hw4.07

advertisement

Stat 502

Homework 4

Assigned 10/25/07

Due 11/1/07

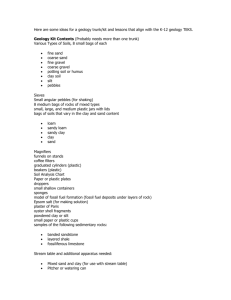

1. Clay surface roughness: A 3x3 factorial design was used to explore the effects

of three sources of clay (I, II, III) and three ceramic molds (A, B, C) on surface

roughness. Five replicates of each clay-mold combination were prepared and all

45 randomly placed within a furnace before firing. The response is a measure of

surface roughness. The data are in the file claymold.rough.dat.

(a) Examine these data graphically. What do you think about the data and

effects of the two factors (clay source and ceramic molds) based just on this

graphical examination of the data. Can you see any features of the data that

you must pay attention to in formal statistical analysis?

(b) Might a transformation be useful for these data? Why?

(c) Write out the treatment effects model for the experiment and compute the

least squares estimates of the parameters of this model. (This model may be

on a transformed scale, depending on your answer to part (b).)

(d) Compute the ANOVA table, including a column for the “Expected mean

squares” (which you won’t get from R output). Is an additive model justified?

Summarize your conclusions about the effects of clay source and ceramic

molds.

(e) Compute a 95% confidence interval for the contrast in cell means that you

would use to contrast the difference between molds A and B using clay from

source II with the difference between molds A and B using clay from source

III. If you use the “Least Significant Difference” framework for hypothesis

testing, do the results in part (d) authorize you to proceed with a test of the

significance of this contrast?

(f) Is there an optimal combination of clay source and mold if we are interested

in minimizing the measure of surface roughness? That is, is there one

combination of clay source and ceramic mold that has a mean score

significantly less than all the other treatment combinations? Explain what

statistical methodology you use to answer this question.

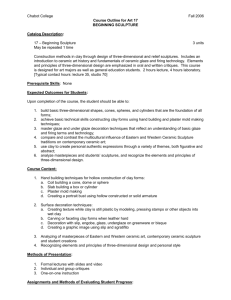

2. Plastic laminate cutting: The data below are production data for four different

machines (1, 2, 3, 4) cutting four different types of laminated plastics (A, B, D, D).

(a) Plot these data so that you can visualize the machine and plastic effects and

comment. Do you observe any “bad values”? Explain.

(b) There are no replications for the combinations of the “treatments” of Machine

and Plastic, so consider an additive model. Then, for a range of values of the

exponent λ (e.g., {-1, -.5, 0, 1/3, .5} evaluate the F statistic for the test of a

machine effect on production using the power transformation Yλ where Y

denotes production. Similarly, evaluate the F statistic for the effect of the

type of plastic over these same values of λ. Does this help you determine an

appropriate transformation? Choose your preferred transformation and plot

the usual diagnostics using the residuals from the fit of the additive model on

the transformed scale. What conclusions do you draw?

Plastic 1

2

3

4

A

1271

1440

612

605

Machines

B

C

4003

1022

1651

372

1664

829

2001

258

D

2643

5108

1944

2607