What are aseptic cartons? - Nicholas School WordPress Network

advertisement

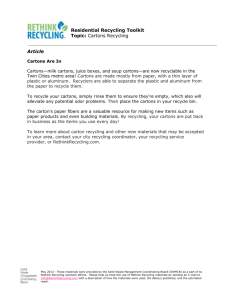

Master’s Project Proposal Cost Benefit Analysis of Aseptic Carton Recycling in Bandung, Indonesia By Marc-Antoine Dunais October 1, 2008 Duke Environmental Leadership Masters of Environmental Management Proposal Approved By: ____________________________________________ Prof. Randall Kramer Nicholas School of the Environment and Earth Sciences Page 1 of 9 1 Introduction Growing populations, rising incomes, and changing lifestyles contribute to severe waste management problems in many urban centers around the world (UNEP-IETC HIID 1996). In low-income Asian countries, a majority of municipal solid is inadequately processed. This leads to serious environmental problems that affect the health of humans and animals and cause economic and welfare losses. These impacts take the form of contamination of surface and ground water through leachate, soil contamination, air pollution through open air incineration of waste, and spreading of diseases by vectors such as rodents (Zurbrügg 2002). Jakarta, the capital of Indonesia, is a sprawling city of 8-10 million people that is located on the northwestern coast of the island of Java. The constant influx of people from all over Indonesia has created severe waste management problems in the city. While some of the waste is processed to landfills, a lot of it is burnt at transfer points, on blocks of land, and in front of household premises. This creates smoke and odor impacts on surrounding areas. Some of the waste is dumped in unauthorized areas and some ends up in rivers, contributing to flooding in the city during the rainy season, as well as pollution of rivers and coastal waters (Pasang H 2007). In response to corporate commitments to environmental sustainability, along with new legal requirements on waste management, several large firms in Indonesia are looking at ways to reduce the waste created from the discarded packaging of their products. Tetra Pak Group, a global leader in the production of aseptic cartons, has been especially proactive in exploring and setting up recycling systems for its products around the world. What are aseptic cartons? Page 2 of 9 Aseptic cartons are made primarily of paperboard (75 percent) with thin layers of plastic (20 percent) and aluminium (five percent), allowing liquid food to be safely stored at room temperature without preservatives (Tetra Pak 2007). One of the leading companies to produce these cartons is Tetra Pak. Source: (Tetra Pak Canada 2006) Recycling of aseptic cartons Tetra Pak’s achievements in recycling its products globally suggest that Indonesia also has the potential to benefit from recycling of aseptic cartons. In 2007, 22 billion Tetra Pak packages (16% of total production (Tetra Pak 2008)) were recycled in 49 market companies worldwide (Tetra Pak). The selection of the most optimal waste management method and technology depends among other on local conditions such as transport distances, collection systems, markets for the recovered material, and legislation. In some countries, cartons must be used for their energy value (e.g. Denmark). Elsewhere, collection systems depend on laws (Germany) or culture (India) (Tetra Pak 2008). However, in many countries there is no infrastructure for managing household waste such as aseptic cartons usefully. Such is the case of Indonesia. Page 3 of 9 1.1 Recycling of Tetra Pak aseptic cartons in Indonesia Efforts to begin a recycling program for aseptic cartons in Indonesia began in earnest at the initiative of Tetra Pak Indonesia in 2003 (Nazech). In collaboration with a local NGO, Dana Mitra Lingkungan (DML) and the Office for Pulp and Paper, or Balai Besar Pulp dan Kertas (BBPK), a parastatal research institution, a range of activities have been initiated. These efforts include: Raising waste scavengers’ awareness of the value of Tetra Pak cartons Initiating education programs at local primary schools to collect used milk cartons for recycling Establishing a Carton Collection Network that links scavengers, recyclers and buyers, with the aim to ensure a continuous supply of discarded aseptic cartons to recycling plants Tetra Pak packing paper was first recycled in Bandung, West Java, in 2004. This activity also succeeded in establishing collector groups in 12 TPS (Intermediate Waste Transfer Stations).The collector groups are organized at seven transfer points, resulting in two to three tons of recovered aseptic carton which are sent to factories. In 2006, the recycling program expanded to East Java and has continued operations ever since (Nazech) while a similar programme has been setup in Bali. Challenges with recycling aseptic cartons in Indonesia Notwithstanding the progress made by Tetra Pak to initiate recycling programs in large urban areas, problems remain in creating a sustainable and efficient system that generates social, financial and environmental benefits. Whereas recycling firms in Bandung and East Java have found markets for selling pulp recycled from the cartons, it is still difficult to recover and sell the polyethylene and aluminum (“polyfoil”) component. With a production of about 1.5 Page 4 of 9 billion packages in Indonesia in 2007, Tetra Pak estimates that it currently only recycles less than one percent of this amount (Akiyama 2008). Another constraint is selling recovered materials at a price that ensures sufficient profit margins for recyclers. Recycling costs need to take into account the purchase of discarded cartons, the resources used to recycle the cartons and their processing. In 2008, research by BBPK, the research institute retained by Tetra Pak to explore opportunities for recovering ALL components of aseptic cartons, revealed that one cost-effective option of using polyfoil from aseptic cartons was to use it as a coagulant. However, it is as yet unclear what market prospects exist for this use (Akiyama 2008). Master’s project scope and focus This Master’s Research project responds to the challenges faced by Tetra Pak Indonesia in promoting the recycling of its aseptic cartons in the city of Bandung. The research will explore the costs and benefits of recycling aseptic cartons and provide recommendations for increasing recycling capacity at BBPK. Research questions Can BBPK’s sales of recovered Tetra Pak materials (pulp and polyfoil) cover all costs arising from sourcing, transporting and recycling discarded cartons and unused Tetra Pak packaging?1 If not, what options are available to BBPK and Tetra Pak to increase recycling capacity? 