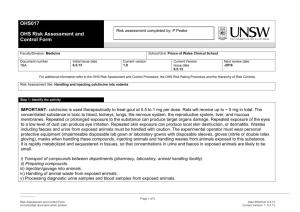

OHS Risk assessment and control form

advertisement

OHS017 Risk assessment completed by: K. Wyse Staff/student number:z8903240 OHS Risk assessment and control form For additional information refer to the OHS Risk Assessment and Control Procedure, the OHS Risk Rating Procedure and the Hierarchy of Risk Controls. Faculty/Division: Medicine Document number School/Unit: Lowy Cancer Research Building Initial Issue date 1/2/2011 Current version 1.0 Current Version Issue date Next review date 1/2/2014 1/2/2011 Risk Assessment title:- Selection of footwear for Lower ground wash up and solution preparation area Step 1:- Identify the Activity and the location of the activity Description of activity:- Selection of Footwear for lower ground wash up area Description of the location of the activity:- Treatment of PC2 waste and gowns, preparation of solution and washing of glassware. Step 2: Identify who may be at risk by the activity: A number of people may be at risk from any activity. This may affect the risk controls needed. These people may include fellow workers, visitors, contractors and the public. The location of the activity may affect the number of people at risk UNSW Lower ground wash up and solution preparation staff only Steps 3 to 7: Identify the hazards, risks, and rate the risks Staff working in this area must at all time wear enclosed footwear (see Type A low shoe diagram found in Australian Standard 2210.1) with a nonslip sole except when handling corrosive solutions. If staff are handling corrosive solutions, they must wear non-absorbent enclosed footwear with a nonslip sole. Justification: In the case of exposure to crush injury or slippery floors non-absorbent shoes offer no extra protection over absorbent shoes. In the case of exposure to corrosive chemical hazards non absorbent shoes do offer considerably more protect and must be worn when handling these chemicals. Most (90%) of thePC2 waste is solid so non absorbent shoes offer minimal extra protection. If footwear is exposed to PC2 waste they can be chemical decontaminated or autoclaved before leaving the area. _____________________________________________________________________________________________________________________________________________________________________________ Page 1 of 5 Risk Assessment and Control Form Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 3.2, 27/09/2010 Tasks Hazards Associated risks (Step 3) (Step 4) Risk rating with existing controls * Additional risk controls required Risk Rating with additional controls * (Step 5) (Step 6) (Step 7) Existing risk controls C Treatment of PC2 waste and gowns Exposure to PC 2 organisms Environment and biological hazard Enclosed footwear with non slip soles Use of dishwasher Slippery floors\chemical exposure Slip trip and fall\chemical exposure Enclose footwear with Non slip soles Solution preparation Chemical hazard Chemical exposure Enclosed non-absorbent footwear with non-slip soles Moving items though the tunnel and around the area Crush injury from fork lift, falling object and trolleys Injury to feet Enclosed footwear with non-slip sole L R 1 Rare Low 2 possible Medium 3 Unlikely Medium 4 Rare Medium C Step 8 : Implement additional controls Date all controls implemented : I(name): Ken Wyse 1/2/2011 have implemented the controls identified in step 6 (signature) Step 9 :List Legislation related to this document List legislation, standards and codes of practice relevant to this risk assessment Australian Standard AS/NZS 2210 _____________________________________________________________________________________________________________________________________________________________________________ Page 2 of 5 Risk Assessment and Control Form Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 3.2, 27/09/2010 L R Personal Protective Clothing and Equipment Guideline OHS659 Step 10:- Authorisation Authorised by: Date: Signature: Step 11:- Sign off All persons performing these tasks must have read and understood the risk assessment Risk assessment name and version number: I have read and understand this risk assessment Name Signature Date _____________________________________________________________________________________________________________________________________________________________________________ Page 3 of 5 Risk Assessment and Control Form Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 3.2, 27/09/2010 _____________________________________________________________________________________________________________________________________________________________________________ Page 4 of 5 Risk Assessment and Control Form Uncontrolled document when printed Date Effective: 01/01/2007 Current Version: 3.2, 27/09/2010 UNSW Concise OHS Risk Rating Table OHS696 1. 2. 3. 4. 5. What you need to do Consider what can go wrong that can hurt someone Determine what the most likely outcome would be - Consequences Determine how likely those consequences are - Likelihood Calculate the risk rating Required action CONSEQUENCES: Severe Major Moderate Minor Insignificant How severely could someone be hurt? death or permanent disability to one or more persons hospital admission required medical treatment required first aid required injuries not requiring first aid LIKELIHOOD: Almost certain Likely Possible Unlikely Rare How likely are those consequences? expected to occur in most circumstances will probably occur in most circumstances could occur at some time is not likely to occur in normal circumstances may occur only in exceptional circumstances CONSEQUENCES LIKELIHOOD Insignificant 1 Minor 2 Moderate 3 Major 4 Severe 5 Almost certain A M H H VH VH Likely B M M H H VH Possible C L M H H VH Unlikely D L L M M H Rare E L L M M M Risk level Very high High Medium Low Required action Act immediately: The proposed task or process activity must not proceed. Steps must be taken to lower the risk level to as low as reasonably practicable using the hierarchy of risk controls. Act today: The proposed activity can only proceed, provided that: (i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls; (ii) the risk controls must include those identified in legislation, Australian Standards, Codes of Practice etc. (iii) the risk assessment has been reviewed and approved by the Supervisor and (iv) a Safe Working Procedure or Safe Work Method has been prepared. (v) The supervisor must review and document the effectiveness of the implemented risk controls. Act this week: The proposed task or process can proceed, provided that: (i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls; (ii) the risk assessment has been reviewed and approved by the Supervisor and (iii) a Safe Working Procedure or Safe Work Method has been prepared. Act this month: Managed by local documented routine procedures which must include application of the hierarchy of controls. ______________________________________________________________________________________________________________________ Page 5 of 5 UNSW Concise OHS Risk Rating Table Effective date: 01/01/07 Uncontrolled document when printed Current Version: 3.1,16/07/2008