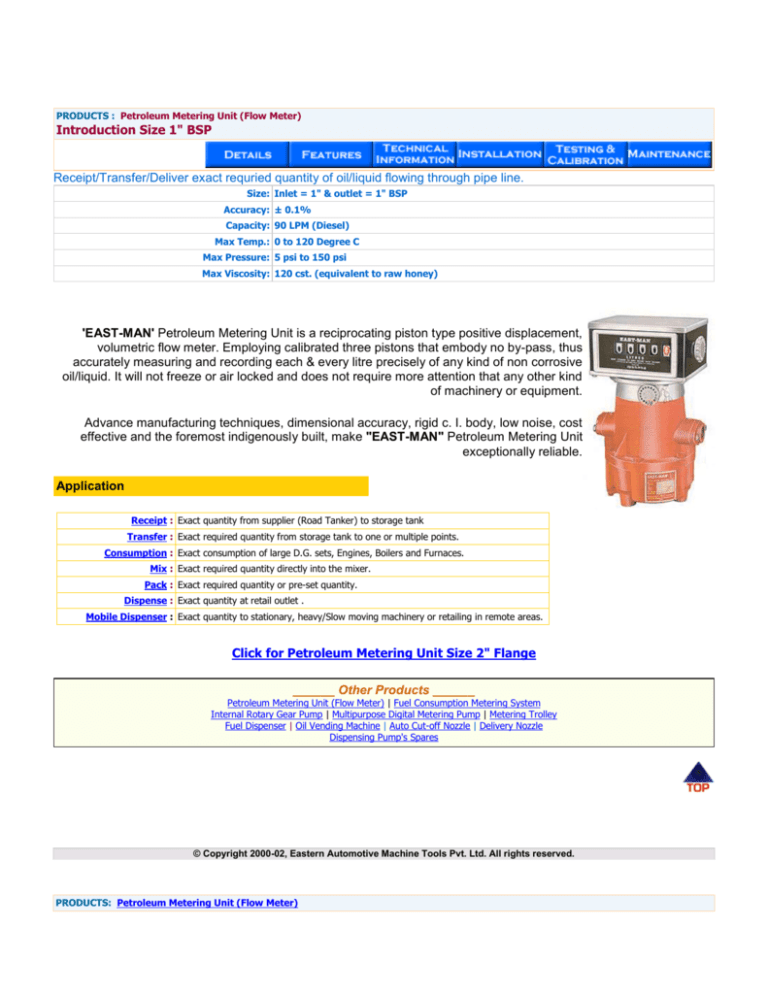

PRODUCTS : Petroleum Metering Unit (Flow Meter)

Introduction Size 1" BSP

Receipt/Transfer/Deliver exact requried quantity of oil/liquid flowing through pipe line.

Size: Inlet = 1" & outlet = 1" BSP

Accuracy: ± 0.1%

Capacity: 90 LPM (Diesel)

Max Temp.: 0 to 120 Degree C

Max Pressure: 5 psi to 150 psi

Max Viscosity: 120 cst. (equivalent to raw honey)

