Varian 356-LC Technical Paper

advertisement

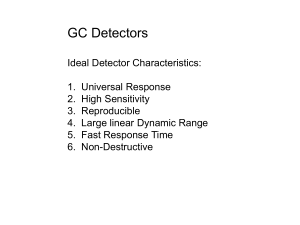

For Internal Use Only Varian 356-LC Refractive Index Detector Introduction The Varian 356-LC differential refractometer is a universal detector designed for highperformance analyses where the refractive index of a flowing liquid with respect to a reference is required. Its small cell volume, high sensitivity, and accurate temperature control make it well suited for use as a detector in automated and manual high performance liquid chromatography. Figure 1: Varian 356-LC Refractive Index Detector The Varian 356-LC Refractive Index Detector can be operated as a stand-alone HPLC detector or can be integrated into a Liquid Chromatography System. The detector is controlled remotely by Galaxie Chromatography Workstation software, through serial communications. For information on operating the detector using a desktop PC, refer to the Galaxie Chromatography Workstation manual. Principle of Operation In a deflection type refractive index detector a light beam is focused towards a flow cell containing a reference and sample compartment (see figure 2). As the light beam passes through both the sample and reference compartments of the cell, the light undergoes a deflection in proportion to the difference in refractive index between the two liquids. The amount of deflection is measured using a photodiode, which is subsequently converted to an electrical signal at the output. Page 1 of 20 For Internal Use Only Figure 2: Principle of RI detection When both cells contain pure solvent, the system is calibrated to zero by means of a parallel zero-plate that positions the beam on the two detector diodes I1 and I2 in such a manner that the measured light intensities (I1 and I2) of the two diodes are virtually identical; see figure 2.2a. When the sample cell contains a solution with a different refractive index to that of the solvent, the light beam is geometrically proportionally deflected depending on the relative change of the refractive index (according to Snell’s refraction law). This results in a change of the light intensities I1 and I2, proportional to concentration and refractive index of the sample solution. From these intensity changes the signal value is calculated and indicated on the output display. I1 I1 I2 (a) Zero Refraction I2 (b) Refracted light beam Figure 3: Example of light beam shift on detector diodes. Refractive index is a bulk property of the mobile phase and is a dimensionless constant that normally decreases with increasing temperature. Consequently RI detectors are very sensitive to changes in ambient temperature (0.001 °C) and need accurate control over their thermal surroundings. RI detectors are also sensitive to flow-rate changes and cannot be used for gradient elution. ! The refractive index is highly temperature dependent. The change per 1 °K for pure water is ~ 1x10 -4 RIU and ~ 5x10 -4 RIU for typical organic solvents. NOTE Page 2 of 20 For Internal Use Only Instrument Design The Varian 356-LC is based around the outer-casing of the ProStar 325 UV detector. The internal layout of the Varian 356-LC is shown in figure 4 and comprises 4 components: 1. 2. 3. 4. Refractive index block assembly Main PCB Power Supply Mains inlet Figure 4: Layout of Varian 356-LC Internal components Page 3 of 20 For Internal Use Only Refractive Index Block Assembly The RI block assembly is the main component of the Varian 356-LC and comprises an outer stainless steel casing, which holds an optical bench insulated by 13mm thick EPP (expanded polypropylene). 1 5 4 6 2 7 3 8 1. Zero-glass motor 2. Photodetector 3. LED 4. Zero-glass 5. Cell outlet tubing 6. Flowcell 7. Mirror 8. Cell inlet tubing Figure 5: Cross-section of Varian 356-LC refractive index block The optical bench assembly of the Varian 356-LC is shown in figure 5. The complete optical bench is located on anti-vibration mounts in order to eliminate the effect of physical disturbance on the detector response. The LED light source has a wavelength of 880 nm and a high power in order to maximise the amount of light striking the photodiodes. The photodetector is located at 45° to the incident light source and a mirror, located behind the flowcell, allows easy alignment of the beam. In order to equalise the amount of light striking the photodiodes (i.e. Auto-zero), a zero-glass (‘null’ glass) plate is located just in front of the photodetector. The position of the zero-glass is controlled by a motor. The flowcell has been specifically designed to minimise mixing effects within the cell, and to