18th European Symposium on Computer Aided Process Engineering – ESCAPE 18

Bertrand Braunschweig and Xavier Joulia (Editors)

© 2008 Elsevier B.V./Ltd. All rights reserved.

Dynamic Modelling of a Rotating Disk Contactor

Using the Primary and Secondary Particle Method

(PSPM)

Menwer M. Attarakiha,*, Moutasem Jaradatb, Hussein Allabounb, Hans-Jörg

Bartc and Naim M. Faqird

a

Al-Balqa Applied University, Faculty of Eng. Tech., Chem. Eng. Dept., P.O.

Box: 15008, 11134-Amman, Jordan

b

Jordan University of Science & Tech., Chemical Eng. Dep., P.O. Box: 15008,

22110 Irbid, Jordan

c

University of Kaiserslautern, Institute of Thermal Process Eng., P.O. Box:

3049, D-67653 Kaiserslautern, Germany

d

University of Jordan, Faculty of Eng. & Technology, Chemical Eng. Dept.,

11942, Amman, Jordan.

Abstract

A reduced mathematical differential model based on the secondary and primary particle

method to predict the steady and dynamic behaviours of hydrodynamics and mass

transfer in liquid-liquid extraction column (RDC type) is developed. The reduced model

consists of five coupled nonlinear partial differential equations that are dominated by

convection with nonlinear source terms. For this reason, special discretization

techniques based on the finite volume method are utilized. The unsteady state analysis

reveals the fact that the largest time constant is due to the solute concentration in both

phases. On the contrary, the response of the dispersed phase mean properties is very fast

when compared to the solute concentration one. Additionally, the solute concentration

response in both phases shows a highly nonlinear behaviour due to step changes in the

input variables.

Keywords: dynamic modelling, liquid extraction, RDC, model reduction.

1. Introduction

Dynamic simulation of Liquid-liquid extraction columns (LLEC) is now wide spread.

Unfortunately, the dynamics and control of these units could be problematic; partially

due to their multiphase nature, and partially due to the difficulty of online

measurements of important output variables. The understanding of this dynamic

behavior can be notably used in the design of process control strategy or the start-up and

shutdown procedures [5,11]. Attempts to model the dynamic behavior of extraction

columns are foundered because of the discrete nature of the dispersed phase. The natural

frame work of taking this into account is the population balance approach [2]. However,

due to the mathematical complexity of the resulting model it is not feasible to use it for

dynamic and online control purpose where short computational time is needed. To

reduce the complexity of these models without loosing the dynamic information, it is

obvious that a suitable reduction technique is needed. Accordingly, the concept of the

primary and secondary particle method (PSPM) [1] is utilized to reduce the bivariate

2

M.M. Attarakih et al.

population balance model to a self contained dynamic model with one primary and two

secondary particles. The secondary particles could be envisaged as a fluid particles

carrying information about the distribution as it is evolved in space and time. This

information reflects the particle - particle interactions (breakage and coalescence) and

transport (convection and diffusion). On the other hand, primary particles carry the

mean properties of the population such as total droplet concentration; mean droplet

diameter dispersed phase hold up and so on. So, the main objective of this work is to

develop a reduced mathematical model capable of describing the dynamic behavior of a

Rotating Disk Contactor (RDC) using a differential model.Accordingly, the state of any

droplet is represented by a bivariate (joint) density function f d , c (d , c y ; t , z )d c y

y

accounting for the number of droplets having sizes and concentrations in the ranges

[d , d d ] [cy , cy cy ] per unit volume of the contactor. This allows the discontinuous

macroscopic (breakage and coalescence) and the continuous microscopic (interphase

mass transfer) events to be coupled in a single spatially distributed population balance

equation (SDPBE).

2. The population balance model

The general SDPBE for describing the coupled hydrodynamics and mass transfer in

LLECs in a one spatial domain could be written as:

f d , c y ( )

t

[u y f d , c y ( )]

z

2

[ i f d , c y ( )]

i 1

i

in

in

f d , c y ( ) Qy f y

( d , c y ; t ) ( z z y )

Dy

z

z Ac vin

(1)

In this equation the components of the vector [d cy z t ] are those for the droplet

internal coordinates (diameter and solute concentration), the external coordinate is z and

t is time. The velocity vector along the internal coordinates is given by [d cy ] . The

source term represents the net number of droplets produced by breakage and

coalescence per unit volume and unit time in the coordinates range [ , ] . Note that

the dispersed phase velocity, u y , relative to the walls of the column is determined in

terms of the slip ( u0 ) velocity with respect to the continuous phase [3].

