AIC_12504_sm_suppinfo

advertisement

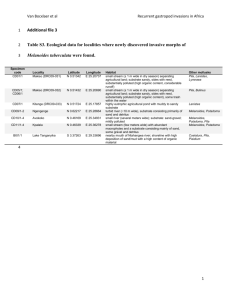

Supporting Information Undulating Topography of HfO2 Thin Films Deposited in a Meso-Scale Reactor using Hafnium (IV) tert butoxide Kejing Li Box 870203, Chemical and Biological Engineering Department, The University of Alabama, Tuscaloosa, AL 35487, USA Lin Zhang Center for Composite Materials and Structures, Harbin Institute of Technology, Harbin 150001, PR China David A. Dixon Box 870336, Chemistry Department, The University of Alabama, Tuscaloosa, AL 35487, USA Tonya M. Klein* Box 870203, Chemical and Biological Engineering Department, The University of Alabama, Tuscaloosa, AL 35487, USA * E-mail: tklein@eng.ua.edu Two MKS Pirani gauges were equipped before (P1) and after (P2) the flow cell to measure the pressure difference. Temperature Profile of the Meso-Reactor In the flow through cell, there are several components. The tubing wall thickness is 0.889 mm, 0.2 mm for the stainless steel (ss) sheet, 1.5 mm for the Al sheet, and 1.2 mm for the Kalrez® gasket. The main rectangular body is made of ss, with a top section and a bottom section. The two sections are sealed together by a Kalrez® O-ring. The thermal profile is an important issue in the deposition process. A minimization of the temperature gradient would help the uniformity of film deposited as the diffusion and reaction rate are exponentially dependent on the substrate temperature. In normal operating conditions, it is usually difficult to get a complete profile of the substrate temperature for two reasons: (1) the substrate is usually in a closed vessel which makes it difficult to attach a thermocouple inside; and (2) the thermocouple only measures one spot at a time on the surface. With the aid of high performance computers, finite element analysis (FEA) enables a prediction of the temperature distribution on the substrate surface without having to disassemble the compartment during the experiment. Finite element analysis (FEA) simulation using the ANSYS multiphysics 11.0 was performed to investigate the thermal heat flow loss due to heat convection in air and the temperature distribution on the surface of Si substrate. The geometry was generated using the actual dimensions and all of the components were modeled according to the real system, since simplification of the structure can cause a significant accuracy drift. The model was generated by 3-D thermal elements and nodes, meshed with Solid87 elements and a total number of 314851 nodes. The following assumptions are made in order to simplify the model: 1)The temperature distribution is calculated during steady state; 2) Radiation is negligible at temperatures below 250ºC and not considered. 3) Thermal coefficients of each component at 1 atm are taken from the CRC Handbook of Thermal Engineering (Kreith F. The CRC Handbook of Thermal Engineering (1st edition), Boca Raton, FL: CRC Press, 1999.) and the manufacturer’s website (http://www.harricksci.com). 4) The thermal contact resistance is negligible between the top plate and bottom plate as these plates are polished flat fastened with good contact by two screws. Compared to the volume of the substrate together with the heating or supporting coils, the thin films deposited at thermal CVD conditions are normally less than 100 nm and the heat released from the reactions has a negligible influence on the substrate temperature which has a much bigger volume compared to the thin film. We assume that the reaction heat (either exothermic or endothermic) has a fast transfer speed through the thin film. The substrate temperature can be controlled the same as the one with no thin film deposition and the substrate temperature profile can be assumed to be the adsorption/reaction temperature profile of the substrate. The heat transport equations for the flow-through cell without gas flow can be described as three sections: (1) the faces open to air, (2) copper heat generation rods, and (3) the main section. On the faces open to air, the general heat transport equation can be described by Fourier’s Law and Newton’s Law of Cooling, where the convection equals the conduction at steady state: k A T h(T Tsur ) 0 (S-1) B.C.: T 25C , 2T 0 (S-2) Where k is the thermal conductivity, A is the cross area, h is the convection coefficient, and T∞ and Tsurf is the room temperature and wall surface temperature, respectively. The copper heater has a power range from 0 to 100 W, depending on the desired temperature for the Si substrate, which determines the final component temperature profile. k 2T q 0 , where q is the rate of heat generation per unit copper volume. Within other components without heat generation, the heat flux is simply based on the heat diffusion equation: k 2T 0 where a corresponding k is applied with respect to different materials and temperatures. Figure S2 shows the temperature distribution predicted on the reactor. Supporting Information Figure S2 (a) is an overview of the temperature at the reactor cross section. With a heat power 80W, the top heating plate is about 100 degrees higher than the bottom plate. Figure S2 (b) is the temperature distribution on the Si substrate surface. It shows