ENERGY TRANSFER IN TURBO MACHINES

advertisement

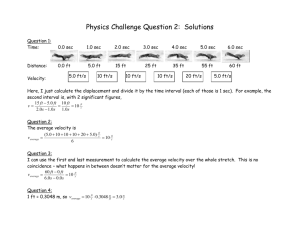

INTRODUCTION TO TURBO MACHINES Turbomachine is defined as a device in which energy transfer takes place between a flowing fluid and a rotating element resulting in a change of pressure and momentum of the fluid. Energy is transferred into or out of the turbomachine mechanically by means of input/output shafts. PRINCIPAL PARTS OF A TURBO MACHINE 1. Rotating element consisting of a rotor on which are mounted blades. 2. Stationary element in the form of guide blades, nozzles, etc. 3. Input/output shafts. 4. Housing Schematic cross sectional view of a steam turbine showing the principal parts of a turbo machine. Functions: 1. The rotor functions to absorb / deliver energy to the flowing fluid. 2. The stator is a stationary element which may be of many types:a. Guide blades which function to direct the flowing fluid in such a way that energy transfer is maximized. b. Nozzles which function to convert pressure energy of the fluid to kinetic energy c. Diffusers which function to convert kinetic energy to pressure energy of the fluid. 3. The input /output shafts function to deliver / receive mechanical energy to or from the machine. 4. The housing is a protective enclosure which also functions to provide a path of flowing fluid. While a rotor & input /output shaft are essential parts of all turbo machines, the stator & the housing are optional. 1 CLASSIFICATION OF TURBO MACHINES: 1. According to the nature of energy transfer: (a)Power generating turbo machines: In this, energy is transferred from the flowing fluid to the rotor. Hence, enthalpy of the flowing fluid decreases as it flows across. There is a need for an output shaft. Ex: Hydraulic turbines such as Francis turbine, Pelton wheel turbine, Kaplan turbine, steam turbine such as De-Laval turbine, Parsons Turbine etc, Gas turbines etc, (b)Power absorbing Turbo machines: In this, energy is transferred from the rotor to the flowing fluid. The enthalpy of the fluid increases as it flows there is a need for an input shaft. Ex: Centrifugal pump, Compressor, blower, fan etc, (c)Power transmitting turbo machines: In this energy is transferred from one rotor to another by means of a flowing fluid. There is a need for an input / output shafts. The transfer of energy occurs due to fluid action. Ex: Hydraulic coupling, torque converter etc, Schematic representation of different types of turbo machine based on fluid flow. (a) Axial flow fan. (b) Radial outward flow fan. (c) Mixed flow hydraulic turbine. 2 2. Based on the type of fluid flow: (a) Tangential flow in which fluid flows tangential to the rotor Ex: Pelton wheel etc, (b)Axial flow in which the fluid flows more or less parallel to the the axes of the shafts /rotors. Ex: Kaplan turbine, Axial flow compressor. (c)Radial flow in which fluid flows along the radius of the rotor this is again classified as: Radially inward flow. Ex: Old fancies turbine. Radially outward flow. Ex: Centrifugal Pump (d) Mixed flow which involves radius entry & axial exit or vise-versa. Ex: Modern francises turbine & Centrifugal Pump. 3. Based on the type of Head: (a)High head &low discharge .Ex: Pelton wheel. (b)Medium head &medium discharge. Ex: Francis turbine. (c)Low head & high discharge. Ex: Kaplan turbine. Differentiate between a turbo machine &a positive displacements machine. Sl.n 1. 2. Particulars Action Positive displacements machine In this class of machine, energy transfer takes place between a moving surface & a near static fluid. There is positive entrapment of the fluid involving a change in its specific volume during energy transfer. Operation In this type, we generally come across, reciprocating motion &the energy transfer happens in an unsteady process. As a result stopping the machine at any instant will leave a certain amount of fluid in a machine in a state different to that of the surroundings. Note: positive displacements machine with rotary action are also possible. Ex: gear pump, screw pump. Turbo machine In this class of machine, energy transfer takes place between a rotating elements &flowing fluid.there is no entrapment of the fluid & during energy transfer the fluid pressure & momentum change. In this type, there is only rotary motion & energy transfer takes place in a steady process. Since there is no entrapment, stopping the machine at any instant would lead to the fluid quickly attaining the state of the surroundings. 3 3. Mechanical 4 Conversion efficiency 5. 6. 7. 8 This is characterized by complex mechanical features involving the presence of many mechanical links parts such as valves, push rods, connecting rods, cranks etc, are common in this type. Due to numerous mechanical parts the weight of the machine is more & hence this would need a heavier foundation. Due to positive entrapment during energy transfer conversion efficiency is high. This characterized by a simple mechanical design & does not involve too many mechanical linkages. Hence, this is lighter & would also need a lighter foundation. In the absence of face change during the energy transfer process cavitations problems are negligible .surging is not encountered since there is no rotary motion. Face change during energy transfer is a distinct possibility & hence cavitations possibility is a problem encountered .surging & choking is a phenomenon associated with centrifugal compressors leading to instabilities in flow & high vibration which may lead to failure of the machine. In the absence of positive entrapment, energy transfer happens in a dynamic process &hence conversion efficiency is comparatively low. Mechanical Due to numerous mechanical links, losses In the absence of too many links, efficiency are considerable & mechanical efficiency mechanical efficiency is low. is low. Volumetric Since, the fluid as to pass ,through valves In the absence of valves efficiency the actual volume of the fluid passing volumetric efficiency is very high through the machine is significantly less &close to 100%. than the maximum value possible . Hence volumetric efficiency is low. Power to The presence of too many mechanical In the absence of too many weight ratio elements & a heavy foundation resulting mechanical parts the power to power to weight ratio being comparatively weight ratio is significantly higher lower for the same capacity. (almost 10-15 times higher for the same capacity) Surging &Cavitations 4 Static & Stagnation state: Static state: Fluid at rest is said to be in a static state properties measured of fluid at rest are called static properties but in a turbo machine we only deal with moving fluid. Hence static property incase of a moving fluid would be measured by an instrument which is at rest relative to the fluid. In other words static temperature of moving fluid particles would be measured by a thermometer moving with the same speed as that of the fluid particles. Stagnation state: Stagnation state is defined as the end state of a fititous, work free, isentropic process during the course of which the macroscopic potential & kinetic energies of the fluid are reduced to zero. Even though stagnation state can never be achieved by any real process, it is very important concept in the analysis of turbo machine, if due care is taken & errors are properly accounted for the instruments such as Pitot tube, thermocouple etc, gives stagnation properties. 