Word Document - Iowa State University Extension and Outreach

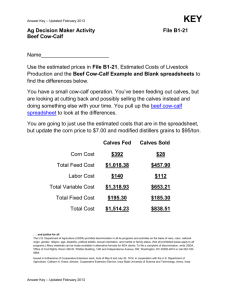

advertisement

November 2002 Grain Management Thoughts for Fall - - - Iowa Quality Cull Beef Cow Marketing - Rodent Control Around Livestock Facilities Ask a Specialist - - - - - - - - - - - - - - - - - - 1 2 2 3 Grain Management Thoughts for Fall by Joel DeJong, ISU Extension Crops Field Specialist In the fall I often get questions about grain storage, grain shrink, and other management questions. Some answers I know. At other times I find great information on the Internet. Here are a couple of common questions for this time of year that you might find useful, too. Last week a person called and asked how much per bushel his drying costs increased when his propane costs went from $.50 per gallon to $.80 per gallon. From a University of Minnesota publication found on the web I learned that, in high temperature drying, propane use equals about .02 gal/bu per percentage point of moisture removed. By doing a little math, I learned that the propane cost per point went from 1 cent to 1.6 cents. What, I was also asked, is the recommended storage moisture for clean, aerated corn? For up to 6 months 15% is O.K., for more than 6 months, 13% is recommended. If corn quality is poor, drop each 1 percentage point. This Minnesota web site provides information on grain drying, management of grain in storage (including when and how to run your aeration fan), and other great hints: http://www.extension.umn.edu/topics.html?topic =4&subtopic=44 . If you don’t have internet let me know and I will get a couple of the publications that can give you some great help! What about shrink? How much am I actually losing when I dry down my corn. The National Corn Handbook has a good article on this topic. It can be found on the web at: http://www.extension.iastate.edu/Publications/N CH61.pdf . This publication discusses water shrink, handling loss, custom drying and grain sales alternatives. Another question - How much phosphate and potash are removed when stalks are baled? Recent information from John Sawyer, our ISU Extension Soil Fertility Specialist, indicates that the removal of 1 ton of corn stover (entire plant except for the grain) removes about 5.9# of phosphate and 25 pounds of potash. A ton of soybean stover (stems, not leaves) removes about 2.8 pounds of phosphate and 9.9 pounds of potash. When bales of these products are harvested for bedding, perhaps it is wise to consider this in the application rates if the soils test in the very low, low or optimum categories. What do you lose if a field burns? Check out this 10/23/00 article for a good discussion: http://www.ipm.iastate.edu/ipm/icm/2000/10-232000/dryfallfires.html - and also some of the numbers behind those removal rate amounts mentioned in the previous paragraph, too. Managing your crop is a year around business and requires a lot of knowledge. Don't forget to check at your local Extension office for help in answering questions you might have! 10. The CHIPS Board and ILCC feedlot reserves the right to disqualify any cow at any time if a problem arises with a cow. Animals may be sold or returned to original owner upon reimbursement for expenses. Iowa Quality Cull Beef Cow Marketing Program by Dennis DeWitt, ISU Extension Livestock Field Specialist Objectives The principle objective of the Iowa Quality Cull Beef Cow Marketing Program is to provide information to area beef producers they can use in adding value to their beef cow enterprise. This program provides cow-calf producers information on feedlot performance, average daily gain, and carcass merit data on cull beef cows. This information can be used by the producer to change feeding programs or as a basis for change in a producer’s marketing program. Cows may have ultra-sound data collected after delivery to establish baseline information and to evaluate changes in backfat, ribeye area and %IM fat. Health Requirements Cows should be open; dehorned or polled; in good health; free of foot rot, pink eye, draining abscesses, cancer eye or any other contagious diseases. Rules 1. Iowa cow-calf producers with Iowa cows only will be accepted. No Back Tagged Cows Allowed. If more entries are received than there is pen space, priority will be determined by entry date. 2. A pen reservation fee of $25 per cow must accompany entry form. The balance of the feeding program costs will be financed at 8% interest. Final settlements will be made after harvest of the entire group. 3. Entries are due Monday November 4. A minimum of 50-cows is required in the marketing group. 4. Delivery is Monday November 18 to Iowa Lakes Community College Farm, Emmetsburg. 