Chap 10 Learn Obj

advertisement

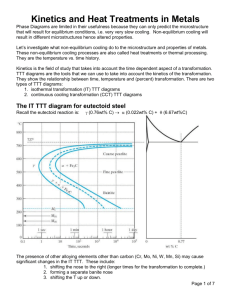

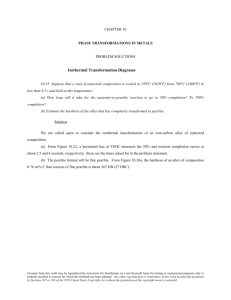

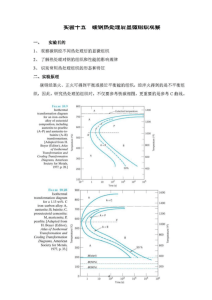

CHAPTER 11 PHASE TRANSFORMATIONS LEARNING OBJECTIVES 1. Cite the two distinct steps that are involved in the formation of particles of a new phase. 2. (a) For nucleation, make a schematic plot of change in free energy versus nucleus radius, and on this plot label the critical radius and the activation free energy. (b) On this same plot sketch another schematic curve for nucleation at a higher temperature. 3. (a) Cite the difference between homogeneous nucleation and heterogeneous nucleation. (b) Sketch and label on the same plot, schematic free energy-versus-nucleus radius curves for both homogeneous and heterogeneous nucleation. 4. (a) Sketch and label on the same plot, schematic nucleation rate-versustemperature curves for both homogeneous and heterogeneous nucleation. (b) Now, for each curve, indicate the degree of supercooling. 5. On a single plot, sketch and label schematic nucleation rate-versustemperature, growth rate-versus-temperature, and overall reaction rateversus-temperature curves. 6. Make a schematic fraction transformation-versus-logarithm of time plot for a typical solid-solid transformation, and then note nucleation and growth regions on the curve. 7. For some solid-solid reaction, given values of the constants k and n, compute the fraction transformation after a specified time. 8. Given a fraction transformation-versus-logarithm of time curve at some temperature, be able to determine the overall rate of the transformation. 9. Define the terms supercooling and superheating. 10. Explain how an isothermal transformation diagram for some alloy is generated from a series of isothermal fraction transformation-versuslogarithm of time curves. 11. Describe the difference in microstructure for fine and coarse pearlites, and then explain this difference in terms of the isothermal temperature range over which each transforms. 12. Briefly describe the microstructures of bainite and spheroidite. 13. Briefly describe martensite in terms of its crystal structure and microstructure. 14. Describe the difference between thermally activated and athermal transformations, and then cite one example of each transformation type. 15. Describe the heat treatment that is necessary to produce martensite, and explain why it forms instead of pearlite or bainite. 16. Given the isothermal transformation diagram for some iron-carbon alloy and also a specific isothermal heat treatment, be able to describe the microstructure that will result. The microstructure may consist of austenite, a proeutectoid phase, fine pearlite, coarse pearlite, spheroidite, bainite, and/or martensite. 17. Given a continuous cooling transformation diagram for some particular alloy and a specific cooling curve, describe the resulting microstructure that exists at room temperature. 18. Define what is meant by the critical cooling rate, and given a continuous cooling transformation diagram, schematically plot the critical cooling curve. 19. Describe or diagram how alloying elements other than carbon alter the continuous cooling transformation diagram for a steel. Now explain, in terms of this alteration, how alloying elements make a steel more "heat-treatable." 20. Schematically diagram how tensile strength, hardness, and ductility vary with carbon content for steels having microstructures consisting of fine and coarse pearlite, and spheroidite. Also, explain why hardness and strength increase with increasing carbon content. 21. Explain briefly why fine pearlite is harder than coarse pearlite, which in turn is harder than spheroidite. 22. Qualitatively compare the mechanical characteristics of bainite and ironcarbon alloys that have other microstructures. 23. Cite two reasons why martensite is so hard and brittle. 24. Describe the microstructure of tempered martensite. 25. Describe the heat treatment necessary to produce tempered martensite. 26. Compare the properties of martensite and tempered martensite, and also explain the properties of tempered martensite in terms of its microstructure. 27. For tempered martensite, schematically plot how hardness depends on tempering time at constant temperature, and briefly explain this behavior. 28. For tempered martensite, schematically plot how yield strength, tensile strength, and ductility depend on tempering temperature (at constant tempering time), and then explain this behavior. 29. (a) Describe the phenomenon of temper embrittlement. (b) Note what procedures cause it to occur. (c) List measures which may be taken to prevent/eliminate it. 30. Describe briefly and qualitatively the procedure necessary to transform one steel microstructure into another (e.g., bainite to spheroidite). 31. (a) Describe the one-way shape memory phenomenon, and (b) Explain the phenomenon in terms of phase transformations. 32. Using a phase diagram, describe the two heat treatments (solution and precipitation) that are involved in the precipitation hardening of a binary alloy. Explain why each heat treatment is carried out and what happens to the microstructure during each heat treatment. 33. (a) Schematically plot how the room temperature yield and tensile strengths, and hardness depend on the logarithm of time for the precipitation heat treatment at constant temperature. (b) Explain the general shape of these curves in terms of the mechanism of precipitation hardening (i.e., dislocation-precipitate particle interactions). 34. Cite two necessary requirements for an alloy to be precipitation hardenable. 35. For polymeric materials, briefly describe, from a molecular perspective, (a) crystallization, (b) melting, and (c) the glass transition. 36. For polymer crystallization, given values of the constants k and n, compute the fraction crystallization after a specified time. 37. Schematically plot specific volume versus temperature for crystalline, semicrystalline, and amorphous polymers, noting glass-transition and melting temperatures. 38. (a) List four characteristics or structural components of a polymer that affect its melting temperature. (b) Note the manner in which each characteristic/component influences the magnitude of Tm. 39. (a) List six characteristics or structural elements of a polymer that influence its glass transition temperature. (b) Now note how each of these characteristics/elements affects the magnitude of Tg.