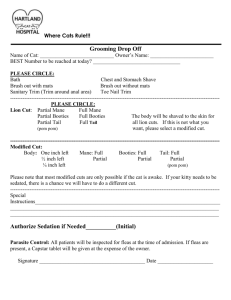

Preparation of [Al3W10O38]7-

advertisement

![Preparation of [Al3W10O38]7-](http://s3.studylib.net/store/data/007481037_1-608f0da8c83a6fe8dcc1536ea4cf044c-768x994.png)

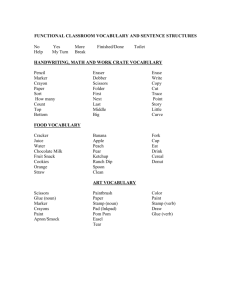

Supplementary Information for“Equilibrating metal-oxide cluster ensembles for oxidation reactions using oxygen in water” Nature 414, 191 Contents: 1. Preparation and characterization of M7[Al3W10O38] (M = Li+, Na+, K+). 2. Synthesis and composition of equilibrated cluster ensembles optimized for delignification of wood-pulp samples. 3. Papermaking properties of POM delignified commercial pulp samples. 4. Pulp washing: Analysis of POM delignified fiber samples. 5. Determination of CO2 evolved during oxidative mineralization of solubilized lignin and polysaccharide fragments. 6. Measurements, control experiments and methods used in mass-balance calculation of theoretical CO2 values. 1. M7[Al3W10O38] (M = Li+, Na+, K+). Step 1. Preparation of K6[Al2W11O39]. K9[AlW11O39]13H2O (Weinstock, I. A., Cowan, J. J., Barbuzzi, E. M. G., Zeng, H. & Hill, C. L. J. Am. Chem. Soc. 121, 4608-4617 (1999)), (50.18 g, 15.48 mmol) was slurried in 150 mL of water. The solution was then stirred and heated to 60 C using an oil bath. A solution of AlCl36H2O (15.48 mmol in 10 mL of water) was then added over 4 h, during which time the suspended material dissolved. The solution was then stirred for an additional 30 min. and stored at 0 C overnight to give a colorless crystalline solid. The solid was collected by filtration and washed several times with cold water. Yield 18.06 g (36%; mixture of positional isomers). Anal. Calcd (found) for K6[Al2W11O39]16H2O: H, 1.0 (0.87); W 62.75 (62.75); Al 1.67 (1.58); K 7.23 (7.28). 27Al NMR (D2O, ppm): 74.0 (1/2 = 85.6 Hz), 8.5 (1/2 = 289 Hz). IR (KBr, cm-1): 947, 877, 800, 764, 742, 686, 530, 495, 472. Step 2. Preparation of M7[Al3W10O38]. K6[Al2W11O39]16H2O (13.60g, 4.29 mmol) was dissolved in 20 mL of 2 water in a 100-mL round bottom flask and heated with stirring to 85 C using an oil bath. KOH (36.5 mmol in 2 mL of water) was added dropwise; the pH was kept below 10.5. The solution was cooled to room temperature, after which a white precipitate was collected by filtration and washed with cold water. Yield 5.64 g (86.6% based on the 2:1 stoichiometric hydrolysis and rearrangement of [Al2W11O39]6- to positional isomers of [Al3W10O38]7-). Anal. Calcd (found) for K7[Al3W10O38]14H2O: H, 0.92 (1.06); W 60.21 (60.28); Al 2.65 (3.10); K 8.96 (9.02). 27Al NMR (D2O, ppm): 74.9 (tetrahedrally coordinated central Al atom, relative intensity 1), 13.7 (octahedrally coordinated addendum Al atoms, relative intensity 2). IR (KBr, cm-1): 939, 790, 756, 740, 698, 530, 499. K7[Al3W10O38]14H2O (10 g, 3.27 mmol) was dissolved in 25mL of water and passed through a Na+ charged cation-exchange column (ca. 100 mL column of amberlite IR-120 (plus); 1.9 meq/mL). The resultant solution of the more soluble Na 7[Al3W10O38] was evaporated to dryness: 27Al NMR (D2O, ppm): 75.1 (1/2 = 176.6 Hz, relative intensity 1), 13.8 (1/2 = 1787 Hz, relative intensity 2). High resolution 183W NMR spectra were obtained using concentrated solutions of the highly soluble Li + salt, prepared by addition of LiClO4 to a slurry of Na7[Al3W10O38] in D2O and filtration of NaClO4. 