B3 permanent bracing Carter

advertisement

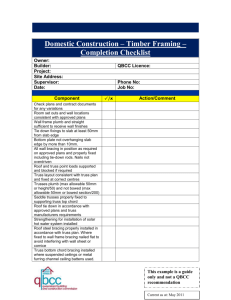

Welcome to “Permanent Bracing, B3 & Risk Management” Presented By: Marvin Strzyzewski, PE, Truss Engineering Company Jason Owens, MiTek Industries, Inc. Sponsored By: Carter Components CONTACT INFO HERE!!!!! 1 Outline Permanent bracing Overview Challenges Collaborative projects BCSI-B3 Summary Sheet Valuable risk management tool 2 Importance Crucial to safety & overall performance Disregarding = performance issues or collapse Everyone benefits from correct permanent bracing. 3 Loads in Plane 4 Lateral Loads WIN D C I M S SE I AD LO 5 Permanent Building Stability Bracing The lateral force resisting system for the building that resists forces from gravity, wind, seismic, and/or other loads. 6 Purpose of Bracing Support truss & its members at right angles so they will stay in their design position 7 Bracing Importance: Prevents buckling Helps maintain truss spacing Resists & transfers lateral loads 8 Temporary vs. Permanent Temporary restraint/bracing Provides support during installation Permanent restraint/bracing Provides during the lifetime of the structure Resists applied loads Temporary restraint/bracing can be used to permanently restrain and brace a truss. 9 Truss System Bracing 10 Challenges Challenges include: Misunderstanding of requirements Assumption it’s someone else’s responsibility Getting paid Re q en m e ui r ts $ 11 Challenges Misunderstandings Î Friction Doesn’t serve the interests of the: Client Performance & safety of structure Professionals’ liability Everyone benefits from understanding permanent bracing. 12 Collaborative Projects Design Community SBC Industry • Improved process • Comprehensive approach • Clearer language, requirements, etc 13 Collaborative Projects Projects include: IBC 2006 & 2007 supplement ANSI/TPI 1-2007 Chapter 2 BCSI and BCSI-B3 Summary Sheet 14 Design Responsibilities Permanent Bracing Design Î Registered Design Professional 2.3.2.4 Required Information in the Construction Documents. The Registered Design Professional for the Building.shall provide information sufficiently accurate and reliable to be used for facilitating the supply of the Structural Elements and other information for developing the design of the Trusses for the Building, and shall provide the following: (g) Permanent Building Stability Bracing; including Truss anchorage connections to the Permanent Building Stability Bracing. Design Responsibilities TPI 1-2007 2.3.3 REQUIREMENTS FOR THE PERMANENT MEMBER RESTRAINT/ BRACING OF TRUSS SYSTEMS TPI 1-2007 2.4.3 REQUIREMENTS FOR THE PERMANENT MEMBER RESTRAINT/ BRACING OF TRUSS SYSTEMS TPI 1-2007 CHAPTER 2: STANDARD RESPONSIBILITIES IN THE DESIGN AND APPLICATION OF METAL PLATE CONNECTED WOOD TRUSSES 16 Terminology One who designs trusses Truss Design Engineer – RDP required Truss Designer – RDP is not required (Building Designer) 17 Component Design 18 Truss-to-Truss Connections 19 Permanent Restraints Truss Design Engineer/Truss Designer specifies the location of permanent restraints required for individual trusses. 20 Truss Submittal 21 Registered Design Professional ANSI/TPI 1-2007 2.4.2.3 Review Submittal Package. The Building Designer shall review the Truss Submittal Package for compatibility with the Building design. All such submittals shall include a notation indicating that they have been reviewed and whether or not they have been found to be in general conformance with the design of the Building. 22 Restraint Design 23 Restraint Load Transfer 24 Lateral Load Transfer 25 Ceiling Diaphragm 26 Roof Diaphragm 27 Truss-to-Girder The above figure is a unique case that may require more forces to be considered. 