COSHH – Control of Substances Hazardous to Health

advertisement

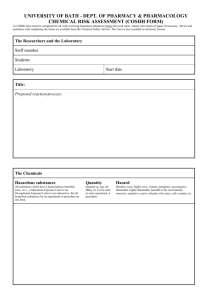

011 – COSHH Guidance Guidance No: COSHH Guidance Issue Date and Version Number: To be added Page: 1 of 10 Review Date: Related Policies: To be added (or sooner if there is a change in legislation or to reflect best practice) Name To be added Position Contact Number Head Teacher To be added Introduction The Control of Substances Hazardous to Health (COSHH) Regulations are in place to protect people from substances that can be hazardous to health. Substances not assessed or authorised must not be brought into or used in any school. Definitions Where they are applicable in a school, the COSHH regulations cover the delivery, handling, storage, use and disposal of substances that can cause ill health. The substances can: Be used directly in work e.g. chemicals, paints or cleaning materials; Arise from work e.g. dusts, fumes and waste products; Occur naturally e.g. fungal spores or bacteria. The substances can cause harm by inhalation, ingestion, absorption or injection through the skin. Some examples of the effects of hazardous substances include: Skin irritation, dermatitis or even skin cancer from frequent contact with oils. Asthma resulting from sensitisation to paints containing isocyanides. Being overcome by toxic fumes. Poisoning by drinking toxic liquids from bottles thought to contain water or soft drinks. Cancer, which can appear years after exposure to carcinogenic substances at work. Infection from bacteria and other micro-organisms (biological agents). Many substances are subject to control by exposure limits. These are classed as Workplace Exposure Limits (WEL’s). Exposure is controlled by limiting the duration of use and the concentration of the substance used. Where applicable the WEL for a substance will be described in the hazard data sheet. Duties Head Teachers / Heads of Department Duties Assess the risks All processes, which use or generate substances hazardous to health, must be assessed and a COSHH risk assessment developed. If the process is simple and the risk is very low, the results of the assessment (e.g. "no significant risk") may be recorded on the COSHH assessment. Prevent or adequately control exposure o Ensure that control measures are used o All employees are required to make proper use of control measures and to report defects. Head Teachers must take all reasonable steps to ensure that they do so, including providing them with suitable training, information and supervision. Ensure that controls are maintained o All control measures must be maintained to ensure they are kept in efficient working order and good repair. o Engineering controls and respiratory protective equipment (RPE) have to be examined and, where appropriate, tested at suitable intervals. o Local exhaust ventilation (LEV) 'annual' tests (normally arranged through the local maintenance authority) and weekly visual checks (by users) should be recorded. Arrange for routine exposure monitoring (if necessary) o The regulations all require that exposure to hazardous substances is prevented or, if this is not reasonably practicable, adequately controlled. There may be a requirement for exposure of school employees to hazardous substances to be monitored on a regular basis, normally to make sure that control remains adequate. Information, instruction, training and supervision o Staff must be provided with suitable and sufficient information, instruction and training about the nature of the substances they work with or are exposed to, the risks created by this exposure and the precautions they should take. o All staff must also be instructed on emergency procedures. Ensure that appropriate actions are taken o Any remedial actions required as a result of the assessment should be considered and an action plan drawn up by the Head Teacher or other suitable person, who should also monitor progress. The requirement for planning for emergencies must not be overlooked. Review the assessment o All assessments must be reviewed to ensure they are still valid. All assessments must be reviewed at least once in every 5 years. If there are no changes to the process and it is a low risk one, a review must be undertaken every 5 years. If there are changes to the process or if there is reason to believe it is no longer valid, a review must be undertaken immediately. For substances which are more toxic, review must be carried out more frequently than every 5 years, to ensure that the controls remain adequate. o The criteria for review are as follows: Change of Head Teacher An initial review should take place shortly after implementation of any control measures introduced as a result of the assessment to check their effectiveness (timescales will vary according to the risk – higher risks will require shorter timescales). Should an accident or incident occur, or if there is any ill health which could have been linked to the process. When there has been a significant change in the task procedure, technology, substances or process, Employees Duties All staff have a duty to comply with the