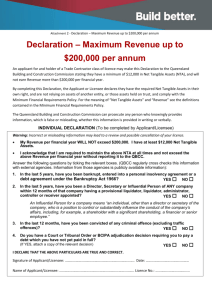

EXAMPLE ONLY

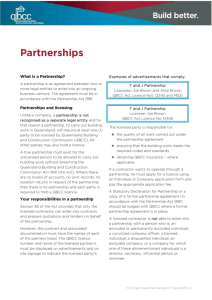

advertisement

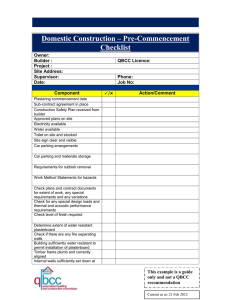

Domestic Construction – Timber Framing – Completion Checklist Owner: Builder: Project: Site Address: Supervisor: Date: Component QBCC Licence: Phone No: Job No: / Action/Comment Check plans and contract documents for any variations Room set outs and wall locations consistent with approved plans Wall frame plumb and straight sufficient to receive wall finishes Tie down fixings to slab at least 50mm from slab edge Bottom plate not overhanging slab edge by more than 10mm. All wall bracing in position as required on approved plans and properly fixed including tie-down rods. Nails not overdriven Roof and truss point loads supported and blocked if required Truss layout consistent with truss plan and fixed at correct centres Trusses plumb (max allowable 50mm or height/50) and not bowed (max allowable 50mm or bowed section/200) Saddle trusses properly fixed to supporting truss top chord Roof tie down in accordance with approved plans and truss manufacturers requirements Strengthening for installation of solar hot water system installed Roof steel bracing properly installed in accordance with truss plan. Where fixed to wall frame bracing nailed flat to avoid interfering with wall sheet or cornice Truss bottom chord bracing installed where suspended ceilings or metal furring channel ceiling battens used. This example is a guide only and not a QBCC recommendation Current as at: May 2011 Domestic Construction – Timber Framing – Completion Checklist Owner: Builder: Project: Site Address: Supervisor: Date: Component QBCC Licence: Phone No: Job No: / Action/Comment Binders installed Transfer noggings installed connecting bracing walls to trussed roof frame Non load bearing walls set down a minimum of ceiling batten depth + 10mm from the level of external load bearing walls. Non load bearing walls connected to trusses with slotted wall brackets where required. Entry bulkheads straight and level Ceilings nogged for plaster sheet joins and at change of direction Internal door opening sizes consistent with plans Bottom plate removed from all internal doorways Internal bulkheads installed plumb and straight Plumbing duct and vent pipe framing plumb and straight Lintel sizes as shown on approved plan Windows fixed in accordance with window manufacturers requirements or Aust Window Assoc. recommendations Windows plumb and level Bath properly framed up and supported with appropriate clearance for tiles and sheeting Nogging installed for WC cistern and toilet roll holder Nogging installed for ensuite cistern and toilet roll holder Nogging installed for bathroom towel rails Nogging installed for ensuite towel rail Noggings installed for panel lift door Noggings installed for clothes dryer Other noggings required and installed This example is a guide only and not a QBCC recommendation Current as at: May 2011 Domestic Construction – Timber Framing – Completion Checklist Owner: Builder: Project: Site Address: Supervisor: Date: Component QBCC Licence: Phone No: Job No: / Action/Comment Manhole correctly positioned & framed. Fascia fixed and aligned properly Fascia properly aligned for external cladding or brickwork where there is no eaves overhang Trimmers and battens installed to eaves to properly fix eaves lining Temporary bracing removed Windows checked to ensure they are not damaged House swept and clear of debris Site clear of rubbish Frame inspection passed Sub-Contractor: QBCC Licence: This example is a guide only and not a QBCC recommendation Current as at: May 2011