Final Report - B-COOL

advertisement

B-COOL TST4-CT-2005-012394

1/17

B-COOL

Number: TST4-CT-2005-012394

Acronym: B-COOL

Title: Low Cost and High Efficiency CO2 Mobile Air

Conditioning System for Lower Segment Cars

Final Report

Publishable Version

Report Version:

01

Report Preparation Date:

24.02.2009

Classification:

Publishable

Contract Start Date:

November, 30th, 2008

Duration:

42 Months

Project funded by the EU

Sixth Framework Program

Contract N°012394

B-COOL TST4-CT-2005-012394

2/17

Document History

Version File Name

Author(s) Revised Approved

0.1

Strupp

Final_report_publishable.doc

Malvicino

Malvicino

Date

B-COOL TST4-CT-2005-012394

3/17

DOCUMENT HISTORY ....................................................................................................... 2

1

INTRODUCTION .......................................................................................................... 4

2

R-744 AS A REFRIGERANT FOR MOBILE AIR CONDITIONING.............................. 5

3

TESTING PROCEDURES ............................................................................................ 6

3.1

3.2

4

BASELINE VEHICLE CHARACTERISTICS ................................................................ 8

4.1

4.2

5

FIAT PANDA:....................................................................................................................................... 8

FORD KA: ........................................................................................................................................... 8

R-744 SYSTEM ARCHITECTURE ............................................................................... 8

5.1

5.2

6

FUEL CONSUMPTION ........................................................................................................................... 6

COOL DOWN ....................................................................................................................................... 7

THE FIAT PANDA B-COOL SYSTEM .............................................................................................. 9

THE FORD KA B-COOL SYSTEM ................................................................................................... 9

SYSTEM PERFORMANCE ........................................................................................ 10

6.1

6.2

FUEL CONSUMPTION ......................................................................................................................... 10

COOL DOWN ..................................................................................................................................... 11

7

LCCP - LIFE CYCLE CLIMATE PERFORMANCE .................................................... 11

8

ON BOARD SAFETY ................................................................................................. 13

9

NVH ............................................................................................................................ 14

10 LEAK RATE AND SYSTEM RELIABILITY ................................................................ 15

11 COST ANALYSIS....................................................................................................... 15

12 CONCLUSIONS ......................................................................................................... 16

REFERENCES .................................................................................................................. 17

B-COOL TST4-CT-2005-012394

4/17

1 Introduction

The B-COOL Project was fully devoted to the development of a low cost and high

efficiency air-conditioning system based on a vapor compression cycle using CO2 identified with the acronym R-744 when used as refrigerant fluid.

Methods to assess performance, fuel annual consumption and environmental impact were

identified, within the Project, and constituted a first step towards EU new standards.

The EU, as Greenhouse Gas emission reduction measure, proposed the ban for Mobile

Air Conditioning systems of fluids having a Global Warming Potential higher than 150 (i.e.

R134a) with possible future complementary measures - e.g. measurement of the MAC

fuel consumption – and this initiative represents a challenge and an opportunity for OEMs

and Mobile A/C Suppliers to increase their competitiveness.

R-744 is one promising candidate to

replace the present used fluid, named

R134a. Besides safety, reliability and

efficiency, the additional cost, estimated

in the range of 70 - 150 Euro with

reference to the low priced car systems,

represents a serious challenge to its

diffusion.

This is even more relevant considering

the lower priced cars that constitute up

to 80% of the present EU car market

considering the recent EU enlargement.

The Project has been carried out by a

consortium constituted by 2 major

Figure 1 - The B-COOL consortium

OEMs,

4

suppliers

and

three

acknowledged

excellence

centers

gathering skilled European scientists and engineers in this specific field.

The project has been focused, at first, to the identification of the most appropriate testing

procedures so to be able to qualify in realistic way a mobile air conditioning in terms of fuel

consumption and performances (thermal comfort). A specific activity has also been

launched to verify the safety-related issues.

The major effort has been devoted to the development of the A/C systems for a Fiat Panda

with automatic air conditioning and a Ford KA with manual control.