regulations in relation to COSHH. Some employees have regular contact with chemicals and substances, examples would be site agents, cleaners and design & technology (D&T) staff. D&T staff are specifically trained in the safe use and storage of chemicals, but also can obtain further information through CLEAPSS. D&T staff must also clearly brief all students in the safe use of chemicals and substances used for teaching purposes, prior to commencement of a class. Personal Hygiene o Personal Protective Equipment (PPE) o Staffs are not to eat, drink or smoke in any place which they have reason to believe to be contaminated by chemicals. They must practice a high standard of personal hygiene utilising facilities provided for washing. Wear, in a proper manner, any PPE provided. Store PPE when it is not in use in the storage locations provided. PPE records should be maintained and PPE should be replaced when necessary. Competence o Those who complete COSHH assessments should have received some basic health and safety training, and have an understanding of the chemicals being used. A material safety data sheet (MSDS) which is typically provided with the chemical should be used to assist in the development of the COSHH assessment. Material Safety Data Sheets (MSDS) These are provided by the manufacturer or supplier of the substance at the time of purchase. All the information needed for a COSHH assessment will be included in the data sheet and can be transferred to the risk assessment form. Suppliers must provide safety data sheets for dangerous chemicals to the recipient of the chemicals, but only if the chemicals are to be used in connection with work. Safety data sheets do not have to be provided when dangerous chemicals are sold through shops for use by the public, as long as enough information is given in another form, for example on the package. Safety data sheets are important to make the school safe and to protect the environment. More specifically, a safety data sheet contains information to help you write a risk assessment as required by COSHH. The safety data sheet itself is not an assessment. However, it will describe the hazards of a chemical, helping you to assess the probability of those hazards (i.e. the risk) arising in the school. It will not take into account local working conditions or the health, age and experience of those using the substances. Categories of Danger Highly Flammable (F) Extremely flammable (F+) Toxic (T) Very toxic (T+) Corrosive (C) Harmful (Xn) Irritant (Xi) Sensitising by inhalation (Xn) Sensitising by skin contact (Xi) Dangerous to the environment (N) Explosive (E) Oxidising (O) Risk Phrases R1 R2 R3 R4 R5 R6 57 R8 R9 R10 R11 R12 R13 R14 R15 R16 Explosive when dry. Risk of explosion by shock, friction, fire or other source of ignition. Extreme risk of explosion by shock, friction, fire or other sources of ignition. Forms very sensitive explosive metallic compounds. Heating may cause an explosion. Explosive with or without contact with air. May cause fire. Contact with combustible material may cause fire. Explosive when mixed with combustible material. Flammable. Highly flammable. Extremely flammable. Extremely flammable liquefied gas Reacts violently with water. Contact with water liberates extremely flammable gases. Explosive when mixed with oxidizing substances. R17 R18 R19 R20 R21 R22 R23 R24 R25 R26 R27 R28 R29 R30 R31 R32 R33 R34 R35 R36 R37 R38 R39 R40 R41 R42 R43 R44 R45 R46 R47 R48 R49 R50 R51 R52 R53 R54 R55 R56 R57 R58 R59 R60 R61 R62 R63 R64 R65 R66 R67 R68 Spontaneously flammable in air. In use, may form inflammable/explosive vapour-air mixture. May form explosive peroxides. Harmful by inhalation. Harmful in contact with skin. Harmful if swallowed. Toxic by inhalation. Toxic in contact with skin. Toxic if swallowed. Very toxic by inhalation. Very toxic in contact with skin. Very toxic if swallowed. Contact with water liberates toxic gas. Can become highly flammable in use. Contact with acids liberates toxic gas. Contact with acid liberates very toxic gas. Danger of cumulative effects. Causes burns. Causes severe burns. Irritating to eyes. Irritating to respiratory system. Irritating to skin. Danger of very serious irreversible effects. Limited evidence of a carcinogenic effect. Risk of serious damage to the eyes. May cause sensitisation by inhalation. May cause sensitisation by skin contact. Risk of explosion if heated under confinement. May cause cancer. May cause heritable genetic damage. May cause birth defects Danger of serious damage to health by prolonged exposure. May cause cancer by inhalation. Very toxic to aquatic organisms. Toxic to aquatic organisms. Harmful to aquatic organisms. May cause long-term adverse effects in the aquatic environment. Toxic to flora. Toxic to fauna. Toxic to soil organisms. Toxic to bees. May cause long-term adverse effects in the environment. Dangerous to the ozone layer. May impair fertility. May cause harm to the unborn child. Risk of impaired fertility. Possible risk of harm to the unborn child. May cause harm to breastfed babies. Harmful: may cause lung damage if swallowed. Repeated