1 Currently, Tetra Pak pays for the collection and transportation of pre consumer aseptic carton waste from factories to BBPK Page 5 of 9 Objectives 1. Determine the cost of recycling 1 kg of aseptic cartons, factoring in processing expenses (collection, transportation, sorting, cleaning, recycling, storage etc) 2. Based on the results of (1), identify the break even price for selling recovered pulp and polyfoil from aseptic cartons 3. Identify willingness to pay (WTP) by prospective buyers for the components of recovered carton materials (pulp and polyfoil) 4. If there is significant discrepancy between prospective buyer WTP and the selling price for recovered carton materials, identify and assess options available for BBPK to reduce recycling costs of aseptic cartons Methodology 1. Recycling data collection and analysis: This data will be used to determine the real cost of recycling 1 kg of aseptic cartons. Information on costs for collecting, transporting, inspecting, sorting and disposing aseptic cartons from existing collection centers to BBPK, and the current monthly volume of collected aseptic cartons, will be sought from BBPK; costs for collecting and transporting pre consumer waste from Tetra Pak factories to BBPK will be sought from Tetra Pak Indonesia; costs for recycling 1 kg of aseptic cartons (human resources, electricity, maintenance, packaging) will be sought from BBPK; Yields in terms of volume of recovered materials from 1 kg of aseptic cartons will also be sought from BBPK. This information will make it possible to identify the break even price for selling recovered materials from aseptic cartons 2. Willingness to Pay (WTP) study: To identify the WTP of prospective or potential buyers of pulp and polyfoil, the Contingent Valuation Method (CVM) will be applied using an open-ended question format (Hanley N 2001). As a result of this study, it will be determined whether break even selling price and WTP differ at a significant degree. Page 6 of 9 3. Cost Benefit Analysis (CBA): The CBA will assess the costs and benefits of recycling aseptic cartons at BBPK in Bandung. Benefits and costs will be based on a mean price derived from steps one and two, converted into present value terms using an appropriate discount rate. If possible, the benefits will also factor in monetary terms the savings in terms of foregone landfill costs (e.g. based on tipping fees). The CBA will be carried out over the expected lifetime of the recycling facility, and sensitivity analysis will be applied to determine the relative impact of increases in energy prices (including fuel costs for transportation) and personnel wages. The CBA will show whether recycling can be costeffective for BBPK if it internalizes all the processing costs for the aseptic cartons that are used. If the CBA does not show any net benefits for recycling aseptic cartons for the stated WTP, then it will be necessary to consider if increasing recycling capacity at BBPK can reduce the relative operational costs. 4. Recommendations: A set of recommendations will be made for BBPK and Tetra Pak in light of the results of the study. These will outline measures that both parties can implement to make recycling more effective in Bandung. Outputs Written report to be submitted as part of Master’s degree requirement Powerpoint presentation to be submitted as part of Master’s degree requirement Powerpoint presentation to be presented to Tetra Pak Communications and Marketing divisions in Jakarta To the extent that Tetra Pak and BBPK are the main beneficiaries of this research, it is expected that the results will be used by both parties and hopefully by other Tetra Pak offices in other countries. Page 7 of 9 Faculty Advisors The primary advisor for this project is Professor Randall A. Kramer, Nicholas School of the Environment and Earth Sciences. Sources of information and support Data for this research will be sourced from PT. Tetra Pak Indonesia and BBPK. Other sources of information will include Dana Mitra Lingkungan, Yayasan Kontak Indonesia (YSI) and AMPL, two non-profits involved in waste management and recycling. All parties (except for YSI) have already been contacted and are aware and supportive, in principle, of this dissertation. Page 8 of 9 References Akiyama, M. M. (2008). M. M. Akiyama. Jakarta. Hanley N , S. J., B White (2001). Introduction to Environmental Economics, Oxford University Press. Nazech, E. K. M. Program Daur Ulang Kemasan Kertas Tetra Pak. D. M. Lingkungan. Jakarta. Pasang H , M. G., and S Guntur (2007). "Neighbourhood-based waste management: A solution for solid waste problems in Jakarta, Indonesia." Waste Management 27: 14. Tetra Pak. "Environmental Performance." Retrieved July 22, 2008, from http://markets.tetrapak.com/environmentalperformance/content/frset_main.asp?navid=146. Tetra Pak (2007). "Aseptic Carton Structure." http://www.tetrapakrecycling.co.uk/tp_structure.asp. Retrieved July 22, 2008. Tetra Pak (2008). "Recycling Technologies." Retrieved September 10, 2008, from http://www.tetrapak.com/environment/recycling_and_recovery/recycling_technologies/Pages/ default.aspx. Tetra Pak (2008). "Tetra Pak Group Markets." Retrieved July 22, 2008, from http://markets.tetrapak.com/environmentalperformance/content/frset_main.asp?navid=146. Tetra Pak Canada (2006). "Environmental Focus." Retrieved September 28, 2008, from http://www.tetrapak.ca/email/enviro-images-sept/english.html. UNEP-IETC HIID (1996). International Source Book on Environmentally Sound Technologies for Municipal Solid Waste Management, United Nations Environment Programme (UNEP), International Environmental Technology Centre (IETC). Zurbrügg, C. (2002). Urban Solid Waste Management in Low-Income Countries of Asia: How to Cope with the Garbage Crisis. Urban Solid Waste Management Review Session, Durban, Durban, South Africa. Page 9 of 9