183W NMR Li7[Al3W10O38] (D2O, ppm): -88.7, -117.9, -138.3, -139.9, -174.3, - 179.6, -227.2, -232.7 ppm. 2. Synthesis and composition of equilibrated cluster ensembles optimized for delignification of wood-pulp samples. Optimized systems include equilibrated ensembles of Si(IV), 0.9 V(IV), 1.0 Mo(VI) and 10.1 W(VI) in the indicated molar ratios (1.0:0.9:1.0:10.1) and in which the dominant specie(s) are Keggin anion(s) of the formula [SiVMoW10O40]5- and/or [SiVW11O40]5-. Further modification of this system involves partial replacement of some 3 of the W by 0.05 to 0.10 molar equivalents of Mn(III). Inclusion of Mn dramatically increases the rate of reoxidation of the reduced solution by O2. One of these (Si, V, Mo, W in molar ratios 1.0:0.9:1.0:10.1) has been scaled up (20 L reactions) to provide kilogram quantities of delignified industrial fiber samples. Detailed description of the species present in these optimized and complex systems (each contain structural and positional isomers of the dominant specie and are additionally complicated by the presence of Mn in several paramagnetic valence states) and of the reactions that occur during delignification and POM reoxidation/lignin mineralization, although extraordinarily difficult, is in progress. Preparation of 15 L of a 0.5 M (i.e., 0.5 M Si(IV)) equilibrated solutions in which the dominant specie(s) are Keggin anion(s) of the formula [SiVMoW10O40]5and/or [SiVW11O40]5- designated (based on molar ratios of cations present) as “Na6.9SiV0.9Mo1.0W10.1”. The following are weighed and mixed as solids: 1.0 eq. (993.1 g) Na2SiO3 (anhydrous, 92.2%), 4.9 eq. (1,500.0 g) NaOH (98%), 0.45 eq. (618.8 g) V2O5 (99.2%), 1.0 eq. (1,090.5 g) MoO3 (99%) and 10.1 eq. (17,583.7 g) WO3 (99.88%). Use of an experimentally determined “density factor” of 0.422 indicates that a 0.5 M solution has a density of 2.185 g/ml a total weight of 32,773 g. To achieve this, 10,980 g of water need to be added to the precursors mixture. About 90% of the water is placed in the reactor vessel. The mixed dry solids are poured into the reactor vessel with periodic mixing and adequate ventilation. The heats of solution of the NaOH and Na2SiO3 as well as the initial reaction are exothermic and can result in a boil-over if the solids are added too rapidly. The reactor vessel is sealed and heated to 200 ºC for 3 hours under 100 psi 4 (cold) of O2 with continuous rapid stirring (about 500 rpm). The reactor is then cooled. If necessary, any residual solids are allowed to settle overnight; the solution is then decanted and filtered. Prior to use in delignification, the solution is treated with ozone in a glass vessel and concentrated to about 0.6 M (density 2.422). When combined with pulp for use in delignification, water in the pulp fibers contributes to give a final concentration of 0.5 M. Preparation of 250 ml of a 0.5 M (i.e., 0.5 M Si(IV)) optimized equilibrated POM solution designated (based on the molar ratios of cations present) as “Na6.5SiV0.9Mn0.1W10Mo”. Combination of the oxides of the d- and p-group cations indicated in Table S1 below with 6.5 equivalents of NaOH gives a self buffering POM solution with an appropriate pH value (5-6). The molar quantities indicated in the Table S1 below were added to 188 ml H2O in a 600 ml reactor equipped with standard stirring. Oxygen (200 - 250 psi) was added and the mixture stirred (1000 rpm) while heated to 200 ºC for 5 hours, then cooled, vented, opened and the solution filtered. This gives solutions with densities of about 2.2 g/ml and pH values in the range of 5-6. Table S1. Starting materials for synthesis of optimized POM solution. WO3 MoO3 Na2SiO3 V2O5 NaOH MnO2* moles 1.250 0.1250 0.1250 0.005625 0.5625 0.01250 equivalents 10.00 1.000 1.000 0.4500 4.500 0.1000 * The manganese dioxide used was activated grade; during synthesis, Mn(IV) is reduced (most probably by water) to Mn(III). 