3. The primary and secondary particle concept

In the finite difference methods the particle size is discretized into a finite number of

sections ( N pp ), where the population in each section is considered to behave like a

single particle. In the PSPM framework of discretization, this single particle will be

called the primary particle and it will be responsible for the reconstruction of the

distribution. The interaction between the primary particles in different sections, due to

breakage and coalescence events, results in a new primary particle with no

representative size due to the discrete approximation of the distribution. Because the

newly-birthed particle could not conserve any of its low order moments but one, the rest

of the low-order moments are predicted with low accuracy and hence the associated

integral quantities. To overcome this fundamental problem of the sectional methods,

N sp secondary particles in the PSPM are generated in each section ( i ) with positions

Dynamic modelling of a rotating disck conactor using the primary and secondary

particle method (PSPM)

3

( d j i ) and weights ( wj i ) where i 1,2,...N pp , j 1,2,...Nsp The secondary particles are

exactly equivalent to the number of quadrature points in Gauss-like quadratures or the

QMOM [7]. Accordingly, each secondary particle could conserve or reproduce two

low-order moments and in general 2 N sp moments in each section. The way in which the

PSPM works is started by envisaging the dispersed phase as contiguous N pp primary

particles. Each primary is associated with the desired number of secondary particles

which carry detailed information about the distribution. The active particle mechanisms

such as breakage and coalescence occur through interactions between the secondary

particles. It is obvious now that Nsp N pp particles are contributing in the breakage and

coalescence events. Due to the increase of the number of interacting particles, more

information is gathered about the distribution itself. This distribution could be

reconstructed from the secondary particles by averaging the total weights of the

secondary particles with respect to the smallest domain containing these particles

associated with the ith primary particle and locating them at the mean size of the

secondary particles. In pure mathematical sense, the above presentation is equivalent to

applying the QMOM to each size partition of an arbitrary width:

resulting

in

a

set

of

low

order

[di 1/ 2 , di 1/ 2 ] : i 1,2,...N pp

moments: r i : r 0,2,...2 N sp 1 , where the details of this approach are found in [1].

4. The one-primary two-secondary particle model (OPTSPM)

This reduction technique retains the whole information furnished by the number

concentration function and averages out the solute concentration coordinate without any

simplifying assumptions regarding the form of the bivariate density function. For the

general case, the secondary particles (associated with any primary particle of mean

position located at [d , c y ] ) are assumed to have two different sizes ( d1 and d 2 ) and two

equal weights ( w1 and w2 ). Using this idea, any mean (integral) property associated with

a given primary particle ( i ) could be written mathematically as:

di 1/ 2

i

g r r d r g (d , c y ) f d ,c

i

y

(d , c y )d c y

(2)

di 1/ 2 0

The above equation is said to be unclosed if the bivariate density inside the integral is

not know in advance. Fortunately, using two-equal weight secondary particles leads to

the following closure equation [1].

g r

i

x1 r g (d1i , c y ) x2 r g (d 2i , c y )

i

i

(3)

Where r 0,1,3 , i 1,2,...N pp and x j 0 is the 1/ 2 , x j 1 and x j 3 are the fractional

i

i

i

length and mass of secondary particle j respectively. The secondary particle sizes and

weights are found from an explicit algebraic models derived recently in [1], while c y is

tracked directly using Eq.(5) below. Now, the OPTSPM could be obtained from the

continuous SDPBE above by first integrating out the solute concentration by the formal

application of Eq.(2) to Eq.(1). The result is an unclosed set of integro-partial

differential equations that are easily closed by using the closure given by Eq.(3).