The cars have been fully characterized following the identified procedures before and after

the R-744 A/C system installation.

B-COOL TST4-CT-2005-012394

5/17

2 R-744 as a refrigerant for mobile air conditioning

Compared to conventional refrigerants, the most remarkable property of R-744 is the low

critical temperature of 31.1°C, so a vapour compression cycle operating at normal ambient

temperatures works close to and even above the critical pressure of 7.38 MPa. This leads

to three distinct features of R-744 systems:

Heat is rejected at supercritical pressure in many situations. The system will then use a

transcritical cycle that operates partly below and partly above the critical pressure. Highside pressure in a transcritical system is determined by refrigerant charge or the

expansion device and not by saturation pressure. The system design thus has to

consider the need for controlling high-side pressure to ensure optimized COP and

sufficient cooling capacity.

The pressure level in the system is high (around 3-10 MPa). Components therefore

have to be redesigned to fit the properties of R-744. Due to smaller volumes of piping

and components, the stored explosion energy in a R-744 system is equal to a

conventional system. A benefit of high pressure is that the required compressor

displacement is reduced by 80-90% for a given cooling capacity. Compressor pressure

ratios are low, thus giving favourable conditions for high compressor efficiency.

2=3

4=5

2=3

4

Condenser

Gas Cooler

Compressor

1

IHX

Expansion Valve

5

Compressor

Evaporator

Expansion Valve

6

Evaporator

7=8=1

6

Fig. 0: Simple diagram of R134a

MAC system.

R-134a loop

7=8

Fig. 0: Simple diagram of R744 MAC

system.

R-744 loop

Large temperature variation glide

occurs during heat rejection. At

supercritical

or

near-critical

pressure, all or most of the heat

transfer from the refrigerant takes

place by cooling the compressed

gas without phase change. The heat

exchanger is therefore called gas

cooler instead of condenser. Gliding

temperature can be useful in heat

pumps for heating water or air. With

proper heat exchanger design the

refrigerant can be cooled to a few

degrees above the entering coolant

(air, water) temperature, and this

contributes to high COP of the

system.

Figure 2 - R-744 and R-134a systems

schemes. The Internal Heat Exchanger is

adopted to assure appropriate efficiency to the

R-744

loopdifference of R-744 thermo-physical properties and cycle characteristics

Due

to the

compared to HFC refrigerants, typical efficiency curves (COP, Coefficient Of Performance:

cooling capacity divided by power input) show different trends with different ambient

temperatures.

R-744 tends to be more efficient at lower ambient temperatures, while HFC systems may

be slightly more efficient at higher ambient temperatures. This tendency has been verified

for a variety of applications such as mobile air-conditioning and supermarket refrigeration.

The intersection of the two depicted curves varies depending on various factors such as

cycle layout and component efficiency.

B-COOL TST4-CT-2005-012394

6/17

It shall be emphasized that in this situation, it

would be misleading to base the comparison

indicated in Figure 3 on design-point

conditions, which typically are at an extreme

ambient temperature. A more sensible basis

for comparison is to use mean/average

conditions, or to apply a seasonal analysis

based on climatic variation, as applied in

LCCP (Life Cycle Climate Performance)

calculations.

Figure 3 - COP of R-744 and R-134a

systems at varying ambient temperature

R-744 technology is widely diffused for low

temperature refrigeration and start to be

applied as heat pump and air conditioner [1].

a) Heat pumps and Air Conditioning: Heat pump water heaters, heat pumps for tap water

heating, were commercialized in Japan in 2001 for both residential and commercial

applications. Systems adapted to European conditions are under development. One of the

major advantages is that these transcritical systems are able to provide water at high

temperatures (90 °C) without a substantial drop in COP, compared to systems using HFC

as a refrigerant.

b) Commercial refrigeration: R-744 is an important refrigerant alternative to HFCs in

commercial refrigeration systems. Some of the major companies have introduced direct

systems using solely R-744 as a refrigerant with sub/transcritical cycles, depending on

ambient temperature. Also in the light commercial sector, i.e. stand-alone equipment such

as bottle coolers and vending machines, some of the major companies have introduced R744 technology.

c) Mobile Air Conditioning: Mobile Air conditioning is the application with the largest HFC

emissions and the second largest GHG emissions in R-744-equivalent resulting from

refrigerant emissions. Hafner et al (2004) compared R-744 mobile air-conditioning systems

to R-134a and R-152a systems based on experimental and climate data from different

cities around the world. Compared to HFC-134a R-744 showed an LCCP reduced

by 18 – 48 %.