5 3. Papermaking properties of POM delignified commercial pulp samples. The data presented below are early results. It is likely that better properties will be achieved when the procedures are fully optimized. Comparison of POM delignified pulp with commercial pulp delignified using a totally chlorine-free (TCF) manufacturing process. Softwood furnish, pulped using the kraft (alkaline sulfide) process Starting pulp for lab study: Post 1st O2 stage Bleaching Sequence: Mill: OOZPQP (O-oxygen, Z-ozone, P-alkaline hydrogen peroxide, Q-chelation) Lab: (POM)P POM solution used: equilibrated ensemble of 1.0 Si(IV), 0.9 V(IV), 1.0 Mo(VI) and 10.1 W(VI) in the indicated molar ratios (1.0:0.9:1.0:10.1) and 0.5 M in Si(IV) and in which the dominant specie(s) are Keggin anion(s) of the formula [SiVMoW10O40]5- and/or [SiVW11O40]5- (see item 2. above). POM bleaching conditions: 20-liter reaction vessel 3% pulp consistency 135° C for 1.5 hours Initial pH 5.5, final pH 5.8 H2O2: 2% on pulp, 90° C for 5 hours, pH 12.3 Pulp Properties POM delignification followed by alkaline hydrogen peroxide brightening was found to be approximately 50% more selective than OOZPQP as shown in the Table S2. Higher selectivity is beneficial because it indicates that the POMs oxidatively depolymerize and solubilize residual kraft lignin with less degradative (oxidative) damage to cellulose. Higher selectivity results in higher yield and a stronger pulp. Table S2. Pulp properties 6 Kappa(1) Viscosity(2) Selectivity (k/v) Post 1st O2 Stage 13.1 28.2 --- OOZPQP 4.2 16.1 0.74 (POM)P ~0 17.0 1.17 (1) Kappa 1.5, (2) Viscosity 1.0 Paper Properties - Handsheet Test Results Freeness The (POM)P pulp required slightly more refining than the commercially bleached pulp to develop equivalent Canadian Standard Freeness (CSF). PFI Revolutions (300 CSF) POM Mill 8400 7700 Tear Index At 317 CSF, the (POM)P pulp had a tear index of 11.9 mN-m2/g (standard deviation, SD = 2.1) while the tear index of the TCF mill bleached pulp was 13.5 mN-m2/g (SD = 1.3). This difference was not significant. Tensile Strength Breaking length and tensile index were slightly lower for the (POM)P pulp when compared at 317 CSF. The difference was not significant at the 95% confidence interval. Tensile Index (kN-m/g) (POM)P Mill – TCF 0.0847 (SD = 0.0045) 0.0887 (0.0046) Breaking Length (km) 8.6 (0.4) 9.0 (0.5) Burst Index When compared at 317 CSF, the (POM)P pulp was found to be slightly weaker in burst than the mill pulp [7.7 kPa-m2/g (SD = 0.3) vs. 7.9 kPa-m2/g (SD = 0.3), respectively]. This difference was not significant. MIT Fold 7 The (POM)P pulp had slightly higher folding endurance than the TCF pulp at 317 CSF [2396 folds (SD = 395) vs. 2282 (SD = 297), respectively]. This difference was not significant. Relative to a commercial TCF pulp (OOZPQP): 1. POM delignification followed by alkaline hydrogen peroxide brightening was more selective. 2. (POM)P pulp required slightly more refining to achieve a given freeness. 3. At equal freeness, (POM)P pulp had slightly lower tear, tensile, burst and higher fold. These were not significant differences (95% CI). 4. A POM delignification stage has the potential to replace the OZP stages. In this study the (POM)P pulp brightness was significantly higher than the commercial pulp (81.4 vs. 72.0, respectively). It is expected that the mechanical strength properties of the (POM)P pulp would be superior to those of the TCF pulp if the comparison was done at equal brightness. This work is in progress. Comparison of POM delignified pulp with commercial pulp delignified using a elemental chlorine-free (ECF) manufacturing process. Softwood furnish, pulped using the kraft (alkaline sulfide) process Starting pulp for lab study: Brownstock Bleaching Sequence: Mill: ODEop (O-oxygen, D-chlorine dioxide, Eop- alkaline extraction with oxygen and hydrogen peroxide) Lab: (POM)P POM solution used: equilibrated ensemble of 1.0 Si(IV), 0.9 V(IV), 1.0 Mo(VI) and 10.1 W(VI) in the indicated molar ratios (1.0:0.9:1.0:10.1) and 0.5 M in Si(IV) and in which the dominant specie(s) are Keggin anion(s) of the formula [SiVMoW10O40]5- and/or [SiVW11O40]5- (see item 2. above). POM bleaching conditions: 20-liter reaction vessel 3% pulp consistency 140° C for 1.25 hours Initial pH 5.5, final pH 6.1 8 Pulp Properties POM delignification was found to be more selective than ODE as shown in the Table S3. Data show pulps delignified to closely similar lignin-content (kappa number) values. Table S3. Pulp properties Kappa(1) Viscosity(2) Selectivity (k/v) Brownstock 32.3 24.2 --- ODEop 3.5 15.8 3.4 POM 4.4 18.1 4.6 (1) Kappa 1.5, (2) Viscosity 1.0 Paper Properties - Handsheet Test Results Freeness The initial freeness of the POM bleached pulp was higher (720 vs. 695). This pulp required more refining than the commercially bleached pulp to develop equivalent freeness. PFI Revolutions (500 CSF) POM Mill 5000 4000 Tear Index The unrefined POM bleached pulp had lower tear strength than the commercial pulp. Upon refining the tear strength of the POM pulp increased and exceeded that of the mill bleached pulp. Tear Index [4-ply, lbs-f/basis weight (45 lbs/ream)] @5000 PFI Rev. @500 CSF @Equal Tensile (8.5 km) POM Mill 1.51 1.26 1.50 1.20 1.5 1.4 9 Tear at 85 mullen was approximately 5% higher for the POM bleached pulp. Tensile Strength Tensile strength as measured by breaking length was slightly lower for the POM bleached pulp when compared at equal refining or equal freeness. Breaking Length (km) @5000 PFI Rev. @500 CSF POM Mill 8.2 8.9 8.0 8.4 Burst When compared at equal refining or equal freeness, the POM bleached pulp was slightly weaker in burst than the mill pulp. Burst (psi) @5000 PFI Rev. @500 CSF POM Mill 150 165 140 145 Relative to a mill ECF pulp (ODEop): 1. POM delignification was more selective. 2. POM pulp required slightly more refining to achieve a given freeness. 3. At equal freeness or at equal refining, POM pulp had higher tear, lower tensile and lower burst. 4. POM pulp had slightly higher tear @ 85 mullen. Caustic extraction after POM delignification has been found to have a beneficial effect on pulp and paper properties. Following extraction, brightness increased 15% and strength properties improved (5% increases were seen in tensile, breaking length, and burst. Tear was not affected). In the follow-up study, the POM bleached pulp will be extracted prior to comparison with similarly treated control pulp. It is anticipated that the properties of the POM bleached pulp will exceed those of the commercial ECF pulp. This work is in progress. 4. Pulp washing: Analysis of POM delignified fiber samples. 10 In a preliminary washing study, 0.12 ppm V and 4.0 ppm W were detected in fibers after delignification by 0.05 M K5[SiVW11O40] (3% csc, 0.2 M pH 7 potassium phosphate buffer), washing (two applications of 100 C water at 3% pulp consistency) and alkali extraction (2% pulp consistency, 1% NaOH, 85 C, a standard industry practice) followed by a final room-temperature rinse by water at 3X dilution. Although obtained using starting concentrations of 0.05 M, this early result is significant because the potassium salts used were less soluble than the sodium counter-cation systems reported here. In addition, reaction of K5[SiVW11O40] at pH 7 in phosphate resulted in the formation of relatively insoluble lacunary salts, K9[SiVW10O39]. Importantly, recent data show that removal of V and W by washing alone (prior to alkali extraction) of pulps treated with 0.5 M equilibrating (sodium counter-cation) solutions is diffusion controlled at medium pulp consistency (i.e., pre-alkali extraction metal-cation contents were ca. 50-150 ppm in W, in-line with theoretical diffusion-controlled water displacement values and similar to the pre-alkali extraction values from the earlier work using 0.05 M K5[SiVW11O40]). Alkali extraction and trace-metal analysis of the alkali-extracted pulps is in