biofuelsProtocol

advertisement

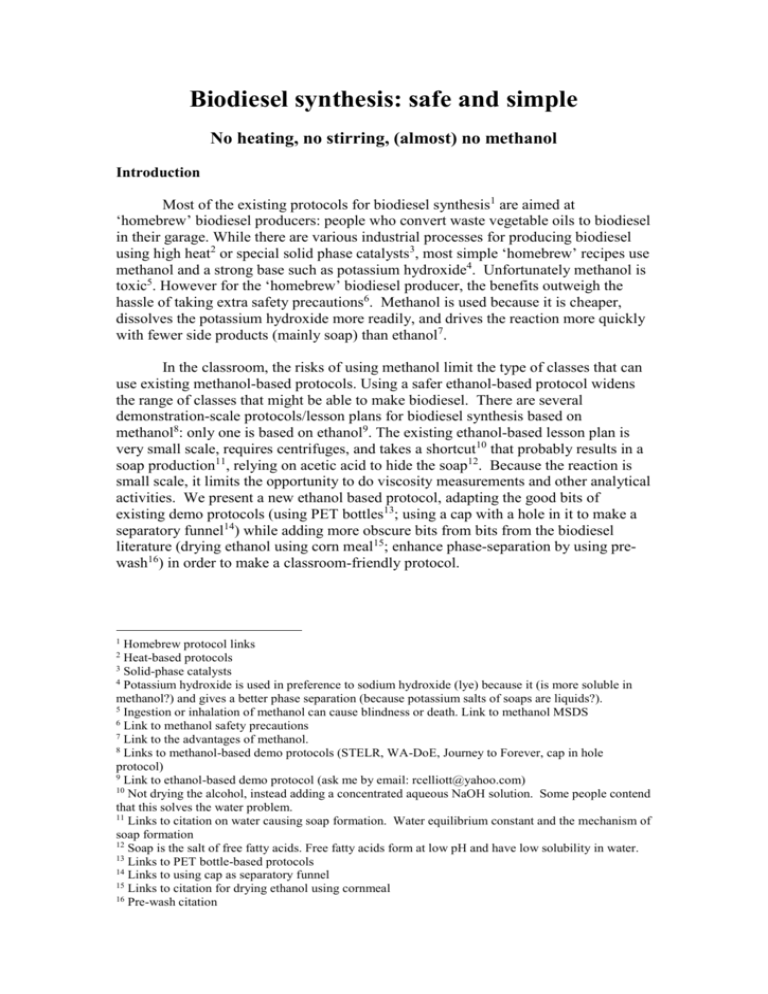

Biodiesel synthesis: safe and simple No heating, no stirring, (almost) no methanol Introduction Most of the existing protocols for biodiesel synthesis1 are aimed at ‘homebrew’ biodiesel producers: people who convert waste vegetable oils to biodiesel in their garage. While there are various industrial processes for producing biodiesel using high heat2 or special solid phase catalysts3, most simple ‘homebrew’ recipes use methanol and a strong base such as potassium hydroxide4. Unfortunately methanol is toxic5. However for the ‘homebrew’ biodiesel producer, the benefits outweigh the hassle of taking extra safety precautions6. Methanol is used because it is cheaper, dissolves the potassium hydroxide more readily, and drives the reaction more quickly with fewer side products (mainly soap) than ethanol7. In the classroom, the risks of using methanol limit the type of classes that can use existing methanol-based protocols. Using a safer ethanol-based protocol widens the range of classes that might be able to make biodiesel. There are several demonstration-scale protocols/lesson plans for biodiesel synthesis based on methanol8: only one is based on ethanol9. The existing ethanol-based lesson plan is very small scale, requires centrifuges, and takes a shortcut10 that probably results in a soap production11, relying on acetic acid to hide the soap12. Because the reaction is small scale, it limits the opportunity to do viscosity measurements and other analytical activities. We present a new ethanol based protocol, adapting the good bits of existing demo protocols (using PET bottles13; using a cap with a hole in it to make a separatory funnel14) while adding more obscure bits from bits from the biodiesel literature (drying ethanol using corn meal15; enhance phase-separation by using prewash16) in order to make a classroom-friendly protocol. 1 Homebrew protocol links Heat-based protocols 3 Solid-phase catalysts 4 Potassium hydroxide is used in preference to sodium hydroxide (lye) because it (is more soluble in methanol?) and gives a better phase separation (because potassium salts of soaps are liquids?). 5 Ingestion or inhalation of methanol can cause blindness or death. Link to methanol MSDS 6 Link to methanol safety precautions 7 Link to the advantages of methanol. 8 Links to methanol-based demo protocols (STELR, WA-DoE, Journey to Forever, cap in hole protocol) 9 Link to ethanol-based demo protocol (ask me by email: rcelliott@yahoo.com) 10 Not drying the alcohol, instead adding a concentrated aqueous NaOH solution. Some people contend that this solves the water problem. 11 Links to citation on water causing soap formation. Water equilibrium constant and the mechanism of soap formation 12 Soap is the salt of free fatty acids. Free fatty acids form at low pH and have low solubility in water. 13 Links to PET bottle-based protocols 14 Links to using cap as separatory funnel 15 Links to citation for drying ethanol using cornmeal 16 Pre-wash citation 2 Dry your ethanol17: Mix ~200 gm Polenta (coarsely ground maize-available from health food stores) with ~500 ml methylated spirits (mostly ethanol -- less efficient18 than the more commonly used methanol19, but also less toxic20) (95% ethanol without denaturing agent is even better, if you can get it). Mix by shaking several minutes, then let stand (20 minutes to overnight) to settle. The solution might still have a slight haze to it. Also, make sure that your glassware is dry. If I am in a