chapter three part three

advertisement

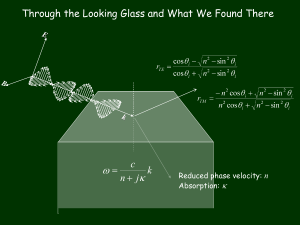

CHAPTER THREE SPECTROMETER DEVELOPMENT 1.0 0.8 Rpolyeth R||polyeth R or T 0.6 Tpolyeth T||polyeth RPTFE 0.4 R||PTFE TPTFE 0.2 T||PTFE 0.0 0 10 20 30 40 50 60 70 80 Incidence angle between interface and unpolarised beam Figure 3.12: The variation of Reflectance and Transmittance of Teflon (PTFE) and Polyethylene with incidence angle with an unpolarised incident beam. the cell windows were 3mm thick, absorbed some of the incoming radiation, and were set at the Brewster angle in either the xz or the yz plane, (figure 3.13). From these results, (figures 3.14 and 3.15), it is clear that the transmitted TuFIR intensity is at a maximum when the cell windows are set at the Brewster angle in the xz plane, provided that the incoming beam is propagating parallel to the z-axis. These calculations also proved that polyethylene was a superior window material to Teflon. window orientated in xz plane y z B cell TuFIR beam E-field vector window orientated in yz plane x cell B Figure 3.13: Relative orientations of the Brewster Window, TuFIR beam and polarisation vector. The dashed line indicates the surface normal. 89 90 CHAPTER THREE SPECTROMETER DEVELOPMENT 1.0 0.8 R or T 0.6 Rpolyeth Tpolyeth RPTFE TPTFE 0.4 0.2 0.0 0 10 20 30 40 50 60 70 80 90 angle between incoming beam and surface normal Figure 3.14: Variation of R and T with incidence angle for a TuFIR beam polarised in the xy plane, at 10o to the x-axis, and the cell window set at the Brewster Angle in the yz plane. 1.0 0.8 Rpolyeth Tpolyeth RPTFE TPTFE R or T 0.6 0.4 0.2 0.0 0 10 20 30 40 50 60 70 80 90 angle between incoming beam and surface normal Figure 3.15: Variation of R and T with incidence angle for a TuFIR beam polarised in the xy plane, at 10o to the x-axis, and the cell window set at the Brewster Angle in the xz plane. 90 CHAPTER THREE SPECTROMETER DEVELOPMENT The final Brewster Cell design is shown in figure 3.16. The Brewster Windows were manufactured separately from the main cell body so that they could be rotated independently, to obtain the optimum sideband transmission. This also means that the main cell isolation valve Pump * = cell ports * * * * TuFIR beam 50cm cone and socket joints * * sample regions * * Polyethylene windows at 54o (Brewster angle) Figure 3.16: The Brewster Window Cell. cell function can be changed in the future by replacing these windows with lenses for a collimating cell or dielectric based meshes for a multi-pass type cell. As with the simple absorption cell, the radicals were generated in a microwave discharge on a sidearm from the cell and pumped through the cell by a Roots Blower. This cell was pumped at the centre so that: 1. it could be used in conjunction with a double discharge system, where radicals were generated in sidearms on both sides of the pump port. Hence, the radicals would be distributed more evenly throughout the cell and the radical concentration in the absorption region would be increased, 2. the distance was reduced between the points where the radicals entered and exited the cell. As the radicals would still be pumped at the same speed as in the previous cell, their residence time within the cell would be reduced and they would be less likely to react and form secondary species within the absorption volume. Consequently, the TuFIR radical spectra would be uncontaminated by other species (except pre-cursor transitions) simplifying the spectral assignments. 91 CHAPTER THREE SPECTROMETER DEVELOPMENT The Brewster Window cell was tested using the lower sideband from the 729.9328GHz laser transition in CD3OD and 27.9GHz microwaves. The sideband throughput was maximised without the absorption cell in position. Its maximum AM modulated intensity was 467mV at the LIA, on 40dB gain. The sideband intensity was unaffected when the main cell body was in position. With the Brewster windows attached to the cell, the maximum sideband intensity dropped to 425mV, 91% of its original value. This was very close to the theoretical maximum transmission intensity of 93%, and indicated that very little of the incoming radiation was scattered, reflected or absorbed by the cell windows. In addition, the maximum transmission intensity occurred when the windows were positioned in the xz plane, (as predicted previously). The same sideband was used to measure the TuFIR spectrum of the J=3433 rotational transition in CHF3. The full K-band progression was recorded in both the simple and the Brewster Window absorption cells, at a total cell pressure of 3mT. Each spectrum was built from 8 individual scans, taken with the FPI plates in place, (table 3.4). Microwave Frequency Range Scan Range (GHz) (GHz) 1 27.8-28.0 701.7328-701.9328 -wave for which Spectrometer Transmission optimised (GHz) 27.9 2 27.6-27.8 701.5328-701.7328 27.7 3 27.4-27.6 701.3328-701.5328 27.5 4 27.2-27.4 701.1328-701.3328 27.3 5 27.0-27.2 700.9328-701.1328 27.1 6 26.8-27.0 700.7328-700.9328 26.9 7 26.6-26.8 700.5328-700.7328 26.7 Scan No. Table 3.4: Scan ranges used to construct the TuFIR test spectrum for each cell. These spectra are compared in figure 3.17. The spectral intensities are distorted in both spectra due to variations in the maximum attainable sideband power across this frequency range. The line intensities also depend on the nuclear spin statistics of CHF3, (see Chapter 5). However, the S:N ratio from the BW cell is 225:1 compared with 150:1 in the original absorption cell. This is shown more clearly in figure 3.18, where the spectra have been expanded to show the K=9 to K=12 transitions. The noise level and 92 CHAPTER THREE SPECTROMETER DEVELOPMENT spectral resolution are comparable in both spectra, but all the K transitions are significantly more intense in the BW cell spectrum. In terms of N/V, the spectrometer sensitivity increased to 4x1011molec.cm-3 and when the FPI plates were removed, N/V was 1x1011 molec.cm-3. Original cell 701.75 702.00 702.25 702.50 702.75 703.00 703.25 703.50 Frequency (GHz) Brewster Window cell 701.75 702.00 702.25 702.50 702.75 703.00 703.25 703.50 Frequency (GHz) Figure 3.17: A comparison of the intensities of the J=3433 rotational spectrum in CHF3 recorded using two different absorption cells. 93 CHAPTER THREE SPECTROMETER DEVELOPMENT 0.10 Brewster Window Cell Original Cell sideband max. K=9 K=12 0.08 Intensity (arb units) 0.06 K=10 K=11 0.04 0.02 0.00 -0.02 x100 -0.04 -0.06 -0.08 -0.10 702.04 702.06 702.08 702.10 702.12 Frequency (GHz) Figure 3.18: Expansion of the K=9 to K=12 region of the J=3433 rotational transition in CHF3. Different spectral intensities are achieved in each absorption cell under the same experimental conditions. 3.4 Computerised Control using LabView In 1996, the data acquisition system on the TuFIR Spectrometer was completely redeveloped. Over the preceding 18 months, the original Klystron microwave source had been replaced with the Microwave Synthesiser [17], and the LIA was updated from an analogue to a digital model [18]. The existing computer system (a Viglen 286 PC and a 4-bit National Instruments PCI-GPIB card) lacked the speed and memory capabilities that were required to communicate with the new instruments. It was not possible to modify the original computer programme (written in Quick Basic and run in Dos 5) to record TuFIR spectra. The computer system was therefore replaced with a Hyundai 486 PC (60MHz-clock speed) and a 16-bit AT-GPIB card and in 1997 the PC was upgraded 94 CHAPTER THREE SPECTROMETER DEVELOPMENT again to a Gateway 2000 Pentium PC, (120MHz-clock speed). The TuFIR control programme was rewritten by the author in LabView4 [19]. LabView is a custom-made scientific and engineering instrumentation programme designed by National Instruments [19]. It is based on a graphical programming language, ‘G’, that closely resembles ‘C’ and runs in Windows 3.1 or Windows ’95. Unlike traditional programming languages that execute line by line and search linearly through the programme to locate subroutines, graphical programming languages are capable of parallel processing. All non-dependent command functions are executed concurrently, and many calculations can be made at the same time. If the programme is communicating with external instruments, the data flow is obviously limited by the number of bits on the communication board, but if the instruments are linked to the computer independently LabView enables parallel communication and data acquisition. Each LabView programme is known as a Virtual Instrument, (VI), as it appears to imitate a real instrument or instrument function. The VI’s have an interactive user interface (known as the front panel) and a source code equivalent (known as the block diagram). The VI’s use a hierarchical structure, and can be run alone or embedded into other more complex programmes. VI’s that are contained within other programmes are called subVI’s and are analogous to subroutines in text based programming. An icon and connector board is associated with each subVI for this purpose. LabView programmes are highly structured; typically a complex application is divided into a series of tasks, which are then subdivided again into simpler procedures. Each of these procedures will be controlled by its own VI, which is then combined with the other VI’s to accomplish the larger task. Eventually the VI’s controlling each task are combined together in the ‘top level’ VI that controls the whole application. The General Purpose Interface