Lift Truck Safety Manual - The Home Depot

advertisement

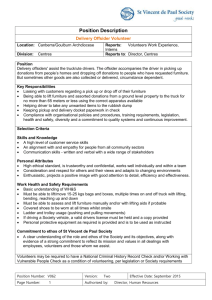

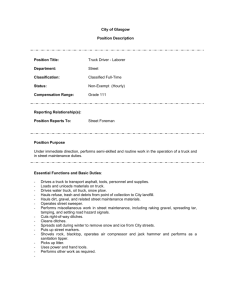

Lift Truck Safety Edwin Ulloa 04/29/2013 2 Lift Truck Safety Table of Contents iii Table of Contents Introduction to Lift Truck Safety ......................................................................................................v Lift Truck Training Overview ........................................................................................................... 3 Web-Based Training .................................................................................................................... 3 Hands-On Training....................................................................................................................... 3 Lift Truck Safety Training Certification............................................................................................ 3 Lift Truck License............................................................................................................................. 3 Visual Safety Inspection .................................................................................................................. 7 Conducting a Visual Inspection ................................................................................................... 7 Inspection Points ..................................................................................................................... 7 How to Handle and Change a Propane Tank .................................................................................. 9 While handling or replacing a propane tank: .............................................................................. 9 Steps for properly changing a propane tank:.............................................................................. 9 How to Properly Charge a Lift Truck Battery ................................................................................ 10 When Charging batteries .......................................................................................................... 10 Tagging Out a Vehicle ................................................................................................................... 11 Operational Controls by Truck ...................................................................................................... 15 Sit-Down Forklift........................................................................................................................ 15 Reach Truck ............................................................................................................................... 16 Order Picker............................................................................................................................... 17 Electric Pallet Jack ..................................................................................................................... 18 Pacer Unit .................................................................................................................................. 19 Hands-on Training ......................................................................................................................... 23 Proper Inspection of Vehicle ..................................................................................................... 23 Drive to a Designated Area ....................................................................................................... 23 Make a U-turn ........................................................................................................................... 23 Backing and Reversing............................................................................................................... 23 Loading/Unloading Techniques................................................................................................. 23 Drive Safely Through Store........................................................................................................ 24 iv Lift Truck Safety Proper Shut Down of Vehicle .................................................................................................... 24 Certification................................................................................................................................... 27 Index.............................................................................................................................................. 