that there is a difference of about 10 °Cdifference along the transverse direction, and the middle area has the highest temperature. With an Omicron Thermo temperature controller, the temperature profile on the substrate was measured to test the above FEA model by taking the reactor apart and measuring five spots on the substrate back (ss sheet). By changing the two heating rods’ temperature from 60 ºC to 250 ºC, it usually took 10 to 15 min. for the bottom substrate to reach thermal equilibrium. As shown in Figure S3, the temperature distribution along the ss plate is wider with a higher heating rod set point. At a set point of 225 ºC, the ss plate is about 100 ºC lower. Compared to the calculated substrate temperature distribution, there are only a few degrees deviation from the experimental values. This indicates that the calculation is accurate enough to determine the Si surface temperature which is difficult to measure in the closed system. Annealing Effect Figure S4 shows a big difference of thickness with annealing effect. There was a large decrease in thickness when with the sample was taken out after 5.5 hours annealing. Desorption occurred during the period. During pumping down, the trapped molecules are also possible to diffuse to downstream on the surface during substrate cooling down before taken out. Pressure difference The pressure difference was measured by two Pirani gauges P1 and P2. The background pressure drop was about 10.7 Pa. The pressure drop between P1 and P2 was measured as a function of time after opening the bubbler valve. As shown in Supporting Information Figure S6, the pressure difference went smaller and reached a steady state after about 3 min. Based on the Clapeyron-Clausius equation, the vapor pressure should increase exponentially with bubbler temperature. However, in flow mode, the evaporation coefficient is usually smaller than 1 due to slower evaporation rate than pumping speed. The vapor pressure as a function of bubbler temperature was measured by two gauges: P1 at upstream and P2 at downstream. The pressure drop ΔP between P1 and P2 as a function of different bubbler temperatures with a crystal ST at 250 ºC can be read from Figure S7. Pressure differences at different crystal ST with bubbler temperature at 50 ºC is shown in Figure S8. ΔP decreases with increasing bubbler temperatures or flow rates, and increases with crystal temperature. The reaction rate can be inferred by the pressure drop. As the reaction rate is proportional to the concentration of reactants and the reaction coefficient, with the same crystal temperature (same reaction coefficient), the concentration should be proportional to the flux. However, decomposition by-products such as tert-butanol from a hydroxylation reaction and tert-butene from β-hydride elimination can lead to different pressure effects. As a result, below 65 ºC higher bubbler temperatures have higher adsorption or reaction rates and a smaller pressure decrease. At 75 ºC, however, there is a return of the pressure drop, which indicates that the reaction becomes more mass transfer limited due to a lower diffusion coefficient at higher pressure. Supporting Information Figure S8 shows the pressure readings at different crystal setting temperatures. The crystal temperatures were all above the decomposition temperature of 185 ºC. The pressure difference is larger with higher crystal temperatures, indicating a faster reaction rate. It can also be deduced that more adsorption occurred than decomposition reactions by the fact that pressure decreased after the cell instead of increased. Heating Cords Inlet φ=8.4 Outlet φ=3.6 50.0 29.0 7.5 16.0 Figure S1. Schematic drawing of ATR flow through cell. Unit in mm. (a) (b) Figure S2. (a) Temperature profile on the flow through cell cross section with a power of 80W; (b) temperature distribution on the Si surface with a power of 80W. Set T ( C): 120 250 225 200 175 150 120 100 80 60 o o Bottom plate temperatures ( C) 140 100 80 60 40 -25 0 Axial distance (mm) 25 Figure S3. Measured temperatures on ss sheet at the back of Si substrate. 100 Thickness (nm) 90 80 1 hr precursor at 250 ºC 70 19 hrs annealing after 1 hr in air 60 1hr precursor + 5 hrs annealing 50 40 0.0 1.0 2.0 3.0 Y (cm) 4.0 5.0 Figure S4. Thickness along the axis for HTB deposited on H-Si(100) crystal with bubbler at 65 ºC and crystal setting temperature at 250 ºC. 10 sccm 1 sccm 0.15 sccm Velocity (m/s) 15.0 10.0 5.0 0.0 0.0 0.1 0.2 z (cm) Figure S5. Velocity profile of the flow at 1.7 Pa-L/s. 0.3 0.4 80.0 P1 P2 Pressure (Torr) 70.0 60.0 50.0 40.0 30.0 20.0 10.0 0.0 0 100 200 300 Time (s) 400 Figure S6. P1 and P2 pressures as a function of time. The substrate is native oxide with a bubbler temperature at 50 °C. 50.0 P1 Pressure (Pa) 40.0 P2 30.0 20.0 10.0 0.0 20 40 60 Bubbler Temperature (o C) 80 Figure S7. P1 and P2 pressures as a function of different bubbler temperatures. The substrate ST is 250 °C. 50.0 P1 P2 Pressure (Pa) 40.0 30.0 20.0 10.0 0.0 150 200 250 300 350 o Reactor Set Temperature ( C) Figure S8. Pressures upstream P1 and downstream P2 as a function of different reactor or substrate setting temperatures. The bubbler temperate is 50 °C.