3. hyperspectral image detection technology of meat quality

advertisement

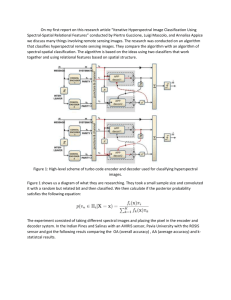

Study on the Meat Quality Detection Techniques FU Yan, GUO Pei-yuan, SUN Mei, LIN Yan XU Ran-ran School of Computer Science and Information Engineering Beijing Technology and Business University Beijing, China e-mail address :ggppyy@126.com Zolix Instruments Co., Ltd Beijing, China Abstract—This paper describes AOS and ATS detection techniques, computer vision detection technology, NIR detection technology, hyperspectral image detection technology. Hyperspectral image detection technology for meat quality detection has become a research hotspot. The basic principle of hyperspectral image detection technology and the research status in meat quality detection using Hyperspectral image at home and abroad are introduced in the paper. The prospect of future research in meat quality detection using Hyperspectral image detection technology is proposed to researchers on the related study as a reference. Keywords-meat quality; nondestructive detection technique; Hyperspectral image detection technology 1. INTRODUCTION In recent years, with the rapid growth of consumption of livestock meat and meat products, people put forward the higher request of meat quality. For the meat, mo st consumers are concerned about the meat quality and price. It makes demands of meat processing industry, meat safety, edible quality evaluation, identification of meat authenticity and adulteration and so on[1]. The quality of meat and its products is related to the most people's health problems. Therefore, if can rapidly and accurately identify meat quality, it becomes a serious problem that should be solved , in order to reduce the risk of eating the meat which is containing clenbuterol, heavy metals, microorganisms, water and other issues. The meat organoleptic quality usually measure from general color, tenderness , flavor of the meat , water retention and so on. More traditional detection methods is detrimental testing , such as organoleptic detection, physical and chemical detection, microbiological chemical testing and so on. At present, the meat quality detection technology research has had certain achievement in the scope of the world, such as meat chemical composition analysis, the determination technology of the freshness of meat, using image processing technologies for livestock body classification and meat quality detection, and has developed into instrument equipment in practical production. Especially Dane and German, who have developed the production line which can detect meat quality online based on near infrared spectroscopy technology (NIR)[2]. This article describes various methods of meat quality nondestructive testing in the modern testing field, including artificial olfactory and artificial taste detection technology, computer vision detection, NIR detection, This project was supported by Beijing Municipal Natural Science Foundation (4092012). The authors are FU Yan, Master,GUO Pei-yuan, Professor, SUN Mei, Associate Professor, and LIN Yan, Master, School of Computer Science and Information Engineering, Beijing Technology and Business University, Beijing, China; Xu Ran-ran, engineer, XU Ran-ran, Zolix Instruments Co., Ltd, Beijing, China. Corresponding author: GUO Pei-yuan. hyperspectral image testing technology. Hyperspectral image testing technology used in nondestructive testing of meat quality was highlighted. 2. MEAT QUALITY NONDESTRUCTIVE TESTING TECHNOLOGY 2.1 Artificial Olfactory and Artificial Taste Detection Technology Artificial olfactory and artificial taste detection technology is a new testing technology developed in recent years, which can simulate smell and taste function of humans and animals. Artificial olfactory and artificial taste, which are also called electronic nose and electronic tongue, can be used to identify the smell of food, meat authenticity and adulteration, in order to control the entire production process technology and ensure the product quality. When the pork and the role of various microbial contamination or corruption caused by the decomposition of the enzyme and its sour nature of the fermentation will produce sulfide and ammonia.Therefore, we can use artificial olfactory system testing the variation of the time of sulfide and ammonia concentrations, to determine the freshness of meat. Currently, the study which use artificial olfactory system to test the freshness of meat is quite extensive abroad. Domestic experts have begun to apply artificial olfactory system detecting the freshness of meat. For example, Guo Peiyuan and Qu Shihai[3] build a set of intelligent detection recognition system based on electronic information technology, optical detection technology, image processing and neural network pattern recognition technology. It collected ammonia and hydrogen sulfide released from the process of pork corruption, and collected data as a set of neural network input. It is a reliable basis for determing the freshness of