A Review of Hybrid Particle Technology and its Use in High

advertisement

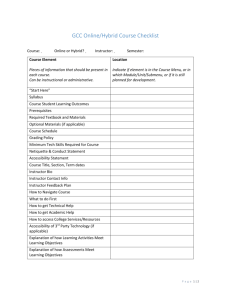

Use of Hybrid Particles in HPLC Applications at Extreme pH Thomas Walter, Waters Corporation, Milford, Massachusetts, USA Hybrid Particle Technology has given rise to an improved class of chromatographic packing materials designed to overcome some of the limitations of existing silica-based reversed-phase columns. The recommended useable range of pH 1-12 is far greater than the useable range of pH 2-8 for classical silicabased reversed-phase columns. The new Xterra™ columns from Waters Corporation feature Hybrid particle Technology (patent pending, Waters Corporation). These columns have been shown to exhibit outstanding performance within the traditional pH range, especially for basic compounds, but additionally allow you to break out of these barriers to a wider range of pH 1-12. These columns combine the broad useable pH range of Polymer-based packings with the speed, peak shape and high temperature stability available in the best of the most recent crop of silica-based reverse phase C8/C18 columns. The Problem of Extreme pH Applications in Silica-based Columns Silica-based reversed-phase packing materials have historically delivered the best combination of desired chromatographic properties under the most common range of conditions. However, silica-based reversedphase columns: Have short lifetimes when the mobile phase pH is below pH 2 (the bonded phase may be stripped off) Have short lifetimes when the mobile phase pH is above pH 8 (the underlying silica support begins to dissolve) Give broad, tailing peaks for many basic compounds Exhibit short column life at high temperatures Waters' new Hybrid Particle Technology exhibits an extended useful pH range and dramatically improved performance for basic compounds, without sacrificing the benefits of silica-based chromatographic supports. Waters’ new Hybrid Particle Technology is now available in XTerra™ columns. Silica-based Packings Traditional silica-based reversed-phase packings are manufactured using silane reagents to derivatize the silanol groups on the surface of silica particles. Because the silanes are much larger than the silanols, not all silanols are derivatized. In addition, the small pores in many silica particles limits ability of bulky reagents such as octadecylsilanes to reach the surface. Surface derivatization is always incomplete, and may leave large areas of residual silanols on the unbonded surface3. Ion-exchange interaction with the acidic residual silanols cause peak tailing for basic compounds. The technology of high-efficiency silica-based packings has advanced dramatically since their introduction in 1973. Consistency of particle size, pore size, and bonded-phase coverage of the particle were important early advances. Recent advances include the use of high-purity silicas such as the Symmetry® family of packings (1) and the incorporation of a polar functional group into the ligand as applied in the SymmetryShield™ packings (2) to improve peak shapes. Despite these advances, silica still deteriorates at alkaline pH values. Polymer-based packings Packings made from organic polymers such as poly(divinylbenzene) are stable over a wide pH range, but suffer from low plate counts and often from distorted peaks. Polymer-based packings swell and shrink in the presence of some solvents, resulting in poor mechanical stability. Hybrid Particle based packings Hybrid organic-inorganic technology provides a novel solution to the problems created by the shortcomings of classical silica-based and polymer-based packing materials. The new XTerra™ packing material from Waters Chromatography is a Hybrid Particle that combines the broad pH tolerance of polymer-based packings with the full range of benefits of silica-based packings. The Hybrid Particle is an organic/inorganic hybrid(3). These materials contain both inorganic (e.g., silica) and organic (e.g., organosiloxane) elements, and share the advantages of both. Equation 1 illustrates the process first described by Unger et al(4), and now used for creating Hybrid Particles. A mixture of two high-purity monomers is used: one forms SiO2 units during the particle formation process and the other forms RSiO1.5 (organosiloxane) units. The resulting particles contain organosiloxane groups incorporated throughout their internal and surface structure. These particles are then surfacebonded to attach reversed-phase groups (e.g., C18, C8). (RO)4Si + n (RO)3SiR* + (1.5 n + 2) H2O SiO2(R*SiO1.5)n + (3 n + 4) ROH The final particle contains an alkyl group (R*) that is incorporated into the matrix of the packing. This approach yields a material that contains both inorganic units (SiO2) and organic units (R*SiO1.5), combined at the molecular level. In the hybrid XTerra™ packing material, every third silicon atom in the matrix is substituted with a methyl group. The carbon content of the packing was determined to be about 7% carbon before surface modifications. 