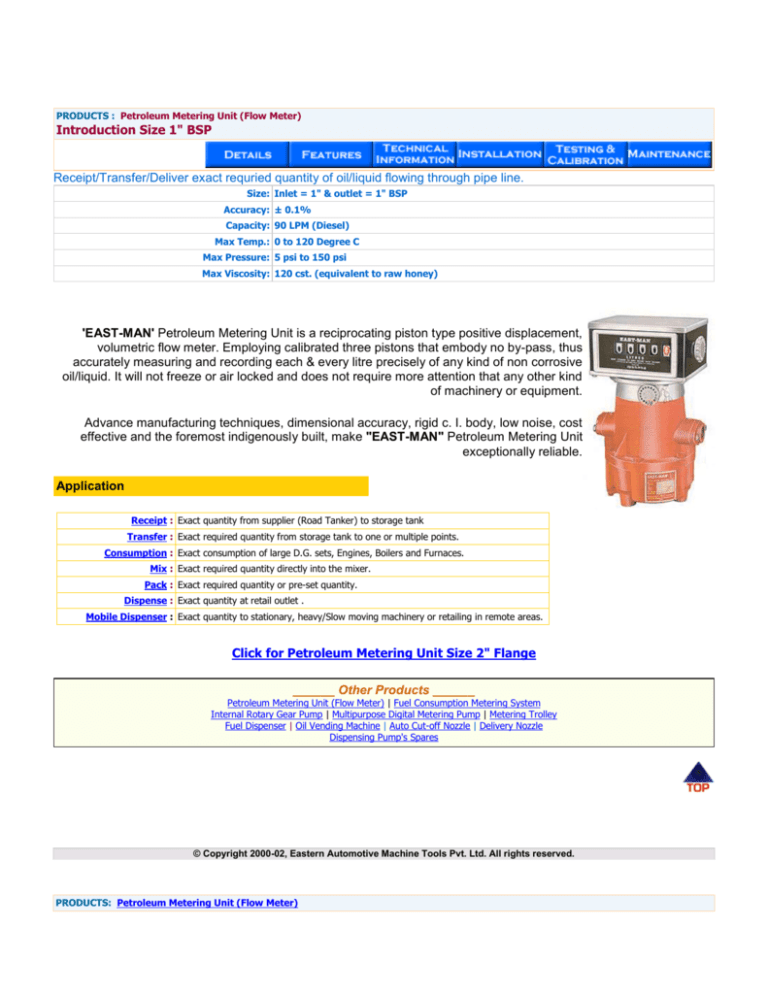

'EAST-MAN' Petroleum Metering Unit is a reciprocating piston type positive displacement,

volumetric flow meter. Employing calibrated three pistons that embody no by-pass, thus

accurately measuring and recording each & every litre precisely of any kind of non corrosive

oil/liquid. It will not freeze or air locked and does not require more attention that any other kind

of machinery or equipment.

Advance manufacturing techniques, dimensional accuracy, rigid c. I. body, low noise, cost

effective and the foremost indigenously built, make "EAST-MAN" Petroleum Metering Unit

exceptionally reliable.

Application

Receipt : Exact quantity from supplier (Road Tanker) to storage tank

Transfer : Exact required quantity from storage tank to one or multiple points.

Consumption : Exact consumption of large D.G. sets, Engines, Boilers and Furnaces.

Mix : Exact required quantity directly into the mixer.

Pack : Exact required quantity or pre-set quantity.

Dispense : Exact quantity at retail outlet .

Mobile Dispenser : Exact quantity to stationary, heavy/Slow moving machinery or retailing in remote areas.

Click for Petroleum Metering Unit Size 2" Flange

______ Other Products ______

Petroleum Metering Unit (Flow Meter) | Fuel Consumption Metering System

Internal Rotary Gear Pump | Multipurpose Digital Metering Pump | Metering Trolley

Fuel Dispenser | Oil Vending Machine | Auto Cut-off Nozzle | Delivery Nozzle

Dispensing Pump's Spares

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.

PRODUCTS: Petroleum Metering Unit (Flow Meter)

Details

MECHANICAL COUNTER

Number of figures

Delivery display: 5 digits (0000.0), Totlizer: 7 digits (000000.0)

Size of figures

Delivery display: 21mm high x 14mm wide, Totlizer display digit: 4mm

high x 2.5 mm wide.

Colour of figures

Delivery display: White on black on four left hand figure, red on white on

right hand figure (designated tenths) Totlizer display: Black on white and

red on white on right hand figure (designated tenths).

Character configuration

0 to 9, tenths indicated by dash in the center of right side of right hand

display figures.

Reset

Knob (Push & turn clockwise to reset zero)

Style of figures

Veeder-Root/Cornell for optimum readability of all primary displays.

Rated Life

50,000 reset cycles or 25,000,000 revolution of right wheel whichever

comes first under normal operating conditions

ELECTRONIC DISPLAY COUNTER

Count Display

Display :Six Figures (0000.00), Totalizer: seven figures (0000000)

Size of Figures

Display: 1" LED, Totlizer (Mechanical) size 4mm high x 2.5 mm wide.

Colour of LED

Green

Character Configuration

Starting figure indicates in the fraction of 10 ml.

Operations

Pulse Count, Thumb Wheel Preset delivery (optional)

Supply Voltage

230 VAC 50/60 Hz.

Power Consumption

12V 600 mA

Accuracy

Count Values ± 1 Count

Memory Back Up

9V battery cell ( the count will not missed in the absence of power).

Operating Temperature

0° To 60° C

Inputs

From transducer fitted in a flameproof enclosure on the meter

Counter

Generally in modules, fitted in control Panel as per specification.

Panel Body

ABS and Sheet Metal

METERING UNIT

Type & duty

Reciprocating piston type volumetric, positive displacement run by

pressure and gravity, made of graded cast iron, bronze, S.S. and mild

steel parts formaximum protection against today's various mixtures.

Capacity

Max. 90 litres per minute.

Max. working pressure

50 psi

Accuracy

Max. permissible error with in the rating capacity of ± 0.1 % of the

measured quantity.

Repeatability

100%

Adjusting Device

In the continuous manner i.e. step less with range of calibration less

than ± 1%

Seals

Viton or Neoprene

Temperature

0 degree to 80 degree C.

