Anesthesia Machine Checkout Procedure Checklist

advertisement

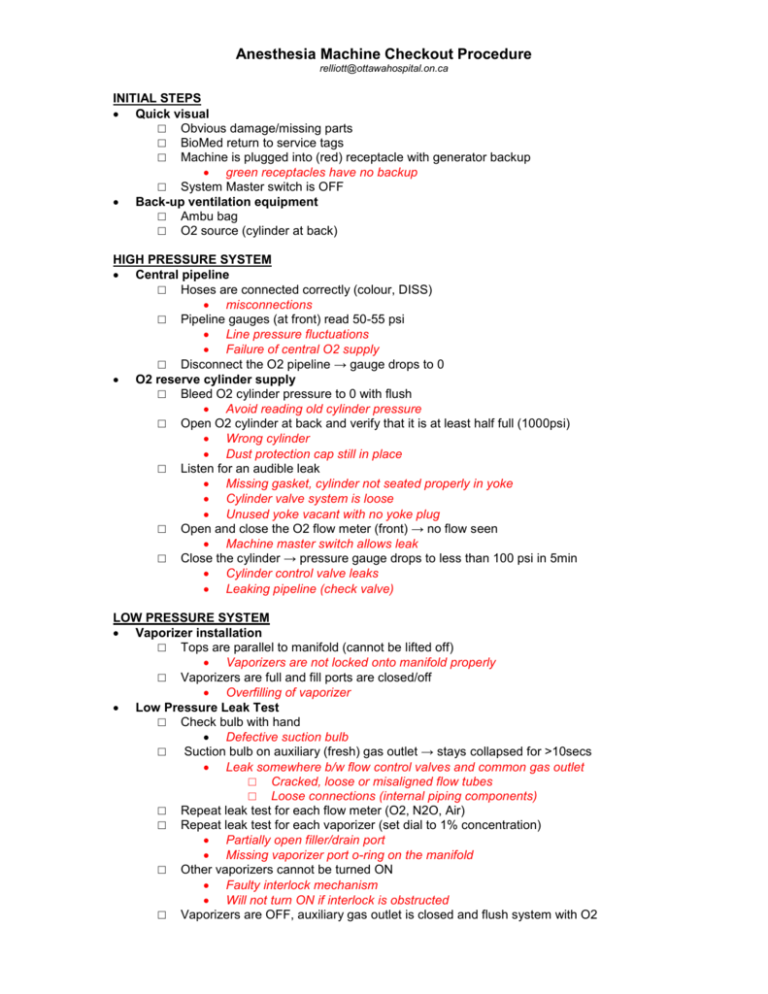

Anesthesia Machine Checkout Procedure relliott@ottawahospital.on.ca INITIAL STEPS Quick visual □ Obvious damage/missing parts □ BioMed return to service tags □ Machine is plugged into (red) receptacle with generator backup green receptacles have no backup □ System Master switch is OFF Back-up ventilation equipment □ Ambu bag □ O2 source (cylinder at back) HIGH PRESSURE SYSTEM Central pipeline □ Hoses are connected correctly (colour, DISS) misconnections □ Pipeline gauges (at front) read 50-55 psi Line pressure fluctuations Failure of central O2 supply □ Disconnect the O2 pipeline → gauge drops to 0 O2 reserve cylinder supply □ Bleed O2 cylinder pressure to 0 with flush Avoid reading old cylinder pressure □ Open O2 cylinder at back and verify that it is at least half full (1000psi) Wrong cylinder Dust protection cap still in place □ Listen for an audible leak Missing gasket, cylinder not seated properly in yoke Cylinder valve system is loose Unused yoke vacant with no yoke plug □ Open and close the O2 flow meter (front) → no flow seen Machine master switch allows leak □ Close the cylinder → pressure gauge drops to less than 100 psi in 5min Cylinder control valve leaks Leaking pipeline (check valve) LOW PRESSURE SYSTEM Vaporizer installation □ Tops are parallel to manifold (cannot be lifted off) Vaporizers are not locked onto manifold properly □ Vaporizers are full and fill ports are closed/off Overfilling of vaporizer Low Pressure Leak Test □ Check bulb with hand Defective suction bulb □ Suction bulb on auxiliary (fresh) gas outlet → stays collapsed for >10secs Leak somewhere b/w flow control valves and common gas outlet □ Cracked, loose or misaligned flow tubes □ Loose connections (internal piping components) □ Repeat leak test for each flow meter (O2, N2O, Air) □ Repeat leak test for each vaporizer (set dial to 1% concentration) Partially open filler/drain port Missing vaporizer port o-ring on the manifold □ Other vaporizers cannot be turned ON Faulty interlock mechanism Will not turn ON if interlock is obstructed □ Vaporizers are OFF, auxiliary gas outlet is closed and flush system with O2 Electrical power and O2 supply failure alarm □ Unplug the machine power from the outlet □ Turn ON master switch □ Verify “Battery Power OK” message □ Plug in power cord → message disappears Battery discharge b/c machine was previously left ON and unplugged from AC outlet □ Turn ON vital signs monitor (allows the gas analyzer to warm up) Verify O2 supply failure alarm Alarm mechanism malfunction □ Drain O2 by pressing the flush □ Listen for the distinctive auditory pattern □ Look for visual message on the vent □ Turn on the O2 cylinder to silence the alarm □ Remove the O2 sensor from the circuit (exposes O2 sensor to room air for later calibration) Test flow meters □ Minimum flows are 25mL/min for O2 and 0mL/min for other gases No flow → broken tip of needle valve □ Test floats through their full range (turn ↓ O2 after turning N2O ↑↓) Sticks → dirt, grease, static Ensure that float does not stick to top of tube □ Inability to provide hypoxic flow rates (N2O:O2 – 3:1 proportioner) by turning ↑N2O and watching for proportional ↑ in O2 Linkage broken or gear stop misaligned □ Turning vaporizers ON does not lower gas flows Obstruction in vaporizer or manifold □ Ensure that low O2 pressure stops N2O flow, but NOT Air → Set all 3 floats to mid-range → Close O2 cylinder → Push O2 flush O2 supply failure alarm sounds (when O2 supply pressure is at 30 psi) and N2O float drops (when O2 supply pressure is at 20 psi), while Air continues □ Close all 3 gas flow controls □ Reconnect the O2 pipeline Verify pipeline pressure (50-55 psi) BREATHING SYSTEM Calibrate the O2 monitor □ Ensure that the monitor reads 21% with sensor in room air Faulty fuel cell if unable to calibrate □ Verify low O2 alarm by breathing on the sensor through mask Crossover b/w O2 supply and other gas (hosp piping, hoses or in gas machine) □ Reinstall sensor in circuit □ Flush breathing system with O2 → monitor should read >95% Wrong gas in central supply/cylinder Check initial status of breathing system □ Set selector switch to “Bag/APL” □ Circuit is complete, undamaged, unobstructed Manufacturing defects □ CO2 absorbent is adequate (colour, quantity) □ Attach gas sampling line to the circuit □ Set all flows to 0/min Check the function of unidirectional valves □ Attach the