hurry to dry the glassware, I just rinse in methylated spirits and leave upside down to drain... the ethanol doesn’t leave drops behind like water. [Polenta does not always have a low moisture content, so you may have to bake it first, or use baked rock salt –which leaves a few NaCl crystals undissolved after you add the NaOH]. I have made the biodiesel work without this step Make the ethoxy anion catalyst: In a closed, glass21 container (to prevent the absorption of water from the air) mix ½ tsp (~1.9 gm) fine-grained caustic soda 17 Some people claim that this is not necessary, saying that adding concentrated NaOH solution somehow binds the water, allowing the reaction to go forward. I suspect that they just haven’t noticed the reduced reaction efficiency and increased soap formed due to the presence of water. 18 Because the equilibrium constant is lower for ethoxy than methoxy, the reaction is goes forward more slowly and is susceptible to water contamination, leading to more soap formation and likely resulting in an incomplete reaction and a failure of the phases to separate. 19 Methanol is cheaper and dissolves the sodium hydroxide more quickly. 20 Methanol can cause blindness or death from ingestion or inhalation: see MSDS. 21 Glass containers are more resistant to NaOH: if you dissolve the NaOH in the PET bottle it is more likely to crack or leak later on. Don’t use containers with aluminium lids- they react with NaOH resulting in the formation of hydrogen gas. (NaOH) with ~100 ml of the dried methylated spirits. It doesn’t hurt to have some of the white cornstarch layer carry over into the reaction. It takes about 10-20 minutes for the NaOH to completely dissolve. If you are careful about the heat (i.e. heat the hot plate up, then turn it off/unplug it) a little gentle heating can speed the NaOH going into solution. You are right at the limit of solubility for NaOH in ethanol; alternatively, use KOH, which is more soluble. I recommend making the ethoxy solution up ahead of time and storing it in a tightly capped glass container. Start the reaction: Add the NaOH/ethanol mix to ~375 ml of vegetable oil (we use canola oil) in a PET bottle22 and mix by shaking briefly. After the first mix, carefully vent the reaction to prevent the build-up of vapour pressure. At first the ethanol will float on top; later, as the oil is converted into soaps23 and more alcohol-soluble substances24, the mixture will begin to form an emulsion and darken; finally, the emulsion will go clear and no more mixing is necessary. Let the reaction continue overnight. If you are in a hurry, I use these proportions ( a bigger reaction holds heat longer): 200 ml ethoxy; 750 ml of oil, pre-heated to 50-60 C). You have to stop the reaction after 20-40 minutes, because otherwise the biodiesel (FAME) gets converted to soap. 22 Demonstrating biodiesel synthesis in a PET bottle. Soap formation citation. 24 Fat (triglyceride) is converted into diglycerides and monoglycerides; diglycerides and monoglycerides are used in foods as emulsifying agents (citation needed). 