pork[4]. Olfaction visualization technology is currently a new branch of artificial olfactory research. It is able to solve some common problems in gas sensors, and compensate for certain deficiencies in the electronic nose system. Its outstanding feature is translating smell information into visual information, so that smell is "visible." Olfaction visualization technology was first proposed by Professor Kenneth S. Suslick from University of Illinois at Urbana - Champaign. It is a visualization methods for qualitative and quantitative analysis based on colors changing of gas to be detected after reaction with chemical reagent[5]. Artificial taste system (ATS) technology started not long, the technology is not mature, yet to be further developed. The combination of artificial olfactory and artificial taste technology can further improve the detection and recognition of food, but the related research is in its infancy. chemical values to make model, low accuracy of quantitative analysis, complicated calculation model established and so on. 2.2 Computer Vision Technology Computer vision testing technology is a practical technology. It obtains the object image with the image sensor (commonly used high-resolution CCD), then convert the image into digital image, understand and identify the image by the criteria for computer simulation of the human, and make the practical techniques of appropriate conclusions. Image processing and image analysis is the core of computer vision technology[6-7]. Most of the current nondestructive testing method used only a single means of detection, more traditional signal preprocessing techniques and pattern recognition methods. They often only have better information response to one or two indexes, but not evaluate comprehensive using a variety of information. The overall quality of meat is complex, it should be evaluate comprehensive by a number of indicators. Therefore, organic integration of these detection techniques, taking full advantage of multiple information, evaluating meat simply, quickly, accurately and comprehensively is the focus of future research and development. Computer vision system has the advantages of nondestructive ,reliable and fast, so it is widely used in meat quality testing , not only in the visible area, but extends to the near infrared, infrared and other areas, not only in the visible area, but extends to the near infrared, infrared and other areas. Zhang Zhe[8] detect the fat content of pig eye muscle intramuscular with computer vision technology. It is also used to study fluctuations and grading of kidney meat quality. For example, we can detect a clear PSE kidney meat with the 400 ~ 700nm optical reflection measurement system.. 2.3 Near Infrared Spectroscopy Technology Near infrared spectroscopy technology has been a new optical detection technology which has been widely used recently in the food industry. The technology integrated spectroscopy, chemometrics, computers and other multidisciplinary modern analytical techniques. It has the advantage of rapid online analysis, nonpollution, nondestructive analysis, enabling nondestructive testing, enabling remote analysis and detection and so on. It is not only able to detect the chemical composition of meat in the traditional ways, but also involved in sensory quality evaluation, species identification and other aspects of meat quality. It has become a very active research area. Because of that the majority of organic compounds containing different hydrogen groups in meat, the content of these components can be determined by near infrared spectroscopy. And through further analysis can get more information related with the meat quality[2]. There are many domestic and foreign experts using near infrared technology for meat detection. For example, it has been successfully achieved detecting the water changes of meat in the heating process with near infrared fiber optic probe. It provides a new way of effective and reasonable control processing for meat industry[9]. Warnecke-H W studied the influences of additives to fat, moisture and protein content during meat processing with near infrared technology, found that most of the additives affect the absorption of near infrared[10]. Hou Ruifeng and other people in the domestic established a prediction model of total volatile basic nitrogen (TVB-N), classification spectral data by cluster analysis, enabled rapid nondestructive testing of meat[11]. However, near infrared spectroscopy also has its fatal flaws, such as requiring a large representative sample of 3. HYPERSPECTRAL IMAGE DETECTION TECHNOLOGY OF MEAT QUALITY Hyperspectral image detection technology is being more and more favour of researchers at home and abroad. Spectroscopy technique can detect meat material structure, composition and other internal quality information. Computer vision technology can fully reflect the external characteristics of meat. Therefore, hyperspectral images can reflect the overall quality of meat. 3.1 Hyperspectral Image Detection Technology As a new