VWS MOL® catalyser technology: Sustainable disinfection of water

advertisement

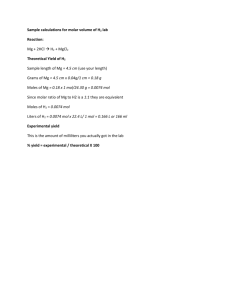

Press release Berkefeld at ACHEMA 2012 VWS MOL® catalyser technology: disinfect water circuits environmentally soundly Celle/Frankfurt, 19 June 2012 – The elimination of biofilms in process water and cooling circuits is indispensable for optimum energy efficiency and operating reliability. With the VWS MOL® catalyser technology, Berkefeld offers an environmentally sound alternative that securely fulfils current regulations and at the same time minimises operating costs. The process is applied to preventive disinfection and for remediation of circuit systems polluted by biofilm. The technology has proved itself in power stations and chemicals production plants in the treatment of cooling water, to protect reverse osmosis systems and in air-conditioning technology. In the treatment of cooling and process water in industrial plants, energy generation and chemicals production, operators must not only have the required quality for the respective application in mind. "Dissolved gases and salts in water favour biological growth and hardness," warns Peter Guttmann, Berkefeld Product Manager for MOL® Technology and expert in cooling water treatment. Without countermeasures, bio-fouling and scaling result in organic and mineral deposits on the surfaces of the water conducting systems. These cause corrosion and increase the pumps' need for energy due to reduced heat transfers and have a negative effect on flow processes. Biofilms also are an ideal breeding ground for legionella harmful to health." For the disinfection of water circuits, Berkefeld offers with VWS MOL® CLEAN and VWS MOL® LIK two new, highly effective and also environment-friendly processes based on solid-state catalysers. Biotenside against biofilms The VWS MOL®CLEAN process rests on the interaction of the VWS MOL® all-metal catalysers, low amounts of the MOL®aktiv E30 operating material and the germs moving freely in the circuit water. In the ensuing reactions, so-called biotensides arise as well as 1/4 Press release water. These dissolve the biofilms in the plant system, prevent regrowth sustainably and thus eliminate bacteria, especially legionella, from safe rooms and biospheres. Due to the elimination of the biofilms, microbiologically induced corrosion is prevented and in addition so-called corrosion inhibitors can work effectively on the free material surfaces. The same effect is achieved by the VWS MOL® LIK process. Here, under the exposure of light in a certain wavelength range highly reactive hydroxyl species are formed and thus biotensides produced. Undesired side effects for people and nature do not occur. MOL® LIK does completely without the use of biocides. Sustainable costs reduction The VWS MOL® technology has proved itself in particular in the disinfection of cooling circuits and reverse osmosis (RO) plants. Thus, the operator of the KNG hard coal power station in Rostock decided after testing it to use VWS MOL® CLEAN for treating cooling water in his natural draught cooling tower with a throughput of 50,000 m³/h. With this process no harmful reaction by-products such as AOX or endotoxins arise. Because the operating material MOL®aktiv E30 disintegrates in water and oxygen, the outflow quality improves for the feeding into surface waters. In addition, the chemicals consumption is considerably reduced. In the use of VWS MOL® CLEAN the catalyser elements are installed in the necessary number at a suitable point of the cooling circuit. Added to that comes a completely prefabricated dosing station. The dosing with MOL®aktiv E30 is made directly at the catalyser via a dosing pipe with dosing valve. The time-controlled dosing is done exactly in line with the respective microbiological burden of the system, as well as the median time the cooling water spends in the circuit. Because due to the water evaporation in the cooling tower an increase in salinity occurs, Hydrex 2240 is to be added as a hardness stabiliser. Berkefeld offers a continual optimally managed cooling water treatment including regular water analyses with recording and recommendations for optimum operational modes while taking account the relevant engineering standards. 2/4 Press release Increased plant performance Berkefeld's references also include the industry power station in Hamm, North RhineWestphalia. There, the conventional biocide disinfection of the RO system for treating boiler feed water was replaced by a VWS MOL® LIK module installed upstream. The process resulted in a complete elimination of the biofilm. That boosted the plant's performance and at the same time the costs dropped for the microbiological-related increase of the pump energy consumption of about 5,000 KW/h a year. In addition, the operator benefited from the complete absence of biocide, which also relieved the environment. "The essential advantages of the VWS MOL® catalyser technology are on the one hand the lower operating costs, such as due to longer cleaning intervals and the reduced chemicals consumption. On the other hand, it is more environmentally sound than conventional solutions because biocide is done without and the biofilm elimination effectively prevents legionella," sums up Peter Guttmann. More at http://www.berkefeld.com/en/Product/files/sustainable_disinfection.htm *** Pictures Picture 1 Cooling towers face their operators with considerable challenges. Legionella, corrosion and deposits can negatively affect operational reliability and be risks to health. Picture 2 The newly developed VWS MOL® LIK system for disinfecting cooling and process water does completely without biocides. 3/4 Press release Picture 3 VWS MOL® CLEAN catalysers for biofilm elimination in the natural draught cooling tower of the KNG hard coal power station in Rostock, Germany. Corporate Profile Company profile: 120 years of Berkefeld The Berkefeld water technology company celebrates in 2012 its 120th anniversary since its founding by Wilhelm Berkefeld in Celle. The company trades under the name VWS Deutschland GmbH. It is a subsidiary of Veolia Water Solutions & Technologies, one of the internationally leading suppliers of solutions and plants for treating drinking, process and waste water. The product offer encompasses solutions for a broad range of applications, from building and swimming baths technology to power stations and industrial companies, such as beverage, food and pharmaceuticals producers, and laboratories, municipalities and international aid organisations. http://www.berkefeld.com/en/ Veolia Water Solutions & Technologies, subsidiary of Veolia Water, is a leading design & build company and a specialized provider of technological solutions in water treatment. With 10,767 employees, Veolia Water Solutions & Technologies recorded revenue of €2.315 billion in 2011. www.veoliawaterst.com Veolia Water, the water division of Veolia Environnement, is the world leader in water and wastewater services. Specialized in outsourcing services for municipal authorities, as well as industrial and service companies, it is also one of the world’s major designers of technological solutions and constructor of facilities needed in water and wastewater services. With 96,651 employees in 69 countries, Veolia Water provides water service to 103 million people and wastewater service to 73 million. Its 2011 revenue amounted to €12.617 billion. www.veoliaeau.com Contact BERKFELD VWS Deutschland GmbH Veolia Water Solutions & Technologies Stefan Jakubik, Pressesprecher - Leiter Marketing & Kommunikation Lückenweg 5, 29227 Celle, Germany Telefon: +49 (0) 5141 803 – 174; Mobil: +49 (0) 151 1255 9226 stefan.jakubik@veoliawater.com http://www.berkefeld.de 4/4