Max. Viscosity

120 Centistokes or equivalent to raw honey

MECHANISM

We adapted the world wide proven technology as in the petrol pump machines. The

unit has three Teflon pistons connected by yokes with a wobble plate. Inlet and

discharge of liquid are calibrated by a triangular valve and a seat, operating above

the pistons. The operation of this meter is simple, liquid came through the entrance

port, goes down through the sides of valve along the valve intake, then into the end

of a cylinder. When it does this, it forces the piston upward. A similar movement of

liquid to the end of the next piston moves the liquid out through the discharge port.

To put it simply, an 'EAST-MAN' petroleum metering unit is merely a liquid engine

with three Teflon pistons operating with in three cylinders, just like an automobile

engine. The movement of the three pistons measures liquid just if you were

continually filling up three measuring cans with liquid and pouring them off.

Click for Petroleum Metering Unit Size 2" Flange

______ Other Products ______

Petroleum Metering Unit (Flow Meter) | Fuel Consumption Metering System

Internal Rotary Gear Pump | Multipurpose Digital Metering Pump | Metering Trolley

Fuel Dispenser | Oil Vending Machine | Auto Cut-off Nozzle | Delivery Nozzle

Dispensing Pump's Spares

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.

PRODUCTS : Petroleum Metering Unit (Flow Meter)

Technical Information

“EAST-MAN” Petroleum Metering Unit (Liquid Flow Meter) are positive displacement,

reciprocating piston type Meters, designed for high sustained accuracy and continues volumetric

measurement of any non corrosive liquid flowing through a pipe line. Especially suited to check

the Exact Receipt, Transfer, Consumption, Dispensing, Mixing, Packaging of Oils/Liquids. This

unit is also widely adaptable to other various type of services. It will not freeze or get air locked

and does not require more attention than any ordinary type of Meter or equipment.

Advance manufacturing techniques, dimensional accuracy, rigid C. I. Body, low noise. Cost

effective and foremost indigenously built, make “EAST-MAN” Petroleum Metering Unit

exceptionally reliable.

Digital Display, Digital Display with pre-set Quantity/Amount, Three Digital Display i. e. Quantity,

Amount and Price are also available on request.

Specifications

Accuracy

± 0.1 %

Max. Showing capacity

10,000 litres

Repeatability

100 %

Max. Recording capacity

1,00,000,00 litres

Size

1" x 1" BSP

Max. Working pressure

5 psi to 50 psi

Delivery

90 lpm

Max. Viscosity

120 centistokes(Raw Honey)

Operating temp.

0 Degree C to 120 Degree C

Weight

33 kg. Appx.

Adjusting Device

In the continuos manner i. e. stepless with range of calibration less than ± 1%.

MATERIALS OF CONSTRUCTION

BODY

C. I.

SLEEVES

Stainless steel

PISTONS

Teflon

SEAT

Gun metal

VALVE

C. I.

SEAL

Nitrile/Neoprene

Remaining Parts

M. S., Brass, Alum.

All Meter Part contacted with

liquid in S. S. 304/316

On request

Performance curve shows pressure drop though the

meter, required to operate at various capacities

Click for Petroleum Metering Unit Size 2" Flange

______ Other Products ______

Petroleum Metering Unit (Flow Meter) | Fuel Consumption Metering System

Internal Rotary Gear Pump | Multipurpose Digital Metering Pump | Metering Trolley

Fuel Dispenser | Oil Vending Machine | Auto Cut-off Nozzle | Delivery Nozzle

Dispensing Pump's Spares

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.

PRODUCTS : Petroleum Metering Unit (Flow Meter)

Installation

Close

INSTALLATION OF PETROLIUM METERING UNIT

INSTALLATION AND MOUNTING

Meter should have an adequate support and be fastened securely, avoiding strains from piping.

Counter should be conveniently located for operator to read. lt can be faced in four directions.

When used with pump, meter must be on discharge side of the pump.

Use ample size pipe and reduce the number of tees, elbows etc. To a minimum, especially on

gravity operation.

Do not run meter backward. Inlet and outlet or direction arrow are plainly marked on meter body.

Apply pressure compound to male threads only.

PRESSURE AND RATE FLOW

Pressure must never exceed maximum stamped on name plate.

Use soft closing valves to avoid excessive shock pressure.

Do not subject meter to high expansion pressure resulting from temperature rise.

Flow (in litres per minute) must be with in the rated capacity of the meter stamped on name

plate.

AIR AND VAPOR

Where there is any possibility of air or vapor being siphoned or pump through the meter, an Air

Separator is required. We recommend Combination Air Separator, Strainer, NRV assy. click

here to see with pressure gauge (all provided in one product, see picture) to prevent air or vapor

and intrusion of dirt, grit, pipe scale and other foreign matter carried through pipe line. Air or

vapor is discharging from the air separator head. In case of inflammable oil/liquids or bleeding

liquid from the head if any, a vent pipe should be connected from air separator head to storage

or to an empty oil drum. After installation or repair necessary draining, slowly fill the meter with

oil/liquid. Do not allow the meter to run on high speed on air or vapor.