1st law of Thermodynamics for a steady flow machine and determination of stagnation properties 2 2 (V2 V1 ) q w (h2 h1 ) g ( z 2 z1 ) 2 Applying this for the analysis of turbo machine, we arrive at stagnation state. We may write, (V 2 V 2 ) q w (h0 h) 0 g ( z0 z) 2 Where the subscript ‘0’ refers to the stagnation state. It is implicit that just before the process to arrive at stagnation state starts, the fluid is in static state. Hence, we have h0, V0, z0 are the stagnation properties, h, V, and z are the static properties. But we know that in this process q 0, w 0, V0 0, gz 0 0 0 h0 h V2 gz 2 Thus stagnation enthalpy h0 h V2 gz 2 Stagnation entropy s0 s (Since the process is isentropic) We have h0 C PT0 h C PT 5 Substituting in expression for stagnation enthalpy and rearranging V2 gz T0 T 2CP Cp gz which may be called temperature equivalent of height is negligible CP compared to other terms and may be neglected. The term Stagnation temperatu re T0 T V2 2Cp We have the relation Tds dh vdp (For a closed system) ds 0 There fore, dh vdp p0 h0 h vdp p r.h.s.may be integrated only if the relationship between ‘v’&’p’ is known. For an incompressible fluid, h0 h v( p 0 p ) v 2 p 0 p (h0 h) p0 p gz 2 p 0 p (h0 h) p 0 p [( h V2 gz ) h] 2 v 2 is the pressure equivalent of velocity. ‘ρgz’ which is the pressure 2 equivalent of height can be neglected since it is very small compared to other terms. Hence we can write, The term Stagnation pressure p0 p v 2 2 6 Application of 1st &2nd law of thermodynamics of turbo machines: In a turbo machine, the fluctuations in the properties when observed over a period of time are found to be negligible. Hence, a turbo machine may be treated as a steady flow machine with reasonable accuracy & hence, we may apply the steady flow energy equation for the analysis of turbo machine. Hence we may write V 2 V12 q w (h2 h1 ) 2 g ( z 2 z1 ) 2 Where, subscript ‘1’ is at the point of entry & subscript ‘2’ is at point of exit. It is also true that, thermal loses are minimal compared to the amount of work transferred & hence may be neglected. Hence we may write, V2 V2 w (h2 2 gz 2 ) (h1 1 gz1 ) 2 2 w (h02 h01 ) Where, h02 & h01 are stagnation exit & entry respectively. - w = ∆h0. In a power generating turbo machine, ∆h0 is negative (since h02 <h01 ) & hence w is positive. On the same line, for a power absorbing turbo machine, ∆h0 is positive (since h02>h01) &hence w is negative. From the 2nd law of Thermodynamics: Tds dh vdp dw vdp Tds 2 w vdp Tds 1 In the above relation, we note that vdp would be a negative quantity for a power generating turbo machine & positive for power absorbing turbo machine. Hence Tds which is always a positive quantity would reduce the amount of work generated in the former case & increase the work absorbed in the later case. Efficiency of a turbo machine: Generally, we define 2 types of turbo machine .in case of turbo machine to account for various losses 2 type of efficiency is considered: 1. Hydraulic efficiency/isentropic efficiency 2. Mechanical efficiency. 1. Hydraulic efficiency/isentropic efficiency: To account for the energy loss between the fluid & the rotor 7 (η isen) power generating machine = Wrotor W fluid . (η isen) power absorbing machine = W fluid Wrotor 2. Mechanical efficiency: To account for the energy loss between the rotor & the shaft. (η mechanical) power generating machine = Wshaft Wrotor (ηmechanical) power absorbing machine = Wrotor Wshaft When we talk about isentropic efficiency in turbo machine, it is necessary to take into account the values of velocity & heights to determine by what extent stagnation properties deviate from static properties. In the turbo machine, developed 1st the velocities were minimal & hence the static & stagnation properties were more / less same. But in the modern day turbo machines, the velocities are appreciable & hence, the static & stagnation states are different. 8 Plotting on the h-s diagram for the turbo machine Schematic representation of Compression & Expansion process. (a) Power absorbing machine. (b) Power generating machine. (1) power generating machine Wact h01 h02 Wisen Wt t h01 h1 02 Wt s h01 h1 02 1 Ws t h1 h02 Ws s h1 h21 t t Wact h01 h02 1 Wt t h01 h02 t s Wact h01 h02 Wt s h01 h21 s t h h Wact 01 102 Ws t h1 h02 ss Wact h01 h02 Ws s h1 h21 9 (2). power absorbing turbomachine : Wact h02 h01 t t 1 Wisen Wt t h02 h01 t s 1 Wt s h02 h1 Ws t h21 h01 Ws s h21 h1 Wt t h1 h01 02 Wact h02 h01 Wt s h1 02 h1 Wact h01 h21 s t Ws t h1 2 h01 Wact h02 h01 ss Wact h1 2 h1 Ws s h02 h01 Problems: 1. For a turbo machine handling water, the total – total efficiency is 0.7 during flow through the turbo machine, the stagnation pressure increases by 3.5 bar. Determine b. Ideal energy input. c. Actual mechanical energy input. Assuming a mechanical efficiency is 0.09 d. Actual power input for a flow of 3.25 lts/sec. e. Rise in a temperature due to irreversibilities. Assume Cv = 4.187 kJ/kg-K Answer: Given: ηt-t = 0.07 P0=3.5 bar = 3500 kPa ηmech=0.9 Cv=4.187 kJ/kg-K Q=3.25 lts/sec Wisen=-∫vdp=-v∆p/ρ = -3500/1000 =-0.35 kJ/kg Wact = Wisen/ (ηt-t) = -0.35/0.07 = -5 kJ/kg du =Wact - Wisen CvdT = Wact-Wisen dT (Wact Wisen ) Cv dT 1.1105 C 10 2. The initial & final total pressure of a fluid are 1 bar & 10 bar respectively. The initial total temperature is 10 C. What is the work of compression for adiabatic steady flow with a total –total efficiency of 70%. Consider the fluid as air & assume that it behaves like an ideal gas. Answer: Given: P01=1bar; P02=10bar; T01=283K; ηt-t=0.75 p 01v02 p 02 v02 1 p 01 v02 v01 p 02 Wideal v02 1 p 02 mRT02 T01 mRT01 1 1 1 p 01 m3 0.1568 Kg Wideal 264.57 t t Wideal Wact Wact Wideal t t m3 Kg 264.57 Kj 377.94 0.75 Kg 11 Dimensional analysis: Model analysis of a turbo machine: It is a regular procedure adopted to explore the various factors affecting the performance of the turbo machine. The 1st step would be to examine the different variables involved & segregating them into groups. The 1st group involves geometric variables such as length, width, span, and chord length etc, of the turbo machine. The 2nd group involves kinematics variables such as linear velocity ‘v’, angular velocity ‘ω’, acceleration (a), rpm (N), mass flow rate, volume flow rate (Q), etc, The 3rd group involves dynamic variables which are again segregated into 2 types: 1. Fluid variables such as density, specific weight, viscosity, elasticity, surface tension etc, 2. Performance variables such as pressure drop, power input /output, torque, shear force, drag, lift, etc, The choice of the different variables warrants carefull consideration. Similar variables need to be avoided. For example density & specific weight may not be chosen generally Buckingham’s theorem is adapted to determine the various dimensionless groups involved in the group. Problem: (1).A partially submerged body of length L is towed in water of density ρ & viscosity μ at a velocity ‘V’.show that the total resistance R experienced by the body is given as Lg , 2 R L2V 2 f LV V Ans: RαρLVgμ Π1=ρa1Lb1Vc1R M0L0T0=La1(LT)b1(ML-3)c1(MLT-2) a1=-2; b1=-2; c1=-2 π1 =R/(L2V2ρ) Π2=ρa2Lb2Vc2μ M0L0T0=La2 (LT-1) b2 (ML-3) c2 (ML-1T-2) a2=-1; b2=-1; c2=-1; 12 π2=μ/ρLV Π3=ρa3Lb3Vc3g M0L0T0=La3 (LT-1) b3 (ML-3) c3 (LT-2) a 3= 1; b3= -1; c3= 0; π3=Lg/V2 R f 2 2 L V LV Lg 2 0 V Lg R L2V 2 f , 2 LV V The operating characteristics of a gas turbine are presumed to depend on the following physical variables: mass flow rate, initial temperature, initial pressure, temperature drop across the turbine, turbine rotor diameter & speed of the rotor using the 3 functional dimensions of length, mass, &time only. Find the dimensionless parameters which will express the performance of the gas turbine. Note: Since the dimensionless parameters have to be obtained using only the 3 functional dimensions of length, mass & the variables initial temperature & initial drop across the turbine have to be expressed in terms of other variables whose dimensions can be expressed in terms of length, mass & time. This is done as follows: Assuming that the gas behaves like a perfect gas, we may write Intial pressure: Pi RTi Pi i R Since Pi has already been taken into account as one of the variables affecting the performance, we may express Ti in terms of ρi as follows: Work output per unit mass = -∆h= -∆ Cp∆T Ti ∆T= - (W/mass)/Cp Hence, we may go head & express temperature drop interms of work output interms of per unit mass. Thus, the different variable affecting the performance & then MLT form as follows: Sl.no Variable Units MLT form 1. Mass flow rate (m) Kg/s MT-1 3 2. Initial temperature & initial Kg/m ML-3 density(ρi) 13 3. 