3 Testing procedures

3.1 Fuel consumption

The procedure has been conceived to be feasible in the existing testing benches and to be

representative of a real use and has been derived from a study carried out by Armines and

CRF [2].

The procedure is based on a modified NEDC cycle (Normal European Driving Cycle)

where four elementary Urban Cycles have been added to evaluate the effect of the cooldown transient as well as of steady state conditions during the urban cycle (Figure 4).

The test can be performed in a climatic chamber equipped with rolling bench and does not

require major changes to the existing testing facilities and standard testing procedures.

B-COOL TST4-CT-2005-012394

7/17

140

35

Outlet Temperature

Cabin Temperature

Speed

Temperature (°C)

30

Equivalent thermal conditions without

solar irradiation have been identified

under the hypothesis that the solar

cabin soaking can be represented by an

air

temperature

increase.

This

hypothesis introduces an approximation

but simplifies in a crucial way the testing

procedure requirements making it

applicable in almost all the existing

facilities (climatic chamber with rolling

benches and emission and consumption

120

25

100

20

80

15

60

10

40

5

20

0

0

500

1000

Time (min)

1500

Speed (km/h)

To assure an acceptable accuracy level

each test has to be repeated at least

three times.

0

2000

Figure 4 – The testing cycle based on the

New European Driving Cycle (NEDC) that

has been

adopted

to assesssystems).

the fuel consumption of

measurement

mobile air conditioning systems.

The ambient testing conditions are as

follows:

70

T e m p e ra t u ra [° C

]

Temperature

(°C)

60

28°C and 50% R.H. - European Summer:

these conditions can be considered

representative to classify the air

conditioning system with regards to the

fuel consumption and thermal comfort.

The A/C system set point: 20°C.

50

30 km/h

40

60 km/h

90 km/h

IDLE

Head

30

20

Outlets

10

0

0

20

40

60

80

T e m p o [ m in ]

1 00

1 20

1 40

Time (min)

Figure 5 - Cool Down test (43°C - 35%

R.H., 900 W/m2 solar irradiation). The test

start when the air temperature at head level

reached 60°C. A/C is set at maximum

dehumidifier.

system set point:

powerThe

andA/C

in recirculation

mode 20 °C.

35°C and 60% R.H. - Severe Summer:

representative of very high thermal load

(non-European).

The A/C system set point: 23°C.

15°C and 70% R.H. - Dehumidification:

to consider the use of the A/C as a

All tests are performed with the A/C in fresh air mode

A specific procedure has been defined to represent in a realistic way the use of manual

A/C systems and thermal comfort [3].

3.2 Cool down

The test is devoted to qualify the air conditioning system in terms of cooling performance

under severe thermal load (see figure 4) and should be performed in a climatic wind tunnel

with solar irradiation simulation.

B-COOL TST4-CT-2005-012394

8/17

4 Baseline vehicle characteristics

Two low segment cars have been selected

as baseline vehicles:

4.1 Fiat Panda:

1.2 l Gasoline with automatic A/C

COLOUR: black

COMPRESSOR: 60 cc scroll,

transmission ratio = 1.32

FIAT PANDA

Figure 6 – The Ford Ka and Fiat Panda

used to realize the B-COOL vehicle

CONDENSER: 574 x 315 x16

demonstrators

Serpentine Parallel Flow with integrated dryer

EVAPORATOR: 185 x 188 x 58, plates and Fins

EXPANSION DEVICE: thermostatic expansion valve

LINES: 3 lines

4.2 Ford Ka:

1.3 Gasoline with manual A/C (2005 my)

COLOUR: Black

COMPRESSOR: 90 cc scroll, transmission ratio = 1.40

CONDENSER: 400 x 382 x 20

EVAPORATOR: 210 x 240 x 81

EXPANSION DEVICE: orifice & accumulator

LINES: 4 lines

5 R-744 SYSTEM ARCHITECTURE

Both the developed R-744 systems have a

similar architecture (Figure 7) based on

variable displacement piston compressor,

internal heat exchanger and orifice

expansion device and an accumulator. The

compressors, of different type, are of piston

type with have 29 cc displacement modified

to have a maximum displacement of 20 cc.

GAS COOLER

HP SENSOR

LP SENSOR

INTERNAL

HEAT EXCHANGER

CHARGE PORT

FILTER

COMPRESSOR

EVAPORATOR

x

ACCUMULATOR

ORIFICE

Figure 7 - B-COOL R-744 A/C system

scheme

B-COOL TST4-CT-2005-012394

9/17

5.1 THE FIAT PANDA B-COOL SYSTEM

Two versions of R-744 system have been

conceived, one with a separate internal

heat exchanger (figure 8a) and one with

the heat exchanger integrated in the

accumulator (Figure 8b).

The components have been designed and

realized by Dephi, the line, the

accumulator and the internal heat

exchanger by Maflow. Sensata supplied

the temperature and pressure sensors.

The expansion device is a fixed orifice

(0.55 mm) with a bypass at 12 MPa

(Egheloff)

The evaporator fits in the HVAC module

not requiring major changes and the gas

cooler has the same face area of the

baseline condenser. The gas cooler fan,

that is located on the left hand in the

baseline system, has been moved in a

more central position for a more uniform

air flow.

5.2 THE FORD

SYSTEM

KA

EVAPORATOR

ORIFICE

INTERNAL

HEAT EXCHANGER

FILTER

ACCUMULATOR

GAS COOLER

VARIABLE DISPLACEMENT

28 cc COMPRESSOR

with reduced displacement to 15 cc

Figure 8a - First version of B-COOL Fiat

Panda R-744 system. The compressor

position, between the engine and the

firewall led to a characteristic design of the

Internal Heat Exchanger

ORIFICE

EVAPORATOR

FILTER

B-COOL

The Ford KA R-744 system has a more

conventional lay out due to the fact that

the compressor is located in front of the

engine. The components have been

designed and realized by Valeo, the A/C

lines and the internal heat exchanger by

VARIABLE DISPLACEMENT

28 cc COMPRESSOR

with reduced displacement to 15 cc

GAS COOLER

Figure 8b - Second version of B-COOL

Fiat Panda R-744 system: the internal

Heat Exchanger has been integrated in

the accumulator.

Maflow,

who

also

provided

accumulator;

Sensata

supplied

temperature and pressure sensors.

ORIFICE

INTERNAL

HEAT EXCHANGER

ACCUMULATOR

GAS COOLER

Figure 9 - Ford KA B-COOL R-744 A/C

system

the

the

The expansion device is a fixed orifice

(0.50 mm) with a bypass at 12.5 MPa. The

heat exchangers have the same face area

of the baseline components. The

accumulator

replaces

the

R134a

accumulator of the baseline system. The

co-axial tube internal heat exchanger is

designed as a separate component. The

gas cooler size is severely limited by the

front-end package.

B-COOL TST4-CT-2005-012394

10/17

6 System Performance

The demonstrator vehicles have been

characterized following the procedure

above described before and after the

installation of the R-744 systems.

Testing Conditions

Temperature

Humidity

Air Enthalpy

Panda - R-134a

6.1 Fuel consumption

Panda - R-744 1st

The measured data are reported in

the tables 1 and 2. The results of the

two versions of the Panda system

have been included to show the effect

of the system changes (compressor

displacement increase from 15 cc to

20 cc and adoption of the IHX).

