Abstract for NNE Workshop on Instrumentation and Metrology for

advertisement

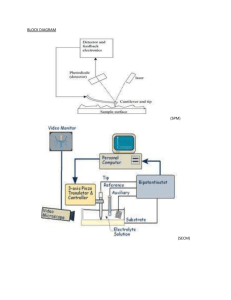

Abstract for NNE Workshop on Instrumentation and Metrology for Nanotechnology Jan. 27-29, Gaithersburg, MD Jeff Rosner – Agilent Technologies Utilizing my educational training in both Electrical Engineering and Materials Science, I have been deeply involved in analytical instrumentation for nearly 30 years. First, at NASA and later at HP/Agilent, I have developed commercial instruments in both chemical analysis and solid-state materials characterization, and have done research in semiconductor processing, industrial inspection, surface science, and biotech using a large variety of analytical techniques. The perspective that I bring is that of an industrial tool supplier to industry. Agilent has long been involved in developing and supporting instruments for measurement and control, and will increasingly play a role in delivering tools enabling nanotechnology research, development and commercialization. The metrology challenge can be discussed in three broad subdivisions: microelectronics, biotech, and bulk materials. In the microelectronics space, we will see dimensions substantially below 100 nm before 2010. Many of the measurement challenges will involve evolution of existing tools; indeed, ellipsometry, surface science techniques, and other R&D and yield management tools will evolve to the need without heroic efforts. Molecular electronics will not be a reality before 2010; tools for this R&D effort will only be developed through intervention, as the market is not sufficient to fund the development and research required. Alternative modalities of scanning probe microscopy (SPM) will continue as the dominant change trends in this area. In mainstream IC scaling, lithography, CD metrology and defect detection are the dominant unsolved problems. Lithography is well funded elsewhere; CD metrology by SEM will ‘run out of steam’ soon and require alternative tools…again, customized SPM tools are the most promising candidates today. Defect detection is moving today from a mix of optical and e-beam tools to full use of e-beam tools, primarily SEM. For elemental work, x-ray spectroscopy on an SEM is still the dominant tool, although field emission Auger is being developed. High-resolution SEM/EDX at very low accelerating voltages is currently limited by detector resolution; microcalorimeters and other alternative approaches to the venerable Si(Li) detector will make a large contribution. Large area high-throughput SPM could be a viable candidate, but there are currently no viable approaches en route to commercialization. Calibration of SPM lateral and vertical scales is still an issue without a widely standardized solution. Linear nanomotors are one possible solution to be funded. There are tremendous opportunities in the biotech sphere for contributions in the tool space. Many of the techniques used today are quite limited. Poised for revolution is the area of optical spectroscopy. This includes the use of fluorescent markers as well as increasingly visible demonstrations of vibrational techniques such as surface plasmon resonance (SPR), surface-enhanced Raman (SERS, particularly the recent demonstrations of tip-enhanced Raman in an SPM format). Quantum dots and other nanoparticle markers offer the advent of multi-channel general-purpose replacements for organic dyes. This will require a new generation of instruments capable of hyperspectral operation (in contrast to the unique laser/filter pair for each channel required for organic dyes) with real-time multivariate analysis. Microscopes, scanners, etc. will all need development for high-throughput operation; high channel-count in vivo cellular imaging represents a huge opportunity to accelerate research in genomic and proteomic pathways. Additionally, new SPM modalities are beginning to emerge, such as chemistry-specific force microscopy. As more biotech work is moving to surfaceimmobilized chemistry, visualizing surface chemistry at the nanoscale is imperative. While many of the components exist, creating toolsets for biotech research staff that are reproducible and sufficiently general-purpose will require a substantial investment in applied research to understand the variability in current demonstrations. These efforts will include work on low-force cantilevers, general-purpose tip functionalization protocols, and force-spectrum image processing algorithms. Finally, the area of bulk materials represents a growing challenge with unknown solutions. Manufacturers of gram and kilogram quantities of both nanoparticles and composites are struggling with today’s tools for microstructure examination. While TEM has emerged as a dominant tool, it remains expensive, time-consuming and practiced exclusively by a few highly trained experts. In response, chemists and materials scientists in this field are reduced to stochastic observations to infer microstructure using bulk measures of spectroscopy, light scattering, SPM, voltammetry, etc. All of these are severely limited in resolution, specificity, and/or sensitivity to some degree. The ‘holy grail’ that this community reaches for is to sample a statistically significant volume of material (# of particles or volume of composite) and know the full chemical constitution of that sample. Techniques like Imago’s LEAP provide promise, but are extremely limited in applicability for fundamental reasons. This is an area looking for revolutionary breakthroughs rather than development engineering, as many of the tools used today are quite mature, and already operating at the limits of their fundamental physics. In summary, the most common theme today is the use of both electron microscopy and SPM for nanotechnology measurements. Both of these techniques have substantial room for improvement, but SPM, in particular represents a large, untapped opportunity for bringing many demonstrated low-force and unique physics modalities into more commonplace use. In contrast, for many problems, fundamental considerations my limit the deterministic measurement approach and stochastic (bulk) measurements will have to suffice; there is much work remaining to validate these measurements to provide the reference to nanostructured.