4. 5. 6. 7. initial pressure(Pi) Final pressure(Pf) Temperature drop Rotor diameter(D) Speed(N) N/m2 or Kg/m-s2 N/m2 N-m/Kg of m2/s2 m s-1 ML-1T-2 ML-1T-2 L2T-2 L T-1 Dimensional analysis in practical situation: Considering a practical situation such as steady flow through a pipe, the performance variables would be pressure drop ∆P. The variables affecting the performance would be as follows: 1. Geometric variable –pipe length L, diameter D 2. Kinematic variable –velocity V 3. Fluid variable-density ρ, viscosity μ, bulk viscosity K, surface tension σ, we may write, ∆P=f (L, D, V, g, ρ, μ, K,σ) Choosing ρ, V, D as the repeating variables L 1 D P 2 V 2 VD 3 4 V2 D V2 5 K V2 6 Dg 14 Physical significance: To study the physical significance, we need to analyze the different types of forces that affect fluid flow. 1. Inertia force: Fi ma m V t Fi AV 2 Fi D V 4 2 2 Fi D V Fi 2 2 2. Viscous force Fv: V D FV V A D FV VD 3. Pressure force Fp=PA α PD2 4. Gravity force: Fg=mg =ρg α ρD3g 5. Elastic force: Fe = KA αKD2 6. Surface tension force Fst=σL α σD 15 DIMENSIONLESS NUMBERS inertia force D 2V 2 DV VLC 1. Reynolds numbers Re= viscous force VD In the above expression, the area was expressed in terms of diameter ‘D’. If it is expressed in terms of any other length dimension which may be called as characteristic length Lc, then Reynolds number would be given by the expression VLC 2. fraud’s number Fr= 3. Weber number Wb = 4. Macchs number M= inertia force V gravity force Dg inertia force V = surface tension force D inertia force V compressib ility force K 5. Eulers number = inertia force V pressure force P Dimensional analysis with specific reference to turbo machine: When analysis is made to predict the performance of turbo machine, the following observation are generally obtained. 1. Geometric Variable – rotor diameter D 2. Kinematic Variable – rotor speed N 3. Dynamic Variables – a. Performance Variables i. Flow rate Q ii. Head H:-head in terms of energy per unit mass with units J/g or head in terms of energy per unit weight with units J/N iii. Power P b. Fluid Variables - density ρ, viscosity μ, bulk viscosity K, Choosing ρ, N, D, as the repeating variables & applying the Buckingham’s theorem, we will get the following dimensionless terms: 16 1. Q - this is referred to as the dimensionless flow rate also called as flow ND 3 coefficient or capacity coefficient or specific capacity. He – this is referred to as dimensionless head also called as head co efficient. N 2D2 In the above expression He is Head in J/Kg or kJ/kg 2. 3. 4. P – this is referred to as the power coefficient & represents power in N 3 D 5 dimensionless form Power coefficient is essentially expressed as a product of flow co efficient & head co efficient. ND 2 – this is another form of Reynolds number. It may be shown that μ is proportional to V. 5. K - which is another form of Mach Number. N 2 D 2 Significance of the dimensionless terms When a performance analysis of a turbo machine is made, the performance characteristic curve in terms of head versus Q is to be plotted. We will get different characteristics curves for different rotor speed as shown in the fig. 17 If a plots are made of H vs. Q for different speeds as shown in the fig, it is applicable for only one turbo machine. As such if we need to do a performance analysis of other geometrically similar turbo machine, the straight forward approach would be to plot a graph of H vs Q for different speeds for each turbo machine which is a cumbersome task. However if a plot is made for head coefficient versus flow co efficient, the characteristics would be independent of N & D & hence would be applicable for all geometrically similar turbomachines. Simplified parameters: For a given turbo machine of diameter D handling a fluid of density ρ we have flow coefficien t Q 1 ND 3 For a given turb omachine since the diameter is a fixed quantity w e can remove it from the terms and write Q 11 N He 12 2 N P 13 3 N These terms are referred to as simplified parameters. Let us conduct a performance test on this turbo machine & a plot a graph of He vs. Q for any speed say N1. 18 Consider a point on this characteristics curve for which the head & the flow rate are Q1 &He1 respectively. Knowing the values of He1, Q1, N1 we can determine the values of π11 & π21. Using the same values of π11& π21, we can determine similar points for the speeds N2, N3, etc, i.e, Q Q Q 11 1 1 3 ................ N1 N 2 N 3 He1 He 2 He 2 2 3 ............. N 12 N2 N2 If these similar points are joined the loci is a parabolic curve which passes through the origin. After this, we can choose one more point on the characteristic curve & repeat the whole exercise to get one more locus of similar points. On the same line many such loci may be drawn. If all such points obtained for a speed say N2 are joined, then we get the performance characteristic curve for sped N2 without having to conduct the performance test. On similar lines it is possible to draw performance characteristic curve for any number of speeds with out having to conduct any performance test. This is the significance & benefit of the simplified parameters. 12 Specific speed: It is noticed that the dimensionless parameters defined for turbo machine contain one geometric variable ‘D’. It would be of some benefit if we were to define a dimensionless term i.e. independent of the geometric variable ‘D’. Such a term would be applicable for all geometrically similar turbo machines for similar flow conditions. One method of getting such a term would be the application of dimensional analysis &buckingam’s theorem . The easier method would be to perform a mathematical operation on the Πterms already obtained so as to eliminate ‘D’. Proceeding on the same line, we get 2 terms of practical significance which do not have the variable D. the 1st term would have variable Q, N, He. The 2nd term would have P, N & He. 1 2 Q N S 3 3 ND 24 1 12 N 2D2 * He 3 4 N Q 3 He 4 This is referred to as specific speed applicable for pumps. Since, speed flow rate & head developed are of significance in pumps. 