maximise laminar flow; especially at high liquid flow rates. In addition, the flowcell is only 6 µL in volume and only 9 µL with the inlet and outlet tubes included. The small volume of the cell allows better temperature control and hence better baseline stability. Page 4 of 20 For Internal Use Only Internal flow path of Varian 356-LC The output from the column should be connected to the inlet of the RI detector using small bore tubing, typically 0.25 mm ID stainless steel or PTFE tubing. The detector outlet should be connected to stainless steel or PTFE-capillary with a minimum internal diameter of 1.0 mm and go directly to the waste reservoir. Under normal flow conditions the solvent from the column enters the sample side of the flow cell (at the bottom) via the heated RI block then out through the top of the cell. The liquid then enters a three-way valve, which directs the solvent through a T-piece connector and out to waste. When the instrument is set to purge mode, the solvent from the column flows through the sample side of the cell, as before, but is then diverted back through the reference side of the flowcell via a three-way valve. On exiting the reference cell, the solvent enters a T-piece connector then flows to waste. The total volume of the inlet tubing is 15 µL whilst the outlet tubing is 459 µL. The flow scheme of the Varian 356-LC detector is shown in figure 6. Figure 6: Varian 356-LC internal flow path Page 5 of 20 For Internal Use Only Detector Electronics The Varian 356-LC electronics comprises a main PCB, located on the left-hand side of the module and a small pre-amp board located in the RI block. The main PCB houses the temperature control, DAC, safety control as well as general control and communication circuitry. The PCB is shielded from the RI block in order to minimise thermal variations resulting from the electronics. The photodetector pre-amp board is located in the RI block and contains the necessary electronics to control the detector’s sensitivity. The pre-amp board is thermally insulated from the flow cell in order to minimise thermal variations that could cause baseline disturbances External Connections The Varian 356-LC can communicate with other modules and devices in the entire HPLC system. All power and signal connections are made on the rear panel of the Varian 356-LC (see figure 8). The connectors on the rear of the panel support communication configurations to a wide range of Varian modules and non-Varian devices, such as autosamplers, pumps, valves and injectors. 1 2 3 4 5 1. Indicator Lights 2. Power Switch 3. Eluent Outlet 4. Eluent Inlet 5. Drain port Figure 7: Front View of Varian 356-LC Page 6 of 20 For Internal Use Only 4 1 5 2 3 6 1. Serial RS232 connector- 24bit digital output 2. Control Firmware flash upgrade connector 3. Connector control I/O –15 pin D type female 4. Analog output-1V 5. Mains switch 6. Mains input Figure 8: Rear View of Varian 356-LC Digital Output The Varian 356-LC is fitted with a standard RS232 (DTE-DCE) 3-wire serial connector that provides a 24bit (10Hz) digital output for connection to a chromatographic acquisition device. For digital output signals, attach the supplied serial cable to the rear of the detector and the other end to a PC. The Varian 356-LC is controlled from a PC using Galaxie™ Chromatography software. Analogue Output For analogue output signals, connect the supplied analogue output cable to the rear of the module. The open end of the analog output cable has two wires, corresponding to positive and negative polarity. This analogue cable requires connection to a Star MIB in order to collect the signal in Galaxie. Connection to a Varian Star 800 Module Interface Box The Star 800 Module Interface Box (MIB) provides analogue-to-digital signal conversion (ADC). Connections are made by connecting the analogue output cable to one of the analog signal input ports on the middle right side of the Star 800 MIB. For more information about connecting your Varian 356-LC to a Star 800 MIB, refer to your Star 800 MIB documentation. Control I/O connector The Varian 356-LC can be connected to auxiliary equipment to pause or stop the operation of a pump or auto sampler if the Varian 356-LC reports an error condition. The Varian 356-LC is equipped with one contact closure, which is normally open, and two TTL logic inputs, both active-low (with internal pull-up resistors to 5V). These inputs can be used to remotely autozero and purge the detector by connecting them to ground, as described in table 1.0 ! Pump stop facility must be employed if instrument is to