Manual Handling/ Ergonomics

advertisement

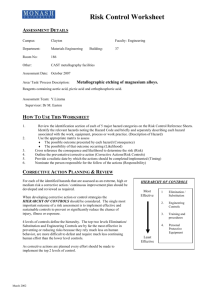

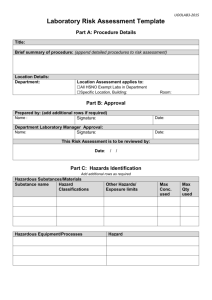

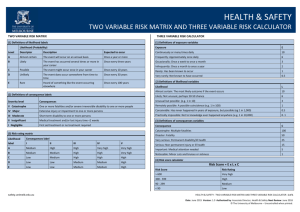

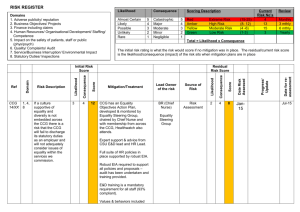

Occupational Health, Safety & Environment Risk Control Worksheets ASSESSMENT DETAILS Campus: Clayton Faculty: Engineering Department: Materials Engineering Building: 37 Room No: G186 Other: Assessment Date: Area/ Task/ Process Description: 1. Electropolishing for metallography using electrolyte containing Nitric Acid and Methanol Assessment Team: Investigator Name of Researcher Name of Project Supervisor Name of Academic in charge Phone # Signature HOW TO USE THIS WORKSHEET 1. 2. 3. 4. 5. 6. Review the identification section of each of 5 major hazard categories on the Risk Control Reference Sheets. Identify the relevant hazards noting the Hazard Code and briefly and separately describing each hazard associated with the work, equipment, process or work practice. (Description of Hazard) Use the appropriate matrix to assess The possible outcome presented by each hazard (Consequence) The possibility of that outcome occurring (Likelihood) Cross reference the consequence and likelihood to determine the risk (Risk) Outline the preventative/corrective action (Corrective Actions/Risk Controls) Provide a realistic date by which the actions should be completed/implemented (Timing) Nominate the person responsible for the follow of the actions (Responsibility) CORRECTIVE ACTION PLANNING & REVIEW HIERARCHY OF CONTROLS For each of the identified hazards that are assessed as an extreme, high or medium risk a corrective action / continuous improvement plan should be developed and reviewed as required. Most Effective When developing corrective action or control strategies the HIERARCHY OF CONTROLS should be considered. The single most important outcome of a risk assessment is to implement effective and sustainable controls to prevent or significantly reduce the chance of injury, illness or exposure. 4 levels of controls define the hierarchy. The top two levels Elimination/ Substitution and Engineering Controls are by far the most effective in preventing or reducing risks because they rely much less on human behavior, are more difficult to defeat and require much less continuing human effort than the lower level controls. As corrective actions are planned every effort should be made to implement the top 2 levels of control. Least Effective 1 Elimination / Substitution 2. Engineering Controls 3. Training and procedures 4. Personal Protective Equipment 1. Preparation of Electrolyte – Nitric Acid Hazard No. Description of Hazard Corrective Actions/ Risk Controls Contact with combustible material may cause fire. C1 Consequence C1 Likelihood L5 Keep locked up. Keep away from sources of ignition. Risk Low Timing All times Harmful by inhalation. C1 Consequence C2 Wear suitable protective clothing including gas mask, safety glasses, gloves, lab coat and closed-toe shoes. Likelihood L3 Risk Medium Timing Causes severe burns. C1 Consequence C2 Likelihood L3 Risk Medium All times in lab Risk of serious damage to eyes. Consequence C2 Likelihood L3 Risk Medium C1 Consequence C2 Likelihood L5 User Responsibility User Wear suitable protective clothing gas mask, including safety glasses, gloves, lab coat and closed-toe shoes. Risk Low Timing All times in lab March 2010 Responsibility Avoid contact with eyes. Wear suitable protective clothing including safety glasses, gloves, lab coat and closed-toe shoes. Timing All times in lab Inhalation and/or ingestion may produce health damage. Responsibility User Do not breathe gas/ fumes/ vapour/ spray. Wear suitable protective clothing including safety glasses, gloves, lab coat and closed-toe shoes. Timing All times in lab C1 Responsibility User Responsibility User Hazard to due spill Consequence C3 Likelihood L3 Risk Low C1 When it spills: - Clean up all spills immediately. - No smoking, naked lights, ignition sources. - Avoid all contact with any organic matter including fuel, solvents, sawdust, paper or cloth and other incompatible materials, as ignition may result. - Avoid breathing dust or vapours and all contact with skin and eyes. - Control personal contact by using protective equipment. - Contain and absorb spill with dry sand, earth, inert material or vermiculite. - DO NOT use sawdust as fire may result. - Scoop up solid residues and seal in labelled drums for disposal. - Neutralise/decontaminate area. Timing Immediately Responsibility User 2. Preparation of Electrolyte – Methanol Hazard No. Description of Hazard Corrective Actions/ Risk Controls Highly flammable. C1 Consequence C1 Keep locked up. Keep away from sources of ignition. Likelihood L5 Risk Low Timing All times Toxic by inhalation in contact with skin and if swallowed. C1 Consequence C2 Likelihood L3 Wear suitable protective clothing including safety glasses, gloves, lab coat and closed-toe shoes. Risk Medium Timing C1 Toxic: danger of very serious irreversible effects through inhalation in contact with skin and if swallowed. Consequence