Panda - R-744 2nd

Ka - R-134a

Ka - R-744

38

38

45

65

70

100

112

126

100

109

The Fiat Panda R-744 1st version

system shows also a slightly

decrease of the thermal comfort at 35

°C that is fully recovered with the

second version of the system. The

Ford Ka has a better performance at

35 °C due to the evaporator

temperature control, the baseline

produced a bit too low outlet

temperature. The lower increase, in

percent, of the fuel consumption of

the Ford Ka with respect to the

reference test point (baseline @ 28

°C) to is due to the quite high baseline

Testing Conditions

Temperature

Humidity

Air Enthalpy

Panda - R134a

Panda - R-744 1st

Panda - R-744 2nd

Ka R134a

Ka - R744

15 °C

28 °C

35 °C

70% R.H.

50% R.H.

60% R.H.

34 J/kg

59 J/kg

91 J/kg

Themal Comfort [1-10 scale]

n.a.

n.a.

n.a.

n.a.

n.a.

8.1

8.1

8.1

8.2

8.5

A/C system

value,

35 °C - 60% R.H.

2.5

2.0

1.5

15 °C - 70% R.H.

1.0

28 °C - 50% R.U

0.5

Panda - R-744 1st

0.0

30

40

50

60

70

80

7.3

7.3

7.7

7.3

7.8

Table 2: Thermal comfort in arbitrary units

measured on a NEDC based testing cycle

3.0

Panda - R-134a

Panda - R-744 2nd

177

180

225

135

143

Table 1: measured fuel overconsumption

on a NEDC based testing cycle - % of the

baseline

system

(R-134a)

fuel

overconsumption at 28 °C 50% R.H. – Note

that the baseline Ford Ka fuel consumption

is rather higher than the Fiat Panda baseline

fuel consumption.

Both the R-744 systems shows a

slightly higher fuel consumption at

higher thermal load (35 °C).

Fuel Add. Cons. [l/100 km]

15 °C

28 °C

35 °C

70% R.H.

50% R.H.

60% R.H.

34 J/kg

59 J/kg

91 J/kg

Fuel Overcunsumption

[% of baseline @ 28 °C]

90

100

Ambient Conditions (H - kJ/kg)

Figure 10 - Fiat Panda fuel consumption increase

due to the air conditioning vs ambient air enthalpy.

The data have been used as input for the LCCP.

fuel

consumption

B-COOL TST4-CT-2005-012394

11/17

6.2 Cool down

The Table 3 synthesizes the results of

T Outlet Mean [°C]

the cool down test comparing the

10'

30'

60'

90'

120'

baseline vehicles with the R-744 A/C

Panda - R134a

9.9

9.3

7.4

10.6

16.9

system equipped demonstrators. The

Panda - R744 1st

10.4

5.4

4.9

7.1

14.3

results shows that the R-744 system are

Panda - R744 2nd

8.0

7.0

7.0

5.0

9.0

Ka R134a

able to guarantee adequate cooling

14.0

9.0

7.0

7.0

17.5

Ka - R744

12.0

5.0

5.0

5.0

19.0

performance event at high thermal load

and the second version of the Panda

system with increased compressor Table 3: cool down test cycle at 43 °C, 30%

displacement allows to achieve better R.H. and 800 W/m2. – see figure 4

performance at the end of the cycle (idling). It should be highlighted that this increase of

cooling power is paid with a fuel consumption increase (see table 1 and figure 10).

Two approaches [4] have been applied

within B-COOL to estimate the LCCP of a

mobile air conditioning system:

bench data: where the analysis is based

on theoretical vehicle models, with typical

engine efficiencies. The defined thermal

load (f{tambient}) of the vehicle(s) and

the corresponding cooling demand is the

basis for performance tests carried out in

test benches as shown in figure 11.

vehicle data: the analysis is based on

measured fuel consumption as function

of ambient temperatures (figure 10),

which can be applied for various

climates.