5. At delivery, all cows will be double ear tagged. The owners cow’s eartag(s) will be removed. 6. Cow death will be a financial loss to the owner. If costs are greater than pre-payments, balance will be billed. 7. There will be an $8.00 per head data collection fee assessed to each cow. 8. Cows will be fed a warm-up ration for 14days. They will be weighed individually again at 28-days after delivery and prior to harvest. Projected harvest will be 70-90 days after delivery. 9. ILCC has the right of refusal of cull cows upon arrival regarding weight, health and temperament. 2 Feeding Method The total feed bill will be split based on an individual cow’s delivery weight, final weight, days on feed, hot carcass weight and calculated yield grade. Heavier, faster gaining and fatter cows will pay a higher feed bill. Cows will be implanted on delivery to the feedlot. Yardage rate will be $.30 per cow per day with no feed markup. Actual costs will be billed for each cow with final total costs deducted from carcass payment. Sponsored by CHIPS Northwest and Iowa Lakes Controlled Grazing, Inc. in cooperation with Iowa Lakes Community College & Iowa Beef Center Contact: Dennis DeWitt, email dewitt@iastate.edu or telephone 712-336-3488 Rodent Control Around Livestock Facilities By Jerry Weiss, ISU Extension Swine Field Specialists Rats and mice can be a major economic threat around swine and other livestock facilities. They consume and contaminate feed and cause feed losses through the gnawing of holes in feed holding and storage areas. They also have been implicated in maintaining or spreading diseases. For effective control, we recommend an integrated pest management (IPM) approach that incorporates the timely use of a variety of costeffective control methods, including: (1) sanitation, (2) rodent-proof construction, and (3) population reduction. The first two are preventive measures. When an infestation already exists, population reduction is typically needed. Reduction techniques include include trapping, toxic baits, and fumigation. Another important component of an effective IPM program is pest population monitoring. Records of trapping success and measures of rodent activity will help to determine the need for additional control efforts. A: You have asked what might be the most common feedlot nutrition question we have gotten over the last 20 years. The answer depends on the type of ration, and the other feed ingredients. If it is dry corn, most research indicates that there is little improvement in the digestibility of the corn in a finishing ration over about 75% grain. Backgrounding rations and beef cow supplementation of dry corn does respond to processing. Expect about a 5% improvement in efficiency. Expect the same for high moisture corn, regardless of the level of grain fed. Many a feces inspector has expressed doubts and skepticism about this. Dr. Steve Loerch of Ohio State University conducted a fascinating demonstration of whole corn feeding that really explains what happens. What Dr. Loerch did (or more likely some lucky graduate student) is count the kernels of corn that actually went into, and out of a steer. The following are the results of the demonstration with steers fed either dry or high moisture corn. The steers on the dry corn ate 22,376 corn kernels. They excreted 1572 kernels. At a total ration digestibility of 85% the cattle should have excreted about a pound and a half of dry manure in a day. That manure would contain 1572 corn kernels even if the digestibility is 90%. That's a lot of corn in the manure pile. And yes, if the corn were cracked it would still be there, just not as visible. Although cats and dogs may kill rodents, they do not provide effective long lasting control in most circumstances. In summary: 1. Eliminate or reduce the number of places rodents can use for shelter. When rodents have no place to hide or nest, they cannot thrive. 2. If rodents are present use traps or rodenticides to reduce their numbers and maintain a good control program. This consists of maintaining bait stations or traps. ISU Extension has a very good publication in the Pork Industry Handbook Titled "Controlling Rats and Mice in Swine Facilities." (PIH-107). Ask a Specialistby Pete Olson, ISU Extension Beef Field Specialist Do you have beef questions you don't have answers to? Questions on nutrition, marketing, reproduction or early weaning? If so log onto the internet and go to www.iowabeefcenter.org and click on "Ask a Beef Specialist" or Click on "Frequently Asked Questions" for an archive of previously asked questions. The answer to your question may have already been asked. If it hasn't, be