Che 551- Tutorials

advertisement

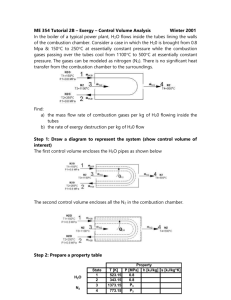

King Saud University – College Of Engineering Dept of Chemical Engineering CHE 551 TUTORIAL 1 1) -Locate the following points for Methane using T-S diagram and determine the remaining properties. A) S= 3.0J/g.K, T= 130K B) p=2atm S= 3.0j/gr.K C) h=200J/gr P=100atm D)Sat liquid, P= 1 atm E) Sat vap T= 140K 2) Determine the following parameters from a P-h Diagram for R22, IF TEV=10C, and Tc=35C 1 ----2 Isentropic compression, 2-----3 Isobar condensation, expansion, 4------1 isobar evaporation. 3-----4 Isenthapic 3) – A Carnot cycle machine operates between the temperatures limits of t1=34C, and t2= -10C, determine the COP, when it is operated as a refrigerating machine, and as a heat engine. - Plot the variation of the COP the evaporator temperatures for a condensing temperature = 34C, Tev=10C, 0C, -8C, -20C. 4) Find the max , and Wmin for 1KW of cooling, for the following gas, Oxygen \ (90K), Nitrogen (77K), Methane (111K), Hydrogen (20.4K), Helium (4.2K), water (373K) if To= 30C. 5) determine the exergy of the following points, and determine the loss of the exergy across the equipement., if we assume that the gas molar flow rate is as follows, (pts 1 and2 = 1mole), pts3 =0.4 mole, pts 4, 5, 6 =0.7 mole. 1 2 4 5 3 6 King Saud University – College Of Engineering Dept of Chemical Engineering CHE 551 TUTORIAL 2 1) An ideal cycle vapor compression refrigerating system using R22 Operates - through a reversed carnot cycle with an evaprating temperature =-15 C, and a condensing temperature = 45C, to provide a total cooling load =.The refrigerant leaves the condenser as a saturated liquid and leaves the evaporator as a saturated vapor. Represent this cycle in P-h chart Calculate the refrigerant effect, the mass flow rate of the refrigerant Determine the ideal theoretical work, and power for the compressor Calculate the coefficient of the performance for this cycle 2) The system descibed above is to be used to liquefy Ammonia in the evaporator. IF The mass flow rate of the refrigerant is constant and = 1.2kg/sec, determine the quantity of ammonia to be liquefied for the following conditions a) NH3 tev= 212 K b) NH3 tev = 265k c) NH3 tev = 214 K In each determine the ideal work required to drive the compressor. King Saud University – College Of Engineering Dept of Chemical Engineering Che 551 Tutorial 3 1) A process for cooling nitrogen is shown in figure 1 and the associated properties of the fluids are given in table 1. Calculate for the nitrogen cooler; - the process efficiency - The losses over the Joule/ Thompson valve and the nitrogen cooler. Assume that the compressors and expander have an efficiency of 80percent Data for Exergy calculations T0= 20 C For nitrogen h0= 11926 Kj/Kmol, so= 111.3Kj/kmol ho - Toso= -20700Kj/Kmol For Freon 22 h0= 23429 Kj/Kmol, so= 98.83Kj/kmol ho - Toso= -5530KJKmol Ho= enthalpy, To= absolute temperature so= entropy PT Pressure Atm Temperature Flow K Kmol/hr Enthalpy KJ/Kmol Exergy KJ/Kmol Nitrogen 1 2 3 4 5 6 10 11 12 18 19 6.2 13.6 13.5 29.6 29.5 42.7 40.0 6.5 6.4 1.45 1.35 309 41.3 313 416 313 361 183 113 169 173 118 1000 1000 1000 1000 1000 1000 1000 1000 1000 1063 1063 12340 15388 12432 15434 12340 13747 7974 6430 8184 8397 6760 4433 6927 6346 8804 8240 9303 10029 7642 5646 1806 3373 20252 28109 8112 9112 577.2 6808 5020 3291 Freon 14 15 16 17 1.05 15.1 15.0 1.15 235 387 313 235 13.1 13.1 13.1 13.1 King Saud University – College Of Engineering Dept of Chemical Engineering CHE 551 TUTORIAL 4 - Pt 1 2 3 4 5 6 7 - A simple Linde cycle is used to liquefy air, as shown in figure 1. - Represent this cycle in a T-S diagram - Calculate the fraction liquefied and complete table 1 Determine the exergy supplied to the system, the exergy taken out of the system, and the exergy loss.( excluding the compressor) Locate the biggest exergy loss (heat exchanger or expansion valve) Calculate the ideal work per kg liquefied ( no heat is assumed to enter or leave the equipmenT) To=300K, Po= 1atm So= 0.904Kcal.kg.K T P K atm 300 174 86 ----298 300 200 -1.3 ----1.0 1.0 h s kcal/kg kcal/kg.k 113.8 66.4 ---24.0 69.8 121.8 122.1 0.522 0.316 0.526 0.026 0.566 0.900 0.904 e kcal/kg -------------------------- M kg/hr 1 ------------------------ H kcal/hr --------------------------------- E kcal/hr ---------------------------- King Saud University – College Of Engineering Dept of Chemical Engineering CHE 551 TUTORIAL 5 A Claude system is to be used for air liquefaction with air at 70 F, 14.7 Psia. The air is compressed to 800 Psia and 60 percent of the compressed air is expanded in an engine having an isentropic efficiency of 70 percent. The ait at the inlet to the expander is at 20F. - Represent this cycle in a TS diagram - Determine the net work supplied per unit of air compressed and per unit of liquid air produced assuming that the expander work is utilised for compression. - Determine the effect on the answers if a heat in leak of 3BTU/ lb air compressed. King Saud University – College Of Engineering Dept of Chemical Engineering CHE 551 TUTORIAL 6 Q1 -A low temperature double distillation column is used to upgrade Natural gas conatining 80percent CH4, 20 percent Nitrogen (more volatile component) in order to produce pure (N2) and s pure (CH4), by means of the low temeprature process as shown in figure. The binary feed is initially at Pressure= P1, , the operating pressure of the lower column. The bottom product from the lower column (E) contains 15 percent of N2 is saturated liquid, is expanded to a lower pressure P2 which is the operating pressure of the top column. The overhead product of the lower column (D) is pure Nitrogen and saturated liquid is first cooled and then expanded to P2 in the top section of the upper column.. The main products obtained are pure Nitrogen (P), saturated vapour, and pure Methane (B) saturated liquid.. - Locate points representing the various streams involved in the process on the enthalpy composition diagram by explaining the method of location, the main assuptions proposed Q 2 A mixture of 60percent propylene and 40 percent propane is to be separated into essentially pure components in a distillation column operating with a reflux ratio of 12:1. The column is incorporated in a vapour recompression cycle as shown in figure 1. On the basis of the data presented in figure 1 a) Determine the flow of propylene to the compressor per 100 kg of feed mixture. b) Evaluate the total and minimum work required for the process and hence its thermodynamic efficiency.