31 Introduction Introduction to Lift Truck Safety Welcome to The Home Depot’s Lift Truck Safety certification manual. The intent of this manual is to prepare, educate, and certify you to operate a lift truck safely and responsibly, at The Home Depot. From the founding of this company in 1978 to present day, our number one priorities at The Home Depot have been customer service and the safety of our customers, vendors, and associates. Please take time to read through this manual, take notes over the material presented in this manual, and study for the assessment. v Lift Truck Safety Course Overview Lift Truck Training Overview Lift Truck Safety Training Certification Lift Truck License Lift Truck Safety Course Overview 3 Lift Truck Training Overview You may have the option in choosing how you would like to earn your Lift Truck Safety Training certification. The first option is to take the web-based training which consists 6 courses, and followed by the hands-on training. The second option is to read through this manual and take notes, take an assessment at your store, and then do the hands-on training. Web-Based Training Course 4460: Lift Truck Safety – Principles of Lift Truck Safety Course 4461: Lift Truck Safety – Sit-down Forklift Course 4462: Lift Truck Safety – Reach Truck Course 4463: Lift Truck Safety – Order Picker Course 4464: Lift Truck Safety – Electric Pallet Jack Course 4465: Lift Truck Safety – Pacer Unit Hands-On Training Certification Number 4461: Sit-down Forklift Certification Number 4462: Reach Truck Certification Number 4463: Order Picker Certification Number 4464: Electric Pallet Jack Certification Number 4465: Pacer Unit Lift Truck Safety Training Certification In order to receive your Lift Truck Safety Certification, you will be required to pass the assessments you take either in the web-based training or the assessment you take in your store after reading through this manual, and pass the hands-on training. Lift Truck License Your Lift Truck Safety License will be given to you by your instructor once you have successfully completed the required assessments and hands-on training. Visual Safety Inspection Conducting a Visual Inspection How to Handle and Change a Propane Tank How to Properly Charge a Lift Truck Battery Tagging Out a Vehicle Visual Safety Inspection 7 Visual Safety Inspection Conducting a Visual Inspection Before operating a lift truck, a visual safety inspection must be performed to ensure that the truck and the environment are suitable for safe use. During a visual inspection the operator may encounter some concerns that will not require the truck to be “tagged out.” Such concerns can include stretch (shrink) wrap on a tire which can be easily removed, or a mess in the operator’s compartment which can also be cleared up. Inspection Points Brakes: When inspecting the brakes, the operator should be observant of any unusual scraping or groaning sounds, burning smells, or whether the truck stops in its own length when the brakes are applied while driving forward. Steering: When inspecting the steering, the operator should be observant of any high-pitched hums or whines, unusual binding when the steering wheel is turned, unintended movements when driving forward and reverse, and any unfavorable reading on the steering gauge in the operator’s compartment. Oil/Fluid Leaks: When inspecting for oil/fluid leaks, the operator should be observant of any hydraulic fluid, water, or oil leaks when the truck is moved. If inspecting a sit-down forklift, the operator should be observant of any propane tank leakages and whether the propane tank is properly secured. *Note: You may reference to the How to Handle and Change a Propane Tank section for more information in securing a propane tank. Tires: When inspecting the tires, the operator should be observant of any worn tires, cracks on the tires, or flat spots on the tires. The operator should also check for missing chunks of rubber or imbedded objects on the tires, stretch wrap on tires, and whether the tires are inflated or are they pneumatic. Forks: When inspecting the forks, the operator should be observant of any jagged or rough spots on the forks, whether the forks raise and lower smoothly, and check the alignment, surface, and straightness of the forks. Transmission: When inspecting the transmission, the operator should be observant of any jerking motions as the truck is in motion, and whether the truck lags before moving forward. Motor or Engine: When inspecting the motor or engine, the operator should be observant of any burning smells or excessive heat radiating from the motor or engine compartment, and check the gauges on the operator’s control panel for any alerts. Remove any stretch wrap or debris sitting on the motor. 8 Lift Truck Safety Warning Devices: When inspecting the warning devices, the operator should be observant that the horn, audible travel alarm, and warning light are functioning. Visual Safety Inspection 9 How to Handle and Change a Propane Tank The small and large sit-down forklifts require the use of liquid propane for fuel, as opposed to the reach truck, order picker, electric pallet jack, and pacer unit which use a battery as their source of energy. Liquid propane is incredibly flammable and dangerous; therefore the propane tanks must be handled with great care. While handling or replacing a propane tank: Do not smoke; keep flammable materials and open flames a minimum of 50’ away. Do not operate a lift truck that has a leaking propane tank. Do not drop the tank. Do not expose the tank to extreme heat temperatures. Change the propane tank in an area outside of the store that’s wellventilated. Use leather work gloves and wear protective eye goggles when handling propane tanks. If propane gets into eyes, rinse eyes with water immediately and get medical treatment. Steps for