Required compressor shaft power [W]

7 LCCP - LIFE CYCLE CLIMATE PERFORMANCE

2500

2000

HFC

R74 4

1500

1000

500

0

10

20

30

40

Ambient temperature [°C]

50

Figure 11 - Bench test data (@ equal

cooling capacities) used as input for LCCP

calculation for Ford Ka

The LCCP estimation in table 4 has been performed considering that:

the materials are from the same region (e.g. Al from North Europe) and assembled in

the same plant (e.g. France), this implies that 1 kg of CO2 is emitted for each kg of and

the installed A/C system.

Entire life time HFC-loss are estimated as equal to 0.4 - 0.65 kg, including 15-25% loss

during service (1x in central & northern EU; 2x in southern EU) and 50% recovery at

End of Life (EoL).

Service is assumed to be requested after 150g HFC loss in S-EU and 180g in C&N-EU.

B-COOL TST4-CT-2005-012394

12/17

Both the calculation methods have been applied:

using the vehicle data (Fig. 10) for the Fiat Panda

using the test bench data for the Ford KA (Fig. 11)

The LCCP calculation has been performed considering three different climate regions:

Athens, Paris and Trondheim.

The results of the analysis are reported

in table 4. There is evidence that the R744 system has a lower LCCP in all the

three evaluated conditions. Even at

higher fuel consumptions of the R-744

system at an improved thermal comfort,

the reasonable HFC-leakage rates

results in higher LCCP values for the R134a systems. In addition to that the

data in the table also show that both the

adopted LCCP calculation approaches

confirm the ranking between the two

systems.

Fuel consumption

measured on-board

Fiat Panda R134a

Fiat Panda R-744

Fiat Panda R- 744 2nd*

Life Time Emissions

Athens

Paris

Trondheim

kg CO2/ 12Years

2871

1244

906

1968

654

310

2535

846

377

*@ higher thermal comfort

Table 4:a

LCCP (Life Cycle Climate

Performance) estimation for R-134a and R744 B-COOL systems tested on board (see

figure 9).

Fuel consumption

measured on bench

Ford Ka R-134a

Life Time Emissions

Athens

Paris

Trondheim

kg CO2/ 12Years

2814

1217

872

1638

552

275

Ford Ka R-744

It should be underlined that, when bench

test data are used as input, the Table 4:b LCCP estimation for R-134a and

procedure risks to underestimate the R-744 B-COOL systems tested at bench

LCCP value, as the tables show: the (see figure 10).

Fiat Panda MAC system has significant

lower fuel consumption than the Ford Ka system when measured on board. To estimate

accurately the effect of vehicle fuel consumption of the MAC during a driving cycle when

bench data are use as input a sophisticated and well tuned vehicle model is required. The

system bench test cannot take into account the effect of on board installation.

The use of on board measurements allows obtaining a more reliable value of the LCCP

value.

B-COOL TST4-CT-2005-012394

13/17

8 On board safety

In the framework of the B-COOL

project, tests and theoretical analysis

have been performed to assess the risk

associated to the R-744 leak in the

cabin so to evaluate if safety devices

are required.

C head

C mean

6

5

4

3

2

1

0

0

1000

2000

3000

4000

t (s)

Figure 12 - R-744 concentration at driver

place with 4 passengers, maximum

ventilation, re-circulation. Sudden leak: all the

charge is released in 60 s. maximum leak

C Feet

C head

C mean

18

16

14

C (% vol.)

The R-744 A/C system has an internal

volume of around 1.2 l to 1.4 l with a

charge in the range of 350 g. The

empty cabin volume of a B-segment

car is around 2.1 m³.

C Feet

7

C (% vol.)

R-744 is a non-toxic refrigerant (as

classified in EN 378), however at

concentration equal or higher than 3%

vol. it causes stimulating effect on the

respiratory centre and could be lethal

at concentration higher than 9% vol.

12

10

The highest peak R-744 concentration

8

6

is theoretically reached when the entire

4

refrigerant of the A/C system is

2

0

discharged in the cabin and 4

0

1000

2000

3000

4000

5000

6000

7000

passengers are on board (air volume

t (s)

reduction of 200 l approx. and the R744 emission due to the respiration).