1 1 2 3 5 5 4 2 P2 (N 2 D2 ) 4 N P NS * * 3 5 5 He N D He 4 19 The above term is defined as specific speed for turbines. Since speed power output &head available are of importance to turbines. Specific speed of a turbo machine would express similar values of the properties involved i.e. N, Q, He, P which would given similar flow condition in all geometrically similar turbo machine. It can be construed that in the plot He vs. Q any one of the loci of similar points have the same value speed. Hence, for different loci we have different values of specific speed. Therefore, in order to make this term significant a condition needs to be imposed. This is taken as the conditions at which the machine operates at maximum efficiency conditions the specific speed of all geometrically similar machine falls in a narrow bandwidth as such we may say that the value of the specific speed obtained would define the type of turbo machine for example a specific speed of pelton wheel varies from 4-70 metric units. Francis turbine from 70-430 units. Kaplan turbine 500-100 metric units. These values have great practical significance. It is known that a pelton wheel is highly suitable for conditions of high head &low discharge while a Kaplan turbine, has optimum efficiency while working under low head & high head &high discharge condition N P from the expression for specific speeds for turbines i.e. Ns 5 He 4 It may be noticed that a high value of head would result in a low specific speed. Units: Specific speed has given by the expression are dimensionless. N Q i.e., non –dimensional specific speed ns 3 He 4 N=rad /sec, He=J/Kg, Q=m3/sec, N P NS 5 He 4 N=rad/sec; P=watt=Kg/m3; He=J/Kg. Suppose, head is in terms of meters of the flowing fluid, when we have He=gH N Q N P Substituting He in ns &Ns, we have n s & NS 5 3 (gHe ) 4 (gHe ) 4 Dimensional form of specific speed: N Q N P & NS ns 5 3 He 4 He 4 20 Metric N-rpm Q-m3/sec H-m P-metric HP S.I.units N-rpm Q-m3/sec H-m P-KW Specific speed of a pump is defined as the speed of the geometrically similar pump which would develop a head of 1m at a flow rate of 1m3/sec. Specific speed of turbines is defined as the speed of geometrically similar turbines which would develop 1Kw of power when working under a head of 1m. Problems: 1. In an axial flow pump with a rotor diameter of 30 cm handles water at a rate of 2.7m3/min. while operating at 1500 rpm, the energy input is 125J/Kg, the total-to total efficiency being 75%. If a second geometrically similar pump with a diameter of 20cm operates at 3000rpm, what are its: (a)flow rate (b)change in total pressure and (c)input power? Answer: D1=.3m He1=125J/Kg D2=.2m ηt-t=75% Q1=2.7m3/min N1=1500rpm N2=3000rpm Q1 Q2 3 N 1 D1 N 2 D23 2.7 * 3000 * 0.2 3 m3 1 . 6 kg 1500 * 0.33 He1 He 2 23 2 2 N 1 D1 N 2 D2 Q2 He2 =222.2 J/Kg = -∆h0 =V∆P0/ηt-t ∆P0 = -222.2*ηt-t*1000 ∆P0 = 166665 pa=166.65 Kpa P=mgH/t = m He = ρQgHe P = ρQ2He2 = 1000*1.6/60*222.2 = 5925.86 W = 5.926 KW 21 2. The quantity of water available for a hydro electric power is 260 m3/sec under a head of 1.73 m. Assuming the speed of the turbine to be 50 rpm & there efficiency to be 82.5%. Find the number of turbines required. Assume Ns = 890 (metric units). We have: N P NS 5 890 H4 50 P 5 1.73 4 P = 1247.255MHP = 917356.05W P0=ηρQgH = .825*1000*260*9.81*1.73 P0=3640343.85 W Number of turbines = P0/P = 3640343.85 / 917356.05 =3.9 =4 3. A maximum flow turbine with a total pressure ratio of 3:1 & inlet total temperature of 1000 K handles air. The impeller diameter & rotational speed are 30 cm &16000 rpm with a total to total efficiency of 83%. Find the power output /Kg/sec of air flow if the rotor diameter is reduced to 20 cm & the rotational speed is 2000 rpm. Given: P01/P02 = 3/1 D2 = 0.2m T01 = 1000K D1 = .3m N1=16000rpm ηt-t = 83% N2 = 2000 rpm He1 = Cp (T01 – T02) Cp(T01 T02 ) * T T C P T01 (1 T02 ) * T T T01 1 P C P T01 1 02 * T T P01 =1005*1000*(1-(1/3).4/1.4)*.83 22 0 .4 1 1 .4 1005 * 1000 * 1 * 0.83 3 W 224720.047 Kg sec 2 He1 He 2 2 2 2 N 1 D1 N D He2 = 1560.55 J/ kg 4. Liquid water of standard density flows at a temperature of 20 C .A static pressure of 10 atm &a velocity of 20 cm/sec. Evaluate the total temperature & total pressure of water. We have: T0 T V2 2C P ` 20 2 293.047 K 2 * 4187 V 2 P0 P 2 1000 * 20 2 P0 1013250 11.97 atm 2 T0 293 5. Air as a perfect gas flows in a duct at a velocity of 60 m/sec. a static pressure of 2 atm. & a static temperature of 300 K. Evaluate the total temperature & total pressure of the air at this point. Assume γ =1.4. Given: V=60 m/sec. T= 300 K P = 2 atm. = 202650 Pa PV = RT P=ρRT I.e. ρ = P/ (RT) =202650/ (287*300) = 2353.65 g/m3 23 T0 T P0 P V2 60 2 300 300.429 K 2C P 2 * 4187 V 2 2 202.95KPa 2.11atm 6. At a stagnation temperature of 400 K & at a stagnation pressure of 8 atm. The outlet total pressure is 1 atm. If the expansion process through the turbine is assumed to be Adiabatic & loss free. Evaluate (1).Work done per Kg of fluid. Assuming it to be incompressible with a specific with a specific weight of 1g/cc.(2) work done per Kg of fluid assuming it to be air behaving as a perfect gas with γ = 1.4 Given: T01 = 400 K P01=8atm. =810600Pa. (1)Wisen vdp vp p P02 = 1 atm. = 101325 Pa (1 8) kj 709 1000 kg P02 1 kj 180078.0078 (2)W C P (T01 T02 ) C P T01 1 kg P01 24 7. Air as a perfect gas undergoes an increase in total pressure of 180mm. of water during passage through a blower. The inlet static pressure is 1 atm temperature is 25 C & the velocity is 50 m/sec. Evaluate the exit total temperature if the process is isentropic. Evaluate the energy added to the air by blower per Kg of air flow per sec. if the flow is steady. If the exit velocity is 135 m/sec. find the exit static temperature &pressure. Given: P 180mm gh 1000 * 9.81 * 0.18 1765.8 Pa P1 1atm m sec T1 298 K V1 50 V2 135 m sec P01 P1 1V12 2 101325 1.184 * 50 2 102805 Pa 2 W He Cp(T01 T02 ) * T T W 0. 4 Kg 104570.8 1.4 1005 * 1 * 299.24 143.336 102805 S P02 1028025 1765.8 104570.8 Pa 0.4 T02 P02 1.4 T01 P01 0 .4 104570.8 1.4 T02 299.24 * 300.69 K 102805 V 2 P2 P02 93529.183Pa 2 P Kg 02 1.2117 3 RT02 M T2 T02 V2 291.622 K 2C P 25 8. The quantity of water available for a hydrostat ion is 310 cumecs water, the head of 1.8m. Assuming the speed of each turbine to be 60 rpm &efficiency to be 85%.find the number of turbines required. The power produced by each. Take specific speed of turbine to be 800metrics. Cumecs=cubic meter per second=310m3/sec. Given: Q=310cumecs H=1.8m N=60rpm Ns=800metric η =.85 P0 = η0 ρgQH =.85*1000*9.81*310*1.8 =4652883 W NS 800 N P 5 H4 60 P 5 4 1.8 P 772.789 MHP 772.789 * 735.5W 568383.43W Number of turbines =P0/P=4652883/568383.43 =8.18=9 9. An output of 10KW was recorded on a turbine 0.5m diameter resolving at 800rpm under head of 20m. What is the diameter & output of another turbine which works under head of 180m at speed 200rpm.Assuming their efficiency are the same .also find the specific speed & suggest the turbine that can be used. Given: P0=10KW=10/0.7533 = 13.6 MHP D1=0.5m N1=800rpm H1=20m H2=180m N2=200rpm η1 =η2 We have: 26 He1 He 2 2 2 2 N 1 D1 N 2 D2 20 180 800 * 0.52 200 * D22 2 D2 6m Specific speed: N P NS 2 5 2 H 24 69.4 200 * P2 5 4 180 P2 52854.89 MHP 52854.89 * 0.7355 38874 KW Effect of Reynolds number Most turbo machines use relatively low viscous fluids like air, water, steam, lightoils, etc; as such the flow is generally turbulent in nature. viscous losses are minimal compared to other losses such as shock losses at entry, turbulent losses, impact losses , impact losses& leakage losses etc, Hence, Reynolds number is not an important parameter when analysis of turbo machines are made for a model & a prototype. If the surfaces have the same relative roughness then Reynolds number may not be a significant factor at all. But for hydraulic machines, the prototype will have a larger value of roughness compared to the model which is generally smooth & polished; they account for such dis similarities. An equation has been suggested by moody to compare efficiencies of a model & a prototype. D P 1 1 m m Dp D 2 Unit Quantities They are parameters measured under conditions of unit head Q (1)Unit flow: QU H It is defined as turbo machine working under a N (2)Unit Speed: N U H It is defined as speed of turbo machine working under a head of 1m. P (3)Unit Power: PU 3 head of 1m. H2 27 It is defined as power produced by a turbo machine working under a head of 1m. Problem: 1. A small scale model of hydraulic turbine, runs at a speed of 350 rpm under a head of 20m produces an output of 8KW.Determine (1) Unit discharge, unit speed, unit power. (2)Assuming a turbine efficiency of a turbine of 79%, determine the output power of prototype which is 12 times the size of a model. (3)Assuming their efficiency are related by Moody’s formula, suggest the type of turbine to be used. Given: N=350rpm H=20m P=8KW P0=η0ρgQH 8*10 3= 0.79*9.81*10 3*Q*20 Q=0.0516 m3/sec Q 1. (1) QU H P (2) PU H 3 2 0.0516 20 8 3 2 0.0115 m3 sec 0.08944 KW 20 N 350 (3) N U 78.26rpm H 20 DP 12 Dm 0.2 1 2. P 1 1 0.76 87.2% 12 NS N P H 5 4 350 * 8 0.7355 20 5 4 27.29metric Pelton wheel turbine is suggested. 