progress. The earlier obtained values (0.12 ppm V and 4.0 ppm W) are comparable to naturally occurring levels in the environment and to those reported in selected food items (e.g., 0.001 ppm V in drinking water and 0.99 ppm V in black pepper (Myron, D. R., Givand, S. H. & Nielsen, F. H. Vanadium content of selected foods as determined by flameless atomic absorption spectroscopy. J. Agric. Food Chem. 25, 297-299 (1977)) and 0.04 ppm W in grains and 0.35 ppm W in coconuts (Kletzin, A. & Adams, M. W. W. Tungsten in biological systems. FEMS Microbiol. Rev. 18, 5-63 (1996)). Vanadium is postulated to be an essential nutrient and is present in popular multiple vitamin formulations. Most diets supply from 10 to 30 g V per day (Nielsen, F. H. in Vanadium Compounds, Chemistry, Biochemistry and Therapeutic Applications, A. S. Tracey and D C. Crans, Eds. (American Chemical Society Symposium Series 711, 11 Washington, D. C. 1999) chap. 23). Natural dietary intake of W is estimated at 8-13 g per day (Kletzin, A. & Adams, M. W. W. Tungsten in biological systems. FEMS Microbiol. Rev. 18, 5-63 (1996)). The low levels of V and W (0.12 and 4.0 ppm, respectively) found in POM treated pulp fibers are comparable to the levels of inorganic elements present in native wood, which correlate with location and include 0.01 to 10 ppm levels of Ba, V, Mo, Co and Pb among numerous others (Young, H. E. & Guinn, V. P. Chemical elements in complete mature trees of seven species in Maine. Tappi J. 49, 190-197 (1966)), are far below those of many trace metals added to paper as impurities in natural clay (aluminosilicate) fillers (3-120 ppm each of Ba, Ni, Cr, Pb, Sn, Zn, Mo, Co, in natural kaolin, which constitutes 20-30% by weight of many papers; data from the Thiele Kaolin Company, Sandersville, GA, USA), and orders of magnitude below those of Ti(IV) added as TiO2, an opacification agent, and Al(III) (in clay fillers). Containerboard (heavy paper) used for applications involving food packaging or processing are always coated with wax or with synthetic polymers such as polyethylene to prevent contact between food and the pulp fibers and associated additives or impurities. According to guidelines established by the Conference of Northeastern Governors (CONEG) to which many U.S. manufacturers conform, coffee filters (typically made from unbleached or bleached kraft pulps) must contain less than 100 ppm total of four toxic heavy metals (these are the only ones included in the Guidelines): Cd, Pb, Hg and hexavalent Cr. 5. Determination of CO2 evolved during oxidative mineralization of solubilized lignin and polysaccharide fragments. Each experimental CO2 value was determined using a quantitative Ba(OH)2 solution according to the reaction shown in equation (1), followed by titrametric determination of the Ba(OH)2 thus consumed. 12 CO2 + Ba(OH)2 (aq) BaCO3(solid) + H2O (1) Analyses were conducted on the head space gases formed during each of the ten reoxidation/oxidative mineralization steps. The Parr reactor was connected through a teflon tube to two columns in series each filled with 200 mL of 0.058 N Ba(OH) 2. A few drops of isopropanol were added to ensure formation of a homogeneous fine-foam that provided effective mass transfer of CO2 (small gas bubbles in the foam) into the Ba(OH)2 solution. A flow of Ar (10 psi) was passed through the Parr reactor in order to ensure that the CO2-rich head-space gases were effectively removed, and a 10-mm Hg (aspirator) vacuum was applied to the outlet side of the columns to avoid backflow of atmospheric CO2 into the system. It is important during this operation to carefully check the outlet pressure of the Ar gas (at the cylinder regulator). If this pressure is too high, the integrity of the columns could be disrupted. The operation was