C2 Likelihood L3 All times in lab Responsibility User Do not breathe gas/ fumes/ vapour/ spray Wear suitable protective clothing including gas safety glasses, gloves, lab coat and closed-toe shoes. Risk Medium Timing March 2010 Responsibility User All times in lab Responsibility User Risk of serious damage to eyes. C1 Consequence C2 Wear suitable protective clothing including safety glasses, gloves, lab coat and closed-toe shoes. Likelihood L3 Risk Medium Timing All times in lab Hazard to due spill Consequence C3 Likelihood L3 Risk Low C1 Responsibility User When it spills: - Remove all ignition sources. - Clean up all spills immediately. - Avoid breathing vapours and contact with skin and eyes. - Contain and absorb small quantities with vermiculite or other absorbent material. Timing Immediately Responsibility User 3. Electropolishing Hazard No. Description of Hazard Corrective Actions/ Risk Controls Risk of electrolyte flying to eyes. Use of safety glasses. H1 Consequence C2 Likelihood L5 Risk Low Electrical hazard associated with electrical equipment. Risk reduced by applying corrective actions. H4 Consequence C1 Likelihood L5 Timing All times in lab Responsibility User Maintain electrical equipment tested and tagged to guarantee safety while using it. Inspect leads, equipment, etc before using to detect any damage. Report any failure conditions. Risk High Timing Before and during process Responsibility User and lab supervisor C1 March 2010 Cleaning samples with the spray gun, ethanol fumes are produced which are harmful when inhaled. Use of the fume cabinet during ethanol cleaning of samples. Ensure good ventilation of fumes checking cabinet before use. Consequence C5 Timing During operation Likelihood L4 Risk Low Responsibility User Ethanol may cause irritation to skin and eyes. It may cause dermatitis after long exposure. C1 Consequence C3 Likelihood L4 Risk Low Use of safety glasses, disposable gloves, laboratory coat and enclosed shoes. Clean up spills and wash hands after use. All tasks involving ethanol should be conducted within the cupboard. Wash hands or any other possible part exposed immediately after contact occurs. Timing During operation Electropolishing process involves the use of dilute corrosive chemicals. Splashes may result in injury requiring first aid treatment. H1 Consequence C4 Likelihood L5 Risk low No change to existing controls. All work should be done in the fume cupboard. Wear proper protective equipment such as safety glasses, latex gloves, lab coat and close toe shoes. Use minimal quantity of etchant. Timing H1 March 2010 Responsibility operator No change to existing controls. Carry out all transfer of reagents and etching in fume cupboard. Wear disposable gloves and safety glasses. Consequence C3 Timing Likelihood L5 Risk low Consequence C2 Likelihood L4 immediately Responsibility operator No change to existing controls. Wear disposable gloves and safety glasses whilst etching. Wash hands thorough after use and before eating. Risk low Timing H1 immediately Inhalation of acid fumes during electropolishing, or transfer between containers. Skin absorption of picric acid. Splashes on skin. H1 Responsibility User immediately Responsibility operator Possible spill of electrolyte when transferring between ventilated cabinet to fume cupboard. Risk of inhalation and skin contact. If a spillage occurs, wash thoroughly with water until there is no residue left. Wear latex gloves to avoid skin contact. Call the safety instructor and leave the room, or use spill kit. Consequence C2 Timing Likelihood L4 Risk low immediately Responsibility operator 4. Mg and Mg Alloys Hazard No. Description of Hazard Corrective Actions/ Risk Controls Contact with water liberates extremely flammable gases C1 Consequence C2 Likelihood L3 Risk Medium Never add water to this product. Keep away from sources of ignition. Ensure that extinguisher is placed in the lab. Timing All times Spontaneously flammable in air C1 Consequence C2 Likelihood L4 Risk Medium Mg dusts, chips, or powders incurred by grinding are flammable. Likelihood L4 Risk Medium All times in lab User Responsibility User When the fires occurs: - Mg dust fires need to be smothered with sand, inert dry powders. - DO NOT USE WATER, CO2 or FOAM. - Use DRY sand, graphite powder, dry sodium chloride basedextinguishers, G-1 or Met L-X to smother fire. - Confining or smothering material is preferable to applying water as chemical reaction may produce flammable and explosive hydrogen gas. -Chemical reaction with CO2 may produce flammable and explosive methane. - If impossible to extinguish, withdraw, protect surroundings and allow fire to burn itself out. Timing Immediately Prepared by: … ………..Date: ……………………Signed:…………………….. March 2010 Responsibility Never add water to this product. Keep away from sources of ignition. Ensure that extinguisher is placed in the lab. Ensure that extinguisher is placed in the lab. Timing All times C1 User Keep away from sources of ignition. Ensure that extinguisher is placed in the lab. Timing Consequence C2 Responsibility Responsibility User