23 Pre-wash: The by-product of the biodiesel reaction is glycerol. Normally in a good, efficient biodiesel synthesis reaction the glycerol with separate into a layer at the bottom of the reaction vessel, taking with it most of the sodium hydroxide and alcohol. In some cases a so-called ‘pre-wash’ is needed to encourage the separation of the glycerol and the biodiesel25. To pre-wash your biodiesel add 20 ml of water, shake, and let stand 30 minutes. If there is no phase separation, add another 5 ml of water, shake, and let stand 30 minutes. Repeat as necessary. The pre-wash volume26 should be between 5 and 15 %. If you put too much water in, you risk forming an emulsion, especially in crude reactions with high content of fatty acids and incomplete reaction products. The top layer is biodiesel: the lower, dark coloured layer is glycerol, NaOH, and methylated spirits. Remove the top layer to a new container for the next stage (Separatory funnel? Fat separator from household store? Baster? - adding water to raise the level to the top of the bottle? Cap with a hole in it, then invert?). This prewash step is not necessary if you only want to test for viscosity and the whoosh factor: it is only to demonstrate the removal of the glycerol in a way similar to the method used by homebrew biodiesel producers. 25 26 Prewash gives cleaner biodiesel citation Prewash volume citation Washing your biodiesel: In a two-litre PET bottle, shake the biodiesel with 1 M NaCl (to help prevent emulsions and speed phase separation), and then let separate for two or three minutes. Replace the cap on the PET bottle with a cap with a hole drilled in it27, invert the bottle, and (in a well ventilated place) drain the wash water out the bottom. (Be careful about disposing of your washes-- ethanol fumes can accumulate in plumbing, plus biodiesel smells funny, so flush with lots of water). Repeat twice. At this point you have the option of doing a final water wash and then letting your biodiesel stand for a week to clarify (see photos) or alternatively, washing more extensively with tap water. The bottom layer is water. The middle layer is soap and mono and diglycerides. If you leave the reaction at 10 C for a week, more glyerides come out of the biodiesel solid (based on my crude observations and the fact that glycerides melt around 1020 C, If I remember correctly).. If you chose to wash further, to slowly drizzle water down through your biodiesel (see photo and notes28). Because our ethanol-based protocol produces a very crude biodiesel with lots of soap and incomplete reaction products, it is very susceptible to emulsions: if you mix by shaking at this point you may form an emulsion. By dripping or slowly drizzling water down from above you avoid forming an emulsion. Many biodiesel protocols recycle the wash water by pumping it up and running it back down through the biodiesel: I don't do that because of the danger that the soap-laden water will mix with the biodiesel and form an emulsion. The white milky layer in the middle is soap (?) and/or triglycerides (?)29. When the water runs clear the washing is finished. With clean biodiesel you should be able to shake it up with water and have it separate into two clean phases within a few minutes. Drying (optional): Let the biodiesel stand in a shallow dish or tray for several days to let any traces of water evaporate. If you want to dispose of your biodiesel, you can add a spoonful of drain cleaner to a little water in a flask on a stir plate. Pour your biodiesel on the top and stir over night. This will convert your biodiesel into soap. 27 Cite PET demo protocol with cap with hole in it. Making a ‘distributor’ from a piece of Tygon tubing (with a 7/64” hole drilled in it), aquarium tubing, and 'NeTaTM 4 mm joiner barb-thread' from an underground sprinkler system 29 Citation for interface layer being soap/TG? 28

![FOCI[3] - Clemson Sustainable Biofuels](http://s2.studylib.net/store/data/005791040_2-3405d51e06eba48ee2e076f677a28aa2-300x300.png)