28 ENERGY TRANSFER IN TURBO MACHINES 29 Analysis of Energy Transfer in turbo machines: Analysis of energy transfer in turbo machines requires a consideration of the kinematics and dynamic factors involved. The factors include changes in the fluid velocity, rotor velocity and the forces caused due to change in the velocity. We apply Newton’s second law of motion as applicable to rotary movement. i.e., Torque is proportional to the rate of change of angular momentum. d (mVr) T dt An another important consideration is the treatment of a turbo machine as a steady flow machine. This involves following assumptions: (1)Mass-flow rate is constant. (2)State of fluid at any given point does not change. (3)Heat and Work transfer are constant. (4)Leakage losses are negligible. (5)Same steady mass of fluid flows through all section. Velocity Components: Fig. velocity components through a rotor 30 The fluid enter the rotor with an absolute velocity say V1 and leaves with an absolute velocity say V2.. The absolute velocity of the fluid will have components in the axial, radial and tangential direction which may be referred to as Va,Vw and Vf respectively. The axial components do not participate in the energy transfer but cause a thrust which is borne by the thrust bearings. The radial components also do not participate in the energy transfer but cause a thrust which are borne by the journal bearings. The only components which participate in the energy transfer is the tangential component Vw. Va1 and Va2 :Axial components of V1 and V2 respectively. Vf1 and Vf2 : Radial components of V1 and V2 respectively. Vw1 and Vw2 : Tangential components of V1 and V2 respectively referred to as whirl velocity, flow velocity. Let the rotor move with an angular velocity . Velocity Triangles: These are formed at the inlet and exit by the combination of rotor velocity of a fluid V, and relative velocity Vr which is the vectorial difference of V and U. Derivation of Euler’s Turbine equation: By Newton’s second law, Torque on the turbo machine 31 d (mVr) dt m T (Vw1 r1 Vw 2 r2 ) t W W P T * sec t T But , r1 u1 r2 u 2 m (Vw1u1 Vw 2 u 2 ) Watt t Is the Euler’s turbine equation. P Head form the Euler’s equation: H 1 (Vw1u1 Vw2 u 2 ) m of fluid . g Alternate form of Euler’s turbine equation: Consider the velocity triangle, we may write, 32 V f21 Vr21 (U 1 Vw1 ) 2 V f21 Vr21 U 12 Vw21 2U 1Vw1 V f21 V12 Vw21 (1) (2) V U Vr21 Vw1U 1 (3) 2 V 2 U 22 Vr22 Vw 2U 2 2 (4) 2 m P (Vw1U 1 Vw 2U 2 ) t m1 2 P [V1 U 12 Vr21 (V22 U 22 Vr22 )] t 2 m V 2 V22 U 12 U 22 Vr21 Vr22 Wactual 1 t 2 2 2 2 1 2 1 Significance of the terms: V 2 V22 -This represents the energy transferred due to change in absolute velocity 1. 1 2 of the fluid and is referred to as dynamic head. U 2 U 22 -This represents the energy transferred due to movement of the fluid from 2. 1 2 one radius to another which gives rise to centripetal / centrifugal action, This is referred to as static head. V 2 V 2 3. r1 r 2 -This represents the energy transferred due to change in relative velocity 2 alone. This also forms the part of static head. U 2 U 22 Vr21 Vr22 represents static energy transfer. The sum 1 2 2 V 2 V22 represents dynamic energy transfer. While 1 2 Impulse and Reaction Turbines: 33 Turbo machines are classified as impulse and reaction machines depending on the relative proportions of the static and dynamic heads involved in the energy transfer. To aid this, we define a term referred to as degree of reaction Rd. Degree of reaction Rd can be defined as the ratio of static head to the total head in the energy transfer. Rd (U 12 U 22 ) (Vr21 Vr22 ) (V12 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) Degree of reaction can be zero, positive or negative. Rd=0, characterizes a close turbo machine for which a static head is equal to zero. In the most general case, this will happen if U1=U2 and Vr1=Vr2. These classes of turbo machines are referred to as impulse machines. In most practical situations Vr2 may be less than Vr1 even though r1=r2. This is generally due to frictional losses. Even then a machine is referred to as an axial flow turbines and pumps would have r1=r2 and if Vr1=Vr2, then they become examples of pure impulse machines. Pelton Wheel, tangential flow hydraulic machines is also example of impulse machine. Velocity Triangles for impulse machine: 34 Fig. Velocity triangle for axial flow impulse machine. The velocity of whirl at exit is to be calculated by general expression, Vw2 U 2 Vr 2 cos 2 If the value obtained is negative, then it suggests that Vr 2 cos 2 U 2 If Vw2 is positive, then OVT would appear as follows: If V2=0, then the OVT would look like 35 Problems: 1. In an axial flow turbine, discharge blade angle are 20 degrees each for both the stator V and the rotor steam speed at the exit of the fixed blade is 140 m/sec.The ratio of a 0.7 U at the entry and 0.76 at exit. Find the inlet rotor blade angle for a mass flow rate of 2.6 Kg/sec.also determine the degree of reaction. IVT 36 Given : stator disch arg e angle 1 20 , rotor disch arg e angle 2 20 , Velocity at stator exit V1 140 m sec Va1 0. 7 U Va 2 0.76 U2 sin ce turbine is axial flow machines,U 1 U 2 . IVT : Va1 V1 sin 20 47.5 m sec Vw1 V1 cos 20 140 cos 20 131.6 m . sec Va1 0. 7 U V 47.5 m U a1 68.4 0.7 0.7 sec 2 2 2 Vr1 Va1 (Vw1 U ) 47.5 2 (131.6 68.4) 2 Vr1 79.3 m sec OVT : Va 2 0.76 U O V T Preferred: 37 Va 2 68.4 * 0.76 Va 2 52 m sec Va 2 52 m 152 sin 2 sec sin 20 U 2 Vr 2 cos 2 Vr 2 Vw 2 Vw 2 68.4 152 cos 20 74.43 V2 V22 Vw22 90.8 sin 1 m sec m sec Va1 Vr1 47.5 37.22 79.3 1 sin 1 m m (Vw1U 1 Vw 2U 2 ) U (Vw1 Vw 2 ) t t P 2.6(68.4)(131.6 74.4) 36.6 KW P (U 12 U 22 ) (Vr21 Vr22 ) Rd (V12 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) Rd (79.3 2 152 2 ) 0.59 (140 2 90.8 2 ) (79.3 2 140 2 ) 2. The axial component of air velocity at the exit of the nozzle of an axial flow reaction state is 180 m/sec.The nozzle inclination to the direction of rotation being 27 degees.Find the rotor blade angles at the inlet and outlet if the degrees should be 50% and the blade speed is 80 m/sec.Also for the same blade speed axial velocity and nozzle angle. Find the degree of reaction if the absolute velocity at the rotor outlet should be axial and equal to 38 the axial velocity at the inlet. IVT OVT Given : Va1 180 m sec R d 0.5 1 27 U 180 m sec (U 12 U 22 ) (Vr21 Vr22 ) Rd 2 (V1 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) 0.5[V12 V22 ] 0.5[Vr21 Vr22 ] [Vr21 Vr22 ] V12 V22 Vr21 Vr22 Note: It may be shown that for a 50% reaction turbine, the velocity triangles are symmetrical and appear as shown. Vr1 V2 V1 Vr 2 tan 1 Va1 Vw1 m sec 180 1 tan 1 46.1 353 180 Vw1 353 Rd (254.5 2 249.9 2 ) 0.018 (396.5 2 180 2 ) (249.9 2 254.5 2 ) 39 Note: Since the condition at the inlet i.e, Va1, 1 and U1 have to remain the same, the IVT does not change only the OVT changes. Radial flow Pump and Compressors: General analysis: IVT O V T (preferred) 40 1.) Vw 2U 2 Vw1U 1 i.e, U 2 U 1 or r2 r1 flow is radially outward . 