1) The packing is as hard as silica and does not swell or shrink in the presence of organic solvents. The pH stability of bonded phases based on these Hybrid Particles exceeds that of silica-based bonded phases. More Than a Surface Modification The molecular structure of the entire Hybrid Particle is a mixture of organic and inorganic groups. The result is a fundamental improvement in the composition of the underlying chromatographic particle. The polymerization process is controlled to create a particle with the right organic/inorganic balance. Too much organic material, and the particle behaves like a polymer – low mechanical strength, low efficiency. Too much inorganic material and the particle behaves like a silica – too many unbonded silanol groups that can cause problems with peak shape for bases and poor stability when used with aggressive mobile phases. Hybrid Particles can be manufactured with pore sizes as small as 2.5 µm, to allow extremely high speed separations. Performance of Hybrid Particle Packed Columns An important feature of the Hybrid Particle packings is their significantly improved pH stability compared to classical silica-based packings. The stability of Hybrid Particle packings has been investigated at both acidic and basic pH. Performance at High Temperature and Low pH The improved stability of Hybrid Particles enables the use of elevated temperatures for extended periods without the degradation of column performance exhibited by classical silica-based packings. The low-pH stability of silica-based reversed-phase columns is determined by two factors: the rate of cleavage of the siloxane (Si-O-Si) bonds that attach the bonded phase to the particle, and the rate of removal of the products of this cleavage by the mobile phase. For a surface bonded Hybrid Particle, the stability of the bonded phase and the stability of the integral methylsiloxane groups are both critical. In the Waters Xterra Hybrid Particle, most of the methylsiloxane units are attached by three siloxane bonds. These methylsiloxane groups have exceptional low-pH stability. Even after exposure to 1 M HCl at 100 °C for 16 hrs, no loss of methyl groups was detected. The bonded phase in the XTerra MS C18 particle also showed excellent stability at low pH, resulting from the use of a trifunctional silane(5). Waters XTerra MS C18 Hybrid Particle columns were exposed to 1% trifluoroacetic acid at pH 1.2 at 50° C, then tested the columns with a standardized test condition. The Hybrid Particle packing worked as well as or better than classical silica-based packings under acidic conditions(6). Performance for Basic Compounds The peak shapes obtained for strongly basic compounds in reversed-phase HPLC are dependent upon the concentration and the acidity of the residual silanol groups on the packing. Steric hindrance limits the extent of derivatization for traditional surface bonded packings(7). Because the new Hybrid Particles contain methylsiloxane groups in place of roughly a third of the siloxane units, the concentrations of residual silanols are much reduced, enabling bonded phases based on Hybrid Particles to deliver exceptional peak shape for basic analytes. High-pH Stability Silica-based packings fail rapidly at very high pH values. The lifetime of columns packed with 5 µm Hybrid Particle was tested at pH 11.5 using a pyrrolidine buffer. The column was run continuously at 30° C at 1 mL/min, and a mixture of basic analytes was injected continuously. The column lasted for over 45 days without deterioration of plate count and peak asymmetry or shifts in retention (other than those due to changes in mobile phase composition)(8). The high-pH stability of silica-based reversed-phase columns is determined by the rate of dissolution of the underlying silica particle (9). After dissolution has proceeded to a critical point, the packed bed abruptly collapses, causing voids and a catastrophic loss of efficiency. Because dissolution requires access of hydroxyl ions to the silica surface, the rate of dissolution depends on the amount of underivatized silica surface. Bonded phases based on Hybrid Particles have an extremely low area of underivatized silica surface because of the methylsiloxane units incorporated throughout their structure. Accordingly, Hybrid Particle columns containing these particles show exceptional lifetimes in high-pH mobile phases. Walter et al compared the stability of a Hybrid Particle Waters Xterra MS C18 column to a series of benchmark silica-based columns. The test columns were