4

M.M. Attarakih et al.

in

in

r

Q

u y r Dy r y r ( z z y ) r , r 0,1,3

t z

z Ac vin

[cyy ]

t

[cyy ] Qy in

cy ( z z y ) Koy c*y (cx ) c y

cyu y Dy

z

z Ac

(4)

in

(5)

While the solute balance in the continuous phase reads :

[cxx ]

[cxx ] Qxin in

cxu x Dx

cx ( z z y ) K oy c*y (cx ) c y

t

z

z Ac

2

6Koy (d j , c y )

j 1

dj

Koy y

(6)

(7)

Expressions for the source term r are a little bit complex and are presented in [1]. The

source term is equal to zero when r 3 as a natural constraint to satisfy the total

dispersed phase mass balance. Note that all the over bar quantities appearing in the

above system of equations are closed using Eq.(3). In particular, the dispersed phase

velocity (with respect to the column walls) u y is closed using the mass average velocity

of two secondary particles and is given by: u y u0 (1 y ) ux . Note that the dispersed

phase represented by a one primary particle is moving with the mass average velocity of

two adjacent secondary particles that is consistent with CFD models [4]. The slip

velocity is given by an algebraic velocity model assuming that the liquid droplets could

reach their equilibrium velocity in a short period of time compared to the system

relaxation time [6]. The continuous phase velocity u x is also function of the relative

dispersed phase velocity, where two types could be distinguished: the oscillatory and

nonoscillatory models [2]. From dynamic point of view the oscillatory model results in

overshoots in the dispersed phase mean properties in response to flow disturbances [2].

5. Spatial coordinate discretization

The system of the model equations (Eqs. 4 to 7 ) comprise a system of conservation

laws that are coupled through the convective and source terms and are dominated by the

convective term for typical values of D y and u y encountered in LLECs (Peclet

No.1103H -2103H). Due to the presence of breakage, coalescence and mass transfer

source terms, the operator splitting technique [9] is applied by first solving the pure

convective model equations using accurate front tracking discretization approaches.

Second, the effect of source terms is taken into account by solving the model equations

with only source terms are included. To insure numerical stability, an adaptive time step

is derived to satisfy the monotonicity condition [9] .

6. Numerical results and discussion

To completely specify the problem, the following geometry is used for a laboratory

scale LLEC: H 2.55 m , z y 0.25 m , zx 2.25 m , column diameter = 0.15 m , the inlet

feed is normally distributed with mean droplet diameter of 3 mm and standard deviation

of 0.5 mm. The inlet solute concentrations in the continuous and dispersed phases are

Dynamic modelling of a rotating disck conactor using the primary and secondary

particle method (PSPM)

5

taken as 50 and 0 kg/m3 respectively, the rotor speed is 120 rpm and the total flow rate

of each phase is taken 1.3910-5 m3/s. The slip velocity (combining the Stock and

inertial regimes) is taken from the work of Wesselingh and Bollen [10]. The chemical

system is water-acetone-toluene, where the direction of mass transfer is from the

continuous to the dispersed phase. The slowing factor and the droplet interaction

functions are described in detail by Schmidt et al. [8].

12

35

30

10

dispersed phase inlet,

number of spatial cells:

100 (left), 200 (middle) & 400 (right)

6

3

20

15

1.0 m

1.0 m

10

5

0

0

35

30

1.0 m

25

20

top of the clumn

2

2.55 m

40

Cx (kg/m )

Cy (kg/m3)

%

45

25

8

4

50

2.55 m

15

0.25

0.25

50

100

150

200

250

300

0

1

350

time ( s )

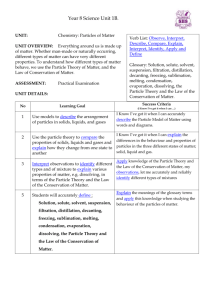

Fig. (1): Spatial convergence of the PSPM

using the response of the dispersed phase

hold up with oscillatory velocity model at

120 rpm.

2

time ( h )

Cx (kg/m3)

Cy (kg/m3)

2.55 m

25

4

6

8

4

6

8

10

60

Cx (kg/m3)

Cy (kg/m3)

2.55 m

40

30

10

30

20

1.0m

10

4

6

8

40

1.0m

20

0

10

4

6

8

10

40

Cx (kg/m3)

15

Cy (kg/m3)

3

50

30

10

0.25 m

5

0

2

time ( h )

x-phase

y-phase

0

10

1

Fig.(2): Response of the solute concentrations

(using the oscillatory (dashed line) and

nonoscillatory (solid line) velocity models) due

to step change in Q yin of magnitude +50%.

