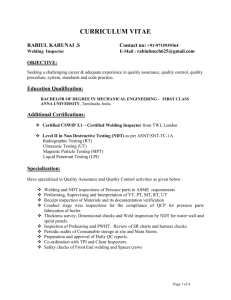

CURRICULUM VITAE

advertisement

NIDHIN JOY THATTIL +97477153890; joy.nidhin23@gmail.com MECHANICAL ENGINEER – QA & QC PROFESSIONAL Seeking challenging assignments in the domain of Quality Assurance and Quality Control PROFILE A competent and result oriented B.Tech Mechanical Engineer with 5 Years of rich experience as Quality Assurance & Quality Control in Marine Projects. ASNT LEVEL II in RT, UT, PT, MT and Certified Welding Inspector (CSWIP 3.1). Excellent Academic Credentials; B. Tech in Mechanical Engineering Capable of handling the construction and quality control activities as specified in the drawings and applicable standards and specification. Experience of total 4 YEARS in Marine Projects. Possess expertise across assembly, installation, erection, alignment and commissioning assistance of structural & piping QA/QC in Marine Project. Honed the skill by completing engineering projects. Efficient communicator with strong negotiation, problem resolution & client need assessment aptitude. Knowledge in ASME, API, AWS, & British Standards. KNOWLEDGE PREVIEW Construction Drawings such as P&ID, Piping Isometric, Equipment, Structural, GAD. Material Inspection, Dimensional Check and Documentation as per Construction Materials Standards such as ASTM / ASME SA 106, SA 515 , SA 516 , SA 105 ,SA 312, SA 240, etc. with ANSI standards of B 36.10, B 16.5, ,API 2B,API 2H,API5L, ASME B31.3, B31.4 and B 31.8. Welding Standards of ASME Section IX, ASME SECTION V, ASME sec II and AWSD1.1. Welding Procedure Qualification, Welder Qualification, P numbers, Selection of Electrodes, Weld Visual Inspection, etc. Radiographic Interpretation of weld joints, Ultrasonic Inspection, Magnetic Particle Inspection and Penetrant Test, Reporting and Documentation. Fabrication of Piping, Structure, Documentation of History Sheet, Test Pack Clearing, etc. CERTIFICATION ASNT Level II Certificate in RT (Radiographic Test) UT (Ultrasonic Test) MT (Magnetic Particle Test) LPT (Liquid Penetrant Test) CSWIP 3.1 : CERT NO – 647051 Expiry Date – April 2018 PROFESSIONAL EXPERIENCE BHARATI SHIPYARD LTD, MANGALORE,INDIA UP OFSHORE – CONSTRUCTION OF PLATFORM SUPPLY VESSEL Quality Assurance & Quality Control Engineer SEPT 2011-APR 2013 Key responsibilities include the following Inward inspection of raw materials prior to start of fabrication to ensure that right materials are used in accordance ABS Standards Field inspection like fit up, dimensional checking as per drawing, final visual of welded joints etc., Welding inspection requirements and preparation of NDT plan. Verification of Personal Qualifications for welders. Monitoring weekly and monthly welder’s performance. Surveillance of welding consumables and welding process SMAW, SAW, FCAW etc., Witnessing vacuum test, pneumatic & Hydrostatic tests. Preparation of inspection reports, punch lists and all related documents for final acceptance., Responsible for the inspection of all welding works in the project covering pressure piping, structural steel in accordance with approved WPS/PQR and applicable Industry Code Practice i.e., ASME sec, IX, II A & II B, ANSI B31.3, AWS D1.1, API 1104 approved QCP & ITP and welding requirements/standards Reporting on QA / QC activities within the framework of weekly / monthly reporting by site management. Assigning NDT requirement as per the Project requirement Reviewing NDT Plan Review of inspection results & reports of UT, RT, MT, and PT. Review and verify documents to ensure that all materials received and conform to the approved Check consumables, quiver in use. Weld identification marked up, weather condition, adequate Interpass cleaning, welding current, voltage, travel speed, polarity. Co-ordinates with commissioning activities. Co-ordination with client and surveyors(ABS) etc. System wise line walks. System wise Reinstatement & inspection for Pre commissioning.. Review of RT films & other NDT reports. Review of PWHT report & chart. Preparation of test pack. Inspection of pressure test (Hydro/Pneumatic test). Final document preparation system wise for project completion dossier. BHARATI SHIPYARD , ANCHOR HANDLING TUG AND SUPPLY VESSEL Quality Assurance & Quality Control Engineer SEPT 2011-APR 2013 Key responsibilities include the following Co- ordinate for NDT activities like radiographic testing, magnet particle testing, Ultrasonic testing and penetrant testing. Monitoring of PWHT of high pressure lines as per ASME B31.3,review the PWHT chart. Surveillance of day to day Fabrication, Welding, Mechanical and Erection Activities on Various Rig Systems Verification of isometric dawning with respect to P&ID Reviewing the approved