2.) Axial entry V1 Va1 Vw1 0 m Vw 2U 2 , Watt t V U H w 2 2 m of fluid . g 3.) P Most of the turbo machines belong to this class. In general, they have a restricted flow area for a given rotor diameter and have low to medium specific speed. Significant aspects: 1.) Flow is outwards from the smaller to larger radius the Euler’s turbine equation. m (Vw1U 1 Vw 2U 2 ) requires that Vw2U 2 Vw1U1 for pumps and i.e., P t compressors which are power absorbing machines. For this sake radial flow compressors and pumps generally have fluid entering at a smaller radius and leaving at a larger radius. 2.) The absolute velocity at inlet is oriented parallel to the axes of the shaft i.e., Va1=V1 and hence there is no whirl component at inlet i.e.,Vw1=0. 3.) Since Vw1=0, the energy transferred is purely a function of exit condition i.e. m P Vw 2U 2 , Watt t V U H w 2 2 m of fluid . g The velocity triangles appear as shown: 41 Head-capacity relationship: V U H w2 2 g U H 2 U 2 V f 2 cot 2 g Q 2 A2V f 2 Q U2 g Q cot 2 U 2 A2 U 22 U 2 cot 2 Q H g g A2 H K 1 K 2 Q (considerin g rotor operating for a given speed .) U 22 K1 g 90 Backward curved 90 Radial vane 90 Forward curved vane vane From the velocity triangles for the 3 types of vanes it may be noticed that the whirl component at exit is least for backward curved vane ( 90 ) and most for a forward 42 curved vane. When operating under similar condition of speed and cross section area. But from a practical view point a high value of exit velocity V2 is not desirable. This is because it becomes necessary to construct a diffuser of unreasonably large dimensions even for moderate sized rotors. Hence backward curved vane with 2 in the range of 2025 degrees is preferred for radial flow pumps and compressors. Forward curved vanes are not preferred while radial vanes ( 90 ) are used in select applications requiring very high pressure. Axial flow pumps and compressors: In axial flow machines, we recognize that the blade tips speed is same at the inlet and exit. Hence, U1=U2. In axial flow pumps and compressors, the energy transfer is achieved in the number of stages involving stators and rotors. The first stage generally as a set of guide blades which functions to act as a nozzle and directs the steam to the rotor in such a way that the relative velocity is tangential to the blade as shown .The subsequent stages of stator which function as diffusers. Hence, the last stage would end with the stator. The direction of fluid flow is parallel to the shaft axes in a general sense and hence the term axial flow, there is no radial component. The stators after each subsequent stage function as diffusers and convert the exit kinetic energy to useful pressure energy. A reasonable assumption is that the axial velocity component Va is constant. i.e.Va1=Va2=Va. While, this is generally true for incompressible fluids. It is a reasonable assumption for compressible fluids too. Since the drop in the axial velocity component is around 5% in each stage. 43 Derivation of expression for head developed in terms of rotor velocity U and rotor blade angles 1 and 2 : From the Inlet Velocity Triangles, we may write U Va [tan 0 tan 1 ] U Va [tan 0 tan 1 ] From the Outlet Velocity Triangles , we may write U Va [tan 2 tan 3 ] tan 0 tan 1 tan 2 tan 3 tan 1 tan 2 tan 3 tan 0 (1) The head developed may be written as 1 (Vw1u1 Vw 2 u 2 ) g U H [Vw 2 Vw1 ] g UVa H [tan 3 tan 0 ] g UVa H [tan 1 tan 2 ] g tan 1 tan 2 tan( 1 2 ) 1 tan 1 * tan 2 H UVa tan( 1 2 )[1 tan 1 * tan 2 ] g 1 90 1 ; 2 90 2 H tan 1 cot 1 ; tan 2 cot 2 ; UVa tan( 1 2 )[1 cot 1 * cot 2 ] (2) g 1 tan 1 * tan 2 1 1 cot 1 * cot 2 1 tan 1 * tan 2 tan 1 * tan 2 H tan( 1 2 ) H UVa g tan 1 tan 2 1 tan 1 * tan 2 (3) tan 1 tan 2 1 tan 1 * tan 2 44 Super position of Velocity triangles: (1) Common Base: (2)Common vertex: Vw2 Represents the change in the whirl component which directly contributes to the generation of head pressure increases in an axial flow pump or compressors happens due to the following reason: (1)Relative velocity is reduced from Vr1 to Vr2 with a subsequent increase in pressure. 45 (2)It may be noticed that absolute velocity has increased from V1 to V2. A high exit velocity is not desirable in pumps desirable in pumps and compressors. Hence, the necessity of a stator at the exit of every stage that will convert velocity energy to pressure energy. Expression for Degree of reaction in terms of rotor velocity and rotor blade angles: We know that, Degree of reaction is given by, 46 (U 12 U 22 ) (Vr21 Vr22 ) Rd 2 (V1 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) Rd (Vr22 Vr21 ) (V12 V22 ) (Vr21 Vr22 ) Vr21 Va2 (Va tan 1 ) 2 Va2 (1 tan 2 1 ) Vr22 Vr21 Va2 (tan 2 2 tan 2 1 ) For a pump it is generally acceptable to write deg ree of reaction as (Vr21 Vr22 ) Rd 2 (V2 V12 ) (Vr21 Vr22 ) Rd Va2 (tan 2 2 tan 2 1 ) (V12 V22 ) (Vr21 Vr22 ) we knowthat , Euler ' s turbine equation for a pump may be written as U 1 (Vw1u1 Vw 2 u 2 ) g V12 V22 Vr21 Vr22 2 2 Degree of reaction is the ratio of suction head to the total head . which may be written as U Rd 1 g Vr22 Vr21 2 g 1 V22 V12 Vr22 Vr21 2g Vr21 Vr22 2 Rd Vw 2U 2 Vw`1U 1 Rd Va2 [tan 1 tan 2 ][tan 1 tan 2 ] 2UVa [tan 1 tan 2 ] Va2 [tan 1 tan 2 ] 2UVa V [tan 1 tan 2 ] Rd a 2U tan 2 tan 1 Rd 47 Turbines: General analysis: They are power generating turbo machines, which run on both incompressible fluids such as water as well as compressible fluids such as gases. The efficiency of turbines may be defined as the ratio of actual work output to the fluid energy input. This involves 2 types of efficiencies: (1)Hydraulic efficiency /isentropic efficiency. (2)Mechanical efficiency. The mechanical efficiency takes care of all losses due to energy transfer between mechanical elements. In the turbines, mechanical efficiency is very high and of the order of 98 to 99%. The hydraulic efficiency takes care of losses during flow. We realize that, turbines must have a residual exit velocity so that flow is maintained. However, this residual velocity so that flow is it represents a lot far as the rotor is concerned. Hence, even if we have idealized friction free flow it is not possible to transfer all the energy in the fluids due to the need to have the final residual exit velocity. Hence, hydraulic efficiency is a product of 2 terms and is given by H *V V -where is referred to as vane efficiency and takes care of frictional loss. Utilization factor: Utilization factor is defined as the ratio of the actual work transferred from the fluid to the rotor in an ideal condition to the maximum possible work that could be transferred in an ideal condition. 