properly changing a propane tank: Step 1) Turn the propane tank valve to the “off” position. Step 2) Turn on the lift truck’s ignition, start the engine and run it until it stops. Step 3) Turn off the ignition. Step 4) Disconnect the hose fitting from the tank. Step 5) Remove the empty tank from the lift truck. Step 6) Place the new tank on the lift truck and turn it until the lift’s securing pin can be inserted into the tank. Step 7) Secure the tank using the attached tank fittings. Step 8) Screw the hose fittings onto the tank. Step 9) Turn the propane tank valve to the “on” position. Correct Mounting of Propane Tank 10 Lift Truck Safety How to Properly Charge a Lift Truck Battery When handling batteries, the operator must take into consideration that batteries contain acid and are electrically live at all times; therefore must be handled with caution. When Charging batteries Do not smoke. Do not operate lift equipment that has a battery with exposed, frayed, or loose wires. Do not charge a battery with frayed wires. Do not disconnect the battery from the charger until the charge is complete and charger is turned off. Only charge battery when the meter reads below 20% strength. Charge in designated charging area with proper equipment. Turn off charger and disconnect the battery by pulling on the plastic connectors, never disconnect by pulling on the wires themselves. Visual Safety Inspection 11 Tagging Out a Vehicle The lift truck operator will need to “tag out” a lift truck if issues such as these are encountered when inspecting the lift truck: There’s unusual scraping or groaning sounds, truck doesn’t stop when brakes are applied, or there’s a burning smell when brakes are applied. The truck’s steering makes a high-pitched hum or whine, the steering gauge in the operator’s compartment displays unfavorable information, or there’s erratic movement when steering. The truck is leaking oil, or any kind of fluids. There’s worn spots, cracked spots, flat spots, imbedded objects, or there’s chunks of rubber missing on the tires. The truck’s forks are cracked or bent, have jagged or rough spots, or don’t raise and lower smoothly. The truck hesitates before moving forward, or there’s a jerking motion while the truck is in motion. The gauges on the operator’s control panel alert that there’s a problem with the motor or engine, or if there’s an unusual burning smell or overheating of the motor or engine. The horn, audible travel alarm, or warning light do not function. Know the Vehicle Controls Operational Controls by Truck o o o o o Sit-Down Forklift Reach Truck Order Picker Electric Pallet Jack Pacer Unit Know the Vehicle Controls 15 Operational Controls by Truck Lift trucks are very similar in the actions they perform, but differ in operational controls. The following diagrams will identify the operational controls by truck and the functions of their controls. Sit-Down Forklift A. B. C. D. E. F. G. H. Accelerator Pedal: Controls the speed of the forklift truck. Raise/Lower: Lifts or lowers the load. Tilt: Tilts the load forward or backward. Side Shift: Shifts the load left or right. Service Brake: Stops the forklift truck. Inching Pedal: Disengages the transmission. Unmarked Security Start Switch: Restricts unauthorized operators. Parking Brake: Sets and releases the emergency brake. 16 Lift Truck Safety Reach Truck A. B. C. D. E. F. Steering Tiller: Controls the steering of the reach truck. Control Handle: Controls the speed, direction, fork, horn, and pantograph. Emergency Disconnect: Cuts off electrical power to the reach truck. Battery Discharge Indicator: Shows the remaining power of the battery. Unmarked Security Start Switch: Prevents unauthorized use of the reach truck. Deadman Pedal: Controls the brake release, enables and disables the travel system, and enables the direction controls. Know the Vehicle Controls Order Picker A. B. C. D. E. F. Directional Indicator: Shows which way you are traveling. Emergency Disconnect: Cuts off all electrical power on the order picker. Multi-function Control Handle: Controls the direction and speed. Pallet Clamps: Helps center and support the pallet. Pedal to Set Clamps: Locks pallet into place. Brake Pedal: Releases the brake. 17 18 Lift Truck Safety Electric Pallet Jack 1. Key Switch: Operates the lift truck when turned to the “On” position. 2. Travel/Brake Control: Stops the lift truck. 5. Rabbit Button: Gives the truck additional power, do not use on the sales floor. 8. Directional/Speed Control: Controls the speed and direction of the truck. 13. Emergency Reverse Button: Reverses the direction of the truck in an emergency. 