quality plans, manuals and scope of work to perform the required inspection.. Prepare hydro test packages, line check of installed piping. Assures that all joints are exposed for examination during pressure test. Confirm repairs, re-testing and re-inspection in accordance with specifications Making a re-instatement punch list and clearing the items Witnessing of Flange joint assembly and bolt torque Ensure the blinds are removed and correct rating gaskets are installed Inspection of gaskets, supports, valves prior to line reinstatement acceptance as per the latest drawing for construction, codes and specification standards. Prepared documents, procedures for inspection method, inspection and testing plan in computerized environment. Clearing of MCC (Mechanical completion certificate) items and punch listing. Control of non-conformities issuance of punch list Coordinating with client/consultants while the inspection is being carried out and offer any clarification is required. Witnessing of pneumatic test, hydro-test, and flushing; system lay-up both in and in erection field. Preparing and maintaining various QA/QC documents and final test packages. Witness of alignment, orientation and dimensions. Pratibha Pipes and Structural Pvt Ltd, India APRIL 2010-AUG 2011 Quality Assurance & Quality Control Engineer Key responsibilities include the following Checking and approval of site quality procedures, inspection and test plans,Conduct Welder Qualification Test and Procedure Qualification Test according to WPS. Fit-up Inspections of the joints. Visual inspection of welds made with SMAW and GTAW processes. Witnessing “HYDRO TESTING” of the pipe lines. NDT section(ultrasonic testing, radiographic testing, penetrant testing ) Review the x-ray film of field joints. Witness of alignment, orientation and dimensions of installed piping. Inspection of gaskets, supports, valves prior to line reinstatement acceptance as per the latest drawing for construction, codes and specification standards. Jacob’s Marine Co Ltd, Cochin, India JULY 2008 – MARCH 2010 INSTALLED THE UNITS OF ADS (AIRCRAFT DEFENSE SHIP) SUCH AS SUSP,SLUP,ICKS,SKI & IDMFP Quality Assurance & Quality Control Engineer Key responsibilities include the following To check the material certificate chemical composition and physical properties. Confirm the material against the certificate. To monitor the welding activities as per Project spec and Procedure. Submission of Job Progress Details to Top Management. Documentation / Submission of Report (Method statement and risk assessment) and to follow up the execution of the project to ensure compliance with company HSE standard and requirements. Attending the meeting with Client in the site and full fill their requirements. Check that the line is complete and ready for test and prepare a punch list of outstanding items. Segregate the punch list into two categories a) Rectification is mandatory prior to pressure test b) Rectification required after pressure test Any change in the drawing make as built Submit the line control sheet to the client for review and obtain approval prior to pressure test Post test requirement to be checked(Bolt,nut,Gaskets and Bolt tightening Or Torque as per approved Procedure) To generate timely and accurate reports on HSE issues to top management in case of HSE violations and noncompliance and participate in raising awareness through circulating HSE memos and periodic letters on the new development in the HSE field. PROJECTS UNDERTAKEN 1) Title: Client: Organization: Role: 2) Title: ANCHOR HANDLING TUG AND SUPPLY VESSEL GREAT OFFSHORE LTD,INDIA BHARATI SHIPYARD LTD. QA/QC ENGINEER. CONSTRUCTION OF PLATFORM SUPPLY VESSEL Client: Organization: Role: UP OFFSHORE TD BHARATHI SHIPYARD QA/QC ENGINEER 3) Title: Client: Organization: Role: Nirmal Life Style, Mumbai Nirmal Life Style, Mumbai Pratibha Pipes and Structural Pvt Ltd QA/QC ENGINEER 4) Title: Client: Organization: Role: AIRCRAFT DEFENCE SHIP GOVT OF INDIA COCHIN SHIPYARD QA/QC ENGINEER ACADEMIC B. Tech in Mechanical Engineering; 2008 (Degree) Calicut University Institute Of Engineering And Technology. COMPUTER SKILL Operating System: Windows. Software package: AutoCAD'2008, Inventor, Ansys & MS Office. PERSONAL DOSSIER Name: Nidhin Joy Thattil Sex: Male Marital status: Single Nationality: Indian Date of Birth: 23-May-1986 Permanent Address: Thattil House, Pudukad (PO), Thrissur. Languages Known: English, Hindi, Malayalam & Tamil DECLARATION I hereby declare that all the information given above are true and correct with the best of my knowledge and I bear the responsibility of the above-mentioned particulars. Place: DOHA, QATAR Date: Nidhin Joy Thattil