48 Wactual (V12 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) Wmax V12 (U 12 U 22 ) (Vr21 Vr22 ) Wactual (V12 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) m 2 V1 (U 12 U 22 ) (Vr21 Vr22 ) 2 m V22 Wmax Wactual t 2 V22 Wactual m[( (Vw1U 1 Vw 2U 2 ) ] 2 Wactual (Vw1U1 Vw2U 2 ) V2 (Vw1U1 Vw2U 2 ) 2 2 Relationship between and Rd : OR Derive an expression for in terms of Rd: 1 [(U 12 U 22 ) (Vr21 Vr22 )] 2g 1 Hd [V12 V22 ] 2g Hs Rd Hs Hs Hd Rd [ H d H s ] H s Rd H s Rd H d H s Rd H d (1 Rd ) Utilization factor may be written as Hs 49 Hs Hd V2 Hs 1 2g substituting for H s , we have Rd H D HD 1 RD Rd H D V12 1 RD 2 g Rd H D H D Rd H D Rd H D 2 g V12 V12 Rd HD V2 R V2 Rd H D 1 d 1 2g 2g V12 V22 2 g 2 Rd V12 V1 Rd H D 2g 2g V12 V22 2 V1 Rd V22 This expression holds good for Rd values between 0 and 1. This cannot be used for Rd=1 (100% reaction). Since, the expression becomes equal to 1 suggesting 100% utilization factor which could obviously lead to residual exit velocity V2 becoming zero. 50 Problems: 1. At a stage in an impulse turbine, the mean blade diameter is 80cm. The rotor speed is 3000rpm. The absolute velocity of the fluid discharging from nozzle inclined at 20 degrees to the plane of the wheel is 300 m/sec. If the utilization factor is 0.85 and the relative velocity at rotor exit equals that at the inlet. Find the inlet and exit rotor blade angles and the power output for the stage for a mass flow rate of 1 Kg/sec. IVT OVT Given : N 3000rpm 1 20 0.85 d 0 .8 m m 1 Kg / sec . t 51 In an impulse turbine U 1 U 2 Vr1 Vr 2 Rd 0; V12 V22 V12 300 2 V22 300 2 m V2 116.2 sec dN * 0.8 * 3000 m U 125.66 60 60 sec 0.85 Vw1 V1 cos 1 300 cos 20 281.90 m sec IVT : Va1 V1 sin 1 300 sin 20 102.6 Vr21 V12 (Vw1 U ) 2 300 2 (281.9 125.66) 2 Vr1 186.96 sin 1 Va1 Vr1 m sec 102.6 186.96 1 33.33 OVT : V22 U 22 Vr22 2UVr 2 cos 2 116.2 2 125.66 2 186.96 2 2 * 125.66 * 186.96 cos 2 2 37.6 P m [Vw1U 1 Vw 2U 2 ] t Vw 2 U 2 Vr 2 cos 2 125.66 186.96 cos 37.6 22.4 m sec P 1 * 125.6 * [281.9 186.96 cos 37.6] 38.3 watt 2. Velocity of a steam outflow of a nozzle from a De-Laval turbine is 1200 m/sec. The nozzle angle is 22 degrees. If rotor blades are equiangular and the rotor tangential speed is 400 m/sec. Compute (1).rotor blade angle (2).Tangential force on the blades. (3).Power output. Assume Vr1=Vr2. Also determine utilization factor. 52 Given : De Laval turbine is an example for an axial flow steam turbine. i.e.U 1 U 2 m sec m U 400 sec 1 22 V1 1200 Vr1 Vr 2 m sec m Va1 V1 sin 1 1200 sin 22 449.5 sec Vw1 V1 cos 1 1200 cos 22 112.6 Vr1 Va21 (Vw21 U 2 ) 449.5 2 (1112.6 2 400 2 ) 842.5 sin 1 m sec Va1 449.5 Vr1 842.5 1 2 32.2 Vr1 Vr 2 842.5 m sec Vw 2 U Vr 2 cos 2 312.9 m sec V22 Vr22 U 2 2 * Vr 2U * cos 2 842.5 2 400 2 2 * 842.5 * 400 * cos 32.2 V2 547.85 m sec P FT * U m U [Vw1 Vw 2 ] t P 1 * 400 * [1112.6 312.9] 570.2 * 10 3 Watts P P 570.2 * 10 3 FT 1425.5 N U 400 V 2 V 2 1200 2 547.85 2 1 2 2 0 .8 V1 1200 2 3. At the nozzle exit of the certain stage in a steam turbine, absolute velocity is 300 m/sec. Rotor speed is 150 m/sec. at a point where the nozzle angle is 18 degrees. If the rotor outlet blade angle. Determine the power output from the stage for a steam flow rate of 8.5 Kg/sec.Assume Vr1=Vr2 and also determine the utilization factor. 53 IVT Given : m V1 300 sec m U 150 sec 1 18 2 1 3.5 m Kg 8.5 t sec P? m U [Vw1 Vw 2 ] t IV T : P m sec m Va1 V1 sin 1 300 sin 18 92.7 sec Vw1 V1 cos 1 300 cos 18 285.3 Vr1 V12 (Vw21 U 12 ) 300 2 (285.3 2 150 2 ) 164 sin 1 m sec Va1 92.7 Vr1 164 1 34.4 54 OVT OVT : 2 34.4 3.5 30.9 Vr 2 Vr1 164 m sec Vw 2 U Vr 2 cos 2 150 164 cos 30.9 9.2 m sec V22 U 2 Vr22 2UVw 2 cos 2 V2 84.7 m sec m m U [Vw1 Vw 2 ] 8.5 * 150 * [285.3 9.2] 352 t sec 2 2 2 2 V V 300 84.7 1 2 2 0. 9 V1 300 2 P 55 4. In a radial inward flow hydraulic turbine the degree of reaction is 0.866 and utilization factor for the runner is 0.968. The tangential speed at inlet and outlet respectively are 11 m/sec and 5.5 m/sec. Draw the IVT and OVT. Assuming that radial velocity is the same at all points on the runner and is equal to 5 m/sec. The absolute velocity at the runner outlet is purely radial with the tangential component. Determine the power output for a volume flow rate of 16m3/sec. IVT OVT 56 Given : Rd 0.866 0.968 m sec m U 2 5.5 sec U 1 11 m sec m 5 sec Vf1 Vf 2 5 V2 V f 2 m3 sec V 2 V22 21 V1 Rd V22 Q 16 0.968 V12 5 2 V12 0.866 * 5 2 V1 11.29 sin 1 m sec V1 11.29 Vf1 5 1 26.5 Vf1 180 1 sin 1 Vr1 1 101.08 Vw1 V1 cos 1 11.29 cos 26.5 10.02 V2 U2 2 tan 1 5 tan 1 42.2 5.5 m [Vw1U 1 Vw 2U 2 ] t Q P [Vw1U 1 ] 1000 * 1.6810.02 * 11 176.4 KW t P 57 5. A hydraulic reaction turbine of radial inward flow type works under a head of 160 m of water at the point fluid entry the rotor blade angle is 119 degrees and the diameter of the runner is 3.65 m and at the exit is 2.45 m. if the absolute velocity at the wheel outlet is radially directed with a magnitude of 15.5 m/sec and radial component of velocity at the inlet is 10.3 m/sec. Determine the power developed by the machine. Assume that 88% of the available head is converted into work and flow rate is 110 m3/sec. Also determine the degree of reaction and the utilization factor. IVT OVT 58 Given : H 160 m d 2 2.45 m 1 119 m sec m V2 15.5 sec Q m3 110 t sec m V f 1 10.3 sec T 0.88 d1 3.65 Q gH 0.88 *100 * 10 * 9.81 * 160 151.9 *10 6 W t If V2 V f 2 then Vw 2 0 P T m Q [Vw1u1 ] [Vw1U 1 ] t t m Vw1U 1 1381.3 sec Vf1 10.3 m Vw1 U 1 5.7 sec tan 61 tan 60 1381.3 U1 5.7 U1 P m m ,34.4 sec sec 1381.3 m Vw1 34.8 40.1 sec m Vr1 11.7 sec d N U1 1 60 U 1 40.1 59 V1 V w1 cos 1 36 m sec 40.1 * 60 210 rpm * 2.45 d N * 2.45 * 210 m U2 2 26.9 60 60 sec N Vr 2 V22 U 22 26.9 2 15.5 2 31.04 m sec 1 1 H s [(U 12 U 22 ) (Vr21 Vr22 )] [( 40.12 26.9 2 ) (11.7 2 31.04 2 )] 855.49 m 2 2 1 1 H d [V12 V22 ] [36 2 15.5 2 ] 527.875 m 2 2 2 2 V V2 21 0.92 V1 Rd V22 6. In a radial flow Francis turbine the runner outer diameter (inlet) diameter is 75cm and inner (outlet) diameter is 50 cm, the runner speed is 400rpm. Water enters wheel at a speed of 15 m/sec at an angle of 15 degrees to the wheel tangent at the point of entry. Discharge at the outlet is radial and absolute velocity is 5 m/sec.Find the runner blade angle at the inlet and draw velocity triangles. What is the power output per unit mass flow rate through the turbine? Find the degree of reaction, utilization factor and static pressure at the turbine inlet. If the static pressure at the exit is 1 atmosphere. IVT OVT 60 Given d1 0.75 m d 2 0. 5 m N 400rpm V1 15 m sec V2 V f 2 5 m sec P 1 atm IVT : d1 N * 0.75 * 400 m 60 60 sec d N * 0.5 * 400 m U2 2 10.5 60 60 sec m Vw1 V1 cos 1 15 cos 15 14.5 sec m V f 1 V1 sin 1 3.8 sec Vf1 6.01 tan 1 180 tan 1 14.5 U Vw1 U1 15.7 107.2 Vr1 V f21 (U 1 Vw21 ) 3.8 2 (15.7 2 14.5 2 ) 4 tan 2 m sec Vf 2 U2 2 25.46 Vr 2 U 22 V22 10.5 2 5 2 11.6 m sec m [Vw1U 1 ] 1 * [14.5 * 15.7] 227.6 Watts t 1 254.8 Kj H s [(U 12 U 22 ) (Vr21 Vr22 )] 127.4 2 2 Kg P V12 V22 j 100 2 Kg Hs Rd 0.56 Hs Hd Hd 61 V12 V22 =0.95 V12 RdV22 W h Cp[T02 T01 ] P P02 P01 1000 P02 P01 227.5 KPa 227.65 P02 P2 V22 2 1000 * 25 113.0 KPa 2 P01 227.5 113 341.45 KPa P02 101325 P1 P01 V12 2 341.45 * 10 3 1000 * 15 2 228.9 KPa 2 Axial flow turbines: General analysis: Most turbines involving compressible flow are axial turbines. Generally, steam and gas turbines are axial flow machines. We know that in all axial turbine machines, U1=U2=U. And hence the alternative form of turbine equation reduces to m1 2 P (V1 V22 ) (Vr21 Vr22 ) t 2 (Vr21 Vr22 ) (V12 V22 ) (Vr21 Vr22 ) Change of fluid pressure in the rotor happens only due to change in the relative velocity component Vr, since, U remains constant. Degree of reaction, Rd Axial flow turbines are of 2 types: (1) Impulse type for which Rd=0.since Vr1=Vr2 and hence power output m1 2 P V1 V22 t 2 (2)Reaction type: Generally any turbine which is not purely an impulse turbine is referred to as a reaction turbine. It is not a 100% reaction turbine. But, it is still referred to as a reaction turbine. Most reaction turbines are designed for 50% reaction which is found to 62 be very advantageous from practical consideration. In the case of steam turbines it is implicit that a reaction turbine is 50% reaction turbine called as parson’s reaction turbine. Velocity diagrams for different values of Rd appear as shown below: V1>V2, Vr1>Vr2 Rd<0(Rd is negative) V1=V2 Rd=100% Vr1=Vr2 Rd=0 V1=Vr2; Vr1=V2 Rd=0.5 V2>V1; Vr2>Vr1 Rd>100% We know that for utilization factor to be maximum, the exit velocity V2 should be minimum. For a given rotor