be left unattended, or if units are stacked NOTE Page 7 of 20 For Internal Use Only Inputs Inputs Outputs I/O Description Remote A/Z –TTL Active Low Remote Purge–TTL Active Low Pump stop contact closure – normally open Ground (to case) Pin No. 7 & ground 14 & ground 3 & 10 1, 5, 6, 11 Table 1.0: Control I/O connector Hydraulic Connection Inlet The eluent from the chromatography system is connected to the LOWER front port of the Varian 356-LC detector via a low dead volume connector. Outlet The eluent from the chromatography system is connected to the UPPER front port of the Varian 356-LC detector via a low dead volume connector. Use tubing of 1.0mm ID (0.040”) or greater on the waste outlet of the Varian 356-LC to minimise backpressure. ! Do not exceed a backpressure of 150PSI on the detector ATTENTION Instrument Controls Front Panel Status Lights Three indicator lights are located at the top left of the front panel of the module. They are: Ready/Run Auto-Zero Purge The following table defines each status: LED Ready/Run Auto-zero Purge Status Ready/Run Not Ready (i.e. changing temp) Error Auto-zero on Auto-zero off Purge on Purge off Colour Green Orange Flashing Green/Orange Green Off Green Off Table 2.0: LED indicator lights Error Conditions The Varian 356-LC is equipped with a number of sensors and error checking facilities to ensure safe operation. If an error is detected the instrument gives an audible warning and the Ready/Run light will flash green & orange. A complete list of instrument errors and remedial actions are given in the troubleshooting section of the operation manual. Software Control The Varian 356-LC requires Galaxie Chromatography Workstation Software and a free Serial (RS-232) communications port (1 to 255) on your PC in order to operate. For futher information, refer to the Operator’s Manual. Page 8 of 20 For Internal Use Only Operational Parameters Purge When Purge is selected, the purge indicator light is highlighted, and solvent flow is diverted through the reference side of the RI cell, instead of the sample side; before going to waste (see figure 2.3). The purge time can be adjusted to compensate for different solvents & eluent flow rates. ! Ensure the purge valve is closed before making a sample injection NOTE Auto-Zero The detector output is re-set to zero when the auto-zero function is selected. An error will occur if the auto-zero process takes longer than 5 mins. Sensitivity The sensitivity of the Varian 356-LC can be adjusted to provide greater flexibility. The three possible sensitivity settings are described below: Sensitivity (µRIU/mV) Low (2.0) Standard (4.0) High (8.0) Application Suitable for highly concentrated samples (e.g. Prep LC) Default setting, ideal for the majority of LC applications Suitable for samples of low concentration in order to maximise signal-to-noise. Changing the detector’s sensitivity will affect the instruments dynamic range; for example, changing the detector from Low to High sensitivity alters the dynamic range from 600µRIU/FS to 150µRIU/FS. Temperature The temperature of the Varian 356-LC can be set between 30-50 °C (1 °C increments) or turned off. The default value is 35 °C. It is recommended that the temperature should be set at least 5°C above ambient temperature in order to ensure a stable thermal environment. The Ready/Run indicator light on the front of the detector turns green when the detector has reached temperature. If the detector temperature is not equilibrated then the Ready/Run light will turn orange. Response Time The Varian 356-LC has a default response time of 1.0secs, with a settable range of 0.1 –5.0 seconds. Lower response time settings remove less baseline noise, produce narrow peaks with minimal peak distortion and time delay. Lower settings also make very small peaks harder to discriminate from baseline noise. Higher response time settings can reduce baseline noise, but will shorten and broaden peaks. Polarity The output of the Varian 356-LC refractive index detector can be either positive or negative; therefore it is essential that the polarity of the detector signal is configured. The polarity parameter is used to invert the sign of the refractive index data. A positive polarity leaves the data unaffected, whilst a negative polarity essentially inverts the chromatogram. Baseline Offset The baseline offset of the Varian 356-LC can be set between the ranges –100 to +100 µRIU. Page 9 of 20 For Internal Use Only Detector Performance The Varian 356-LC detector is a high performance analytical detector having low noise and dispersion