sure to send in your question by clicking on asking a specialist and emailing it to Iowa State University Extension Beef Specialists. You will be answered as soon as possible. So why are you waiting to learn the answer to that question that has been keeping you up at nights. Here is an example of aquestion recently sent in. There may be not nutritional reasons to process the corn, however. If processing improves the uniformity of particle size and aids mixing the total ration, improved feedbunk management may result. In those cases the improved bunk management may improve the efficiency of the cattle even though the corn digestibiltiy may be no different. High Moisture Corn Number of steers 1 Corn intake, lb. 12.75 Supplement intake, lb. 2.25 Kernel intake 16,511 Fecal kernel output 65 Kernel "digestibility" 99.6% Starch in corn 72% Starch in fecal kernels 59% Q: Should I crack the corn for my feedlot cattle or feed it whole? 3 Dry Corn 1 12.75 2.25 22,376 1,572 93% 74% 61% November 2002 FIELD AND FEEDLOT Iowa State University Extension Connection “Mastering the Matrix” ICN on November 6. Landowners, livestock producers, and public officials are invited to attend an ICN meeting at the Sibley High School on Wednesday, November 6 from 7-9 pm. The “Matrix” is required by SF2263 passeed this year by the Iowa Legislature. It is to be used by county boards of supervisors and the Iowa DNR to produce a “statistically verifiable basis for determining whether to approve or disapprove an appliation for construction of a livestock facility”. The Iowa DNR is encouraging livestock producers to go above and beyond the law in proposing new facilities. By using the matrix, 44 factors are outlined, each of which is scored in subcategories for air, water, and community. Producers can select from the cafeteria of options to bolster their scores even though they may already meet state environmental requirements. Speakers on the ICN program include John Lawrence, Iowa State University Economist and John Korslund, pork producer from Eagle Groove. Both served on the Master Matrix Technical Advisory Committee and were involved in the development of the contents of the matrix. Attendees will learn about the reasoning behind the matrix proposal, definitions included in the matrix, factors in scoring of new construction and siting an operation and manure management plan, and the potential impacts on new construction and sitings by working through an example farm. Producers will also learn the “logic” behind the matrix and how to effectively communicate their concerns during the upcoming public comment period. Mike Duffy, ISU Economist, will talk about the availability of funding assistance to livestock producers provided by the Environmental Quality Incentives Program [EQUIP]. Available program details, qualification status and the NRCS approval process will be explained. Producers will also hear of other manure matters and environmental programs. Cost is $10 per person. Pre-registration is requested by calling the Extension Office at 712-754-3648. By Al Grigg, County Extension Director THANK YOU to all who have responded with your e-mail address so we can send you the Field and Feedlot publication electronically. We would still ask those who wish to receive the publication electronically to submit your e-mail address to us. The procedure for you is simple and will take less than 60 seconds: [1] send an email to agrigg@iastate.edu [2] type Field and Feedlot in the subject line and [3] type in your email address in the body. Then you will receive “Field and Feedlot” via e-mail, saving postage costs, and you can read “Field and Feedlot” on your computer. Are you an Iowa resident, 55 years of age or older, looking for a job but do not know where to start? Experience Works, Inc. can provide help. Experience Works is funded by the US Department of Labor and provides work and training to become employed. Employers can also use the services of Experience Works by employing their trainees. For more information on how Experience Works can help you call toll free: 1-800-782-7519. Iowa State University Extension needs your input. Iowa State University Extension recognizes that communities are changing, business trends are different, and technology is rapidly changing the way we operate. A public forum is scheduled for input from the public on how Iowa State University Extension can better serve Iowans through its education programs and services. This opportunity for public input is scheduled for Thursday, November 21 at Western Iowa Tech Community College in Cherokee from 1-4 pm. Contact the Osceola County Extension Office for additional information. 4