SKETCHES

Receipt : Exact quantity from supplier (Road Tanker) to storage tank

Transfer : Exact required quantity from storage tank to one or multiple points.

Consumption : Exact consumption of large D.G. sets, Engines, Boilers and Furnaces.

Mix : Exact required quantity directly into the mixer.

Pack : Exact required quantity or pre-set quantity.

Dispense : Exact quantity at retail outlet .

Mobile Dispenser : Exact quantity to stationary, heavy/Slow moving machinery.

Click for Petroleum Metering Unit Size 2" Flange

______ Other Products ______

Petroleum Metering Unit (Flow Meter) | Fuel Consumption Metering System

Internal Rotary Gear Pump | Multipurpose Digital Metering Pump | Metering Trolley

Fuel Dispenser | Oil Vending Machine | Auto Cut-off Nozzle | Delivery Nozzle

Dispensing Pump's Spares

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.

PRODUCTS : Petroleum Metering Unit (Flow Meter)

TESTING & CALIBRATION

The meter and accessories are carefully inspected and tested before leaving the factory. Meters

are tested and adjusted for accuracy but sealed temporarily. After meter have been installed, it

should again be tested. if calibration is necessary, it is accomplished by removing locking pin

and turning calibrating knob (see picture). If the amount in the test-measured sealed by Weight &

Measured Dept. is less than the counter reads, the adjusting wheel should be turned clock-wise

(viewed from face of knob). If the amount in test- measure is more than counter shows, turn knob

in counter-clockwise direction. After adjusting to give desired calibration, insured the locking pin

in the hole selected. A seal wire should then be slipped through the hole in the pin, through the

hole in bolt head of the counter and wrapped around the rim of the wheel, than the both end of

sealed wire sealed with lead sel.

Always calibrate with the same liquid, meter is to measure.

To obtain the maximum efficiency and accuracy, meter should be tested at regular intervals and

readjusted as necessary.

Click for Petroleum Metering Unit Size 2" Flange

______ Other Products ______

Petroleum Metering Unit (Flow Meter) | Fuel Consumption Metering System

Internal Rotary Gear Pump | Multipurpose Digital Metering Pump | Metering Trolley

Fuel Dispenser | Oil Vending Machine | Auto Cut-off Nozzle | Delivery Nozzle

Dispensing Pump's Spares

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.

Close

PRODUCTS : Petroleum Metering Unit (Flow Meter)

MAINTENANCE

The EAST-MAN Petroleum Metering Unit is a precision unit. If properly installed and maintained,

this unit can give years of trouble free service. However to get the most from unit, a few simple

maintenance routine should be followed.

To ensure highest accuracy and maximum service, only the liquid measured should pass

through the Petroleum Metering Unit.

Install a strainer on inlet side of Unit as close to the Unit as possible. Set procedure for keeping

the strainer basket clean.

Where there is any possibility of air or vapor being siphoned or pump through the meter, an Air

Separator is required. We recommend Combination Air Separator, Strainer, NRV assy. with

pressure gauge (all provided in one product, click here to see installation) to prevent air or

vapor and intrusion of dirt, grit, pipe scale other foreign matter carried through pipe line.

Protect meter against transmission of water. Draw water off storage tank regularly. Never flush

the lines with water after the Petroleum Metering Unit have been installed. If tanks are send

blasted or steam cleaned, remove Unit when flushing tanks and lines. Petroleum Metering Unit is

a measuring instrument and should be kept in best working condition at all times.

It should also be understood that:Unit is only one part of the system and the only one under the control of the user. If the

installation is not carried out accordingly to the standard practice reproduce in this manual, the

unit may not give satisfactory performance. The components going into the manufacture of this

unit are of high quality with close tolerances and selected materials, trouble free service can

therefore be ensured only if original spare parts are used in case replacement become

necessary at any stage. The company shall not responsible for any damage due to negligence

or mishandling.

Click for Petroleum Metering Unit Size 2" Flange

______ Other Products ______

Petroleum Metering Unit (Flow Meter) | Fuel Consumption Metering System

Internal Rotary Gear Pump | Multipurpose Digital Metering Pump | Metering Trolley

Fuel Dispenser | Oil Vending Machine | Auto Cut-off Nozzle | Delivery Nozzle

Dispensing Pump's Spares

© Copyright 2000-02, Eastern Automotive Machine Tools Pvt. Ltd. All rights reserved.