characteristics. The performance of the detector was evaluated in accordance with the ASTM method: (E 1303-95) “Standard Practice for Refractive Index Detectors Used in Liquid Chromatography”: Detector Noise The key performance measure of good analytical performance in an refractive index detector is low noise. The Varian 356-LC has been designed to deliver low noise in order to maximise sensitivity. Noise is affected by the following factors: 1. Detector Temperature 2. The mobile phase 3. Ambient Temperature 4. The response time (digital filtering) 5. Internal electronics According to the ASTM method, refractive index noise is defined according the sampling period: 1. Short-term noise 2. Long-Term noise Shirt-term noise provides information about the detector’s optical and electronic performance, whilst long-term noise is a measure of the detector thermal characteristics. These two noise definitions can also be can be evaluated under different flow conditions: 1. Static (no-flow) 2. Dynamic (with flow), Static noise is determined over 30sec to 1min periods due to its high frequency. This noise is a direct measurement of detector performance, without influence from the pump or autosampler. The stated short-term noise for the Varian 356-LC is <5.0 nRIU. ASTM method states that static short-term noise is evaluated by filling both the reference & sample cell with water and allowing the system to thermally equilibrate for at least 15mins, before recording an hour’s baseline of data. In addition, the detector and water should have been thermally equilibrated with the environment for at least 24 hours. Long-Term Static noise is a measure of Low frequency noise without the influence of the mobile phase. Under dynamic conditions the long-term noise should be higher due to the cooling effect from the mobile phase. Under these conditions the efficacy of the detectors temperature control is evaluated. However, this test should be performed within an environment where the ambient temperature does not vary by more than 2 °C. Page 10 of 20 For Internal Use Only 0.494 0.493 0.492 0.491 0.49 0.489 0.488 0.487 0.486 0.485 0.484 0.483 0.482 0.481 0.48 0.479 µRIU Static Noise_Varian RI S_N# 5, 10, 3 (3).DATA [Varian PL-RI Channel #005] 0.478 0.477 0.476 0.475 0.474 0.473 0.472 0.471 0.47 0.469 0.468 0.467 0.466 0.465 0.464 0.463 0.462 0.461 0.46 0.459 0.458 0.457 0.456 0.455 0.454 0.453 0.452 0.451 0.45 0.449 0.448 0.447 RT [min] 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14 14.5 15 Figure 9: Varian 356-LC Static noise over 15mins (TC 4sec) The static noise of a Varian 356-LC detector is shown in figure 9. The scale ranges by 47nRIU and the Static noise was calculated at 4.19 nRIU, using the ASTM method. From a batch of 10 detectors the average noise level was 2.8 nRIU, with 4.19 being towards the high end. Baseline Drift Detector drift is caused by the system thermally equilibrating. When you first turn the system and lamp on, everything has to come to thermal equilibrium. Depending on the detector set temperature the Varian 356_LC will take 2 hours to equilibrate, however full equilibration will take 24 hours. Baseline drift is affected by three factors: 1. Ambient temperature variations 2. Mobile phase temperature 3. Mobile phase Flow rate Baseline drift is primarily due to a difference in the thermal properties of the detector relative to its surroundings. Large variations in the ambient temperature will manifest themselves as baseline disturbance as the detector’s heating control tries to maintain a constant temperature. By far the biggest influence on baseline drift is the mobile phase. Mobile phase that is not thermal equilibrated with its environment will be at a different temperature than the flowcell in the detector. Therefore as the mobile phase enters the detector it acts to reduce the temperature of the system. Consequently the RI detector compensates to maintain a constant flowcell temperature. This compensation leads to baseline drift. Refractive index detectors are sensitive to 0.001 °C variations in mobile phase temperature, so controlling this parameter is essential for optimal performance. The Varian 356-LC has an insulated optical block to thermally isolate it from its surroundings. In addition, the inlet tubing is embedded in the optical block in order to warm the eluent prior to entering the flowcell. The baseline drift of the Varian 356-LC is specified at <250 nRIU. Page 11 of 20 For Internal Use Only 6.74 µRIU Dynmaic Drift Varian 356-LC S_N#002.DATA 6.735 6.73 6.725 6.72 6.715 6.71 6.705 6.7 6.695 6.69 6.685 6.68 6.675 