spare breathing bag to the inspiratory outlet and close the APL valve completely □ Fill both the test bag and reservoir bag with O2 flush until pressure gauge reads 35cm H20 → pressure should hold if both valves are competent Missing, incompetent valves or incorrectly seated □ Open APL valve → pressure holds, but only the reservoir bag deflates If the reservoir bag deflates before opening APL valve, the expiratory valve is leaking □ If needed, repeat the test on the expiratory inlet with the inspiratory outlet occluded Leak test: Bag/APL valve circuit □ Set the selector switch to Bag/APL □ Close the APL valve and attach the spare breathing bag to the Y-piece □ Inflate the bag with O2 flush to just <40cm H2O □ Circuit pressure holds steady for >10secs □ Ventilator bellows does not move NUMEROUS POSSIBLE LEAK SITES Auxiliary FGF outlet left open CO2 canister not locked into position Faulty canister seals or granules are preventing good seal CO2 drain plug partially open Unidirectional valve housing loose O2 sensor not firmly seated in port or sensor housing is cracked Flow sensor housing cracked Pressure sensing tubing from gauge is not tightly connected (internal) Leak in breathing bag, circuit hoses Unused sampling ports not capped Faulty selector switch → allows cross-over of gas into ventilator circuit Check APL valve and scavenging system □ With APL valve still closed and circuit occluded, squeeze inflated bag until pressure reaches ~70cm H2O → high pressure alarm sounds with 40cm H2O limit is exceeded → APL valve partially releases and reservoir bag on scavenger fills Improperly adjusted APL valve (set to release either too high or too low) No alarm → upper limit is set too high □ Open APL valve slowly until pressure drops below 20cm H2O, then stop → pressure should stabilize and hold → sustained pressure alarm stops Cannot adjust pressure (valve sticking) Sustained pressure limit is high – max set at 30cm H2O □ Open APL valve fully, flush occluded circuit with O2 → circuit pressure stays <10cm H2O Hose from the circuit to scavenger is blocked → scavenging reservoir bag fills and then positive pressure relief valve releases Faulty positive pressure relief valve on scavenger □ APL valve fully open, flows are set to min and circuit is still occluded → circuit breathing bag does not deflate Too much vacuum and faulty negative pressure relief valve → scavenging reservoir bag does deflate No vacuum Needle valve closed VENTILATOR SYSTEM Test automatic ventilation system □ Selector switch set to Ventilator – all flows set to min, breathing bag on Y-piece Defective ventilator relief valve □ Fill bellows with O2 flush b/w ventilator breaths → pressure should not exceed 15cm H2O → release flush Relief valve does not close to allow bellows to fill completely Bellows housing is not fastened tightly □ Set appropriate ventilator parameters for next patient → inspiration: bellows delivers correct tidal volume → expiration: bellows fills completely → volume monitor is consistent with the ventilator → proper action of unidirectional valves Drive gas hose is not firmly attached Connection from absorber to bellows is leaking Volume sensor is faulty Valves stick or do not seat properly □ Remove breathing bag from Y-piece while ventilator is still working □ Low pressure alarm sounds (“Cannot drive Bellows”) until breathing bag is replaced Alarm faulty Ventilator senses pressure 4-9cm H2O with breathing bag off (obstruction) □ Set selector switch back to Bag/APL (turns ventilator OFF) when bellows is fully inflated □ Ventilator bellows does not drift downward Leak somewhere Test manual ventilation system □ Switch in Bag/APL mode □ Ventilate manually and assure inflation and deflation of artificial lung and appropriate feel of system resistance and compliance Faulty APL valve Incorrect pressure adjustment □ Remove second breathing bag from Y-piece FINAL STATUS CHECK Gas machine and breathing systems □ Vaporizers off □ Selector switch to Bag/APL and adjust APL valve to MIN □ Set O2 flow to 3L/min (other gases to 0) □ Attach face mask to Y-piece and through a surgical mask breath in and out through the circuit as a final test □ Set O2 flow to minimum Monitors □ Check that capnometer registers CO2 from your breath □ Apnea alarm sounds after appropriate interval (check alarm settings) □ Check oximeter on your own finger (check alarm settings) □ Make sure manual BP cuff is available □ Patient suction is adequate (thumb test) □ Flashlight available.