35

20

3

4

6

8

time ( h )

10

20

0

0.25 m

4

6

8

10

time ( h )

Fig.(3): Response of the continuous and dispersed phase concentrations due to ± 50% step

changes in the inlet continuous flow rate. Qxin =50 l/h.

Fig. 1 shows the response of the dispersed phase hold up during starting up of the

column with constant rotational speed of 120 rpm, where droplet breakage is considered

only. From numerical point of view, the profiles converge to the fine grid solution (400

6

M.M. Attarakih et al.

spatial cells) where the maximum deviation occurs at the dispersed phase inlet due to

the steep profile. As mentioned above, the oscillatory velocity model results in

overshoots in the hold up profiles along the column. The time lag associated with

distributed systems is also clear and increase away from the feed point. Due to the

discrete nature of the dispersed phase the high velocity of the moving secondary

particles makes the response of the hydrodynamic mean quantities (such as hold up)

much faster than the solute concentration one. In particular, the micro-velocity of mass

transfer by diffusion is much slower than that of convection. This is clear by referring to

Fig. 2 where positive step change of magnitude 50% is made in the dispersed phase

flow rate. First, both velocity models (oscillatory & nonoscillatory) show that the

response of the solute concentration in the dispersed phase is faster than that in the

continuous phase. Second, due to the overshoots in the dispersed phase, the solute

concentration in both phases show also overshoots. Fig. 3 depicts the response of solute

concentration in both phases due to ±50% step changes in the continuous phase flow

rate. It is evident that the concentration of both phases show a highly nonlinear

dynamics that is changing along the column height.

6. Conclusions

A reduced mathematical model is derived based on the concept of the primary and

secondary particles from the detailed bivariate population balance equation. The model

is capable of describing droplet breakage and coalescence without any specific

assumption about the shape of the distribution. The averaged quantities in the reduced

model were closed using a set of derived algebraic models describing the sizes and

weights of the secondary particles. Accordingly, the full dynamic response of the

extraction column could be predicted in short computational times. In this regard, the

model is suitable for control purposes and for simulation packages using the modular

approach. Concerning the column dynamics, the hydrodynamics of the column responds

faster than mass transfer as reported experimentally by Hufnagel and Zamponi et al. [1,

2]. The solute concentration response due to step changes in the inlet flow rates is not

only nonlinear, but also changes with regards to nonlinearity along the column.

References

[1] M. M Attarakih, C. Drumm & H.-J. Bart, Submitted to Chem. Eng. Sci. Journal, (2007).

[2] M. M. Attarakih, H.-J. Bart & N. M Faqir, Chem. Eng. Sci. 61 (2006), 113.

[3] M. M. Attarakih, H.-J. Bart & N. M. Faqir, Chem. Eng. Sci. 59 (2004), 2567.

[4] C. Drumm, M. M. Attarakih, & H.-J. Bart, Submitted to Chem. Eng. Sci. Journal (2007).

[5] H. Hufnagl, M. McIntyre & E. Blass, Chem. Eng. Tech., 14 (1991), 301.

[6] M. Manninen, V. Taivassalo & S. Kallio, On the mixture model for multiphase flow,

Technical Research Center of Finland, VTT Publications, ESPOO, report No. 288,

1996.

[7] R. McGraw, Aerosol Sci. & Tech., 27 (1997), 255.

[8] S. A. Schmidt, S. Martin, M. M. Attarakih, L. Lagar, & H.-J. Bart, Chem. Eng. Sci.,

61 (2006), 246.

[9] E. F. Toro, Riemann solvers and numerical methods for fluid dynamics. 2nd ed.

Berlin: Springer, 1999.

[10] J. A. Wesselingh, & A. M. Bollen, Trans. Inst. Chem. Eng., 77 (1999), 89.

[11] G. Zamponi, A. Stichlmair, E.-D. Gerstlaur, Gilles, Comp. Chem. Eng. 20 (1996),

S963.