6.67 6.665 6.66 6.655 6.65 6.645 6.64 6.635 6.63 6.625 6.62 6.615 6.61 6.605 6.6 6.595 6.59 6.585 6.58 6.575 6.57 6.565 6.56 6.555 6.55 6.545 RT [min] 6.54 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 Figure 10: Varian 356-LC Baseline Drift over 1 hour The baseline drift measured on a Varian 356-LC, which was thermally equilibrated with its surroundings for 24 hours, is shown in figure 10. Over the 1 hour period, the baseline drifted by 53 nRIU, although there were slight undulations over this 1hour period. This drift is below the <250 nRIU/hr. Higher drift measurements were recorded with detectors in laboratories with variable ambient temperature. The dynamic drift is highly dependent on pump performance, so static drift was used as the performance benckmark. For a batch of 10 detectors, the static drift averaged 218 nRIU. Sensitivity (Response Factor) This is defined as “the signal output per unit concentration of the test substance in the test solvent”, in accordance with the following relationship: S R C where: S = sensitivity (response factor), RIU·L/g, R = measured detector response, RIU C = concentration of the test substance in the test solvent (g/L). The Varian 356-LC has three settable sensitivity settings as described below: Detector Setting Low Standard High Sensitivity (mV/µRIU) 2 4 8 The LOW (2 mV/µRIU) settings is achieved by reducing the LED current by 50%., whereas the HIGH setting (8 mV/µRIU) is obtained by increasing the signal gain value to 200. The sensitivity setting has a direct impact on baseline noise measurements. If the sensitivity is doubled, so will the noise. Therefore all noise measurements should be taken at the STD setting. Page 12 of 20 60 For Internal Use Only Figure 11: Sensitivity determination using KCl solution Linear & Dynamic Range The range of concentrations of the test substance in the test solvent, over which the sensitivity of the detector is constant to within 5% defines the detector’s linear range. The Varian 356-LC is linear across its full range of response, which is 600 µRIU Dynamic Range is defined as “That range of concentrations of the test substance in the test solvent, over which an incremental change in concentration produces an incremental change in detector signal”. The upper limit is the highest concentration at which a slight further increase in concentration will give an observable increase in detector signal. The dynamic range is the ratio of these upper and lower limits. The dynamic range is larger than or equal to the linear range, but obviously cannot be smaller. The dynamic range of the Varian 356-LC is 600 µRIU. Flow cell performance The flow cell is a critical part of the system. There are several characteristics of the flow cell that are important to its overall performance. A flow cell should not spread the chromatographic bands as they pass through the through the system. To do this, most manufacturers minimize the volume of the flow cell. However, a low volume flow cell is not sufficient to minimize band spreading. The flow cell also has to be designed so that the mobile phase can sweep the sample into the cell and out of the cell without having anywhere in the cell for the sample to collect. This is usually referred to as unswept volume. Good flow cell design tries to eliminate unswept volume. The Varian 356-LC has a flow-efficient design to minimiae unswept volume. The flow cell has a diamond-shaped profile; to eliminate corners or “dead” spots where eddy turbulence can occur (typically at the inlet and outlet). The flow cell volume has also been reduced to 6µL in order to minimise band broadening. The low volume cell and flow-efficient profile combine to give the Varian 356-LC superior peak shape and resolution and shown in figure 12. Page 13 of 20 For Internal Use Only Figure 12: Glucose Peak data at 1 mL/min for Varian 356-LC & Shodex RI –101 (Response Time 1 s) The peak widths at different flow rates are given in the table, below: Flow Rate (mL/min) 1.0 0.5 Width 50% Height (s) Width 5% Height (s) Asymmetry 356-LC SHODEX 356-LC SHODEX 356-LC SHODEX 1.8 4.8 3.6 5.4 4.2 10.2 8.1 11.4 1.64 1.70 1.28 1.4 Liquid Volume (µL) SHOD 356-LC EX 30 60 40 45 The peak widths measured on the Varian 356-LC are 50% narrower than the Shodex detector at 1 mL/min, whereas at 0.5 mL/min the 356-LC is 12.5% narrower. Figure 12 shows that the Varian 356-LC has between 5-8% better resolution than the Shodex RI-101 detector for a typical sugar separation. Page 14 of 20 For Internal Use Only Sample: Sugar Standards ea.1.25mg/ml Column: Polaris 5 NH2 (p/n