heated to 50 °C and exposed to a mobile phase containing a pH 10 triethylamine (TEA) buffer. The columns were periodically flushed with water and methanol and tested for efficiency with acenaphthene. The XTerra MS C18 column lasted twice as long as the best benchmark columns (6). with 2.5 µm Hybrid Particles it is possible to maintain maximum efficiency and achieve high throughput. The result is significantly reduced gradient run times with maximum resolution. Conclusion Hybrid Particle technology extends the advantages of silica-based HPLC packings to cover the pH range from pH 1 to pH 12 with no loss of efficiency or capacity. The surface chemistry of Hybrid Particle packings is identical to the surface chemistry of classical silicas. This makes the use of the packing as simple as the use of any other reversed-phase packing. The pH stability of Hybrid Particle packings extends the pH range accessible for reversed-phase packings. This opens up new options in the manipulation of the selectivity of a separation. The increased pH stability also results in improved ruggedness of the packing under normal operating conditions. Exploiting the Extended pH range A pH shift is a very powerful tool for separating analytes of different charge. For example, ibuprofen and toluamide overlap at alkaline pH, but a shift to a weakly acidic pH results in a clean separation. Even for compounds of the same charge, pH shifts can change the elution order. At acidic pH, doxepin elutes before imipramine and nortriptyline. Conversely, at alkaline pH nortriptyline and doxepin elute very close to each other, and imipramine elutes last. The best separation between the three tricyclic antidepressants occurs around pH 7 and pH 8. While the recommended range for silica-based packings is normally pH 2 to pH 8, Hybrid Particle packings can be used from pH 1 to pH 12. This expands the range of mobile phase conditions available to the chromatographer. Now it is possible to run basic analytes on a high-performance packing under nonionizing conditions. This provides new opportunities to manipulate selectivity, as well as the reproducibility of an assay. If one uses a packing at intermediate pH values, the retention of ionic, especially basic, analytes is highly susceptible to small changes in mobile phase pH. This is not so when the analytes are either fully ionized or not ionized at all, i.e. at low and high pH values. Consequently, the reproducibility of an assay improves at high and low pH. Using standard silica particles, the inability to maintain efficiency at high linear velocities with usable column backpressure often limits the speed of analysis. However, the stability of the Hybrid Particle at high temperatures makes it possible to achieve high speeds. At temperatures up to 80 °C, system backpressure is reduced and column efficiency improved. In addition, Hybrid Particle bonded phase packings currently available At the time of printing, four Hybrid Particle bonded phases are commercially available, all from Waters Chromatography, 34 Maple Street, Milford MA 01757, (800) 252-4752. The XTerra RP8 packing and the extended chain length XTerra RP18 packing include a carbamate group inserted into the chain. The best peak shapes and wettability in 100% water are the key properties of the XTerra RP packings. The XTerra MS C8 and XTerra MS C18 packings are made using a trifunctional silane. These packings are designed for LC/MS applications, where very low bleed is critical. Both the XTerra RP packings and the XTerra MS packings are fully endcapped. References 1. U. D. Neue, D. J. Phillips, T. H. Walter, M. Capparella, B. Alden, R. P. Fisk, "The Relationship between the Quality of a Reversed-Phase Column and the Quality of a Pharmaceutical Analysis", LCGC, June 1994 2. J. O'Gara, B. Alden, T. H. Walter, C. Niederländer, U. D. Neue, " Simple Preparation of a C8 HPLC Stationary Phase with an Internal Polar Functional Group", Anal. Chem. 67 (1995), 67, 3809 3. Laine, R.M., Sanchez, C., Brinker, C.J., Giannelis, E., Organic/Inorganic Hybrid Materials, Materials Research Society, Symposium Proceedings Vol. 519, 1998. 4. Unger, K.K., Becker, N., Roumeliotis, P., J. Chromatog. 125 (1976), 115. 5. Neue, U.D., Walter, T.H., Alden, B.A., Jiang, Z., Fisk, R.P., Cook, J.T., Glose, K.H., Carmody, J.L., Grassi, J.M., Cheng, Y.F., Lu, Z., Crowley, R.J. American Laboratory, in press 6. the original Pharma article, in press. 7. Berendsen, G.E., Pikaart, K.A., de Galan, L., J. Liq. Chrom. 3 (1980), 1437. 8. Neue, U.D., Walter, T.H., Alden, B.A., Jiang, Z., Fisk, R.P., Cook, J.T., Glose, K.H., Carmody, J.L., Grassi, J.M., Cheng, Y.F., Lu, Z., Crowley, R.J.., American Lab,(31:22) 36-3 (1999) 99-0947 9. Kirkland, J.J., van Straten, M.A., Claessens, H.A., J. Chromatog. A 691 (1995), 3.