carried out for 1 h in order to ensure that all the CO2 in the head space was transferred into the Ba(OH)2 column. At room temperature at neutral pH, the solubility of CO2 in water is sufficiently high that exhaustive efforts must be taken to ensure mass-transfer of the dissolved gas into the headspace and subsequently into the Ba(OH)2 solution. To accomplish this, a steel reflux condenser was inserted between the Parr reactor and the Ba(OH)2 column, the reactor was heated to 100 C, and Ar was passed gently through the refluxing system. The operation was stopped after ca. 30 min at which time the consumption of CO2 by reaction with Ba(OH)2 (observed as precipitation of BaCO3) had clearly stopped. The supernatant from the Ba(OH)2 column was titrated to a phenolphthalein endpoint using 0.101 N HCl. The titrations were performed in triplicate and average values are reported in Table S4. 13 6. Measurements, control experiments and methods used in mass-balance calculation of theoretical CO2 values. Theoretical CO2 values were calculated by mass balance from decreases in lignin content and changes in pulp mass. Lignin content was determined after each delignification step using a standard method (Useful method um-246; Technical Association of the Pulp and Paper Industry (TAPPI) Useful Test Methods 1991, TAPPI Press, Atlanta, GA, 1991, p. 43). In the 10-cycle experiment, fiber samples were removed for lignin analysis after each delignification step. Because the final lignin content in each case was small, relatively large amounts of the pulp were required for accurate lignin analysis, leaving insufficient quantities for equally accurate overall fiberyield determinations. Therefore, in order to obtain highly accurate values of changes in total fiber mass during delignification, the first 5 delignification/oxidative mineralization cycles reported in Figs. 2 and 3 were repeated in their entirety under conditions identical to those used in the 10-cycle experiment. This repetition of the first 5 cycles was carried out solely for the purpose of obtaining accurate yield data. The yields of the entire fiber masses collected after the delignification steps of each of these 5 cycles were then determined. Data demonstrating that the 5 cycles carried out for the purpose of obtaining fiber-yield measurements were identical to those used to obtain lignin content data was provided by measurement of solution densities and pH values before and after each delignification reaction, by measurement of %-reduction of the POM solution after each delignification reaction (Table S5) and by 51V and 27Al NMR. 14 Fiber-mass yields. The fiber-yield determinations were carried out as follows. First, four identical untreated pulp samples (from red and jack pine, 5% lignin by weight; ca. 2.5 g in each sample) were carefully weighed, oven dried to constant weight, and the water content determined by difference. The average of the four water-content values (all within 2% of one another) was used to calculate the %-moisture and thus dry mass of the untreated fibers. The moisture-content value was then used to calculate the actual dry masses of the pulp samples used in the 5 delignification reactions in the 5 cycles. After each of these 5 delignification reactions, the pulp fibers were washed thoroughly with water and the entire fiber mass dried to constant weight (Table S5). Mass-balance calculations. The difference between changes in lignin mass and in total fiber mass were assigned to dissolution of polysaccharide components of the predominantly cellulose fibers as follows: Mass of lignin removed = [dry-fiber mass weight-% lignin]o [dry-fiber mass weight-% lignin]f (2) Mass of dissolved polysaccharides = [(dry-fiber mass)o – (dry-fiber mass)f] (mass of lignin removed) (3) The results (changes in mass of lignin and of polysaccharides) are reported in Table S6. 