detection technology, hyperspectral image technology focus optics, optoelectronics, electronics, information processing, computer science and other fields of advanced technology, which organic combined the traditional two dimensional imaging techniques and spectroscopy. The technology has a characteristic of super multiband, high spectral resolution and one map. Therefore, hyperspectral technology has a greater detection advantage and detection accuracy in agricultural and livestock products, food quality and safety testing[12]. Hyperspectral imaging technology has been used in fruit internal quality, surface contamination and bruises testing[13], vegetable maturity and internal quality testing, and applied to the internal quality of the meat inspection[14]. The hardware components of hyperspectral image detection is including light source, CCD camera, computer equipped with image acquisition card and monochromator. The spectral range is 200-400nm, 400-1000nm, 900-1700 nm, 1000-2500 nm. Hyperspectral image detection system based on image spectrometer is shown in Fig.1. It is mainly composed of the matrix CCD camera and image spectrometer. When it works, image spectrometer will divide the light of reflect or transmit from test objects into monochromatic light source, and then went into the CCD camera. The system uses "push broom type" imaging method to get the hyperspectral image, matrix CCD detector makes horizontal arrangement completed horizontal scan (X direction) in the optical focal plane of the vertical direction. Acquire the information of the image of the test object with all wavelengths of each pixel in strip space. At the same time, in the process of advancing conveyor belt of detection system, the arrangement of detectors sweep out a ribbon track to complete the vertical scan (Y direction). Integrated vertical and horizontal scanning information, three-dimensional hyperspectral image data of samples can be got, as shown in Fig.2. At home and abroad, there have been some related research reports in hyperspectral image detection technology of meat quality. For example, Jinjun Xia[15] studied scattering properties of different beef in the near infrared spectral range. They found that the value of beef tenderness and the scattering of spectrum has a higher correlation. This indicates that the use of spectral scattering properties can predict tenderness of beef. Cluff[16] and other people predict beef tenderness with hyperspectral scattering properties. They predicted the highest correlation coefficient was 0.76. However, there is no related research reports based on hyperspectral image detection technology meat quality parameters of the test. blue line is the position of the waveform of bacteria. As a result, the study to detect fish plaque with hyperspectral image detection technology is feasible and practical significance. CCD Grating spectrometer a.749nm b.PC-6 Figure 3. The plaque of Hyperspectral principal component analysis Imaging lens Light source Computer Electricity move stage Sample Figure 1. Hyperspectral imaging system conflduration Figure 4. The position of plaque and no wavelength curve fitting At the same time, they also studied the detection of pork quality and related issues with hyperspectral image detection technology. Hyperspectral images are got in the near infrared range. Grayscale and 3D stereo false color picture of fresh pork samples in near infrared range hyperspectral images within a band is shown in Fig. 5. It can be seen from the figure, the near infrared images are not very good. But a large amount of reflectivity information can contribute to the follow-up analysis. Figure 2. 3d hyperspectral imaging data Guo Peiyuan, Fu Yan and other people is studying the relevant issues about fish quality testing with hyperspectral image detection technology. Hyperspectral images are obtained in the 400-1000nm wavelength range of 512 bands. We can get the effective characteristic wavelength with principal component analysis. For example, fish hyperspectral images collected by the hyperspectral imaging system, which was carried out by principal component analysis, can clearly see some parasites in the sixth principal components band image, which is shown in Fig.3. From the figure, we can clearly identify the plaque location of hyperspectral images after principal component analysis. Fig.4 shows the location of nonplaque and plaque wavelength curve fitting graph. Red line in this figure is the position of the waveform to nonbacterial, a. Gray image b. 3D stereo false color Figure 5. Pork sample hyperspectral image detection gray image and 3 D stereo false color 3.2 Outlook of Meat Quality Hyperspectral Image Detection Technology Hyperspectral image detection combines the advantages of spectroscopy and imaging study. Testing the quality of meat using hyperspectral image detection technology is rising in recent years. This paper through a fish plaque detection, the preliminary study shows that hyperspectral imaging technology can visualize the analysis