17. Horn Button: Sounds the lift truck’s horn. 20. Lift/Lower Button: Raises and lowers the forks. Know the Vehicle Controls 19 Pacer Unit Steering Tiller: Moves the truck left and right. Control Handle: Controls the speed, and the forward/backward movements of the truck. Control Handle Decal: Identifies all functions of the control handle. Key Switch: Turns the truck on and off. Emergency Power Off Button: Controls the power to electrical circuits, and disconnects traction and lift system power. Hands-on Training Proper Inspection of Vehicle Drive to a Designated Area Make a U-turn Backing and Reversing Loading/Unloading Techniques Drive Safely Through Store Proper Shut Down of Vehicle Hands-on Training 23 Hands-on Training The hands-on training portion of the certification process consists of a series of tasks that must be completed without error. Once these tasks are completed, the lift truck operator may receive his certification. Proper Inspection of Vehicle In this section of the hands-on training, the lift truck operator will be observed by the instructor to ensure that a thorough inspection of the vehicle is conducted before operating the vehicle. Drive to a Designated Area The lift truck operator must ensure that all directions are clear of pedestrians, obstacles, and debris. The operator will also be required to start the vehicle correctly, maintain forks 4-6 inches from the ground, and drive a minimum of 20 feet at a safe speed to designated area without hitting anything. There will also be a practice zone with cones in which the operator will be required to drive through them without hitting them. Make a U-turn When getting ready to make a U-turn, the lift truck operator must ensure that there is an adequate amount of space to safely complete a U-turn without hitting anything. The operator must also drive at a safe speed, and follow all zone of safety rules while making the U-turn. Backing and Reversing The backing and reversing portion of the hands-on training is one of the most important training sections. Because the lift truck operator will be required to drive for long distances on the sales floor when material loaded on the truck’s forks obstruct the operator’s front view. In the hands-on training, the operator will be required to drive for a distance of 20 feet in reverse at safe driving speeds without hitting anything. The operator will also be tested on their ability to drive through a set of practice cones in reverse without hitting them. 90 degree left and right turns must be completed while driving in reverse then come to a complete stop and lower the forks until they are resting on the floor. Loading/Unloading Techniques Knowing how to load and unload are essential elements to driving a lift truck at the home depot, for the lift operator will be required to pull orders, down stock, and load customer's merchandise on to their vehicles. In the loading portion of the training, the lift truck operator will be evaluated on their ability to drive to the designated area, identify the load to lift, elevate the platform slowly, return the vehicle to the designated location, and bring the lift truck to a complete stop. In the unloading portion of the 24 Lift Truck Safety training, the lift truck operator will be evaluated on their ability to drive to the designated area, identifies the load to be unloaded, picks up load safely and slowly, lowers the load slowly, unload the load at the appropriate location, return the vehicle to the designated location, and bring the lift truck to a complete stop. *Note: Before loading/unloading merchandise, barricade gates must be placed on the opposite isle to prevent any customers from entering the opposite isle. The lift truck operator must also ensure that there is another associate (the spotter) guarding the opposite isle from customers trying to enter it. Drive Safely Through Store The lift truck operator will have to drive the lift truck throughout the sales floor. The instructor will be observing that the truck is maneuvered at safe speeds, safe distances away from customers, and that all warning devices are used as needed. Proper Shut Down of Vehicle In the proper shut down section of the hands-on training, the lift truck operator will be required to drive to a designated area and park the lift truck safely. Once the truck has been parked, the parking brake must be set, and all equipment on the lift truck must be shut down. The operator will then have to correctly connect the battery to the charger, and return all flags and barricade gates to their appropriate location. Lift Truck Certification Index 27 Certification After successfully completing the assessments and the hands-on training, the associate will be given a lift truck license. The lift truck license is a certification of completion of the lift truck safety course. The associate will only be able to drive the trucks for which the associate has received training on. The lift truck license must be attached to the associate’s apron at all times. Index Index 29 Index 31 Index A Accelerator, 15 Assessment, v, 3 M Medical Treatment, 9 Motor, 8 B Battery, 9, 11, 17, 28 Brakes, 7 O Oil, 7 P C Caution, 11 Charging, iii, 11 Parking Brake, 15 Propane Tank, iii, 5, 7, 9, 10 S D Deadman Pedal, 17 E Engine, 8 Service Brake, 15 Shut down, 28 Smoke, 9, 11 Spotter, 28 Steering, 7, 17, 23 T F Tagging Out Flammable, 9 Fluid Leaks, 7 Forks, 7 Tag Out, iii, 5, 12 Tires, 7 Transmission, 8 G Gauges, 8, 12 U Unloading, 28 H Horn, 8, 12, 17, 21 Unload, iii, 25, 27 Unmarked Security Start Switch, 15, 17 U-turn, iii, 25, 27 I W L Warning Devices, 8, 28 Web-based Training, 3 Wires, 11 Inspection, 7, 27 Loading Z Load, iii, 25, 27, 28 Zone of Safety, 27