Reference Documents - Faculty of Engineering

advertisement

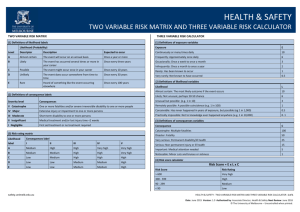

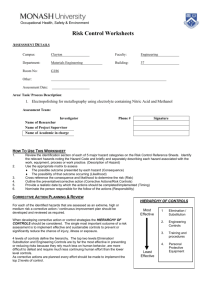

Risk Control Worksheet ASSESSMENT DETAILS Campus: Clayton Faculty: Engineering Department: Materials Engineering Room No: 186 Other: CAST metallography facilities Building: 37 Assessment Date: October 2007 Area/ Task/ Process Description: Metallographic etching of magnesium alloys. Reagents containing acetic acid, picric acid and orthophosphoric acid. Assessment Team: Y.Lizama Supervisor: Dr M. Easton HOW TO USE THIS WORKSHEET 1. 2. 3. 4. 5. 6. Review the identification section of each of 5 major hazard categories on the Risk Control Reference Sheets. Identify the relevant hazards noting the Hazard Code and briefly and separately describing each hazard associated with the work, equipment, process or work practice. (Description of Hazard) Use the appropriate matrix to assess The possible outcome presented by each hazard (Consequence) The possibility of that outcome occurring (Likelihood) Cross reference the consequence and likelihood to determine the risk (Risk) Outline the preventative/corrective action (Corrective Actions/Risk Controls) Provide a realistic date by which the actions should be completed/implemented (Timing) Nominate the person responsible for the follow of the actions (Responsibility) CORRECTIVE ACTION PLANNING & REVIEW For each of the identified hazards that are assessed as an extreme, high or medium risk a corrective action / continuous improvement plan should be developed and reviewed as required. When developing corrective action or control strategies the HIERARCHY OF CONTROLS should be considered. The single most important outcome of a risk assessment is to implement effective and sustainable controls to prevent or significantly reduce the chance of injury, illness or exposure. 4 levels of controls define the hierarchy. The top two levels Elimination/ Substitution and Engineering Controls are by far the most effective in preventing or reducing risks because they rely much less on human behavior, are more difficult to defeat and require much less continuing human effort than the lower level controls. As corrective actions are planned every effort should be made to implement the top 2 levels of control. March 2002 HIERARCHY OF CONTROLS Most Effective Least Effective 1 Elimination / Substitution 2. Engineering Controls 3. Training and procedures 4. Personal Protective Equipment Hazard No. H1 Description of Hazard Corrective Actions/ Risk Controls Etching process involves the use of dilute corrosive chemicals. Splashes may result in injury requiring first aid treatment. Consequence Likelihood C4 No change to existing controls. All work should be done in the fume cupboard. Wear proper protective equipment such as safety glasses, latex gloves, labcoat and close toe shoes. Use minimal quantity of etchant. Risk L5 low Timing Inhalation of acid fumes during etching, or transfer between containers. H1 Consequence Likelihood C3 low Skin absorption of picric acid. Splashes on skin. Likelihood C2 Responsibility operator No change to existing controls. Carry out all transfer of reagents and etching in fume cupboard. Wear disposable gloves and safety glasses. Risk L5 Timing immediately Responsibility operator No change to existing controls. Wear disposable gloves and safety glasses whilst etching. Wash hands thoroughly after use and before eating. H1 Consequence immediately Risk L4 low Possible explosion of crystals Timing immediately Responsibility operator Regular checks of etchant bottle. Containers of piocric acid must be inverted gently at least every 4 weeks to prevent the risk of drying out of picric acid in the upper section of the container H1 Consequence C2 Likelihood L4 Risk Low Timing March 2002 immediately Responsibility operator Possible spill of etchants when transferring between ventilated cabinet to fume cupboard. Risk of inhalation and skin contact. If a spillage occurs, wash thoroughly with water until there is no residue left. Wear latex gloves to avoid skin contact. Call the safety instructor and leave the room, or use spill kit. Consequence Timing immediately Responsibility operator Timing immediately Responsibility operator H1 Consequence March 2002 C2 Likelihood L4 Likelihood Risk Low Risk Notes Picric acid is toxic and is absorbed through the skin. Hands should be washed thoroughly after use as an added precaution. Gloves must be worn whilst etching. Etching reagents must be made up by qualified and experienced staff only,(Irek Kozicki at Monash University SPME) using standard practices for the safe handling and mixing or chemicals. Reference Documents MSDS for picric acid MSDS for orthophosphoric acid MSDS for acetic acid March 2002