Bus, (GPIB), is a communication system for interconnected electronic devices [20]. It was designed to operate at rapid data transfer rates (1Mbyte/s) so the total number of instruments on the bus and the physical distance between them is restricted. The instruments must be linked in a ‘star’ or ‘linear’ configuration, (figure 3.19), with not more than 4m of cable between any two devices, and an average device separation of 2m over the whole bus. No more than 15 devices should be connected to the bus, and only 10 of these can be powered up at any one time. 95 CHAPTER THREE SPECTROMETER DEVELOPMENT Linear Formation Star Formation Device 1 Device 1 Device 2 Device 2 Device 4 Device 3 Device 3 Device 4 Figure 3.19: Star and Linear connection configurations for GPIB devices. On the TuFIR spectrometer, a linear configuration is used to link the PC, LIA and Microwave Swept Frequency Synthesiser, (SFS). The maximum distance between these devices is only 1m. Every device on the bus is assigned its own specific address. In this experiment the PC was addressed 0, the SFS 2, and the LIA 3. The GPIB carries devicedependent and interface messages. Device dependent messages (also called data) contain information such as set-up instructions, machine status, and measurement results. Interface messages are used to manage the bus itself. They are used to initiate and clear the bus, as well as addressing data to the correct instrument. GPIB devices are known as talkers, listeners, or controllers. The controller manages all the information on the GPIB and has to be used to change the active talker or listener. A talker is a device that is sending information over the bus; a listener is a device that is receiving information. There can be multiple controllers on the GPIB but there is only ever one controller in charge (CIC). The PC (or more specifically the GPIB board in the PC) is usually the CIC. The ANSI-IEEE 488.2 standard governs exactly how a controller should manage the GPIB, the standard messages that compliant devices should understand, error or status messages from the devices, and protocols to configure devices connected to the bus. However, every GPIB compatible instrument is developed with a unique set of 96 CHAPTER THREE SPECTROMETER DEVELOPMENT control commands. Traditionally, a separate subroutine must be called to control each GPIB function or command. In LabView there are common sets of VI’s that have been pre-programmed into the software for this purpose. An instrument driver, (ID), is a collection of VI’s that have been written to specifically control a certain instrument on a particular communication interface, e.g. DAQ, GPIB, RS232, VISA. A vast library of ID’s is available free over the Internet [21], covering an extensive range of equipment. This is the main advantage of LabView over other instrumentation control software, so it is not always necessary to learn or understand all the GPIB device-specific commands to control a particular instrument. However, certain modifications are usually necessary to match the ID VI’s to a particular application. The TuFIR control programme was used to set-up the spectrometer instrumentation as well as to record the TuFIR spectra. The programme was planned by subdividing the scan and set-up functions into smaller tasks, then linking them together with the aid of a logic diagram. The final design is summarised in figure 3.20. The control programme was opened from a shortcut icon on the Windows ’95 Desktop. When the programme was running none of the VI source code was visible to the user and most of the VI front panels were hidden. The final programme menus are given in figure 3.21. On entering the programme the user is forced to enter background information about the scan then set-up the instrumentation. The user can then chose to re-set the instrumentation, scan a spectrum, or quit the whole programme. The ‘set-up’ menu allows the user to set certain instrument parameters with the computer rather than the instrument itself. In the scan ‘option’, the user sets the non-instrument specific scan parameters. Once the user has started the data acquisition, the data is plotted on the screen in ‘real-time’. The scan can be aborted at any time. At the end of the scan, the programme switches to an ‘interactive’ spectrum display. In this mode the user can expand parts of the spectrum, or measure peak frequencies. The spectrum can also be saved and/or printed at this point. When the user quits from the interactive mode the programme returns to the scan menu. The whole scan process can be repeated without the user having to return to the main menu. When the user quits the whole programme, LabView is closed down and the computer switches back to Windows ’95. 97