15 Calculation of the theoretical CO2 values is based on the following equations (4-7). For CO2 attributed to mineralization of lignin, the formula weight (FW = 196 amu) of a typical -O-4 linked coniferyl alcohol (CA) monomer unit was used: (C10H12O4)n + 11 O2 10 CO2 + 6 H2O (4) For CO2 attributed to mineralization of dissolved polysaccharides, the formula weight of a glucose monomer of cellulose (FW = 162 amu) was used: (C6H10O5)n + 6 O2 6 CO2 + 5 H2O (5) Evaluating the results from equations (2) and (3) using equations (4) and (5) finally gives the mass of CO2 (MW = 44.01) from lignin and polysaccharide respectively: Mass of CO2 derived from lignin = [(mass of lignin removed)/196] 44.01(10 mol CO2/mol of CA) (6) Mass of CO2 derived from polysaccharides = [(mass of dissolved polysaccharides/162) 44.01(6 mol CO2/mol of glucose) (7) 16 Summation of the CO2 values from equations (6) and (7) gives the theoretical CO2 values reported in Figure 2 and here in Table S6. The error bars assigned to the theoretical CO2 values in Figure 2b (6.3%) were determined from variability in yield and lignin-content data. Uncertainties associated with experimental data (5%) are minimum values based on titrations of Ba(OH)2 solutions. Due to removal of solution for analysis after each step, the volume of POM solution decreased slightly over the 10-cycles (Tables S5 and S6). However, the massbalance measurements and calculations made it possible to determine the concentrations of organic compounds dissolved during each delignification reaction. Thus, theoretical and experimental CO2 data are reported in reference to the specific solution volumes present during oxidative mineralization. Accordingly, all CO2 values in Tables S4 and S6 and in Figure 2b are reported in units of mg/L of POM solution. Table S4. CO2 Evolved in Each Mineralization Step of the 10-cycle Experiment Summarized in Figure 2a. Cycle Vol. of HCl Avg. Final conc. CO2 Conc. (0.101 N; mLb ) (mL) of Ba(OH)2 (mg/L) (Al(III)) Final Red. pH of POM M) (M) (%) 14.7 1 15.7 14.6 0.03709 920 0.5 7.65 13.3 14.5 0.03664 940 0.5 7.66 13.7 13.4 14.5 2 14.7 17 14.3 14.4 3 15.0 14.2 0.03595 970 0.5 7.65 14.6 14.3 0.03625 957 0.5 7.66 14.5 14.5 0.03661 941 0.5 7.65 14.8 14.7 0.03714 918 0.5 7.67 14.0 14.7 0.03718 916 0.5 7.66 14.0 14.9 0.03761 897 0.5 7.66 14.8 14.9 0.03755 900 0.5 7.66 14.5 14.9 0.03766 895 0.5 7.67 14.7 13.2 15.1 4 14.7 13.1 14.5 5 14.5 14.5 15.0 6 14.4 14.7 14.8 7 15.1 14.2 15.4 8 15.0 14.3 14.9 9 14.9 14.9 15.0 10 15.0 14.7 a The initial pH of the solution used in the 10-cycle experiment was 7.30. 18 b After each mineralization reaction, three 20 mL aliquots of the Ba(OH)2 solution were titrated using 0.101 N HCl. Table S5. Fiber-Mass Yields. Cycle Solution Dry fiber mass (g) volume Initial Final Yield Conc. Final Reduction (%) (Al(III)) pH of POM M) (mL) (%) 1 250 2.50 2.37 94.8 0.50 7.52 14.0 2 246 2.46 2.37 96.3 0.50 7.45 13.0 3 244 2.44 2.34 95.9 0.50 7.65 14.0 4 241 2.41 2.31 95.9 0.50 7.60 14.0 5 237 2.37 2.26 95.4 0.50 7.60 14.0 a The initial pH of the solution used in the 5-cycle experiment was 7.30. Table S6. Changes in Mass of Lignin and Polysaccharide Components and CO2 Evolved During Oxidative Mineralization in the 10-cycle experiment. Cycle Solution Initial volume dry fiber (mL) mass (g) 1 250 2.50 2 242 3 Change in mass (mg) Lignin Poly- Total CO2 Total CO2 Experimental Theoretical saccharide (mg/L) (mg/L) 79.67 6.17 920 830 2.40 74.00 12.06 940 840 235 2.30 68.58 16.38 970 835 4 230 2.30 68.06 15.28 957 840 5 225 2.20 72.25 13.30 941 890 6 217 2.17 68.10 13.30 918 875 7 210 2.10 69.47 10.61 916 900 19 8 201 2.00 64.57 11.83 897 890 9 195 1.90 66.12 8.92 900 910 10 187 1.87 62.12 9.03 895 900