speed U, the minimum value of V2 is obtained only if V22 is axial and the velocity triangles would look as shown: Velocity triangle for maximum utilization factor condition.: 63 V2 V1 sin 1 V12 V22 V12 Rd V22 max imum V12 V12 sin 2 1 V12 Rd V12 sin 2 1 max imum cos 2 1 1 Rd sin 2 1 Form the expression, it is clear that max imum will have the highest value if 1 =0. But 1 =0, results in V2=0 which is not a practically feasible condition. The zero angle turbines which would have 1 =0 appears as shown: Though the zero angle turbines are not practically feasible it represents the ideal condition to be aimed at. In a Pelton wheel, we arrive at a condition wherein the jet is deflected through an angle of 165 to 170 degrees. Though an angle of 180 degrees would be the ideal condition as in case of a zero angle turbine. Impulse turbine designed for maximum utilization: 64 cos 1 AC 2U OA V1 cos 1 U 2 V1 U is referred to as a blade speed ratio which will have limiting value of 0.5 V1 for a zero angle turbine. But in practical situation, 1 is in between 20 to 25 degrees. But varies from 0.45 to 0.47. The blade speed ratio is very useful performance parameter and it may be noted that the closer its value is to 0.5, the better it is. The ratio Expression for power output: Kj P (Vw1U 1 Vw 2U 2 ) Kg Vw 2 0 for max imum condition. P Vw1U but , Vw1 V1 cos 1 2U P 2U 2 Reaction turbine: We know that, cos 2 1 max imum 1 Rd sin 2 1 For a fixed value of 1 , as Rd increases max imum . But for Rd=1 (100% reaction turbine), this equation doesn’t holds good. Let us examine how max imum is affected by Rd. Case (1): Rd=1, 65 (Vr21 Vr22 ) Rd 2 (V1 V22 ) (Vr21 Vr22 ) Vw1=Vw2 Hence by Euler’s turbine equation P (Vw1U1 Vw2U 2 ) P U [Vw1 Vw2 ] P U 2Vw 2 P 2UV cos 1 2UV1 cos 1 V12 2UV1 cos 1 2 2UV1 cos 1 V22 2UV1 cos 1 1 2(2UV1 cos 1 ) 1 V22 1 4UV1 cos 1 For maximum utilization V2 needs to be axial. If V2 is to be axial, then V1 also should be axial which means that the denominator of the expression becomes equal to infinity which reduces to to zero. This only means that 1 should be as low as possible to get meaning full values of max imum . This represents contradicting condition and hence Rd=1 is not preferred. Case (2): Rd>1 V2>V1, Vr2>Vr1 V12 V22 V12 Rd V22 As Rd> tends to zero. 66 In this case, V2>V1and hence V2 can never be axial and hence the condition for max imum [An axial orientation for V2 can never be met] V12 V22 The utilization factor is given by 2 V1 Rd V22 As Rd increases, decreases. This means that the stator has to function to not only diffuse V2 to as low a value as possible but also turn the fluid through a very large angle. This results in the poor flow efficiency and hence Rd greater than 100% is not practically preferred. Case (3): Rd<0 [negative Rd] Vr1>Vr2 (Vr21 Vr22 ) Rd 2 (V1 V22 ) (Vr21 Vr22 ) V12 V22 V12 Rd V22 For this condition, it is noticed that rd is negative denominator increases, decreases. Vr2<Vr1, also means that the pressure is increasing as fluid passes through the rotor. i.e. the rotor is acting like a diffuser. This is not preferred since pressure always has to decrease along the flow path for good flow efficiency. Hence, Rd<0 is not practically preferred. Case (4): Rd=0.5, We know that for a 50% reaction turbine, velocity triangles are similar and for maximum utilization condition the triangle would appear as shown. 67 We notice, 1 2 2 1 The angles are identical but reversed for the rotor and the stator. From the practical view point, manufacturing of blades becomes simple. Since the same blade can be used for either the stator or the rotor by merely reversing the direction. It can also be shown that in a multistage turbines 50% reaction gives maximum stage efficiency. Since Vr2>Vr1, pressure reduces along the flow path in the rotor resulting in high flow efficiency. In general, n Rd value between 0 and 1 is preferred due to practical considerations. From the velocity triangle it can be noted that Vw1=U m P [Vw1U1 Vw 2U 2 ] t Vw2 =0 (for maximum utilization factor condition) P U 2 Comparing the energy transfer achieved by 50% reaction turbine with an impulse turbine when both are designed for max imum condition and operating with the same rotor velocities. We notice that an impulse turbine transfers twice as much energy as 50% reaction turbine gives the better flow efficiencies. If multi staging is attempted, the for a given value of energy transfer, a 50% reaction turbine would need twice the number of stages as that of an impulse turbines. In actual practice, when multistage is attempted, the initial stages are designed for an impulse turbine when maximum fluid velocity is available. The subsequent stages are 50% reaction stages. (a)With velocity triangle, explain how degree of reaction affects utilization factor in axial flow turbine and show that a 50% reaction turbine is the most preferred. (b)With velocity triangles, show that axial flow turbines designed for an impulse develops twice as much power as that of 50% reaction turbine when operating under maximum utilization factor coordination. 68 Ans(b) Impulse turbine Expression for power output: Kj P (Vw1U 1 Vw 2U 2 ) Kg Vw 2 0 for max imum condition. P Vw1U but , Vw1 V1 cos 1 2U P 2U 2 We notice, 1 2 2 1 50% Reaction turbine The angles are identical but reversed for the rotor and the stator. From the practical view point, manufacturing of blades becomes simple. Since the same blade can be used for either the stator or the rotor by merely reversing the direction. It can also be shown that in a multistage turbines 50% reaction gives maximum stage efficiency. Since Vr2>Vr1, pressure reduces along the flow path in the rotor resulting in high flow efficiency. In general, n Rd value between 0 and 1 is preferred due to practical considerations. From the velocity triangle it can be noted that Vw1=U m P [Vw1U1 Vw 2U 2 ] t 69 Vw2 =0 (for maximum utilization factor condition) P U 2 50% Reaction Pump and compressors. 50% Reaction Turbine. Radial flow turbines: The general principles are similar to those of radial flow pumps and compressors. The Euler turbine equation takes the form P m [Vw1U1 Vw 2U 2 ] t P 1 2 (V1 V22 ) (U 12 U 22 ) (Vr21 Vr22 ) 2 For positive work output Vw1U1 Vw2U 2 .This is achieved practically by going in for U1 U 2 which means r1>r2. This means that radius at inlet needs to be greater than radius at exit .i.e., the flow should be radically inwards. However, the earliest hydraulic turbines developed were radically outward flow turbines. The first recorded type of such a turbine HERO’S turbine developed around 2000 years ago. 70 In HERO’S turbine, steam is contained in the rotor itself which is provided with nozzles as shown, when steam issues out of nozzles , a reaction force is experienced by the nozzle due to which rotor moves in the opposite direction as indicated. Similarly in principle is the Barker’s mill which is a hydraulic reaction turbine of the radially outward flow type. This is more popular today in the form of lawn sprinkler. The lawn sprinkler would have negligible inlet velocities compared to exit velocity triangle is a straight line with V2 and U2 in opposite direction as shown. It may be shown that lawn sprinkler has poor utilization factor and hence it is not an effective turbine. However in actual practice, radial flow turbines are inward flow turbine which may involve radial entry and exit. E.g.: Old Francis turbine or radial entry and axial turbine or radial entry and axial exit. [Mixed flow], Modern Francis turbine. Fig. Barker’s Mill 71 (a)Radial type Fig. Fig. (b) Mixed flow type Hydraulic Turbine Banki Turbine ******END****** 72