Figure 13 - R-744 concentration at driver

These unrealistic conditions lead to a

place with 4 passengers, no ventilation, remaximum peak concentration of 12%

circulation. Sudden leak: all the charge is

vol. R-744 and temperature controlled

released in 60 s.

has been used to simulate the A/C

system leak in a Fiat panda cabin. The

R-744 concentration is measured by means of sensors (accuracy ± 20 ppm in the range of

0-10000 ppm) placed at the driver and back passenger places at breath and at feet level.

A test matrix has been followed considering different leak rate, ventilation level,

recirculation and passenger presence. The air outlet has been oriented to the driver’s

head, and the vents at the front passenger seat are closed so to increase the R-744

concentration at the driver’s head.

On the basis of literature data and tests it has been found that the R-744 concentration

increase due to the passenger presence can be estimated in:

0.5 %vol./passenger: recirculation and no ventilation

0.1 %vol./passenger: recirculation and max ventilation

B-COOL TST4-CT-2005-012394

14/17

The tests represent worst-case scenarios

with the highest pressure in the evaporator

and the front panel outlets oriented to the

face of the occupant.

The tests results show that the most critical

cases are:

leak in recirculation mode and no

ventilation

sudden leak in recirculation mode and

full ventilation

and indicate that the risks due to the R-744

release in the cabin can be prevented

safely by:

Figure 14 - Two mini-sheds used to

evaluate the system tightness in the

ARMINES-CEP laboratory

managing properly the recirculation flap

detecting critical leak by means of conventional diagnostic tools (e.g. pressure and

temperature sensor monitoring), so no additional sensors are strictly required

In addition to that, it is important to remark that:

If the leak happens when the engine and/or the electrical systems are OFF (e.g.

parking) sensors or other active devices are useless because not active and R-744

concentration drops rapidly to non critical values just when the door is open

If the leak happens when the engine and/or the electrical systems are ON a critical

leak can be detected elaborating properly the signal of pressure and temperature

sensors and the information available on the vehicle network. The activation of fresh

air mode and ventilation can prevent any risk.

9 NVH

The noise and vibration may represent an issue for the R-744 systems. The compressor is

the main source, while the lines are another risky element. The B-COOL system has

shown limited problems related to NVH. The NVH level is aligned with the baseline vehicle

characteristics. In general several options can be considered and are still under study to

decrease the negative NVH characteristics:

optimized compressor

non-corrugated flexible lines.

sound insulation and vibration damping material.

mufflers.

B-COOL TST4-CT-2005-012394

15/17

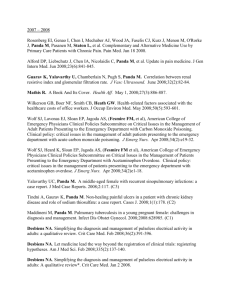

10 Leak rate and system reliability

This issue has been one of the most common in the history of R-744 MAC systems, and

also is important within the context of the B-COOL Project. The leakage rate needs to be

kept under control so that the system only needs to be serviced within the specified

timeframe, while offering good performance.

If a component leaks out of the specified rate, the system will loose its charge and will stop

working, requiring a refill. The most critical issue is the leakage through the compressor

shaft seal.

Other sources of leaks are the seals and fittings, but metallic seals and good tightening of

the fittings are to be used to keep the leakage within specifications.

The B-COOL system leak rate has been measured adopting the concept first developed

for the measurement of leak rate of A/C systems running with R-134a [5] and based on the

measure of the R-744 concentration in an accumulation volume named mini-shed.

The measured leak rate was not acceptable, indicating that further improvements are

required to reach an annual leak rate of about 50g/year that can be considered a

reasonable target maintenance/recharge.

11 Cost analysis

The B-COOL project included the prediction of system cost with a very ambitious target of

an additional cost of 30 Euro/system.