A2013150X021) Column dimensions: 150x2.1mm Column temperature: Ambient Mobile Phase: 25% Water/ 75%ACN Flow Rate: 0.5 ml/min Detector: Varian 356-LC & Shodex R-101 Refractive Index Detectors Injection Volume: 20µl Resolution. (USP) Resolution. (EP) Varian 356-LC Varian 356-LC Shodex Shodex Glucose 0 0 2.1 0 0 Sucrose 2.51 2.54 2.61 2.31 2.34 Maltose 1.65 1.67 3.03 1.56 1.55 Lactose 1.01 1.02 3.34 0.99 0.97 Figure 13: Sugar analysis comparison using an NH2 column (2500 µg/mL ea.) HIGH sensitivity. Name Time [Min] Best Practice for the Varian 356-LC Refractive index detector Place the detector conveniently near your HPLC system. The modular design of the Varian 356-LC Detector enables you to locate it anywhere within the limitations imposed by the length of the power cord, fluid lines and signal cables. In order to keep liquid dead volume as low as possible and to minimize peak broadening in the lines, the distance between the column outlet and the flowcell inlet should be kept to a minimum. Provide approximately four inches of space behind the unit so that the cooling fan intake is not impeded, and to allow easy access to the rear panel. NEVER subject the reference and sample cells to back pressures greater than 7 atm (100 psi). High pressures can break the cells, which are difficult to replace. NEVER place a backpressure regulator (such as Varian part number 0391939300) on an RI detector. Maximum flow cell backpressure is 7 atm (100 psi). When placing more than one HPLC detector in series, always place the RI detector last. Use tubing of 1.0 mm ID (0.040”) or greater on the waste outlet of the Varian 356-LC for less backpressure. Locate the Varian 356-LC in an area that does not incur large temperature changes. The Varian 356-LC has a sophisticated temperature control system but care in choosing its operating environment will ensure better operation, see Installation Site Requirements. Page 15 of 20 For Internal Use Only Always pre-mix and degas the mobile phase. Do not allow pumps to mix solvents for the mobile phase. Use only isocratic conditions. Keep the RI cells clean. When filling the reference cell, ALWAYS use mobile phase that has eluted through the analytical column. Allow mobile phase to flow through the column for 10 minutes prior to filling the reference cell. Troubleshooting/Maintenance The high sensitivity of the detector and the low volume of the flowcell make it imperative that a high standard of solvent purity and general system cleanliness be maintained. A contaminated flowcell can lead to noise and drift problems that are often mistakenly attributed to other areas of the system. Cell Cleaning Procedure Many cases of performance degradation in sensitive instruments with flow-through cells are traceable to cell contamination. The use of filtered solvents with solvent reservoir filters (Varian part number 2718038700), an in-line filter between the pump and detector, and a precolumn will protect the cell from contamination and decrease the amount of cleaning required. However, contamination from trapped particulates or bubbles, from precipitates, or from thin films of residues can still occur. Preparation for Cell Cleaning To introduce cleaning solution into the Varian 356-LC by pump, run tubing directly from the pump outlet to the Varian 356-LC IN port bypassing the column. Some materials should be injected directly into the Varian 356-LC cells by syringe due to their high corrosivity or safety risk. Remember that refractive index cells are stable to only 700 kPa (7 atm). Gently flush the cells under all conditions. If you encounter a large backpressure in the Varian 356-LC, proceed cautiously. Cell Cleaning Hints The following recommendations may be applicable to a variety of cleaning conditions: 1. Clean all internal lines of the Varian 356-LC by injecting cleaning solution with Purge off, and inject cleaning solution again with Purge on. 2. Particulate matter can be removed by forcing liquid through the cell using the syringe and needle with tubing from your Accessory Kit. Sometimes it helps to reverse flow and inject in the OUT port. If liquid purging does not work, try gas purging. Replace cell liquid with a volatile (e.g., acetone) solvent. Purge and dry the cells with clean gas at about 50 psi. Gas flowing through the cell will sometimes dislodge particles. Also try reversing the flow direction. For difficult entrapments, follow the above gas purge procedure with a liquid purge. When liquid hits a particle in a dry cell, it is generally more effective than a continuous liquid purge. 