exposure may cause skin dryness or cracking. Vapours may cause drowsiness and dizziness. Possible risk of irreversible effects. Safety Phrases S1 S2 Keep locked up. Keep out of the reach of children. S3 Keep in a cool place. S4 Keep away from living quarters. S5 Keep contents under ... (there follows the name of a liquid). S6 Keep under ... (there follows the name of an inert gas). S7 Keep container tightly closed. S8 Keep container dry. S9 Keep container in a well-ventilated place. S12 Do not keep the container sealed. S13 Keep away from food, drink and animal foodstuffs. S14 Keep away from ... (a list of incompatible materials will follow). S15 Keep away from heat. S16 Keep away from sources of ignition. S17 Keep away from combustible material. S18 Handle and open container with care. S20 When using, do not eat or drink. S21 When using do not smoke. S22 Do not breathe dust. S23 Do not breathe vapour. S24 Avoid contact with skin. S25 Avoid contact with eyes. S26 In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. S27 Take off immediately all contaminated clothing. S28 After contact with skin, wash immediately with plenty of soap-suds. S29 Do not empty into drains. S30 Never add water to this product. S33 Take precautionary measures against static discharges. S35 This material and its container must be disposed of in a safe way. S36 Wear suitable protective clothing. S37 Wear suitable gloves. S38 In case of insufficient ventilation, wear suitable respiratory equipment. S39 Wear eye / face protection. S40 To clean the floor and all objects contaminated by this material, use .... (there follows suitable cleaning material). S41 In case of fire and / or explosion do not breathe fumes. S42 During fumigation / spraying wear suitable respiratory equipment. S43 In case of fire use ... (there follows the type of fire-fighting equipment to be used.) S45 In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.) S46 If swallowed, seek medical advice immediately and show this container or label. S47 Keep at temperature not exceeding... S48 To be kept wet with (there follows a material name). S49 Keep only in the original container. S50 Do not mix with ... S51 Use only in well ventilated areas. S52 Not recommended for interior use on large surface areas. S53 Avoid exposure - obtain special instructions before use. S56 Dispose of this material and its container at hazardous or special waste collection point. S57 Use appropriate container to avoid environmental contamination. S59 Refer to manufacturer / supplier for information on recovery / recycling. S60 This material and its container must be disposed of as hazardous waste. S61 Avoid release to the environment. Refer to special instructions / safety data sheets. S62 If swallowed, do not induce vomiting; seek medical advice immediately and show this container or label. COSHH Assessment This is the process by which the assessor (someone trained and familiar in the activities and substances used) will identify and list all the substances used in the workplace and make a full assessment as necessary. Only those substances with potential to cause harm will need detailed assessment. Generic assessments can be used provided the assessor checks that the conditions in the workplace, or the way the substance is used do not differ in any significant way from the conditions described in the generic assessment. The assessor will also need to consider the people who might be exposed to the substance as a generic assessment might not take into account teachers with ill health or pupils with asthma etc. COSHH Assessment, a step by step guide: Draw up a complete inventory of the substances in the school detailing how they are used and by whom. At this point consider reducing risks by eliminating processes or substituting substances with less harmful products. Decide which substances need more detailed assessment and number these as a crossreference to the full assessment. The inventory should be regularly reviewed and revised as necessary. Employees must be reminded that only hazardous substances listed on the substance inventory may be used. No hazardous substances may be introduced to the school without Head Teacher authorisation. Consult the material safety data sheets. If these are not available contact the supplier who is legally obliged to provide this information. Transfer the key information from the data sheet to the COSHH risk assessment form checking that all the recommendations for safe storage and use can be met. Again remember to take into account local conditions and individual needs. Many processes and substances will need to be used with ventilation systems such as local exhaust ventilation (LEV), fume cupboards, and forced ventilation systems which ensure a flow of fresh air and the extraction of fumes (for example, where wood work activities are taking place for D&E classes). Where these systems are in the school check that they are working properly and that they have been serviced and tested within the past 14 months. Check that the storage requirements detailed on the material safety data sheet or generic