In order to insure the coherency of cost estimates and to have a common baseline the cost

estimation has been performed with the following main assumptions

the given costs are the ones paid by the car manufacturers which means prices for the

suppliers

as reference an average R-134a system cost has been identified on the basis of the

Fiat Panda and Ford KA A/C loops

and components. The present cost

has been reduced according to the

R-134a

R-744

(reference) Min (%) Max (%)

market trend to estimate the cost in

Compressor

1

1.3

1.7

2011

the electronic control has been

excluded

the reference year is 2011 for R744 production

production volume assumption is

300.000 units/year for all the

components except gas cooler and

evaporator where the selected

Evaporator

Condenser/Gas Cooler

Lines, Accumulator, IHX

Refrigerant

Sensors

Expansion Device

Total

1

1

1

1

1

1

1.5

0.8

2.8

0.3

1.0

1.3

1.8

1.1

3.1

0.3

1.2

1.6

1.5

1.8

Table 5: cost range of a R-744 A/C system,

relative to a 2011 R-134a A/C system

(unitary cost).

B-COOL TST4-CT-2005-012394

16/17

volumes considered are the full production capacity (i.e. 1.4 million units/year).

As synthesized in the table 6, the cost of a 2011 R-744 A/C system ranges from 1.5 to 2

times the cost of a 2011 R-134a loop (e.g. +100 Euro – +150 Euro).

This estimation is far from the original B-COOL target of an additional cost +30 Euro or in

other words a target of 1.2 times the cost of a 2011 R-134a A/C loop. Unfortunately, for

first applications in 2011 on small cars, it seems very hard to reduce the today’s given

figures in a significant way.

12 CONCLUSIONS

Within the B-COOL EU-funded project a R-744 air conditioning system has been

conceived, developed and installed on two vehicle demonstrators representative of the

European A-B segment: a Fiat Panda and a Ford Ka.

The R-744 air conditioning systems have been fully characterized on bench and on board

and compared with the baseline R-134a systems.

The results demonstrate that the performance issues have been solved and R-744 A/C

system can achieve the same efficiency level of present R-134a systems, even if further

developments and testing are required to reach the same reliability levels as with R134a

systems.

The system efficiency will increase when right-sized compressors will be available. The

28cc externally controlled variable capacity compressors, designed for C-segment cars,

when used on small cars, as in this study, in partial load, have a lower efficiency. Those

compressors can be used to validate the rest of the components, and in a first phase of R744 system diffusion, but smaller displacement compressors (15 cc) guarantee better

efficiency.

As it has been previously mentioned, on the short term the cost will be significantly higher

than present R-134a.

If all the OEMs were to switch to R-744 technology and production volumes were increase,

the cost would likely decrease but would hardly reach the same level of R-134a system.

The technical developments within the B-COOL Project have led to specific solutions for

the use of this technology in small cars.

The B-COOL project demonstrated that the R-744 technology for A-B segment cars seems

technologically affordable even if reliability and system additional cost are still open issues

that need to be further investigated.

B-COOL TST4-CT-2005-012394

17/17

REFERENCES

[1] www.R744.com

[2] Méthode de mesure et mesures des surconsommations de climatisations automobiles - Convention

ADEME 01 66 067 - RAPPORT FINAL Référence ARMINES 20152 - Jugurtha BENOUALI, Denis CLODIC

(ARMINES), C. MALVICINO, S. MOLA (CRF)

[3] Mobile air conditioning fuel consumption & thermal comfort assessment procedure, C. Malvicino (a), S.

Mola (a), D. Clodic(b) - (a) Centro Ricerche Fiat, (b) Ecole des Mines de Paris, Center for Energy and

Processes. IIR Gustav Lorentzen Conference on Natural Working Fluids, Trondheim, Norway, May 28-31,

2006

[4] Global environmental &economic benefits of introducing R-744 mobile air conditioning, Armin Hafner &

Petter Nekså, SINTEF Energy Research Trondheim,, Norway, 2nd International Workshop on Mobile Air

Conditioning and Auxiliary Systems. Turin, Italy, November 2007

[5] Measurement of Leak Flow Rates of Mobile Air Conditioning (MAC) Components - How to Reach a

Generic Approach, SAE 2007-01-1186, SAE 2007 World Congress, Yingzhong Yu, Denis Clodic, Ecole des

Mines de Paris, Center for Energy and Processes