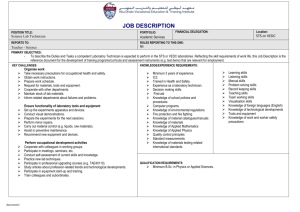

Biotechnology and Biomanufacturing

advertisement

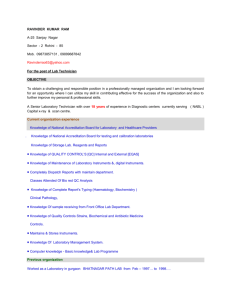

INTRODUCTORY BIOMANUFACTURING A 15 Week Introductory Course for High School/CC Students NBCC Curriculum Outline Minuteman Regional HS Session 1 2 3 Lecture Introduction to Biotechnology Modern Biotechnology: Making pharmaceuticals Basic Microbiology Unit 1 Lab Experience Documentation, Laboratory Notebook, Introduction to Instrumentation, Safety in the Lab Use of Bioengineered Enzymes in Manufacturing Settings Basic Aseptic Technique : Media Preparation, BSC use and Sterile Filter Techniques Job Descriptions and Competencies Process Development Associate, Upstream/Downstream Manufacturing Technician, Instrumentation/Calibration Technician Maintain lab notebook, Prepare samples for specific tests, Perform calibration, follow lab safety procedures PC skills Downstream Technician, Process Development Associate, Chemistry QC technician Maintain lab notebook, use spectrophotometer Analyze data Prepare data base, create tables, graphs Upstream/Downstream Manufacturing Technician Microbiology QC Technician Environmental Health and Safety Technician Perform basic microbiology lab techniques Weigh, prepare and sterilize media, autoclave, perform sterile filtration, test for bioburden Read and understand SOPs, document activities using GMP principles 4 5 6 7 Basic Microbiology Identification of Bacterial Types Unit 2 How do we identify Microbes? Staining, Morphology& Metabolism FDA History and Current Good Manufacturing Practice 21 CFR Parts 210&211 GMP Popcorn Activity Microbiology Technician QC Technician Environmental Health and Safety Technician Instrumentation/Calibration Technician Test for quality of media/reagents Monitor personnel Review Data Validate equipment, methods Facilities Technician QA Documentation Coordinator Upstream/Downstream Processing Technician Microbiologist QC Technician. Chemistry QC Technician Develop, review, revise and update SOP’s Use GMP when working with all documentation Establish plant or material Flow(Dirty/Clean) Basic Techniques, Measurement Process Development Associate, QC technician, Solutions and using balances, Upstream/Downstream Technician, Instrumentation spectrophotometer, Instrumentation/Calibration Specialist pH meter, Preparation of Test buffer/media quality, weigh and dispense reagents, buffers develop protocols Maintain Safe Read and extract information from manuals, understand Environment MSDS, Use PC skills Organism pGlo Process development, QC technician Transformation Transformation of E. Coli Develop protocols, design and or implement experiments 8 9 10 11 12 The Rain Forest: How to find new pharmaceuticals? Bioinformatics DNA search for new medicines Process Development Associate Perform literature search using the internet/library Design and/or implement experiments Isolation of Grow, homogenize Process Development Associate, Upstream Processing Products of and isolate purified Technician, Microbiology QC Technician Biomanufacturing pGLO protein Powerpoint Maintain cultures, screen and clone cultures, prepare Presentation of documentation, prepare buffers/media, design and/or Isolation implement experiments, use instrumentation techniques Perform recovery of product by homogenization, centrifugation and filtration protocols Write approved protocols Adhere to GMPs Proteins and their Preparation and Process Development Associate, Downstream Processing purification use of column Technician chromatography Prepare solutions, Clean environment, Pack columns Column Use of SEC, HIC, Process Development Associate, Downstream Processing Chromatography and Anion Technician, Chemistry QC Technician Exchange Columns Perform protein purification on columns Filter product as necessary Operate and use control systems Sample and manage process testing on material Purity of Product PAGE Chemistry QC Technician Techniques Test Samples Provide information to necessary personnel (QA) Follow GMPs Perform and support validation 13 14 15 16 Bioethics in the Teaming and Biomanufacturing Producting the Best Possible Product Engineering in Process Control Biomanufacturing and Robo Dacto Lab Final Product Analysis For Purity Final Product Polishing and Fill Clinical Trials ELISA Clinical Trial Board Game All Personnel Process Development Associate Validation Specialist Upstream/Downstream Processing Technician Process Control in the maintenance of both growth of cells and purification of product Adhere to GMPs, Health and Safety rules Process Development Associate Chemistry QC technician Microbiology QC technician QA Documentation Coordinator Perform product concentration assays Analyze media components Write/implement approved protocols Test samples Provide customer service Comply with regulations Process Development Associate Downstream Processing Technician Chemistry QC technician Microbiology QC technician QA Documentation Coordinator Perform Protein Purification Prepare final material for animal studies Prepare documentation Test samples Provide customer service Comply with regulations Conform with Health and Safety Procedures Perform testing for sterility of product Manage Documentation/Information and Records