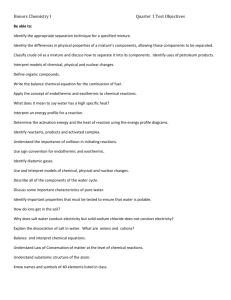

Modern_Separation-Unit_I

advertisement

Modern Separation Processes UNIT- I Review of conventional processes, Recent advances in separation techniques based on size, surface properties, ionic properties and other special characteristics of substances, Process concept, Theory and equipment used in cross flow filtration, cross flow electrofiltration, dual functional filter, Surface based solid – liquid separations involving a second liquid, Sirofloc filter. In Chemical process industries, separation operations are of great importance. Such operations are employed to: (i) separate feed mixture into other mixtures and relatively pure components (ii) recover solvents for recycle (iii) remove wastes (iv) purify reactant feeds (v) recover reactants from reactant effluents for recycle (vi) recover by-products (vii) recover and purify products to meet required specifications. Mechanism of separation: A schematic diagram of a general separation process is shown: The feed mixture can be vapor,liquid or solid. It consists of different chemical species in various compositions. The product streams are two or more differing from each other in their compositions. The separation is accomplished by forcing the different chemical species in the feed into different spatial locations by any of the 5 separation technique. The most common industrial technique (fig.1.7a) involves the creation of a second phase (V,L or S) that is immiscible with the feed phase. The creation is accomplished by energy (heat and/or shaft work) to or from the process or by pressure reduction. A second technique is to introduce the second phase into the system in the form of a solvent that selectively dissolves some of the species in the feed. The use of a barrier (fig. 1.7c) is less common but of growing importance. It restricts and / or enhances the movement of certain chemical species with respect to other species. The addition of solid particles is another technique that is of growing importance (fig. 1.7d). The solid particles act directly or as inert carriers for other substances so as to cause separation. Finally, external fields (fig. 1.7e) of various types are sometimes applied for specialized separations. For all the techniques of fig. 1.7, separations are achieved by enhancing the rate of mass transfer by diffusion of certain species relative to mass transfer all species by bulk movement within a particular phase. Both transport and thermodynamic considerations are crucial in separation operations. The difference in properties of the different species is made use of in separation operations. Some properties of importance are: 1. Molecular properties: -----------------------------------------------------------------------------------------------------Molecular weight Polarizability Van der Waals volume Dielectric constant Van der Waals area Electric charge Molecular shape (acentric factor) Radius of gyration Dipole moment 2. Thermodynamic and transport properties: ------------------------------------------------------------------------------------------------------. Vapor pressure Adsorptivity Solubility Diffusivity ------------------------------------------------------------------------------------------------------ (a)Separation by Phase Addition or Creation: Separation Initial Created Separatng operations or Feed or Added Agent(s) Phase Phase Partial V and / or L and/or Heat Condensation L V Transfer or (ESA) vaporization Flash L V Pressure vaporization reduction Distillation V and / or V and L Heat transfer L (ESA) Extractive V and / or V and L Liquid solvent Distillation L (MSA) & Heat transfer (ESA) Reboiled V and / or V and L Liquid Absorption L absorbent (MSA) & Heat transfer (ESA) Absorption V L Liquid absorbent(MSA) Stripping L V Stripping vapor (MSA) Refluxed Stripping V and / or L V and L Reboiled Stripping L V Stripping vapor (MSA) & Heat transfer(ESA) Heat transfer(ESA) Azeotropic Distillation V and / or L V and L Liquid entrainer (MSA) & Heat transfer(ESA) Liquid-Liquid extraction (2 solvent) L L Two liquid solvents (MSA1 & MSA2) Industrial Example Recovery of H2 and N2 from ammonia by partial condensation and high ressure phase separation Recovery of water from sea water Purification of styrene Separation of acetne and methanol Removal of ethane & lower MW hydrocarbons for LPG production Separation of CO2 from combustion products by absorbing with an aqueous solution of ethanolamine Steam stripping of naphtha, kerosene & gas oil side cuts from crude oil & to remove light oils Separation of products from Delayed coking Recovery of amine absorbent Separation of acetic acid from water using n-butyl acetate as entrainer to form an azeotrope with water Separation of paraffins from aromatics & naphthenes using propane And cresylic acd as solvents Drying L & often S V Evaporation L V Gas (MSA) and/or Heat transfer(ESA) Heat transfer(ESA) Heat transfer(ESA) Crystallization L S (& V) Desublimation V S Heat transfer(ESA) Leaching (L-S extraction) Foam fractionation S L Liquid solvent L G Gas bubbles(MSA) Removal of water from polyvinyl chloride with hot air in a fluid-bed dryer Evaporation of water from a solution of urea & water Crystallization of p-xylene from a mixture with mxylene Recovery of phthalic anhydride from noncondensible gas Extraction of sucrose from Sugar beets with hot water Recovery of detergents from water solutions (1) Osmosis (2) Reverse osmosis (3) Dialysis (4) Microfiltration (5) Ultrafiltration (6) Pervaporation (7) Gas Permeation (8) Liquid membranes Key factors based on which separation occurs. Fig.11.1 shows the key factors enabling separation of a mixture or solution. The