Supplement - AIP FTP Server

Thickness dependence of the exchange bias in epitaxial manganite bilayers

A. L. Kobrinskii and A. M. Goldman

School of Physics and Astronomy, University of Minnesota

116 Church St. SE, Minneapolis, Minnesota 55455, USA

M. Varela and S. J. Pennycook

Materials Science and Technology Division, Oak Ridge National Laboratory

Oak Ridge, Tennessee 37831, USA

Supplementary materials

Conclusions presented in the main text regarding the quality of the studied samples are based to a large extent on the results of the scanning transmission electron microscopy

(STEM) and electron energy loss spectroscopy (EELS) measurements. The following supplementary materials provide additional STEM-EELS data, analysis, and discussion that may be of interest to readers but which go beyond the level of detail sufficient from the standpoint of the main subject of the paper – the effect of the AF layer thickness on the exchange bias. Here, figures are numbered as S1, S2, etc. to distinguish from those in the main text.

As far as the sharpness of the interfaces in the samples that were studied is concerned, we would like to note the particular shape of specimens prepared for STEM. These are wedges that are substantially thicker at the substrate end than at the top surface. This causes the largest electron beam broadening to be found at the lower (i.e. substrate-film) interface, which in turn makes this interface seem wider than the one between the two manganite layers (the F-AF interface) both on Z-contrast STEM images and in EELS elemental profiles.

Physical widths of the interfaces.

In the Z-contrast images of Fig. 2, the film-substrate interface appears to be slightly (by two or three atomic planes) broader than the F-AF interface. This is readily seen from the line traces (Figs. S1 and S2). Indeed, the profile of the film-substrate interface (Fig. S1) seems a couple of planes broader than the F-AF one (Fig. S2). However, differences in widths of this magnitude are what one may expect from a thicker sample or a differently strained interface. The horizontal scale in line traces is in pixels, not in nm.

Calcium content profile and chemical widths of the two interfaces.

The Ca signal in Fig. 5 of the paper does not change at the substrate-film interface as sharply as it does at the F-AF interface. However, the Ca-based chemical width of the substrate interface is still within 4 to 5 unit cells (clearly below 2 nm). Figure S3 shows a magnified view of the elemental profiles at the film-substrate interface. The Ca profile is very noisy, but the average shapes and tails of all the elemental signal profiles are all very similar (with widths below a couple of nm). The data are consistent with an atomically sharp interface if we take into account the expected extent of beam broadening.

We also note that these elemental profiles show normalized integrated intensities. Calcium is the chemical species with the lowest nominal concentration (33%) in the F layer. The

nearly 10% noise observed in Ca signal only amounts to 3% (

x = ±0.03) of the A site dopant in actual Ca composition. For La, the noise level is lower, less than 5% in normalized intensity units. But given the higher nominal La content of 67% in this layer, a

5% noise level also amounts to approximately the same value of

x = ±0.03. Additional factors contributing to substantial noise include carbon contamination of the sample surface, which may cause background subtraction related artifacts because the C K edge is just below the Ca L edge in EELS spectra, and the presence of amorphous layers at the surface, which are a byproduct of the ion milling process. Thus, the enhanced noise level in the Ca signal profile is not unexpected.

The fact that the change in Ca signal occurs over a broader region at the substrate-film interface than at the F-AF interface does not necessarily mean a chemically broader interface but rather is most likely to be attributed to the particular thickness profile of the

STEM-prepared specimens. As it has been already mentioned, they are thicker near the substrate. Hence, a larger electron beam broadening occurs at the substrate-film interface, which makes the interface appear to be broader.

Manganese valence.

The main text briefly describes the essential steps in evaluating the Mn valence. We used the O K edge, namely, the energy separation

E between the pre-peak at the onset of the O K edge and the adjacent main peak. Figure S4 illustrates in detail how this parameter is obtained from the O K edge fine structure. The value of

E has been found to increase linearly with Ca doping, and hence, with Mn oxidation state, in La x

Ca

1-x

MnO

3

(LCMO) bulk samples. This behavior is explained in detail in a separate manuscript by M. Varela and coworkers that is currently under review.

We now would like to consider in more detail the effect of the reduced Mn valence near the substrate surface. Since the substrate material contains oxygen, the signal from the substrate adds to that from the sample near the film-substrate interface, thus interfering with the

E measurement in that region, particularly having in mind the larger beam broadening expected there. The interface position was inferred from EELS as the location where the Ti L and Mn L profiles intersect, at which point roughly 50% of the beam is still in the F layer.

The

E parameter in SrTiO

3

is larger than in the F layer as one can see from the data points at the very right end of the top left panel of Fig. S4(b). We can conclude that any addmixing from the SrTiO

3

O K signal should increase the

E value measured near the interface. Hence, averaging or intermixing signals from the film and the substrate can be ruled out as a possible explanation. Similarly, the observed dip of

E near the substrate cannot be attributed to the interface roughness because it should result in further smearing and averaging of the properties of two adjacent materials. We further note that the elemental profiles (Fig. 5 of the main text) set an upper bound of 2nm for the width of a region where some manganite-titanate interdiffusion could occur. This is well below the

E decay length at the substrate-film interface of about 4 nm in the upper panel of Fig. S4(b).

Therefore, any possible interdiffusion cannot account for the observed

E behavior either.

In summary, the dip in the Mn valence near the interface is real and inconsistent with roughness or interdiffusion. However, this issue has no relevance to the paper, since the F layer has the expected properties well before the F-AF interface is approached.

AF substrate

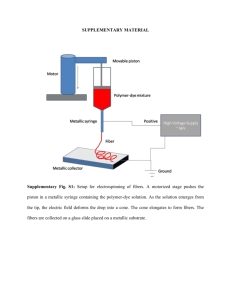

Figure S1. Z-contrast image of the F-AF interface. The inset shows the intensity profile extracted from the region marked by a white box on the image.

AF

F

Figure S2. Z-contrast image of the film-substrate interface. The inset shows the intensity profile extracted from the region marked by a white box on the image.

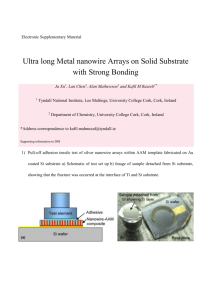

Figure S3. Normalized integrated intensities at the film-substrate interface adapted from Fig. 4. The

Ca profile has been normalized here to unity for comparison purposes.

(a) (b)

Figure S4. (a) EELS O K edge of a LCMO sample showing the pre-peak (fitted with a Gaussian curve in red) and the adjacent peak (blue Gaussian curve); the peak separation is

E (adapted from

M. Varela et al.

, Phys. Rev. B, submitted). (b) The upper panel shows the value of

E obtained by scanning across an AF-F-substrate structure. The lower panel shows the Mn oxidation state value derived from

E. In both cases the black data points show the result of analyzing a raw spectrum and the red data points that of the same spectrum after applying the principal component analysis

(to remove random noise). The approximate interface positions are marked with vertical dotted lines.