of meat quality. Hyperspectral imagery for meat quality testing has good results, researchability and feasibility. Hyperspectral imaging system has obvious advantages in determining the characteristics wavelength of the quality parameters. Through researching and testing, we can determined the most effective characteristics wavelength of meat quality. Designed a number of wavelengths of spectral imaging systems,and then applied to the actual production. In this way, this can greatly improve the detection effectively, to achieve the aim of online, fast and nondestructive testing. REFERENCES [1] [2] [3] [4] [5] [6] [7] 4. CONCLUSION With the development of science and technology, meat quality nondestructive testing technology will integrate a variety of detection techniques direction. Due to hyperspectral image detection technology can obtain extensive images and spectral information of testing meat, it can be nondestructive testing of meat quality and comprehensive evaluation, so it has great potential for development in meat quality testing. Light absorption characteristics of different meat are quite different. The advantage of hyperspectral image detection is that it can choose the best effective characteristic wavelength according to the test target. This increases the potential applications of hyperspectral image detection technology. To extend the field of hyperspectral image detection technology in meat quality testing , we can apply hyperspectral image detection technology to do feasibility studies for other important meat quality, such as freshness, drug residues, heavy metals, processing aids, additives and so on. Nondestructive testing technology of meat quality, especially hyperspectral image detection technology in China is still in the experimental research stage, and did not really put them into actual production. Therefore, it has a very important practical significance to the modern development of meat industry in our country to speed up the market application of meat quality nondestructive testing equipment, and achieve meat online, fast, nondestructive testing. [8] [9] [10] [11] [12] [13] [14] [15] [16] Monin G, “Recent methods for predicting quality of whole meat,” J.Meat Science. vol. 49(2), 1998, p. 231. XU Xia, CHENG Fang, and YING Yi-bin, “Application and Recent Development of Research on Near-Infrared Spectroscopy for Meat Quality Evaluation,” J. Spectroscopy and Spectral Analysis. vol. 29(7), 2009, pp. 1876–1880. XU Shi-hai and GUO Pei-yuan, “Study on detection method to fresh degree of meat based on many message dealing,” J. Journal of Beijing Technology and Business University(Natural Science Edition). vol. 24(5), 2006, pp.26–31. XU Guan-nan, GUO Pei-yuan, and YUAN Fang, “Development of Nondestructive Detection Techniques of Pork Freshness,” J. Journal of Beijing Technology and Business University(Natural Science Edition). vol. 28(1), 2010, pp.14–17. ZOU Xiao-bo and ZHAO Jie-wen, “Nondestructive testing technology of agricultural products and data analysis method,” M. Beijing: Light Industry Press of China. pp. 1–8, 2008. CHEN Chun, “Computer image processing technology and algorithm,” M. Beijing: Tsinghua University Press. pp. 3–15, 2003. LI Ming-jing, LIU Guan-yong, ZHANG Zhi-wei, “The computer vision based beef automatic grading technology,” J. Meat Science. vol. 6, 2007, pp. 18–20. ZHANG Zhe, “The computer vision technology based the fat content determination of pig eye flesh,” J. Swine Industry Science. vol. 2, 2006, pp. 24–25. SHI Su-jia, “The food analytical technology of no-damage by nearinfrared spectroscopy,” J. Food Research and Developent. vol. 3, 2007, pp.177-179. Warnecke H W, lehmann F, chwager K. “Effects of Additives on Results of Near Infrared Analyses” J. Fleischwirtschaft. vol.52(4), pp. 196-200, April 1997. HOU Rui-feng, HUANG Lan, and WANG Zhong-yi, “Preliminary study on detecting freshness of meat with near-infrared spectrum,” J. Spectroscopy and Spectral Analysis. vol. 26(12), pp. 2193–2196, December 2006. A A Gowen, C P Donnell, and PJ Cullen, “Hyperspectral imaging-an emerging process analytical tool for food quality and safety control,” J. Trends in Food Science&Technology. vol. 18, 2007, p. 590. MA Ben-xue, YING Yi-bin, and RAO Xiu-qin, “Advance in Nondestructive Detection of Fruit Internal Quality Based on Hyperspectral Imaging,” J. Spectroscopy and Spectral Analysis. vol. 29, p. 1611, June 2009. Qiao J, Wang N and Ngadi M O, “Non-destructive inspection of Chinese pear quality based on hyperspectral imaging technique,” J. Transactions of the Chinese Society of Agricultural Engineering. p. 1, February 2007. Jinjun Xia, Amanda Weaver, and David E. “Distribution of optical scattering properties in four beef muscles,” J. Sensing and Instrumentation for Food Quality and Safety. p. 75, February 2008. Cluff K, Naganathan G K, and Subbiah J. “Optical scattering in beef steak to predict tenderness using hyperspectral imaging in the VIS-NIR region,” J. Sensing and Instrumentation for Food Quality and Safety. p. 189, February 2008.