difference in these properties of the chemical species present in the mixture decides the separation method. In some cases 2 such properties will be made use of to bring about separation; eg.,Electrodialysis. Here, diffusivity as well as the electric charge of the particular species are exploited to separate them from other species differing in these properties. Filtration: Conventional filtration is the most cost effective method for the separation of large particles and cells from slurries and fermentation broths. The feed is passed through a filter medium, and a filter cake is formed as aresilt of deposition of solids on the filter surface. Plate and frame filters, continuous rotary filters and rotary vacuum precoat filters are the most widely used types. Rotary Vacuum Filter: In this filter, the drum is covered with a layer of precoat, usually diatomaceous earth, prior to filtration. A small amount of coagulating agent or filter aid is added to the feed generally, before it is pumped into the filter. As the drum rotates under vacuum, a thin layer of solids adhere to the drum. The thickness of this layer increases in the suction designed for forming the cake. The layer of solids is washed and dewatered during its passage to the discharge point, where a knife blade cuts off the cake. A vacuum maintained in the drum provides the driving the driving force for the liquid and air flow. Modern Filtration Methods: Pressure-driven membrane processes for Liquid Separation: The most important pressure-driven processes (ΔP across the membrane is the driving force is the driving force for permeation) are: Microfiltration, Ultrafiltration and Reverse Osmosis (also called hyperfiltration). Consider an aqueous stream containing (i) suspended particles-bacteria and blood cells, (ii) large, dissolved molecules-proteins and carbohydrates and (iii) small, dissolved molecules-salts. These solutes have to be separated from the carrier solution. Microfiltration and Ultrafiltration are most commonly used for such systems. (Second option is RO). Microfiltration: Separation of fine particles and colloids from a liquid or separation of particulates from a gas using a porous membrane having pore sizes in the range 100 to 104 nm (0.1 to 10 μm). MF is an old membrane separation process retaining particles of micron size ; one of the traditional use is for separation of microorganisms (eg. separation of yeast from fermentation broth). Ultrafiltration: In Ultrafiltration, the membrane retains particles of submicron size by ultramicroporous membranes. Usually UF retains solutes in the 300-5,00,000 molecular weight range, including biomolecules, polymers, sugars and colloidal particles. As with Reverse Osmosis (RO), MF & UF are pressure driven, with the membrane permselective for the solvent (usually water). MF & UF separate mainly by size occlusion of solutes. Membrane process Micro Filtration Separation Mechanism Sieving Feed Driving force Pressure Difference ΔP < 2 bars Rejected species 0.1 μm to 20 μm Permeated species The suspending medium, L/G Ultra filtration Sieving Liquid Pressure Difference ΔP=2 to 3.5 bars Relatively large molecules (1-100 nm) Solvent, low molecular weight solute Reverse osmosis Solution diffusion Salt solutions, Sea water ΔP =10 to 100 bars or more Dialysis Sieving, Solution diffusion Solutions Concentration difference Pervapora tion Solution diffusion Liquid Activity difference Gas separation Sorption diffusion Gas mixtures Difference of fugacity, or ΔP Low MW Solvent solutes, (generally hydrated water) ions Large Micro solutes, molecules Solvent (5 -50 A) MW 50 to 104 dalton Molecules that have higher affinities for themembrane are preferentially sorbed on the feed side of the membrane and then diffuse through it. The molecules get desorbed on the permeate side under vacuum (for pervaporation) or under the effect of pressure difference causing enrichment. Liquid/ Gas containing suspended particles Applns Separation of cells, sterilization of L/G streams, sep. of emulsified oil from water, clarification of liquids/ beverages in food industry Separation of biomolecules, proteins, emulsions, dispersed droplets, macro Molecules, autopaints from solutions Desalination of sea water,, brackish water, treatment of waste water Haemo Dialysis, Recovery of selected solutes Production of absolute alcohol, dehydration of solvents, removal of trace organics from water Separation of air (O2/N2), CO2 from methane, organic vapors from air or a carrier gas, H2 from other light gases. (c) Reverse Osmosis: If separation of small molecules from a solution is required, a dense or non porous membrane is generally used. In the case of separation of salt from brackish water, the transport of the solvent (water) occurs under the effect of a pressure difference and potable water with only traces of salts is obtained as the permeate. Two types of flow and filtration arrangements: (i) cross-flow filtration and (ii) dead-end filtration. (i) Cross-flow filtration: The feed flows parallel to the membrane surface. Most of the particles or solute retained are swept away with the flowing feed side liquid. A part of the liquid is recirculated if the desired concentration of the retentate is not obtained in a single pass. (ii) Dead-end filtration: The feed flow is normal to the membrane surface. The retained particles or the solute remain on the membrane forming a cake or a gel layer. Particle accumulation on the membrane increases the filtration resistance. 7.2 The Present: Current Status and Potential of the Membrane Industry 313 Fig. 7.7 Use of hydrogen-permeable membranes to recover and reuse hydrogen from hydrocracker purge gas streams.