3. If you suspect that you have a problem with entrapped bubbles, purge with 2propanol. 4. Heating the flow cells may remove marginally soluble material. Page 16 of 20 For Internal Use Only Acid Cleaning 1. Diluted (10–20%) or concentrated nitric acid is a good cleaning solution. 2. The sample and reference cells should be filled with water or air (blown dry) before proceeding. 3. Connect the syringe to the IN or OUT port of the Varian 356-LC. To the opposite port, attach plastic tubing from the cleaning solution. For safety, always draw the cleaning solution through the cells with the syringe. Allow 3 to 10 minutes cleaning time; longer cleaning periods (>1 hour) may harm the cells. 4. Flush acid cleaning solutions from the cells with large amounts of water, such as 1 mL/min. Flush for 15 to 30 minutes. Other Cell Cleaning Procedures If buffers or solutions of high salt content have been in use, the cells may be contaminated by precipitated salt. Large amounts of distilled, deionized water, such as 1 mL/min, for up to several hours, is the simplest clean-up procedure. An elevated cell temperature will speed dissolution. The water wash can be acidified, if the precipitated salt is more soluble in acidic solutions. However, do not use strongly basic (pH 10 or higher) solutions, as these will etch the refractive index cells. If contamination is suspected when a non-aqueous solvent is in use, flush the cells with a solvent that is (1) miscible with your mobile phase, (2) a good solvent for the predicted contaminant, and (3) generally of greater polarity than your mobile phase. A number of HPLC references exist that classify the solvent properties of common HPLC eluents, and these may be used as a guide [L.R. Snyder, Journal of Chromatography, 92, 223 (1974); Journal of Chromatography, 16, 223 (1978)]. Corrosive Solvents Some solvents may corrode the detector if they are left in the detector, and should be thoroughly flushed from the entire system, including the reference and sample flow cell; see Table 3.1 Solvent limitation guide. Strong bases, in particular, can easily etch the quartz cell window. Do not turn the Varian 356-LC power off without rinsing these solvents from the detector. However, certain solvents can be left in the cell at the end of operation. For example, water, acetonitrile, 2-propanol and paraffin-derived hydrocarbons are quite innocuous. They may be left in the Varian 356-LC overnight or over a weekend. Buffers: Even if the buffer is non-corrosive (see Solvent Recommendations, page 63 and Corrosive Solvents, page 90), it is better to keep the solvent flowing at a reduced rate to eliminate the possibility of salt precipitation in the Varian 356-LC cells and tubing. Tetrahydrofuran: Because THF does oxidize, you may find that, if you keep solvent flowing at a reduced rate, the chromatographic system takes less time to re-stabilize upon start-up. Generally a reduced-flow shutdown procedure will minimize re-stabilization time; the time saved is noticeable with THF as the solvent. Organohalocarbons, such as Methylene chloride and Chloroform: Keep a small amount of flow to keep down the amount of corrosive chloride impurities in the cell. Flow Cell Integrity Replacement of the Varian 356-LC flow cell is required when sensitivity deteriorates, or is cracked. Replacement of the flowcell is described below: Page 17 of 20 For Internal Use Only Remove the outer casing. Carefully remove the insulation from the top of the optical block assembly, to expose the RI block. Disconnect the tubing in the centre, connected to the top of the cell assembly, from the T-Piece connector, as shown. Disconnect the tubing, connected to the top of the cell assembly, from the barrel connector as highlighted. Page 18 of 20 For Internal Use Only Using a Hex key, loosen the two screws highlighted, to remove the top half of the flowcell assembly. Using tweezers, carefully remove the flowcell from the assembly. Handle with gloves Do not touch the faces of the flowcell Page 19 of 20 For Internal Use Only Place the flowcell on some lint free cloth to inspect it. To clean the cell, place it in a solution of 20% nitric acid for 10-15minutes. Wash the cell repeatedly in de-ionized water before re-inserting back into the detector Replace the flowcell if it appears cracked or leaking. Checking the Drain Tube The simplest way to check for cell rupture is to observe liquid coming out of the drain tube on the rear panel when liquid is flowing through the detector. However, the optics module would have quite a bit of liquid in it before liquid appears in the drain tube. Page 20 of 20