assessment can be met. Fire resistant cabinets, vented stores or other specialist storage may be required. Some classes of chemicals are incompatible and should be stored separately. Flammable liquids must be stored separately from oxidising substances. Storage containers must be maintained in a good condition. Try to minimise the amounts stored. If storage areas have to be at a distance from the work areas ensure that there are safe means of transporting substances available, e.g. trolleys, carrying baskets etc. Make sure that all substances are clearly labelled with standard hazard labels where appropriate. Never decant substances into unlabelled and inappropriate containers! Check that adequate first aid arrangements and spillage kits are readily available. Where personal protective equipment (PPE) is needed ensure it is suitable, that there are adequate supplies properly stored and maintained in good condition. Ensure that items such as goggles and masks can be adjusted to fit the user and are kept clean. Refusal to wear PPE should be a disciplinary offence for staff, and pupils who refuse to wear PPE should be asked to leave the classroom. Finally ensure that staff, pupils and clients have been told about the assessments and given all necessary training and information where appropriate. Information, Instruction and Training Staffs, and where necessary pupils, contractors and visitors, must be given information, instruction and training in the activities they undertake involving hazardous substances. This information should include the results of the risk assessment and must explain the control measures to be used in order to minimise risks. Staff using hazardous substances must be trained in emergency procedures and have ready access to first aid provision. Staffs who carry out risk assessments must receive specific training where this is considered necessary. All new staff must receive induction training that covers the use of hazardous substances where appropriate. The use of hazardous substances must be restricted to trained/experienced authorised persons who are familiar with the safe use of the substances, the hazards associated with the processes and the safety precautions to be observed. Pupils can use substances under the supervision of authorised persons. Pupils using hazardous substances must be adequately supervised and all safety rules explained to them. Monitoring and Review COSHH assessments should be reviewed regularly, and if There is reason to suspect that the assessment is no longer valid; or There has been a significant change in the work to which the assessment relates. If nothing changes and the process does not represent a particularly dangerous activity then COSHH assessments should be reviewed every year. However this may be too long if: There is a significant change in the way that the work is carried out; or There is a change in the teaching team so that the original assessor has left, or The result of the original assessment is no longer valid because new information has come to light, either because of an updated Safety Data Sheet or because of the results of air monitoring or health surveillance. In these cases, an immediate reassessment may be warranted. Where the materials involved are particularly toxic then more frequent reassessment may be necessary on a regular basis as an added check to ensure that the control measures have remained adequate. “Review” does not mean “re-assess”. It simply means checking whether: The process is still carried out in the same way and for the same duration as described on the original assessment; The information on the current health and safety data sheet is the same as when the assessment was carried out; The control measures in use are the same as those recorded previously. The review section on the assessment form can then be signed and dated, with a comment that there are no changes. Disposal All chemicals should be disposed of in a responsible manner. Check the hazard data sheet for the manufacturer's recommendations. Try to avoid disposal problems by buying in quantities appropriate to your needs. Chemicals for disposal should be clearly labeled and placed in a secure, designated area until ready for collection. Do not mix chemicals for disposal. Records That Must Be Kept In order to ensure and demonstrate compliance with the COSHH Regulations the following records must be kept: Substance inventory Risk assessments for each work / teaching activity including any hazardous substances in use. Records of the issue of personal protective equipment and any training in the use and care of the equipment. Health surveillance records where these are applicable. Such records have to be kept for 40 years. Records of maintenance and testing of local exhaust ventilation systems. These records have to be kept for five years. Records of routine testing of fume cupboards and forced ventilation systems. Records of the disposal of chemicals. Records of the routine monitoring of safe working procedures. Training records. Unless otherwise stipulated it is recommended that records be kept for five years.