28 Truss-to-Bearing 29 Design Responsibilities TPI 1 is referenced in: IBC IRC Design Responsibilities Follows language in BCSI BCSI – method of permanent restraint/bracing BCSI can be referenced on Truss Design Drawings 31 Responsibilities Permanent Building Stability Bracing Responsibility of the RDP for the Building/Building Designer Truss Design Drawings provide information regarding assumed support for the truss 32 Truss Placement Diagram 33 Collaborative Projects Documents address: Real-world issues Contractual relationships BCSI-B3 Î Risk management tool 34 B3 Summary Sheet Standard industry bracing details & guideline text for: Top chord plane Bottom chord plane Web member plane 35 B3 Summary Sheet B3 also covers: Web member reinforcement Gable end frame restraint & bracing Restraint & bracing of piggyback trusses 36 Multiple Formats 11" x 17" 18" x 24" CAD format for electronic plans 37 Incorporate into Plans Formats offer flexibility Print plans on reverse side Incorporate in electronic plans Ensures installers receive bracing information 38 Incorporate into Plans Document that the RDP or Building Designer provided: Standard industry bracing details 39 Incorporate into Plans B3 outlines: Additional bracing is required beyond what is included in the TDD Valuable risk management Consistent message 40 BCSI-B3 Summary Sheet 41 Proper Installation Proper installation and bracing is very important 42 Temporary & Permanent With planning: Much temporary bracing can be used as permanent bracing More efficient 43 Advance Meeting Hold a meeting to: Ensure permanent bracing is identified Review construction documents Truss Submittal Package Truss Design Drawings Truss Placement Diagrams BCSI, B3 44 Advance Meeting Site-specific conditions Truss member permanent bracing plans Special permanent bracing conditions 45 Long Span Trusses B3 applies to many projects For trusses spanning > 60' Consult a Registered Design Professional 46 Materials Common materials: Wood structural panels Gypsum board sheathing Stress-graded lumber Proprietary metal products Metal purlins & straps 47 Materials Specifics provided by the RDP for the Building or Building Designer 48 Attachment Requirements Minimum attachment requirements 49 3 Planes Bracing required is required within: Top chord plane Bottom chord plane Web member plane Without permanent bracing, all members will buckle 50 Truss Design Drawing Provides information on support of the top chord TC: Sheathed or 6ft oc purlins 51 Truss Design Drawing Use rows of Continuous Lateral Restraint with Diagonal Bracing See Truss Design Drawing for support of bottom chord BC: Rigid ceiling or 10ft oc CLR 52 Truss Design Drawing 53 Web Member Web member permanent bracing Wind & seismic forces 54 Diagonal Bracing Install 45° to Continuous Lateral Restraint Repeat every 20' or less 55 Lateral Restraint Always diagonally brace the Continuous Lateral Restraint. 56 Web Buckling Methods for resisting web buckling 57 Web Buckling When specific information isn’t provided 58 Web Member Restraint Specified on TDD Resists buckling under vertical loads 59 Web Member Restraint Additional bracing transfers lateral loads Provided by the RDP for the Building/Building Designer 60 Design Tables Design tables & details Assist the RDP for the Building/Building Designer Based on design assumptions Do not replace flow of loads analysis 61 Gable End Frame Profile matches adjacent trusses Bottom Chord Plane restraint/bracing Exception: special bracing for an end wall 62 Gable End Frame Prohibited by some building codes Proper bracing can be impossible Special bracing may be required by the RDP for the Building/Building Designer 63 Sway Bracing Installed at RDP of the Building’s/ Building Designer’s discretion Stabilized the truss system Minimizes lateral movement 64 Sway Bracing Installed continuously Distributes loads 65 Piggyback Assemblies Use rows of 4x2 lumber Add structural sheathing or bracing frames 66 Piggyback Assemblies See Truss Design Drawing Spacing for Lateral Restraint Thickness of restraint Connection requirements 67 Piggyback Assemblies Repeat at 10' o-c, or as specified 68 Summary 69 B3 & BCSI B3 and BCSI booklet Provide standard industry details & guidelines Review planes of the truss Offer guidelines for special conditions 70 B3 Summary Sheet Condenses information Can be incorporated into plans Ensures installers receive crucial bracing information www.sbcindustry.com/b3.php 71 BCSI Produced by SBCA & TPI Industry’s guide to jobsite safety & truss performance www.sbcindustry.com/bcsi.php 72 B3 & BCSI www.sbcindustry.com 608/274-4849 73 Cold-Formed Steel CFSB3 Summary Sheet CFSBCSI booklet Based on concepts of wood versions www.cfsc.sbcindustry.com 74 BCSI – Best Practices for Handling, Installing, Bracing & Restraining For more info on: Truss repairs Girders Fall protection Jobsite storage Truss handling Toe-nailing for uplift Temporary bracing Construction loading 75 www.sbcindustry.com 76