Electronic Supplementary Materials (ESM) for: Lipase

advertisement

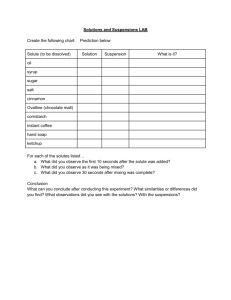

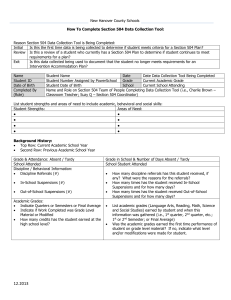

Electronic Supplementary Materials (ESM) for: Lipase-Catalyzed Synthesis of Saccharide-Fatty Acid Esters Utilizing Solvent-Free Suspensions: Effect of Acyl Donors and Acceptors, and Enzyme Retention Activity (JAOCS) Ran Ye, Douglas G. Hayes* Department of Biosystems Engineering and Soil Science, University of Tennessee, Knoxville, TN 37996-4531 *To whom correspondence should be addressed: 2506 E.J. Chapman Dr., Knoxville, TN 37996-4531. Tel: (865) 974-7991, FAX: (865) 974-4514, E-mail address: dhayes1@utk.edu Figure S1. Effect of acyl acceptor type (given in legend) on the time course of reaction for immobilized Rhizomucor miehei lipase- (RML-) catalyzed synthesis of saccharide-oleic acid esters in a packed-bed bioreactor (PBBR)-based bioreactor system at 53oC that utilizes solvent-free suspensions of saccharide crystals. Plotted are the a. ester concentration, b. saccharide concentration, and (inset) liquid-phase water concentration. Bioreactor system and conditions described in Table 1 of the main paper. Figure S2. Effect of acyl acceptor type on the time course of reaction for RMLcatalyzed synthesis of saccharide–caprylic acid esters in a packed-bed bioreactor (PBBR)-based bioreactor system at 53oC that utilizes solvent-free suspensions of saccharide crystals. saccharide concentration, and Plotted are a. ester concentration, b. (inset) liquid-phase water concentration. Bioreactor system and conditions described in Table 1 of the main paper. Figure S3. Effect of acyl acceptor (given in legend) on the time course of reaction for RML-catalyzed solvent-free synthesis of saccharide–lauric or myristic acid esters in a stirred bioreactor (STBR) at 65oC that utilizes solventfree suspensions of saccharide crystals. Plotted are the a. ester concentration, b. saccharide concentration, and (inset) liquid-phase water Operating conditions described in Table 1 of the main paper. concentration. Optical light microscopy of suspensions before and after centrifugation Experimental Suspension droplets (after and/or before centrifugation) were carefully removed to a slice and covered by a cover-slip gently avoiding the existence of air bubbles. Afterwards the prepared samples (magnification, X 40) were probed using a light microscope with integrated 3 mega pixel digital camera (Micromaster* Inverted digital microscopes with infinity optics, from Fisher Scientific, Pittsburgh, PA USA). Figure S4. Images from light microscopy, 40X magnification, of suspensions for 4 different acyl acceptors ( a xylose, b glucose, c sucrose, and d fructose) in solvent-free media (Fructose-oleic acid esters/ oleic acid, 25/75, w/w) at 25oC after forming suspensions as mentioned in Table 1 of the main paper, but before the centrifugation step is invoked. Figure S5. Images from light microscopy, 40X magnification, of suspensions for 4 different acyl acceptors (a xylose, b glucose, c sucrose, and d fructose) in solvent-free media (fructose-oleic acid esters/ oleic acid, 25/75, w/w) at 25oC after completion of centrifugation. Further conditions are given Table 1 of the main paper. Figure S6. Images from light microscopy, 40X magnification, of suspensions for two different acyl acceptors before centrifugation (80oC): a fructose and b glucose; and after centrifugation 25oC: c fructose and d glucose) in solvent-free media (fructose-oleic acid esters / caprylic acid / oleic acid 25 / 72.1 / 2.9 w/w/w). Operating conditions for the preparation of suspensions in fatty acid equal those of Fig 4 of the main paper. Figure S7. Time course of reaction for the solvent-free synthesis of fructose oleate at 65oC in PBBR-based bioreactor system with in-situ water removal method (Vacuum+N2 gas bubbling) for determining the operational stability of immobilized R. miehie lipase (RML) Plotted are the average and standard deviation (error bars) for the four successive runs. Further information is given in Table 3.